Legaspi 04 mass_deacidification

1 like376 views

The document discusses mass deacidification methods for preserving paper documents. It provides an overview of the history of paper production and acidification issues. Various deacidification methods are examined, including solvent-based, fine dust, and aqueous treatment approaches. Recommendations are given for standards, production processes without alum or lignin, and maintaining proper documentation and evaluation of any mass deacidification workflow.

1 of 13

Download to read offline

Recommended

Desiccant Calculation Chart

Desiccant Calculation ChartThan Nguyen

?

This desiccant calculation chart below is specifically for estimating how much clay or silica gel desiccant you need.Dicyandiamide formaldehyde

Dicyandiamide formaldehydeprimary information services

?

Presentation by

Primary Information Services

www.primaryinfo.com

mailto:primaryinfo@gmail.com

Download PDF Version at

/thorapadi/presentations

See You tube Channel

https://www.youtube.com/user/ch600091/videos?view_as=subscriber§®§Ú§ç§Ñ§Ý§î§é§Ö§ß§Ü§à §®. §µ§Ü§â§Ñ?§ß§ã§î§Ü§Ñ §â§Ö§Ô?§à§ß§Ñ§Ý§î§ß§Ñ §è§Ú§Ó?§Ý?§Ù§Ñ§è?§ñ

§®§Ú§ç§Ñ§Ý§î§é§Ö§ß§Ü§à §®. §µ§Ü§â§Ñ?§ß§ã§î§Ü§Ñ §â§Ö§Ô?§à§ß§Ñ§Ý§î§ß§Ñ §è§Ú§Ó?§Ý?§Ù§Ñ§è?§ñ§§Ö§ß§Ñ §±§à§ß§à§Þ§Ñ§â§Ö§ß§Ü§à

?

§¬§Ñ§â§Ñ-§®§å§â§Ù§Ñ §³. §®§Ñ§ß§Ú§á§å§Ý§ñ§è§Ú§ñ §ã§à§Ù§ß§Ñ§ß§Ú§Ö§Þ (1)

§¬§Ñ§â§Ñ-§®§å§â§Ù§Ñ §³. §®§Ñ§ß§Ú§á§å§Ý§ñ§è§Ú§ñ §ã§à§Ù§ß§Ñ§ß§Ú§Ö§Þ (1)§§Ö§ß§Ñ §±§à§ß§à§Þ§Ñ§â§Ö§ß§Ü§à

?

This is why snow is awesome!

This is why snow is awesome!Stacii Rackhamm

?

Snow is beautiful to look at both during the day and at night. It makes cities and rural areas look more charming when blanketed in snow. Playing in the snow is fun and allows people to enjoy activities like building snowmen, making snow angels, sledding, tubing, skiing, snowboarding, and the winter sport of skeleton. Snowflakes have an amazing scientific structure and winter fashion includes snow boots, snow pants, and parkas. Animals like pandas, puppies, and cats also enjoy and look adorable playing in the snow. Snow provides the opportunity for catching snowflakes on your tongue, sledding, snowmobiling, horse-drawn sleigh rides, snowshoeing, snowball fights,Overview research project DAYSI ORELLANA

Overview research project DAYSI ORELLANAdaysiorellana

?

This document provides an overview of a research project conducted by four students on the influence of the internet on education. The research aims to determine how education has changed due to the rise of internet access and whether students use the internet as an educational tool or distraction. The document outlines the research topic, title, problem statement, questions, objectives, justification, theoretical framework and subtopics to be explored, including the influence of new technologies, internet as a tool for teachers and students, advantages and disadvantages of internet and cell phone use, and examples of technology advances in El Salvador. It concludes by describing a field visit to a private school in El Salvador where students were interviewed about their internet use for schoolwork, research and entertainment.§±§Ñ§ß§Ñ§â§Ú§ß §ª. §ª§ß§æ§à§â§Þ§Ñ§è§Ú§à§ß§ß§Ñ§ñ §Ó§à§Û§ß§Ñ §Ú §Ô§Ö§à§á§à§Ý§Ú§ä§Ú§Ü§Ñ

§±§Ñ§ß§Ñ§â§Ú§ß §ª. §ª§ß§æ§à§â§Þ§Ñ§è§Ú§à§ß§ß§Ñ§ñ §Ó§à§Û§ß§Ñ §Ú §Ô§Ö§à§á§à§Ý§Ú§ä§Ú§Ü§Ñ§§Ö§ß§Ñ §±§à§ß§à§Þ§Ñ§â§Ö§ß§Ü§à

?

§§ñ§ê§Ö§ß§Ü§à §´. §´§â§Ñ§ß§ã§æ§à§â§Þ§Ñ§è?§ñ §á§à§Ý?§ä§Ú§é§ß§Ú§ç §ã§Ú§ã§ä§Ö§Þ §Ó §Ü§â§Ñ?§ß§Ñ§ç §¸§Ö§ß§ä§â§Ñ§Ý§î§ß§à? §¡§Ù??

§§ñ§ê§Ö§ß§Ü§à §´. §´§â§Ñ§ß§ã§æ§à§â§Þ§Ñ§è?§ñ §á§à§Ý?§ä§Ú§é§ß§Ú§ç §ã§Ú§ã§ä§Ö§Þ §Ó §Ü§â§Ñ?§ß§Ñ§ç §¸§Ö§ß§ä§â§Ñ§Ý§î§ß§à? §¡§Ù??§§Ö§ß§Ñ §±§à§ß§à§Þ§Ñ§â§Ö§ß§Ü§à

?

Birch Street Uptown Lounge Presentation

Birch Street Uptown Lounge Presentationbirchstreetuptownlounge

?

The document contains the URL www.birchstreetuptownlounge.com repeated multiple times without any other text or context. It provides no other essential information beyond the website address.§¢§å§â§ñ§Ü §£. §µ§â§à§Õ§Ý§Ú§Ó§à§Ö §Õ§Ú§ä§ñ §Þ§Ñ§â§Ü§ã§Ú§Ù§Þ§Ñ. - §³§Ú§Þ§æ§Ö§â§à§á§à§Ý§î, 2011. - 152 §ã.(§à §Ô§Ý§à§Ò§Ñ§Ý§Ú§Ù§Ñ§è§Ú§Ú)

§¢§å§â§ñ§Ü §£. §µ§â§à§Õ§Ý§Ú§Ó§à§Ö §Õ§Ú§ä§ñ §Þ§Ñ§â§Ü§ã§Ú§Ù§Þ§Ñ. - §³§Ú§Þ§æ§Ö§â§à§á§à§Ý§î, 2011. - 152 §ã.(§à §Ô§Ý§à§Ò§Ñ§Ý§Ú§Ù§Ñ§è§Ú§Ú)§§Ö§ß§Ñ §±§à§ß§à§Þ§Ñ§â§Ö§ß§Ü§à

?

Roozgaar complaints - what is truth ?

Roozgaar complaints - what is truth ?Roozgaar Complaints

?

Roozgaar.com provides career, resume, salary, and emerging career assistance to help users. The document claims that all complaints against Roozgaar.com submitted by competitors are fake reviews intended to undermine the company. It encourages users to register on Roozgaar.com for assistance and provides contact information for the company.Canadian Federal System

Canadian Federal Systemjuddteacher

?

The document provides an overview of Canada's federal system of government, including its historical origins, constitutional framework, and three levels of government. It describes how the British North America Act established Canada's written constitution and divided powers between the federal and provincial governments. It also explains the key features of Canada's parliamentary system, including the legislative, executive, and judicial branches of government at both the federal and provincial levels. The document outlines the roles and responsibilities of institutions like Parliament, the Prime Minister, Cabinet, and the public service in Canada's democratic system of governance.Legaspi 02 data_curation_powerpoint

Legaspi 02 data_curation_powerpointBobby-Dhea Santos

?

The document discusses strategies for long-term storage and preservation of digital data. It covers topics such as digitization of physical materials like microfilm and tapes, challenges with file formats and storage media becoming obsolete, and the complexity of preserving "born digital" content over long periods of time. The presentation also addresses criteria for prioritizing what content to digitize, technical aspects of digital preservation systems, and challenges around defining what it means to ensure access and usability of stored data in the long run.Sla data curation

Sla data curationBobby-Dhea Santos

?

The document discusses challenges and best practices for data curation and long-term storage of digital data. It addresses issues with digitizing materials like microfilm and tapes, as well as challenges of storing "born digital" documents. The document outlines criteria for prioritizing what materials should be digitized to preserve for research. It also examines semantic problems in defining "long-term" storage and ensuring data can be accessed over long periods of time despite changing technologies.§²§Ú§é§Ñ§â§Õ §·§Ñ§â§â§Ú§ã §±§ã§Ú§ç§à§Ý§à§Ô§Ú§ñ §Þ§Ñ§ã§ã§à§Ó§í§ç §Ü§à§Þ§Þ§å§ß§Ú§Ü§Ñ§è§Ú§Û

§²§Ú§é§Ñ§â§Õ §·§Ñ§â§â§Ú§ã §±§ã§Ú§ç§à§Ý§à§Ô§Ú§ñ §Þ§Ñ§ã§ã§à§Ó§í§ç §Ü§à§Þ§Þ§å§ß§Ú§Ü§Ñ§è§Ú§Û§§Ö§ß§Ñ §±§à§ß§à§Þ§Ñ§â§Ö§ß§Ü§à

?

Confederacy conferences

Confederacy conferencesjuddteacher

?

The document summarizes the key conferences that led to Canadian Confederation:

- The Charlottetown and Quebec City conferences in 1864 laid the groundwork for a united Canada and discussed forming a federation with a central and provincial governments.

- The 72 Quebec Resolutions outlined the structure of government and terms for provinces to join Confederation.

- Despite objections from some Maritimes, the London Conference in 1866 finalized the details and received royal assent, establishing the Dominion of Canada through the British North America Act of 1867.¡¾Œg¼ù£¡¡¿×îÐÂÊÂÀý¤òº¬¤á¤¿¥ª¥¦¥ó¥É¥á¥Ç¥£¥¢¤Ç¤Î¿Î½ð¶¯»ÅäÐÅ¡¡

¡¾Œg¼ù£¡¡¿×îÐÂÊÂÀý¤òº¬¤á¤¿¥ª¥¦¥ó¥É¥á¥Ç¥£¥¢¤Ç¤Î¿Î½ð¶¯»ÅäÐÅ¡¡Suguru Ohta

?

2013,12,18¤Ë¿ª´ß¤µ¤ì¤Þ¤·¤¿¡¾Œg¼ù£¡¡¿¥ª¥¦¥ó¥É¥á¥Ç¥£¥¢¤Ç¤Î¿Î½ð¶¯»··‰Ó¥»¥ß¥Ê©`¤Ë¤Æ¤´Éܽ餵¤»¤Æ¶¥¤¤Þ¤·¤¿ÄÚÈݤǤ¹¡£Öêʽ»áÉ票¥Ó¥ê©`¡¡Ì«Ìï׿Northwest rebellion 1885

Northwest rebellion 1885juddteacher

?

The Metis people in western Canada saw their traditional way of life threatened by incoming settlers and the division of land into plots. Led by Gabriel Dumont and Louis Riel, who returned from exile at Dumont's request, the Metis petitioned the government to recognize their rights and create a homeland but were ignored. When negotiations failed, violence broke out between the Metis and North-West Mounted Police at Duck Lake, and later between Metis and Canadian militia at Batoche, where the Metis were ultimately defeated despite holding out for three days against overwhelming odds. Riel was captured and later hanged for treason, marking the end of the Northwest Rebellion of 1885.SoftControl - Company Introduction

SoftControl - Company IntroductionSoftControl.net Ltd.

?

SoftControl - Short Company Introduction. Since 1993 we served 200+ companies and helping them to boost their capabilities and to grow their business. Get more information about our Services and Products, short and to the point.

Visit our website: http://www.softcontrol.net

Tugas pak alan

Tugas pak alanMuhammad Fajar Fadil

?

Sistem kontrol robot terdiri dari kontroler, manipulator, dan sumber daya. Kontroler berfungsi sebagai pengendali gerakan manipulator dan dapat beroperasi secara otomatis maupun manual. Ada dua jenis kontrol robot, yaitu loop terbuka dimana output kontroler tidak mempengaruhi kinerja dan loop tertutup dimana kontroler dapat menyesuaikan gerakan berdasarkan hasil aktual. Sensor internal dan eksternal digunakan untuk mengontrol posisi dan lingkungan robot.Sla introrev

Sla introrevBobby-Dhea Santos

?

This document discusses preservation and conservation of historical documents. It begins with an overview of different mediums used over time for bearing information, such as clay, papyrus, paper and microfilm. It then shows examples of illuminated manuscripts, incunables, and block books. The document outlines key aspects of preservation and conservation such as cooperation, education, and disaster preparedness. It discusses various methods for paper deacidification and shows examples of damage from water, mold, ink corrosion and the vinegar syndrome affecting microfilms. The document concludes with basic considerations for preservation and restoration of books as cultural assets, including discussions on originality, minimal intervention and reversibility of restoration methods.Sla intro

Sla introBobby-Dhea Santos

?

This document discusses preservation, conservation, and data curation of historical documents. It provides examples of different types of historical documents like illuminated manuscripts, incunables, and photographs. It then discusses the various threats documents face like water and mold damage, ink corrosion, and vinegar syndrome in microfilms. The document outlines methods for preservation like deacidification processes and disaster preparedness. It also discusses conservation and restoration techniques with the goals of securing the text, respecting the originality and historical traces, and using reversible methods. Case studies of flood damage and fires are presented along with before and after photos of restoration projects.Sla definition

Sla definitionBobby-Dhea Santos

?

Preservation aims to prolong the life of records and metadata through non-interventive means. Conservation treats and repairs individual items to slow decay or restore usability. Restoration returns something to its original condition through repairing or cleaning. Data curation actively manages data through its life cycle for scholarship, science, and education including authentication, archiving, management, preservation, retrieval, and representation.Digital archives

Digital archivesBobby-Dhea Santos

?

1) The Supreme Court of the Philippines has digitized its archival collection in order to provide maximum access to legal sources and preserve original documents.

2) The archival collection includes primary sources like laws and court decisions from 1900 to present, as well as secondary sources. Materials are prioritized for digitization based on period and volume.

3) The digitization process involves scanning documents, converting images to text using OCR software, editing files, and making the collection available online through a searchable database and on CDs. This ensures preservation of sources and improves access for the judiciary, law schools, and public.More Related Content

Viewers also liked (18)

§§ñ§ê§Ö§ß§Ü§à §´. §´§â§Ñ§ß§ã§æ§à§â§Þ§Ñ§è?§ñ §á§à§Ý?§ä§Ú§é§ß§Ú§ç §ã§Ú§ã§ä§Ö§Þ §Ó §Ü§â§Ñ?§ß§Ñ§ç §¸§Ö§ß§ä§â§Ñ§Ý§î§ß§à? §¡§Ù??

§§ñ§ê§Ö§ß§Ü§à §´. §´§â§Ñ§ß§ã§æ§à§â§Þ§Ñ§è?§ñ §á§à§Ý?§ä§Ú§é§ß§Ú§ç §ã§Ú§ã§ä§Ö§Þ §Ó §Ü§â§Ñ?§ß§Ñ§ç §¸§Ö§ß§ä§â§Ñ§Ý§î§ß§à? §¡§Ù??§§Ö§ß§Ñ §±§à§ß§à§Þ§Ñ§â§Ö§ß§Ü§à

?

Birch Street Uptown Lounge Presentation

Birch Street Uptown Lounge Presentationbirchstreetuptownlounge

?

The document contains the URL www.birchstreetuptownlounge.com repeated multiple times without any other text or context. It provides no other essential information beyond the website address.§¢§å§â§ñ§Ü §£. §µ§â§à§Õ§Ý§Ú§Ó§à§Ö §Õ§Ú§ä§ñ §Þ§Ñ§â§Ü§ã§Ú§Ù§Þ§Ñ. - §³§Ú§Þ§æ§Ö§â§à§á§à§Ý§î, 2011. - 152 §ã.(§à §Ô§Ý§à§Ò§Ñ§Ý§Ú§Ù§Ñ§è§Ú§Ú)

§¢§å§â§ñ§Ü §£. §µ§â§à§Õ§Ý§Ú§Ó§à§Ö §Õ§Ú§ä§ñ §Þ§Ñ§â§Ü§ã§Ú§Ù§Þ§Ñ. - §³§Ú§Þ§æ§Ö§â§à§á§à§Ý§î, 2011. - 152 §ã.(§à §Ô§Ý§à§Ò§Ñ§Ý§Ú§Ù§Ñ§è§Ú§Ú)§§Ö§ß§Ñ §±§à§ß§à§Þ§Ñ§â§Ö§ß§Ü§à

?

Roozgaar complaints - what is truth ?

Roozgaar complaints - what is truth ?Roozgaar Complaints

?

Roozgaar.com provides career, resume, salary, and emerging career assistance to help users. The document claims that all complaints against Roozgaar.com submitted by competitors are fake reviews intended to undermine the company. It encourages users to register on Roozgaar.com for assistance and provides contact information for the company.Canadian Federal System

Canadian Federal Systemjuddteacher

?

The document provides an overview of Canada's federal system of government, including its historical origins, constitutional framework, and three levels of government. It describes how the British North America Act established Canada's written constitution and divided powers between the federal and provincial governments. It also explains the key features of Canada's parliamentary system, including the legislative, executive, and judicial branches of government at both the federal and provincial levels. The document outlines the roles and responsibilities of institutions like Parliament, the Prime Minister, Cabinet, and the public service in Canada's democratic system of governance.Legaspi 02 data_curation_powerpoint

Legaspi 02 data_curation_powerpointBobby-Dhea Santos

?

The document discusses strategies for long-term storage and preservation of digital data. It covers topics such as digitization of physical materials like microfilm and tapes, challenges with file formats and storage media becoming obsolete, and the complexity of preserving "born digital" content over long periods of time. The presentation also addresses criteria for prioritizing what content to digitize, technical aspects of digital preservation systems, and challenges around defining what it means to ensure access and usability of stored data in the long run.Sla data curation

Sla data curationBobby-Dhea Santos

?

The document discusses challenges and best practices for data curation and long-term storage of digital data. It addresses issues with digitizing materials like microfilm and tapes, as well as challenges of storing "born digital" documents. The document outlines criteria for prioritizing what materials should be digitized to preserve for research. It also examines semantic problems in defining "long-term" storage and ensuring data can be accessed over long periods of time despite changing technologies.§²§Ú§é§Ñ§â§Õ §·§Ñ§â§â§Ú§ã §±§ã§Ú§ç§à§Ý§à§Ô§Ú§ñ §Þ§Ñ§ã§ã§à§Ó§í§ç §Ü§à§Þ§Þ§å§ß§Ú§Ü§Ñ§è§Ú§Û

§²§Ú§é§Ñ§â§Õ §·§Ñ§â§â§Ú§ã §±§ã§Ú§ç§à§Ý§à§Ô§Ú§ñ §Þ§Ñ§ã§ã§à§Ó§í§ç §Ü§à§Þ§Þ§å§ß§Ú§Ü§Ñ§è§Ú§Û§§Ö§ß§Ñ §±§à§ß§à§Þ§Ñ§â§Ö§ß§Ü§à

?

Confederacy conferences

Confederacy conferencesjuddteacher

?

The document summarizes the key conferences that led to Canadian Confederation:

- The Charlottetown and Quebec City conferences in 1864 laid the groundwork for a united Canada and discussed forming a federation with a central and provincial governments.

- The 72 Quebec Resolutions outlined the structure of government and terms for provinces to join Confederation.

- Despite objections from some Maritimes, the London Conference in 1866 finalized the details and received royal assent, establishing the Dominion of Canada through the British North America Act of 1867.¡¾Œg¼ù£¡¡¿×îÐÂÊÂÀý¤òº¬¤á¤¿¥ª¥¦¥ó¥É¥á¥Ç¥£¥¢¤Ç¤Î¿Î½ð¶¯»ÅäÐÅ¡¡

¡¾Œg¼ù£¡¡¿×îÐÂÊÂÀý¤òº¬¤á¤¿¥ª¥¦¥ó¥É¥á¥Ç¥£¥¢¤Ç¤Î¿Î½ð¶¯»ÅäÐÅ¡¡Suguru Ohta

?

2013,12,18¤Ë¿ª´ß¤µ¤ì¤Þ¤·¤¿¡¾Œg¼ù£¡¡¿¥ª¥¦¥ó¥É¥á¥Ç¥£¥¢¤Ç¤Î¿Î½ð¶¯»··‰Ó¥»¥ß¥Ê©`¤Ë¤Æ¤´Éܽ餵¤»¤Æ¶¥¤¤Þ¤·¤¿ÄÚÈݤǤ¹¡£Öêʽ»áÉ票¥Ó¥ê©`¡¡Ì«Ìï׿Northwest rebellion 1885

Northwest rebellion 1885juddteacher

?

The Metis people in western Canada saw their traditional way of life threatened by incoming settlers and the division of land into plots. Led by Gabriel Dumont and Louis Riel, who returned from exile at Dumont's request, the Metis petitioned the government to recognize their rights and create a homeland but were ignored. When negotiations failed, violence broke out between the Metis and North-West Mounted Police at Duck Lake, and later between Metis and Canadian militia at Batoche, where the Metis were ultimately defeated despite holding out for three days against overwhelming odds. Riel was captured and later hanged for treason, marking the end of the Northwest Rebellion of 1885.SoftControl - Company Introduction

SoftControl - Company IntroductionSoftControl.net Ltd.

?

SoftControl - Short Company Introduction. Since 1993 we served 200+ companies and helping them to boost their capabilities and to grow their business. Get more information about our Services and Products, short and to the point.

Visit our website: http://www.softcontrol.net

Tugas pak alan

Tugas pak alanMuhammad Fajar Fadil

?

Sistem kontrol robot terdiri dari kontroler, manipulator, dan sumber daya. Kontroler berfungsi sebagai pengendali gerakan manipulator dan dapat beroperasi secara otomatis maupun manual. Ada dua jenis kontrol robot, yaitu loop terbuka dimana output kontroler tidak mempengaruhi kinerja dan loop tertutup dimana kontroler dapat menyesuaikan gerakan berdasarkan hasil aktual. Sensor internal dan eksternal digunakan untuk mengontrol posisi dan lingkungan robot.§§ñ§ê§Ö§ß§Ü§à §´. §´§â§Ñ§ß§ã§æ§à§â§Þ§Ñ§è?§ñ §á§à§Ý?§ä§Ú§é§ß§Ú§ç §ã§Ú§ã§ä§Ö§Þ §Ó §Ü§â§Ñ?§ß§Ñ§ç §¸§Ö§ß§ä§â§Ñ§Ý§î§ß§à? §¡§Ù??

§§ñ§ê§Ö§ß§Ü§à §´. §´§â§Ñ§ß§ã§æ§à§â§Þ§Ñ§è?§ñ §á§à§Ý?§ä§Ú§é§ß§Ú§ç §ã§Ú§ã§ä§Ö§Þ §Ó §Ü§â§Ñ?§ß§Ñ§ç §¸§Ö§ß§ä§â§Ñ§Ý§î§ß§à? §¡§Ù??§§Ö§ß§Ñ §±§à§ß§à§Þ§Ñ§â§Ö§ß§Ü§à

?

§¢§å§â§ñ§Ü §£. §µ§â§à§Õ§Ý§Ú§Ó§à§Ö §Õ§Ú§ä§ñ §Þ§Ñ§â§Ü§ã§Ú§Ù§Þ§Ñ. - §³§Ú§Þ§æ§Ö§â§à§á§à§Ý§î, 2011. - 152 §ã.(§à §Ô§Ý§à§Ò§Ñ§Ý§Ú§Ù§Ñ§è§Ú§Ú)

§¢§å§â§ñ§Ü §£. §µ§â§à§Õ§Ý§Ú§Ó§à§Ö §Õ§Ú§ä§ñ §Þ§Ñ§â§Ü§ã§Ú§Ù§Þ§Ñ. - §³§Ú§Þ§æ§Ö§â§à§á§à§Ý§î, 2011. - 152 §ã.(§à §Ô§Ý§à§Ò§Ñ§Ý§Ú§Ù§Ñ§è§Ú§Ú)§§Ö§ß§Ñ §±§à§ß§à§Þ§Ñ§â§Ö§ß§Ü§à

?

§²§Ú§é§Ñ§â§Õ §·§Ñ§â§â§Ú§ã §±§ã§Ú§ç§à§Ý§à§Ô§Ú§ñ §Þ§Ñ§ã§ã§à§Ó§í§ç §Ü§à§Þ§Þ§å§ß§Ú§Ü§Ñ§è§Ú§Û

§²§Ú§é§Ñ§â§Õ §·§Ñ§â§â§Ú§ã §±§ã§Ú§ç§à§Ý§à§Ô§Ú§ñ §Þ§Ñ§ã§ã§à§Ó§í§ç §Ü§à§Þ§Þ§å§ß§Ú§Ü§Ñ§è§Ú§Û§§Ö§ß§Ñ §±§à§ß§à§Þ§Ñ§â§Ö§ß§Ü§à

?

More from Bobby-Dhea Santos (8)

Sla introrev

Sla introrevBobby-Dhea Santos

?

This document discusses preservation and conservation of historical documents. It begins with an overview of different mediums used over time for bearing information, such as clay, papyrus, paper and microfilm. It then shows examples of illuminated manuscripts, incunables, and block books. The document outlines key aspects of preservation and conservation such as cooperation, education, and disaster preparedness. It discusses various methods for paper deacidification and shows examples of damage from water, mold, ink corrosion and the vinegar syndrome affecting microfilms. The document concludes with basic considerations for preservation and restoration of books as cultural assets, including discussions on originality, minimal intervention and reversibility of restoration methods.Sla intro

Sla introBobby-Dhea Santos

?

This document discusses preservation, conservation, and data curation of historical documents. It provides examples of different types of historical documents like illuminated manuscripts, incunables, and photographs. It then discusses the various threats documents face like water and mold damage, ink corrosion, and vinegar syndrome in microfilms. The document outlines methods for preservation like deacidification processes and disaster preparedness. It also discusses conservation and restoration techniques with the goals of securing the text, respecting the originality and historical traces, and using reversible methods. Case studies of flood damage and fires are presented along with before and after photos of restoration projects.Sla definition

Sla definitionBobby-Dhea Santos

?

Preservation aims to prolong the life of records and metadata through non-interventive means. Conservation treats and repairs individual items to slow decay or restore usability. Restoration returns something to its original condition through repairing or cleaning. Data curation actively manages data through its life cycle for scholarship, science, and education including authentication, archiving, management, preservation, retrieval, and representation.Digital archives

Digital archivesBobby-Dhea Santos

?

1) The Supreme Court of the Philippines has digitized its archival collection in order to provide maximum access to legal sources and preserve original documents.

2) The archival collection includes primary sources like laws and court decisions from 1900 to present, as well as secondary sources. Materials are prioritized for digitization based on period and volume.

3) The digitization process involves scanning documents, converting images to text using OCR software, editing files, and making the collection available online through a searchable database and on CDs. This ensures preservation of sources and improves access for the judiciary, law schools, and public.Legaspi 03 d_rizal_mss_powerpoint

Legaspi 03 d_rizal_mss_powerpointBobby-Dhea Santos

?

This document discusses the conservation of Jose Rizal manuscripts by Reinhard Feldmann at Aquinas University in Legaspi from April 10th to 12th. It provides before and after photos documenting the restoration of the front board, spine, back board, pages, and binding of manuscripts including Noli Me Tangere and El Filibusterismo. The conservation addressed damages and stabilized the structure of the rare manuscripts.Legaspi 05 emergency-1

Legaspi 05 emergency-1Bobby-Dhea Santos

?

The document outlines ten aspects of conservation including determining damage, passive conservation methods, restorative ethics and techniques, mass deacidification, format conversion methods, disaster preparedness, and organization and financing. Specific techniques are described for freeze-drying water damaged materials and restoring fire damaged books through reconstructing the book block, removing ashes, stabilizing pages, and pressing. The goal of restoration is to conserve original paper substances and structures.Legaspi 01 introduction_notes_powerpoint

Legaspi 01 introduction_notes_powerpointBobby-Dhea Santos

?

1) The document discusses preservation, conservation, and data curation of libraries and historical documents. It covers topics like paper decay over time, disaster preparedness, deacidification methods, and restoration techniques.

2) Key aspects of preservation and conservation discussed include cooperation, education, research, financial resources, addressing paper decay, disaster planning, and individual restoration treatments.

3) The conclusion emphasizes that libraries, archives, and museums contain important cultural traditions that serve as a spiritual home for nations, especially as societies progress into the future.What is AUNILO?

What is AUNILO?Bobby-Dhea Santos

?

AUNILO is the ASEAN University Network Inter-Library Online, which was established in 1997 to enhance information sharing and collaboration among the member university libraries of the ASEAN University Network (AUN). AUNILO's goal is to support the development of an ASEAN virtual university. It currently has 30 member university libraries across Southeast Asia. In 2014, AUNILO provided a capability building training for its librarians to develop their skills in areas like grant writing, conference participation, research publication, learning management systems, web development, and database management. The training was led by speakers from universities in Malaysia and the Philippines.Recently uploaded (20)

BISNIS BERKAH BERANGKAT KE MEKKAH ISTIKMAL SYARIAH

BISNIS BERKAH BERANGKAT KE MEKKAH ISTIKMAL SYARIAHcoacharyasetiyaki

?

BISNIS BERKAH BERANGKAT KE MEKKAH ISTIKMAL SYARIAHInterim Guidelines for PMES-DM-17-2025-PPT.pptx

Interim Guidelines for PMES-DM-17-2025-PPT.pptxsirjeromemanansala

?

This is the latest issuance on PMES as replacement of RPMS. Kindly message me to gain full access of the presentation. Helping Autistic Girls Shine Webinar ºÝºÝߣs

Helping Autistic Girls Shine Webinar ºÝºÝߣsPooky Knightsmith

?

For more information about my speaking and training work, visit: https://www.pookyknightsmith.com/speaking/NUTRITIONAL ASSESSMENT AND EDUCATION - 5TH SEM.pdf

NUTRITIONAL ASSESSMENT AND EDUCATION - 5TH SEM.pdfDolisha Warbi

?

NUTRITIONAL ASSESSMENT AND EDUCATION, Introduction, definition, types - macronutrient and micronutrient, food pyramid, meal planning, nutritional assessment of individual, family and community by using appropriate method, nutrition education, nutritional rehabilitation, nutritional deficiency disorder, law/policies regarding nutrition in India, food hygiene, food fortification, food handling and storage, food preservation, food preparation, food purchase, food consumption, food borne diseases, food poisoningInventory Reporting in Odoo 17 - Odoo 17 Inventory App

Inventory Reporting in Odoo 17 - Odoo 17 Inventory AppCeline George

?

This slide will helps us to efficiently create detailed reports of different records defined in its modules, both analytical and quantitative, with Odoo 17 ERP.Full-Stack .NET Developer Interview Questions PDF By ScholarHat

Full-Stack .NET Developer Interview Questions PDF By ScholarHatScholarhat

?

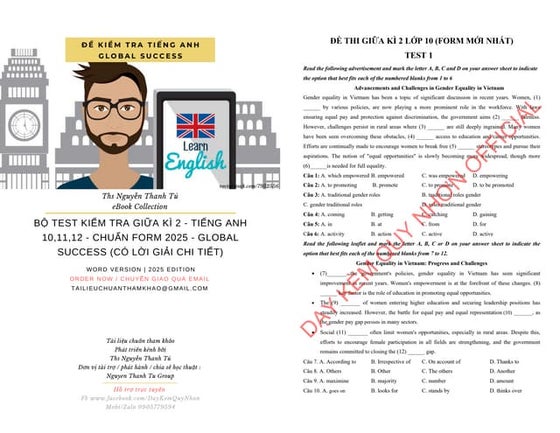

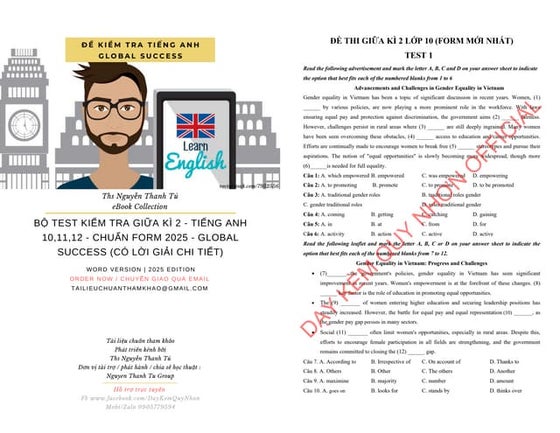

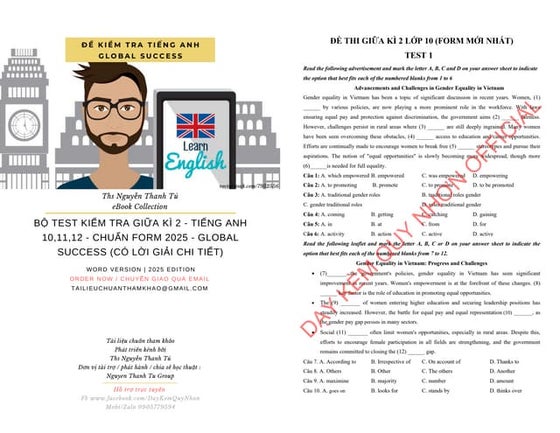

Full-Stack .NET Developer Interview Questions PDF By ScholarHatB? TEST KI?M TRA GI?A K? 2 - TI?NG ANH 10,11,12 - CHU?N FORM 2025 - GLOBAL SU...

B? TEST KI?M TRA GI?A K? 2 - TI?NG ANH 10,11,12 - CHU?N FORM 2025 - GLOBAL SU...Nguyen Thanh Tu Collection

?

https://app.box.com/s/ij1ty3vm7el9i4qfrr41o756xycbahmgFunctional Muscle Testing of Facial Muscles.pdf

Functional Muscle Testing of Facial Muscles.pdfSamarHosni3

?

Functional Muscle Testing of Facial Muscles.pdfMeeting the needs of modern students?, Selina McCoy

Meeting the needs of modern students?, Selina McCoyEconomic and Social Research Institute

?

NAPD Annual Symposium

¡°Equity in our Schools: Does the system deliver for all young people?¡±One Click RFQ Cancellation in Odoo 18 - Odoo ºÝºÝߣs

One Click RFQ Cancellation in Odoo 18 - Odoo ºÝºÝߣsCeline George

?

In this slide, we¡¯ll discuss the one click RFQ Cancellation in odoo 18. One-Click RFQ Cancellation in Odoo 18 is a feature that allows users to quickly and easily cancel Request for Quotations (RFQs) with a single click.RRB ALP CBT 2 RAC Question Paper MCQ (Railway Assistant Loco Pilot)

RRB ALP CBT 2 RAC Question Paper MCQ (Railway Assistant Loco Pilot)SONU HEETSON

?

RRB ALP CBT 2 RAC Question Paper MCQ PDF Free Download. Railway Assistant Loco Pilot Mechanic Refrigeration and Air Conditioning Important Questions.ASP.NET Interview Questions PDF By ScholarHat

ASP.NET Interview Questions PDF By ScholarHatScholarhat

?

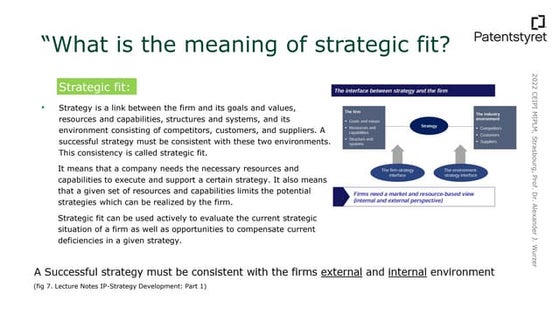

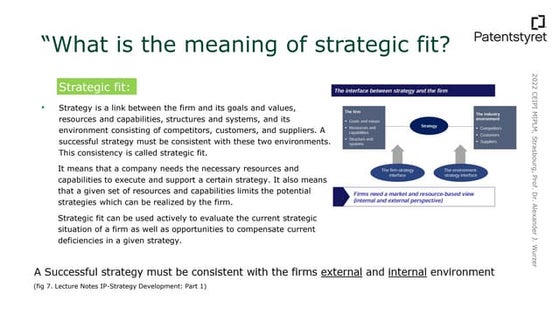

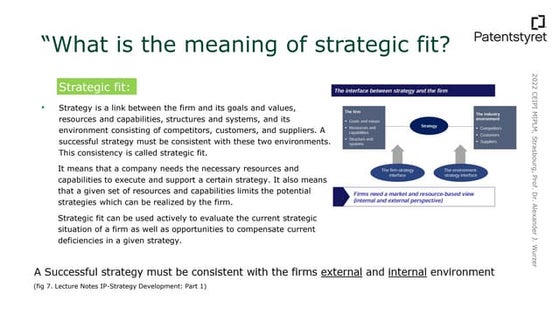

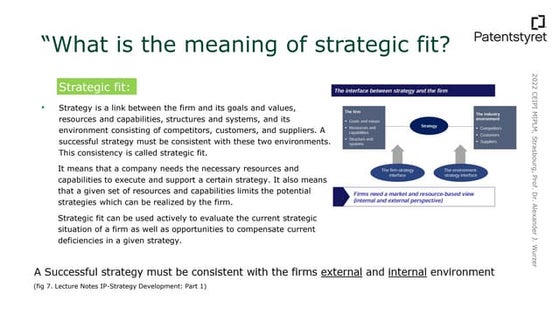

ASP.NET Interview Questions PDF By ScholarHatOral exam Kenneth Bech - What is the meaning of strategic fit?

Oral exam Kenneth Bech - What is the meaning of strategic fit?MIPLM

?

Presentation of the CEIPI DU IPBA oral exam of Kenneth Bech - What is the meaning of strategic fit? Unit 1 Computer Hardware for Educational Computing.pptx

Unit 1 Computer Hardware for Educational Computing.pptxRomaSmart1

?

Computers have revolutionized various sectors, including education, by enhancing learning experiences and making information more accessible. This presentation, "Computer Hardware for Educational Computing," introduces the fundamental aspects of computers, including their definition, characteristics, classification, and significance in the educational domain. Understanding these concepts helps educators and students leverage technology for more effective learning.Intellectual Honesty & Research Integrity.pptx

Intellectual Honesty & Research Integrity.pptxNidhiSharma495177

?

Research Publication & Ethics contains a chapter on Intellectual Honesty and Research Integrity.

Different case studies of intellectual dishonesty and integrity were discussed.How to Configure Proforma Invoice in Odoo 18 Sales

How to Configure Proforma Invoice in Odoo 18 SalesCeline George

?

In this slide, we¡¯ll discuss on how to configure proforma invoice in Odoo 18 Sales module. A proforma invoice is a preliminary invoice that serves as a commercial document issued by a seller to a buyer.B? TEST KI?M TRA GI?A K? 2 - TI?NG ANH 10,11,12 - CHU?N FORM 2025 - GLOBAL SU...

B? TEST KI?M TRA GI?A K? 2 - TI?NG ANH 10,11,12 - CHU?N FORM 2025 - GLOBAL SU...Nguyen Thanh Tu Collection

?

Legaspi 04 mass_deacidification

- 1. Reinhard Feldmann Mass De-acidification Legaspi, Aquinas University 10th to 12th April 2014

- 2. ? History ? Deacidification or Digitasation? ? Recommendations ? Standards: ISO 9706 ? Production in alcaline medium ? No use of alum ? Buffering substance (Calcium carbonate 2 %) ? No use of wood fibres (no Lignin) Paper decay and mass de-acidification Mass de-acidification I: Introduction

- 3. Deacidification methods Deacidification methods ? Solvents ? Fine dust method ? Aqueous treatment

- 4. Deacidification methods Deacidification (solvents): Papersave

- 5. Deacidification methods Deacidification (fine dust): bookkeeper

- 8. Necessity of paper deacidification 1798 First paper making maschine 1807 Invention of Illig 1807 Industrially produced paper 1844 Wood as a new source Since 1980/1990: Neutral or alcaline production Mass deacidification II: Special problems and workflow

- 9. Conclusions | Practical hints | Agenda: ? Detailed recording system ? Information exchange ? Internal check of workflow ? Regular reporting ? Scientific evaluation Mass deacidification

- 10. 1.) Pre-Cleaning of the books 2.) Deacidification and drying

- 11. Observing the books during the deacidification process. Process-Center (automatic unit) for deacidification. Results are recorded for control

- 12. Filter for extraction of dust and dirt

- 13. Testing pen for pH value of the paper