CSN840 Pallet™ Product Presentation

- 1. CSN840 Pallet ™ Product Presentation November 2009

- 2. Product Overview What is the CSN840 Pallet™? An attended, static system for the automatic collection of dimensions, weight and identification of pallets Designed for the CEP and Freight Forwarding Industries Reason to invest? Revenue Recovery!

- 3. Customer Needs System Configurations Operation Key Specifications Features and Benefits Working Principle Contents

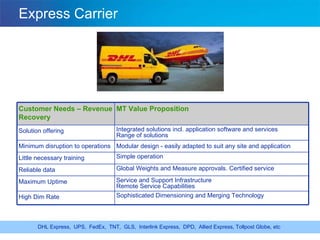

- 4. Express Carrier DHL Express, UPS, FedEx, TNT, GLS, Interlink Express, DPD, Allied Express, Tollpost Globe, etc Customer Needs – Revenue Recovery MT Value Proposition Solution offering Integrated solutions incl. application software and services Range of solutions Minimum disruption to operations Modular design - easily adapted to suit any site and application Little necessary training Simple operation Reliable data Global Weights and Measure approvals. Certified service Maximum Uptime Service and Support Infrastructure Remote Service Capabilities High Dim Rate Sophisticated Dimensioning and Merging Technology

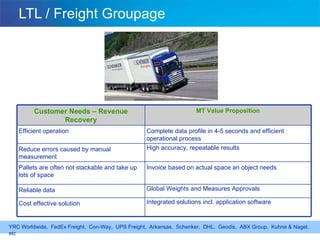

- 5. LTL / Freight Groupage Customer Needs – Revenue Recovery MT Value Proposition Efficient operation Complete data profile in 4-5 seconds and efficient operational process Reduce errors caused by manual measurement High accuracy, repeatable results Pallets are often not stackable and take up lots of space Invoice based on actual space an object needs Reliable data Global Weights and Measures Approvals Cost effective solution Integrated solutions incl. application software YRC Worldwide, FedEx Freight, Con-Way, UPS Freight, Arkansas, Schenker, DHL, Geodis, ABX Group, Kuhne & Nagel, etc

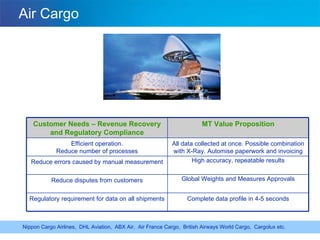

- 6. Air Cargo Nippon Cargo Airlines, DHL Aviation, ABX Air, Air France Cargo, British Airways World Cargo, Cargolux etc. Customer Needs – Revenue Recovery and Regulatory Compliance MT Value Proposition Efficient operation. Reduce number of processes All data collected at once. Possible combination with X-Ray. Automise paperwork and invoicing Reduce errors caused by manual measurement High accuracy, repeatable results Reduce disputes from customers Global Weights and Measures Approvals Regulatory requirement for data on all shipments Complete data profile in 4-5 seconds

- 7. Warehouse Needs (1/3) Customer Needs: Efficient collection of accurate volume and identification of all inbound items Reduce time and errors associated with manual measuring (get rid of tape measure and guesswork) 100% inventory accuracy and maximisation of resources ( > 80% occupied at normal inventory levels) MT Value Proposition: Real-time database update with accurate item information Simplify documentation process; avoid human errors Improve productivity and resource capacity planning through increased data transparency Information to update database Put-away Picking Checking Shipping Packing Receiving

- 8. Warehouse Needs (2/3) Customer Needs: Audit picking accuracy; require 100% shipping accuracy Avoid shipping air (shipping small items in large boxes); reduce packing material and shipping costs Increase productivity; avoid packing and repacking MT Value Proposition : Increase profitability by reducing number of returns Improve service quality and order fulfilment times Automatically decide packaging requirements for lowest transport rates Quality Control Put-away Picking Checking Shipping Packing Receiving

- 9. Warehouse Needs (3/3) Customer Needs: Efficient collection of accurate volume, weight and identification of all outbound items Improved carrier selection criteria (not just based on weight and guesswork) Effective integrated solution to reduce backcharges MT Value Proposition: Improve profitability with real-time item information for cost-effective carrier selection and revenue protection Collect shipping statistics that enable you to negotiate better prices with your transport company Increase load planning effectiveness Know actual transport costs Put-away Picking Checking Shipping Packing Receiving

- 10. Modular Design Choose the right component for the application Dimensioner CSN840.3 – designed to measure any surface Workstation Workstation with 17” monitor available, keyboard and controller Embedded Application Software OCTO™ – Advanced merging technology with simple and informative user interface Handheld Barcode Reader Datalogic Gryphon, long range Scale Choose from variety of MT scales

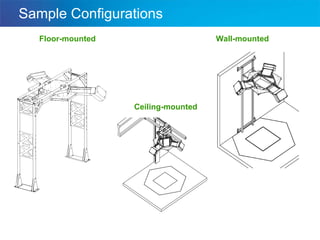

- 11. Sample Configurations Floor-mounted Wall-mounted Ceiling-mounted

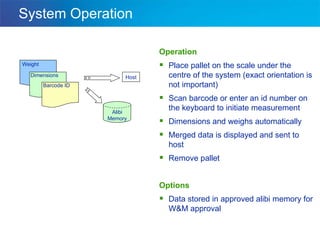

- 12. System Operation Operation Place pallet on the scale under the centre of the system (exact orientation is not important) Scan barcode or enter an id number on the keyboard to initiate measurement Dimensions and weighs automatically Merged data is displayed and sent to host Remove pallet Options Data stored in approved alibi memory for W&M approval Weight Dimensions Barcode ID Host Alibi Memory

- 13. User Interface Graphical operator screen Illustrative interface providing immediate feedback for operator measuring pallets Statistics showing system performance Warning messages Clear warnings Early warning of system failure Remote operator screen Monitor system performance at remote location Centralised system surveillance for efficient maintenance

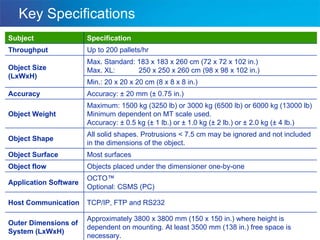

- 14. Key Specifications Subject Specification Throughput Up to 200 pallets/hr Object Size (LxWxH) Max. Standard: 183 x 183 x 260 cm (72 x 72 x 102 in.) Max. XL: 250 x 250 x 260 cm (98 x 98 x 102 in.) Min.: 20 x 20 x 20 cm (8 x 8 x 8 in.) Accuracy Accuracy: ± 20 mm (± 0.75 in.) Object Weight Maximum: 1500 kg (3250 lb) or 3000 kg (6500 lb) or 6000 kg (13000 lb) Minimum dependent on MT scale used. Accuracy: ± 0.5 kg (± 1 lb.) or ± 1.0 kg (± 2 lb.) or ± 2.0 kg (± 4 lb.) Object Shape All solid shapes. Protrusions < 7.5 cm may be ignored and not included in the dimensions of the object. Object Surface Most surfaces Object flow Objects placed under the dimensioner one-by-one Application Software OCTO™ Optional: CSMS (PC) Host Communication TCP/IP, FTP and RS232 Outer Dimensions of System (LxWxH) Approximately 3800 x 3800 mm (150 x 150 in.) where height is dependent on mounting. At least 3500 mm (138 in.) free space is necessary.

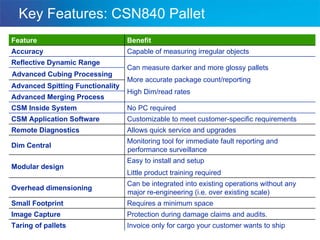

- 15. Key Features: CSN840 Pallet Feature Benefit Accuracy Capable of measuring irregular objects Reflective Dynamic Range Can measure darker and more glossy pallets More accurate package count/reporting High Dim/read rates Advanced Cubing Processing Advanced Spitting Functionality Advanced Merging Process CSM Inside System No PC required CSM Application Software Customizable to meet customer-specific requirements Remote Diagnostics Allows quick service and upgrades Dim Central Monitoring tool for immediate fault reporting and performance surveillance Modular design Easy to install and setup Little product training required Overhead dimensioning Can be integrated into existing operations without any major re-engineering (i.e. over existing scale) Small Footprint Requires a minimum space Image Capture Protection during damage claims and audits. Taring of pallets Invoice only for cargo your customer wants to ship

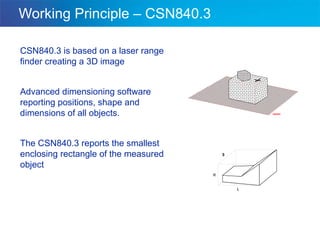

- 16. Working Principle – CSN840.3 CSN840.3 is based on a laser range finder creating a 3D image Advanced dimensioning software reporting positions, shape and dimensions of all objects. The CSN840.3 reports the smallest enclosing rectangle of the measured object

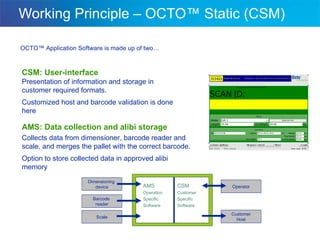

- 17. Working Principle – OCTO™ Static (CSM) AMS: Data collection and alibi storage Collects data from dimensioner, barcode reader and scale, and merges the pallet with the correct barcode. Option to store collected data in approved alibi memory CSM: User-interface Presentation of information and storage in customer required formats. Customized host and barcode validation is done here OCTO™ Application Software is made up of two… Dimensioning device Barcode reader Customer Host Operator AMS Operation Specific Software CSM Customer Specific Software Scale

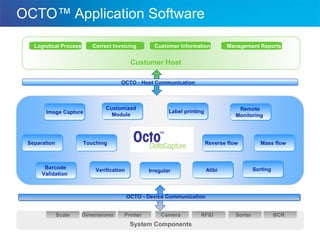

- 18. OCTO™ Application Software Scale System Components Barcode Validation Irregular Verification Alibi Sorting Image Capture Remote Monitoring Customized Module Dimensioner Printer Camera RFID Sorter BCR OCTO - Host Communication OCTO - Device Communication Correct Invoicing Logistical Process Customer Information Management Reports Customer Host Mass flow Label printing Separation Reverse flow Touching

- 19. Global Service We are where you are!