Siddhesh Poster ICEF 2015

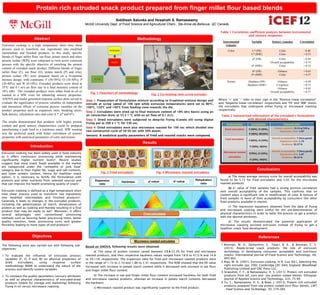

- 1. Abstract Objectives Methodology Conclusions Siddhesh Salunke and Hosahalli S. Ramaswamy McGill University Dept. of Food Science and Agricultural Chem., Ste-Anne-de-Bellevue, QC Canada References The following work was carried out with following sub- objectives: 1. To evaluate the influence of extrusion process variables (F, O, P and W) on physical properties of dried extrudates, using response surface methodology (RSM) to understand the nature of the process and identify system variables. 2. To compare the quality parameters (sensory attributes as well as physical characteristics) of extruded-dried products (stable for storage and marketing) following frying in oil versus microwave roasting. Protein rich extruded snack product prepared from finger millet flour based blends Results Where ŌĆś+ŌĆÖ and ŌĆś-ŌĆÖ refer to their sign in the ŌĆ£Positive linear correlationŌĆØ and ŌĆ£Negative linear correlationŌĆØ respectively and ŌĆśFRŌĆÖ and ŌĆśMWŌĆÖ shows the extrudates that undergone either frying or microwave roasting respectively. 1.Brennan, M. A., Derbyshire, E., Tiwari, B. K., & Brennan, C. S. (2013). Ready-to-eat snack products: the role of extrusion technology in developing consumer acceptable and nutritious snacks. International Journal of Food Science and Technology, 48, 893-902. 2.Riaz, M. N. (2001). Extrusion cooking. In R. Guy (Ed.), Selecting the right extruder (pp. 200). Cambridge CB1 6AH, England: Woodhead Publishing Limited and CRC Press LLC. 3.Sirawdink, F. F., & Ramaswamy, H. S. (2011). Protein rich extruded products from tef, corn and soy protein isolate blends. Ethiopian Journal of Applied Science and Technology, 2(2), 75-90. 4.Yu, L., Ramaswamy, H. S., & Boye, J. (2013). Protein rich extruded products prepared from soy protein isolate-corn flour blends. LWT - Food Science and Technology, 50, 279-289. Expansion ratio Hardness a*-value b*-value Rehydration ratio Fried extrudates Microwave roasted extrudates Design-Expert┬« Software Component Coding: Actual Expansion Ratio (After frying) Design Points 2.1 1.73 X1 = A: Finger millet flour X2 = B: Oat Flour X3 = C: Potato Starch Actual Component D: WPI = 5.00 A: Finger millet flour (100%) B: Oat Flour (100%) C: Potato Starch (100%) Expansion Ratio 65.00 25.00 35.00 61.25 21.25 31.25 57.50 17.50 27.50 53.75 13.75 23.75 50.00 10.00 20.00 1.85 1.9 1.95 2 Design-Expert┬« Software Component Coding: Actual Hardness ((N)) Design Points 46.96 18.78 X1 = A: Finger millet flour X2 = B: Oat Flour X3 = C: Potato Starch Actual Component D: WPI = 5.00 A: Finger millet flour (100%) B: Oat Flour (100%) C: Potato Starch (100%) Hardness ((N)) 65.00 25.00 35.00 61.25 21.25 31.25 57.50 17.50 27.50 53.75 13.75 23.75 50.00 10.00 20.00 30 35 40 Design-Expert┬« Software Component Coding: Actual a * value Design Points 7.72 3.16 X1 = A: Finger millet flour X2 = B: Oat Flour X3 = C: Potato Starch Actual Component D: WPI = 5.00 A: Finger millet flour (100%) B: Oat Flour (100%) C: Potato Starch (100%) a * value 65.00 25.00 35.00 61.25 21.25 31.25 57.50 17.50 27.50 53.75 13.75 23.75 50.00 10.00 20.00 5 5.5 6 6.5 Design-Expert┬« Software Component Coding: Actual a * value Design Points 9.7 6.87 X1 = A: Finger millet flour X2 = B: Oat Flour X3 = C: Potato Starch Actual Component D: WPI = 5.00 A: Finger millet flour (100%) B: Oat Flour (100%) C: Potato Starch (100%) a * value 65.00 25.00 35.00 61.25 21.25 31.25 57.50 17.50 27.50 53.75 13.75 23.75 50.00 10.00 20.00 9 9 9.5 10 Design-Expert┬« Software Component Coding: Actual b * value Design Points 2.78 -8.16 X1 = A: Finger millet flour X2 = B: Oat Flour X3 = C: Potato Starch Actual Component D: WPI = 5.00 A: Finger millet flour (100%) B: Oat Flour (100%) C: Potato Starch (100%) b * value 65.00 25.00 35.00 61.25 21.25 31.25 57.50 17.50 27.50 53.75 13.75 23.75 50.00 10.00 20.00 -4 -3 -2 Design-Expert┬« Software Component Coding: Actual b * value Design Points 15.21 7.82 X1 = A: Finger millet flour X2 = B: Oat Flour X3 = C: Potato Starch Actual Component D: WPI = 5.00 A: Finger millet flour (100%) B: Oat Flour (100%) C: Potato Starch (100%) b * value 65.00 25.00 35.00 61.25 21.25 31.25 57.50 17.50 27.50 53.75 13.75 23.75 50.00 10.00 20.00 11 12 Design-Expert┬« Software Component Coding: Actual Rehydration Ratio (Percent (%)) Design Points 423 95.15 X1 = B: Oat Flour X2 = C: Potato Starch X3 = A: Finger millet flour Actual Component D: WPI = 5.00 B: Oat Flour (100%) C: Potato Starch (100%) A: Finger millet flour (100%) Rehydration Ratio (Percent (%)) 25.00 35.00 65.00 21.25 31.25 61.25 17.50 27.50 57.50 13.75 23.75 53.75 10.00 20.00 50.00 150 200 200 250 250 300 Design-Expert┬« Software Component Coding: Actual Rehydration Ratio (Percent (%)) Design Points 87.96 51.09 X1 = A: Finger millet flour X2 = B: Oat Flour X3 = C: Potato Starch Actual Component D: WPI = 5.00 A: Finger millet flour (100%) B: Oat Flour (100%) C: Potato Starch (100%) Rehydration Ratio (Percent (%)) 65.00 25.00 35.00 61.25 21.25 31.25 57.50 17.50 27.50 53.75 13.75 23.75 50.00 10.00 20.00 50 55 60 Design-Expert┬« Software Component Coding: Actual Hardness ((N)) Design Points 39.11 14.78 X1 = A: Finger millet flour X2 = B: Oat Flour X3 = C: Potato Starch Actual Component D: WPI = 5.00 A: Finger millet flour (100%) B: Oat Flour (100%) C: Potato Starch (100%) Hardness ((N)) 65.00 25.00 35.00 61.25 21.25 31.25 57.50 17.50 27.50 53.75 13.75 23.75 50.00 10.00 20.00 26 28 30 30 32 32 34 34 36 Design-Expert┬« Software Component Coding: Actual Expansion Ratio Design Points 2.41 1.86 X1 = A: Finger millet flour X2 = B: Oat Flour X3 = C: Potato Starch Actual Component D: WPI = 5.00 A: Finger millet flour (100%) B: Oat Flour (100%) C: Potato Starch (100%) Expansion Ratio 65.00 25.00 35.00 61.25 21.25 31.25 57.50 17.50 27.50 53.75 13.75 23.75 50.00 10.00 20.00 2 2.1 2.2 Step 1: Preparation of formulation mixture according to D-optimal mixture design and extrude at screw speed of 100 rpm while extrusion temperatures were set to 80┬░C, 100┬░C, 120┬░C and 140┬░C from feeding zone towards the die. Step 2: Extrudates were dried up to final moisture content of 18% (dry basis) using an air convection dryer at 55 ┬▒ 1 ┬░C with an air flow of 0.1 m/s. Step 3: Dried extrudates were subjected to deep-fat frying (Canola oil) using digital frying pot at 200 ┬▒ 1 ┬░C for 330 sec. Step 4: Dried extrudates were also microwave roasted for 100 sec which divided into two consecutive cycle of 50-50 sec with 50% power. Sensory & analytical quality parameters of fried and roasted snacks were compared. Fig. 2 Co-rotating twin screw extruderFig. 1 Flowchart of methodology Table 1 Correlation coefficient analysis between instrumental and sensory responses Table 2 Summarized information of the extrudateŌĆÖs formulation with desired characteristics Fig. 3 Fried extrudates Fig. 4 Microwave roasted extrudates Introduction Extrusion cooking has been widely used in food industry as it offers continuous processing while maintaining significantly higher nutrient levels4. Recent studies suggest that most snack foods available in the market are categorized under the ŌĆ£unhealthy or junk foodŌĆØ category due to their higher fat, sugar and salt contents, and lower protein content. Hence for healthier snack option, it is necessary to fortify the formulation with proteins and other nutrients from selected sources and that can improve the health promoting quality of snack1. Extrusion cooking is defined as a high temperature short time shear process used to transform raw ingredients into modified intermediate and finished products2. Generally it leads to changes in the extruded products, including the gelatinization of starch, denaturation of protein as well as cooking and thereby resulting in a final product that may be ready to eat4. Moreover, it offers several advantages over conventional processing methods such as favoring faster processing times, better quality retention, lower processing costs and greater flexibility leading to more types of end-products3. a) The mean average sensory score for overall acceptability was found to be 5.15 for fried extrudates and 5.65 for the microwave roasted products. b) a* value of fried samples had a strong positive correlation with overall acceptability of the samples. This confirms that oil content plays a significant role in modification of color & texture of fried samples in favor of their acceptability by consumers like other fried products available in market. c) The regression equations obtained from the data of frying and microwave cooking were useful for the pre-determination of physical characteristics in order to tailor the process to get a product with the desired attributes. d) The results demonstrated the potential application of microwave roasting assisted extrusion instead of frying to get a healthier snack food development. Instrumental response Variable Sensory response Correlation Color L* (FR) L* (MW) Color Color - 0.40 + 0.53 a* (FR) a* (MW) Color Overall acceptability Color + 0.44 + 0.75 + 0.53 b* (FR) b* (MW) Oiliness Color + 0.65 + 0.57 Texture Hardness (FR) Hardness (MW) Oiliness Crispiness Oiliness Overall acceptability + 0.50 + 0.75 + 0.85 + 0.77 Extrusion cooking is a high temperature short time shear process used to transform raw ingredients into modified intermediate and finished products. In this study, specific blends of finger millet flour, oat flour, potato starch and whey protein isolate (WPI) were subjected to twin screw extrusion process with the specific objective of enriching the protein content of extruded snack product. Different blends of finger millet flour (F), oat flour (O), potato starch (P) and whey protein isolate (W) were prepared based on a D-optimal mixture design, with constrains: F (50-70%), O (10-30%), P (20-40%), and W (0-10%). Extruded products were dried at 55┬░C and 0.1 m/s air flow rate to a final moisture content of 18% (db). The extruded products were either fried in oil or roasted in a MW oven for enhancing sensory properties. ANOVA and model generated response surface plots served to evaluate the significance of process variables on independent and interaction effects of extrusion process variables on the product properties such as expansion ratio, breaking stress, bulk density, rehydration ratio and color (L*, a* and b*). The results demonstrated that products with higher protein content and good sensory characteristics could be prepared transforming a junk food to a nutritious snack. MW roasting was the preferred snack with better correlation of sensory properties with analytical parameters of color and texture. Based on ANOVA, following results were obtained: a) The value of protein content varied between 13.4-22.2% for fried and microwave roasted products, and their respective hardness values ranged from 18.8 to 47.0 N and 14.8 to 39.11N ,respectively. The expansion ratio for fried and microwave roasted products were in the range of 1.73 to 2.10 and 1.86 to 2.41 respectively. The RSM showed that the ER value increased with increase in potato starch content while it decreased with increase in oat flour and finger millet flour content. b) The increase in oat and finger millet flour content increased hardness for both fried and microwave roasted products, whereas an increase in potato starch contents decreased the hardness. c) Microwave roasted product was significantly superior to the fried product.