Supplier Development Program - UNDP, Pakistan

- 1. SUPPLIER DEVELOPMENT PROGRAMME POWERED BY: UNDP, PAKISTAN Building Comprehensive Markets & Generating Equitable Growth M Bilal Khattak SDP Consultant

- 2. CONTENTS ï What is SDP? ï Mission &Vision ï Why SDP? ï EstimatedTime with Stages ï Methodology ï What SDP offers to Lead Company and SupplierCompany? ï Requirement for ParticipatingCompanies in SDP ï Cost, support & subsidies for Lead Company & Supplier Companies D EV E L O P M E NT P R O G R A M M ES U P P L I E R

- 3. WHAT IS SDP? D EV E L O P M E NT P R O G R A M M ES U P P L I E R What is Supplier Development? ï§ Supplier Development is the process of working with certain suppliers on a one-to-one basis to improve their performance (and capabilities) for the benefit of the buying organization (Lead Company). What is UNDP â SDP (Supplier Development Program) ? ï§ UNDP Pakistan aims to Implement system through SDP: ï§ That transforms the business relationship between a Leader Enterprise (Large and Medium) and its suppliers ï§ Enhance the Pakistani economy by strengthening the competitive capacities of different sectors Main Objectives of SDP ï§ To increase the social and economic profitability of participating enterprises ï§ Promote the incorporation of latest technologies, teamwork, entrepreneurial and associative integration practices in the companies that promote their development and give them a long- term viability.

- 4. SDP MISSION &VISION ï To Contribute to increased competitiveness and creation of decent work in small and medium enterprises in Pakistan ï To strengthen value chains, based on the implementation of an efficient methodology ï To build strategic relationships with supply companies demanding goods and/or services D EV E L O P M E NT P R O G R A M M ES U P P L I E R âBecome a lead and reference programme in development of suppliers for Pakistan, that helps improve the performance of strategic sectors and generates opportunities by articulating them with the market, through capacity building of small and medium enterprisesâ MISSION VISION

- 5. WHY SDP? D EV E L O P M E NT P R O G R A M M ES U P P L I E R The Supplier Development Programme can: ï§ Reduce the Cost: Cost reduction that helps to maintain the supplierâs profit margin ï§ Resolve Serious Quality issue: Quality improvement that both reduces reject costs and/or increase reliability of buyerâs goods or manufacturing processes ï§ Develop new routes to supply ï§ Ensure quality control at supplier locations ï§ Increase profitability of all the participants in the chain: ï§ Boost Company Sales ï§ Develop a product or service not currently available in market place ï§ Generate competition for a high price product or service dominating market ï§ Improve business alignment between the Lead Company and Supplier ï§ Better Policies, Purchasing Practices, Strategy, and trained people to replicate the SDP to the rest of the production chain

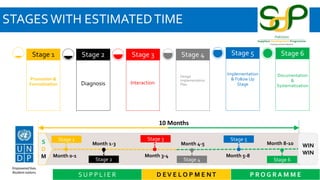

- 6. STAGESWITH ESTIMATEDTIME D EV E L O P M E NT P R O G R A M M ES U P P L I E R Promotion & Formalization Stage 1 Stage 2 Stage 3 Stage 4 Implementation & Follow Up Stage Stage 5 Documentation & Systematization Stage 6 Diagnosis Interaction Design Implementation Plan 10 Months Month 8-10 Stage 1 Stage 3 Stage 5 Stage 2 Stage 4 Stage 6 Month 0-1 Month 1-3 Month 3-4 Month 4-5 Month 5-8 S D M WIN WIN

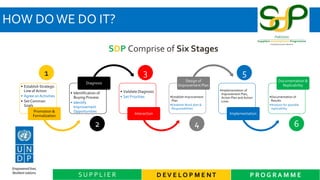

- 7. HOW DO WE DO IT? D EV E L O P M E NT P R O G R A M M ES U P P L I E R âĒ Establish Strategic Line of Action âĒ Agree on Activities âĒ Set Common Goals Promotion & Formalization âĒ Identification of Buying Process âĒ Identify Improvement Opportunities Diagnosis âĒ Validate Diagnosis âĒ Set Priorities Interaction âĒEstablish Improvement Plan âĒEstablish Work plan & Responsibilities Design of Improvement Plan âĒImplementation of Improvement Plan, Action Plan and Action Lines Implementation âĒDocumentation of Results âĒAnalysis for possible replicability Documentation & Replicability SDP Comprise of Six Stages 1 3 5 2 4 6

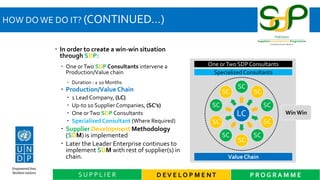

- 8. HOW DO WE DO IT? (CONTINUEDâĶ) D EV E L O P M E NT P R O G R A M M ES U P P L I E R ï In order to create a win-win situation through SDP: ï One orTwo SDP Consultants intervene a Production/Value chain ï Duration : Âą 10 Months ï Production/Value Chain ï 1 Lead Company, (LC) ï Up-to 10 SupplierCompanies, (SCâs) ï One orTwo SDP Consultants ï Specialized Consultant (Where Required) ï Supplier Development Methodology (SDM) is implemented ï Later the Leader Enterprise continues to implement SDM with rest of supplier(s) in chain. LC SC SC SC SC SC SC SC SC SC SC Value Chain One orTwo SDP Consultants WinWin SpecializedConsultants

- 9. WHAT SDP OFFERSTO LEAD COMPANY AND SUPPLIER COMPANY? Lead Company achieves ïž Develops more reliable suppliers on price, quality, delivery times, servicesâĶ ïž Improves LC productivity by greater performance thanks to reduction of faults and delays ïž Better policies and purchasing practices ïž Flexibility in its supplies ïž Strategy, SDP Manual, and trained people to replicate the SDP to the rest of the production chain Supplier Company achieves ïž Vision and clarity about its sales (it allows investments/ improvement projects) ïž Increases sales and/or profits ïž More competitive prices ïž Improves customer satisfaction: price, time, quality, service,Technical assistance ïž Culture of quality and continuous improvement D EV E L O P M E NT P R O G R A M M ES U P P L I E R ASSC : Assessment System of Supplier Certification Certification itself by Lead Company to its Supplier Companies

- 10. WHAT SDP OFFERSTO LEAD COMPANY AND SUPPLIER COMPANY? (CONTINUEDâĶ) D EV E L O P M E NT P R O G R A M M ES U P P L I E R LongTerm Corporate Supply (Globally) Certainty Joint Investment Strategic Partners MidTerm Training & Information Communication Technical Assistance ShortTerm DeliveryTime Timely Payment Quality Flexibility Cost Reduction Competitive Price âĒ Outcome Levels: SDP investment must show specific Returns. SDP Perspective: Measure Short-term Activity, Mid-term pipeline and Long-term growth âĒ Building Trust: Flexible relation and communication, between Lead Company and Supplier Company âĒ Information and linkage with support institutions to develop SMEÂīs

- 11. REQUIREMENT FOR PARTICIPATING COMPANIES IN SDP D EV E L O P M E NT P R O G R A M M ES U P P L I E R Not reluctant to involve different areas/departments of the company Wish to Improve purchase practices and promote Plans of Improvement Timely Delivery of required information for diagnostic, impact assessment and subsidy Legalization: Wish to change/Implement legislation, regulation, systems or procedures Improving environmental performance and sustainability within the supply chain Wish to Implement SupplierCertification System (for Lead Company) Market Access: Have no Links with sustained market and have limited BusinessVision Finances: Limited access to Financial resources and have Poor Financial Controls Operation: Have Low quality products, under-developed process and Non Calculation of Production costs Formation of groups without strong links and Limited distribution of responsibilities

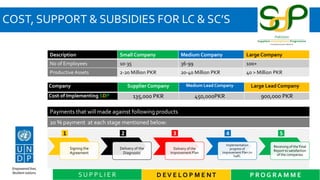

- 12. COST, SUPPORT & SUBSIDIES FOR LC & SCâS D EV E L O P M E NT P R O G R A M M ES U P P L I E R Description Small Company Medium Company Large Company No of Employees 10-35 36-99 100+ Productive Assets 2-20 Million PKR 20-40 Million PKR 40 > Million PKR Company Supplier Company Medium Lead Company Large Lead Company Cost of Implementing SDP 135,000 PKR 450,000PKR 900,000 PKR Signing the Agreement Delivery of the Diagnostic Delivery of the Improvement Plan Implementation progress of Improvement Plan (in half). Receiving of the Final Report to satisfaction of the companies Payments that will made against following products 20 % payment at each stage mentioned below: 1 2 3 4 5

- 13. THANKYOU ! UNDP - Supplier Development Program