saravanan WHOP

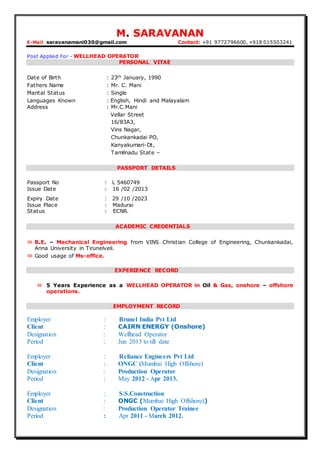

- 1. M. SARAVANAN E-Mail: saravanamani030@gmail.com Contact: +91 9772796600, +918 015503241 Post Applied For - WELLHEAD OPERATOR PERSONAL VITAE Date of Birth : 23th January, 1990 Fathers Name : Mr. C. Mani Marital Status : Single Languages Known : English, Hindi and Malayalam Address : Mr.C.Mani Vellar Street 16/83A3, Vins Nagar, Chunkankadai PO, Kanyakumari-Dt, Tamilnadu State ÔÇô PASSPORT DETAILS Passport No : L 5460749 Issue Date : 16 /02 /2013 Expiry Date : 29 /10 /2023 Issue Place : Madurai Status : ECNR. ACADEMIC CREDENTIALS ´â│ B.E. ÔÇô Mechanical Engineering from VINS Christian College of Engineering, Chunkankadai, Anna University in Tirunelveli. ´â│ Good usage of Ms-office. EXPERIENCE RECORD ´â│ 5 Years Experience as a WELLHEAD OPERATOR in Oil & Gas, onshore ÔÇô offshore operations. EMPLOYMENT RECORD Employer : Brunel India Pvt Ltd Client : CAIRN ENERGY (Onshore) Designation : Wellhead Operator Period : Jun 2013 to till date Employer : Reliance Engineers Pvt Ltd Client : ONGC (Mumbai High Offshore) Designation : Production Operator Period : May 2012 - Apr 2013. Employer : S.S.Construction Client : ONGC (Mumbai High Offshore)) Designation : Production Operator Trainee Period : Apr 2011 - March 2012.

- 2. SAFETY COURSES ´âÿ Permit to work system ´âÿ Job hazard analysis ´âÿ Basic gas testing ´âÿ H2S awareness & escape training ´âÿ Personnel survival techniques ´âÿ Fire prevention and fire fighting. ´âÿ Elementary first aid. ´âÿ Personnel safety and social responsibilities. ´âÿ Helicopter underwater escape training. Well Head On-Shore Operations: ´ü Well pad routine checks ´ü Well parameters monitoring and logging ´ü Contact with CCR on need basis for any process / Equipment performance update ´ü Equipment operations observation and inform control / Field Engineer For any abnormalities ´ü Mud pit, Flare pit, Drain system observation for any abnormalities ´ü Well (Jet pump, ESP Pump and Natural ) Opening / Shutting Down as per CCR advice ´ü Well activation ´ü Choke Bean Up / Bean Down as per CCR advice ´ü Pad shutdown for any maintenance ´ü Pad handover to Rig / From Rig ´ü Pad handover to Well Service / From Well Service ´ü Co ÔÇô Ordination with Well services and process activities ´ü PM activities Co ÔÇô Ordination with mechanical crews ´ü To do process Isolation and De-isolation ´ü Cellar pit dewatering during rainy season ´ü Well head sampling ´ü Ensure PTW adherence and mitigative measures ´ü Local parameter checks for comparison with CCR reading ´ü Tool box meeting ´ü Mobile MPFM installation and co-ordination with crews ´ü LG, LIC ,LT, PIC, PT and FIT flushing to reconfirmed ´ü Instrument air compressor start up and parameter monitoring. ´ü Everyday Taking and Calculating Chemical Tanks Reading. ´ü Reporting Daily Shift Activities to Supervisor .

- 3. Well Head Off-Shore Operations: Operation of X-Mas Tree, start up and shut down operations of SSV & SSSV. Operations of Upper Master valve, Lower Master Valve and Crown Valve. Flow line choke changing, taking reading FTHP & STHP Test separator handling. Test of Expansion joint, SSSV and Gas Lift Mandrel, Annulus Holdup Test for Sliding Side Door. Start up of dead well. Well equalizing and Annulus pressure bleeding Oil Manifold operations Adjusting Chokes, Changing flow well to test separators. Pig Launching & Pig Receiving, Taking Flow ÔÇô chart Reading, Handling Isolation permits, Crude Oil sampling, Ph Monitoring CRUDE OIL SEPARATION ´ü Operation of Two Phase and Three Phase Separator (H.P, M.P, L.P ) ´ü Monitor the plant parameters and ensure that working properly. ´ü Adjust the LIC, PIC, TIC and FIC setting points as per control room instructions. ´ü Handover the equipments to inspection and maintenance. ´ü Taking necessary actions when the abnormalities occurring in plant equipments. ´ü Changeover the rotating equipments as per duty roaster. ´ü Make sure the process safeguarding systems are healthy in local panels. ´ü Daily checking of panel switches status and ensure that no one ´ü Isolate and De-isolate the equipments for maintenance according to the authorized isolation certificate. ´ü Checking the critical valves as per LO/LC valve register and update it monthly. ´ü Continuous equipments monitoring during calibration and corrective maintenance of process safeguarding system and Fire and gas system. ´ü Checking the chemical injection pumps and calibrate as per control room record. Water Injection Unit ´ü To inject high pressure treated water to the reservoir for maintains the well pressure ´ü This unit designed to inject high pressure water into the well for maintaining level. Pump type 54 stages ´ü Lube oil level maintain and RPM settings ´ü Centrifugal pump normal discharge pressure is 180Kg/cm2, Plant capacity -18000m3/day.

- 4. Pigging Operation; ´âÿ Pig Launching in Oil Production line, Water Injection and power fluid line ´âÿ Pig Receiving in Oil Production line, Water Injection and power fluid line ´âÿ Using Bi-Di brush and Bi-Di batch pig ´âÿ Biocide Injection during pigging Chemicals Handling: Corrosion inhibitor, Scale inhibitor, Demulsifier , Bio-side, Acroclear, H2s Scavenger Fire & Safety: ´éÀ Have completed H2S Entry/Escape course and hazardous chemical handling. ´éÀ Knowledge of fire and Safety System, Deluge Valve, Sprinkler System, Monitors, Hydrants. ´éÀ Experience in the operation of Fire Extinguishers like Foam, DCP, CO2, Operation usage of fire suit preparation and hot work and familiar with breathing apparatus etc. Declaration; I hereby declare that the above information furnished is true to the best of my knowledge & belief. DATE : yours sincerely PLACE : Chunkankadai saravanan.M