SumantaMukherjee

- 1. Sumanta Mukherjee Flat No ŌĆō 603, Vardhaman Plaza, Plot No ŌĆō 44, Sec- 20,Roadpali, Kalomboli,Pin- 410218 Contact ŌĆō (0) ŌĆō 9225626022, 9730068659 E-mail ŌĆō MUKHERJEE_SUMANTA7@YAHOO.CO.IN, sumanta.m2@gmail.com

- 2. Responsibilities Handled Present Respo nsibili ties ’ā╝ Day-to-Day Production planning of different batches. ’ā╝ Managing the manpower and deployment as per production schedule. ’ā╝ Co-ordination with sales, technical, purchase, production & stores. ’ā╝ RMŌĆÖs & machine planning & scheduling. ’ā╝ Monthly, weekly & daily basis product wise machine scheduling. ’ā╝ Manpower calculation based on the process requirements. ’ā╝ Quarterly, monthly & weekly basis RM planning. ’ā╝ In-process checking of different products being manufactured. ’ā╝ Ensuring production complying the laid down procedures and parameters. ’ā╝ In-house trouble shooting and improvement activity. ’ā╝ Performance of 5S activities as per TPM & Manufacturing Excellence requisites. ’ā╝ Analysis of ŌĆ£Deviation in product and processŌĆØ and identification of CAPA. ’ā╝ Data analysis of Improvement projects, monthly performance data. ’ā╝ Daily tracking of customer complaints, analyze it & reporting by usage of problem solving tools like Why-Why analysis and C&E. ’ā╝ Batch Quality Rating Index tracking. ’ā╝ First 3 batches product & process standardization in production. ’ā╝ Product cum process audit with respect to adherence to SOP, WIŌĆÖs and Quality Standards. ’ā╝ Assisting departmental Head in implementation of TS-16949, ISO- 14001 & OSHAS-18001. ’ā╝ Technical Support to line personnel as per the requirement. ’ā╝ Problem solving by visiting customer place as per requirement. ’ā╝ Visiting vendor place for vendor auditing. ’ā╝ Provide training to operator & officer on SOP, 5S. ’ā╝ To prepare all the documents of TS ŌĆō 16949 implementation. ’ā╝ Conducting CFT meeting for new batches standardization, FMEA, Customer complain analysis. ’ā╝ Working as bridge in between Technical & Production for establishing new product & batches. ’ā╝ Monthly report generation. Preparation of presentation for MRM. ’ā╝ Working as a coordinator to run the ŌĆ£Strong Manufacturing PracticesŌĆØ activity. ’ā╝ Handling ŌĆ£First Lot ControlŌĆØ activity. ’ā╝ Providing training to new comers on plant practices, 5S, SOPŌĆÖs.

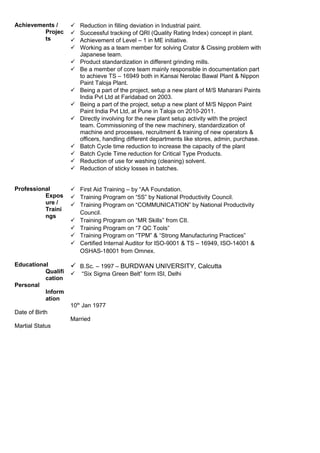

- 3. Achievements / Projec ts ’ā╝ Reduction in filling deviation in Industrial paint. ’ā╝ Successful tracking of QRI (Quality Rating Index) concept in plant. ’ā╝ Achievement of Level ŌĆō 1 in ME initiative. ’ā╝ Working as a team member for solving Crator & Cissing problem with Japanese team. ’ā╝ Product standardization in different grinding mills. ’ā╝ Be a member of core team mainly responsible in documentation part to achieve TS ŌĆō 16949 both in Kansai Nerolac Bawal Plant & Nippon Paint Taloja Plant. ’ā╝ Being a part of the project, setup a new plant of M/S Maharani Paints India Pvt Ltd at Faridabad on 2003. ’ā╝ Being a part of the project, setup a new plant of M/S Nippon Paint Paint India Pvt Ltd, at Pune in Taloja on 2010-2011. ’ā╝ Directly involving for the new plant setup activity with the project team. Commissioning of the new machinery, standardization of machine and processes, recruitment & training of new operators & officers, handling different departments like stores, admin, purchase. ’ā╝ Batch Cycle time reduction to increase the capacity of the plant ’ā╝ Batch Cycle Time reduction for Critical Type Products. ’ā╝ Reduction of use for washing (cleaning) solvent. ’ā╝ Reduction of sticky losses in batches. Professional Expos ure / Traini ngs ’ā╝ First Aid Training ŌĆō by ŌĆ£AA Foundation. ’ā╝ Training Program on ŌĆ£5SŌĆØ by National Productivity Council. ’ā╝ Training Program on ŌĆ£COMMUNICATIONŌĆØ by National Productivity Council. ’ā╝ Training Program on ŌĆ£MR SkillsŌĆØ from CII. ’ā╝ Training Program on ŌĆ£7 QC ToolsŌĆØ ’ā╝ Training Program on ŌĆ£TPMŌĆØ & ŌĆ£Strong Manufacturing PracticesŌĆØ ’ā╝ Certified Internal Auditor for ISO-9001 & TS ŌĆō 16949, ISO-14001 & OSHAS-18001 from Omnex. Educational Qualifi cation ’ā╝ B.Sc. ŌĆō 1997 ŌĆō BURDWAN UNIVERSITY, Calcutta ’ā╝ ŌĆ£Six Sigma Green BeltŌĆØ form ISI, Delhi Personal Inform ation Date of Birth Martial Status 10th Jan 1977 Married