02 simtec 2011 caldeiras

- 1. +1

- 2. Agenda 1. Caracteriza??o da cana de a?úcar 2. Proje??es de produ??o de cana de a?úcar no Brasil 3. Evolu??o das impurezas minerais 4. Evolu??o das impurezas vegetais 5. Evolu??o da demanda de energia elétrica 6. Participa??o do baga?o da cana de a?úcar na matrix energética nacional 7. Pondera??es

- 3. IMPUREZAS VEGETAIS ? Ponteiro ? Folhas Verdes ? Folhas Secas Colmos A?úcar Etanol ELETRICIDADE A Energia da Cana de A?úcar + 608 x Mcal/tc Baga?o com 50% umid. 598 x Mcal/tc Palha com 15% 512 Mcal/tc => => +

- 4. Proje??o de Processamento 634 676 719 763 808 853 898 944 990 1.037 Milh?estc Fonte: Companhia Nacional de Abastecimento

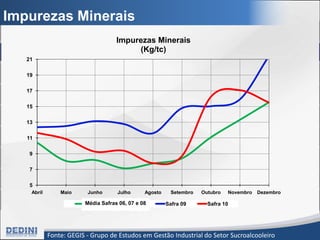

- 5. Impurezas Minerais 5 7 9 11 13 15 17 19 21 Abril Maio Junho Julho Agosto Setembro Outubro Novembro Dezembro Impurezas Minerais (Kg/tc) Méida safras 06;07 e 08 Safra 09 Safra 10Média Safras 06, 07 e 08 Fonte: GEGIS - Grupo de Estudos em Gest?o Industrial do Setor Sucroalcooleiro

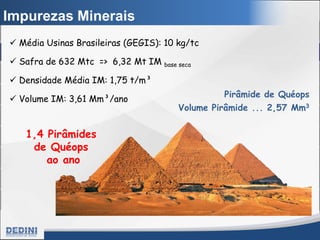

- 6. Impurezas Minerais ? Média Usinas Brasileiras (GEGIS): 10 kg/tc ? Safra de 632 Mtc => 6,32 Mt IM base seca ? Densidade Média IM: 1,75 t/m? ? Volume IM: 3,61 Mm?/ano 1,4 Pir?mides de Quéops ao ano Pir?mide de Quéops Volume Pir?mide ... 2,57 Mm3

- 7. Impurezas Vegetais 30 40 50 60 70 80 90 Abril Maio Junho Julho Agosto Setembro Outubro Novembro Dezembro Impurezas Vegetais (Kg/tc) Méida safras 06;07 e 08 Safra 09 Safra 10Média Safras 06, 07 e 08 Fonte: GEGIS - Grupo de Estudos em Gest?o Industrial do Setor Sucroalcooleiro

- 8. PARTICIPA??O EFETIVA DAS FONTES DE ENERGIA NA MATRIZ Fonte: ANEEL - Banco de Informa??es de Gera??o 80% 9% Baga?o de Cana 18.516 GWh 4% 3% 2% 1% 1% 7% 2010: Gera??o de 18.500 GWh, proveniente do baga?o da cana de a?úcar - 2,1 GWm (8.760 h) Matriz Energética Brasileira

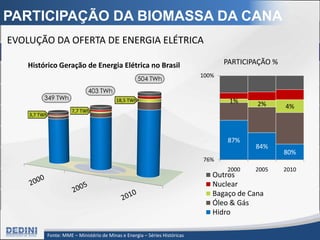

- 9. PARTICIPA??O DA BIOMASSA DA CANA EVOLU??O DA OFERTA DE ENERGIA EL?TRICA Hidroelétricas PARTICIPA??O % 3,7 TWh 7,7 TWh 18,5 TWh Histórico Gera??o de Energia Elétrica no Brasil Outros Nuclear Baga?o de Cana ?leo & Gás Hidro 349 TWh 403 TWh 504 TWh 87% 84% 80% 1% 2% 4% 76% 100% 2000 2005 2010 Fonte: MME – Ministério de Minas e Energia – Séries Históricas

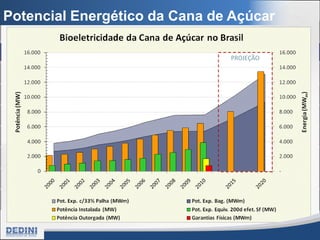

- 10. Premissas – Proje??o da Bioeletricidade Hidroelétricas ? 100% Baga?o voltado a produ??o de energia termelétrica ? Processamento de 33% palha da cana de a?úcar para energia ? Garantias físicas concedidas ? Potência equivalente c/200 dias efetivos de safra ? Caldeiras 67 bar x 520oC ? Combina??o de turbinas de Contra Press?o e Condensa??o ? Processamento de cana de a?úcar: ? Moagem safra 2015/16 ... 808 Mtc ? Moagem safra 2020/21 ... 1.037 Mtc

- 11. Potencial Energético da Cana de A?úcar

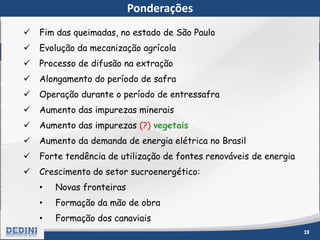

- 12. Pondera??es ? Fim das queimadas, no estado de S?o Paulo ? Evolu??o da mecaniza??o agrícola ? Processo de difus?o na extra??o ? Alongamento do período de safra ? Opera??o durante o período de entressafra ? Aumento das impurezas minerais ? Aumento das impurezas (?) vegetais ? Aumento da demanda de energia elétrica no Brasil ? Forte tendência de utiliza??o de fontes renováveis de energia ? Crescimento do setor sucroenergético: ? Novas fronteiras ? Forma??o da m?o de obra ? Forma??o dos canaviais

- 13. Fontes ? MME - Ministério de Minas e Energia - Séries Históricas ? MME/EPE – Plano Decenal de Expans?o de Energia 2020 ? ANEEL - Agência Nacional de Energia Elétrica - Banco de Informa??o de Gera??o ? CONAB – A Gera??o Termoelétrica com a Queima do Baga?o de Cana de A?úcar no Brasil ? CTC – Biomass Power Generation, Sugar Cane Bagasse and Trash ? GEGIS – Grupo de Estudos em Gest?o Industrial Sucroalcooleira ? Monografia/ESALQ – Aproveitamento Agroindustrial do Palhi?o da Cana de A?úcar

- 14. Histórico das Caldeiras Dedini ZANINI ZANINI M. DEDINI D.Z. Metalúrgica DEDINI Licen?a Zurn p/ Fab. Caldeiras Licen?a Foster Wheeler

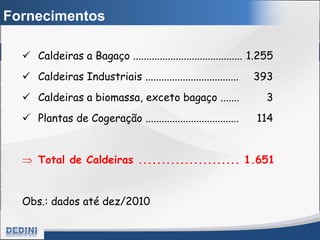

- 15. Fornecimentos ? Caldeiras a Baga?o ......................................... 1.255 ? Caldeiras Industriais ................................... 393 ? Caldeiras a biomassa, exceto baga?o ....... 3 ? Plantas de Cogera??o ................................... 114 Total de Caldeiras ...................... 1.651 Obs.: dados até dez/2010

- 16. Histórico das Caldeiras Dedini 1920 - FUNDA??O “OFFICINAS DEDINI” 1930 - CALDEIRA DEDINI VERTICAL E FOGOTUBULAR 1940 - CALDEIRA AQUATUBULAR TIPO BABCOCK E STIRLING 1945 - CONTRATO COM COMBUSTION ENGINEERING 1951 - CALDEIRA ZANINI 1960 - PROJETOS DEDINI (V 2/4, V 2/5) 1977 - CONTRATO COM FOSTER WHEELER 1979 – CONTRATO COM ZURN – GRELHA ROTATIVA 1981 - CALDEIRA DEDINI - BMP E AT 1985 – CALDEIRA ZANINI - AZ/ZANITEC 1989 - SELO ASME - FABRICA??O E MONTAGEM (S, U, PP) 2000 – CALDEIRA COGEMAX MULTICOMBUST?VEL PARA COGERA??O 2001 – CALDEIRA AT E AZ AT? 250 t/h E GRELHA FLAT PIN HOLE 2005 – CALDEIRA AT-SINGLE DRUM AT? 400 t/h E 120 bar

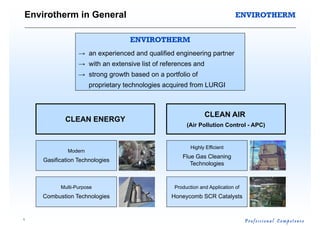

- 17. ENVIROTHERM P r o f e s s i o n a l C o m p e t e n c e1 Envirotherm in General ENVIROTHERM → an experienced and qualified engineering partner → with an extensive list of references and → strong growth based on a portfolio of proprietary technologies acquired from LURGI CLEAN ENERGY CLEAN AIR (Air Pollution Control - APC) Modern Gasification Technologies Highly Efficient Flue Gas Cleaning Technologies Multi-Purpose Combustion Technologies Production and Application of Honeycomb SCR Catalysts

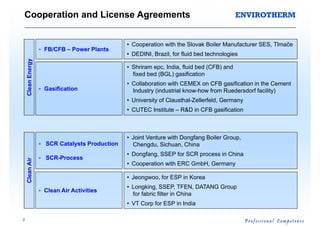

- 18. ENVIROTHERM P r o f e s s i o n a l C o m p e t e n c e2 Cooperation and License Agreements ? SCR Catalysts Production ? SCR-Process ? Joint Venture with Dongfang Boiler Group, Chengdu, Sichuan, China ? Dongfang, SSEP for SCR process in China ? Cooperation with ERC GmbH, Germany ? FB/CFB – Power Plants ? Cooperation with the Slovak Boiler Manufacturer SES, Tlma?e ? DEDINI, Brazil, for fluid bed technologies ? Clean Air Activities ? Jeongwoo, for ESP in Korea ? Longking, SSEP, TFEN, DATANG Group for fabric filter in China ? VT Corp for ESP in India ? Gasification ? Shriram epc, India, fluid bed (CFB) and fixed bed (BGL) gasification ? Collaboration with CEMEX on CFB gasification in the Cement Industry (industrial know-how from Ruedersdorf facility) ? University of Clausthal-Zellerfeld, Germany ? CUTEC Institute – R&D in CFB gasification CleanEnergyCleanAir

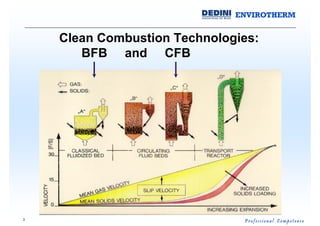

- 19. ENVIROTHERM P r o f e s s i o n a l C o m p e t e n c e3 Clean Combustion Technologies: BFB and CFB

- 20. ENVIROTHERM P r o f e s s i o n a l C o m p e t e n c e4 ? Bubbling and Circulating Fluidized Bed Technologies are a highly accepted base technologies in utility and other industries for combustion of coal, (high/low rank), biomass and various residual materials (sludges, RDF). ? Fluidized Beds represent proven and reliable technologies with numerous reference plants and excellent emission values. ? Downstream technologies for dry dedusting (Electrostatic Precipitator and Fabric Filter) are available with Envirotherm and are designed in accordance with the latest environmental laws/directives. ? BFBs cover the lower capacity range of steam production, CFBs are available for larger units. ? Both Fluidized Bed Technologies offer their specific advantages for their specific range of application. Fluidized Bed Combustion: Available Technologies

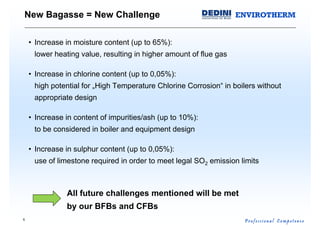

- 21. ENVIROTHERM P r o f e s s i o n a l C o m p e t e n c e5 ? Increase in moisture content (up to 65%): lower heating value, resulting in higher amount of flue gas ? Increase in chlorine content (up to 0,05%): high potential for ?High Temperature Chlorine Corrosion“ in boilers without appropriate design ? Increase in content of impurities/ash (up to 10%): to be considered in boiler and equipment design ? Increase in sulphur content (up to 0,05%): use of limestone required in order to meet legal SO2 emission limits All future challenges mentioned will be met by our BFBs and CFBs New Bagasse = New Challenge

- 22. ENVIROTHERM P r o f e s s i o n a l C o m p e t e n c e6 ? Use of primary air for fluidization and of secondary air for complete combustion as well as for enhanced temperature and emission control ? Injection of fuel directly into the bed via several feeding points in order to support a homogeneous energy input across the combustor cross section ? Proven fluidizing nozzles with low pressure drop, but even air distribution Bubbling Fluidized Bed (1)

- 23. ENVIROTHERM P r o f e s s i o n a l C o m p e t e n c e7 ? Flue gas recirculation for temperature control in case of varying fuel qualities (e.g. season / off-season) ? Bottom ash discharge via multiple openings in the fluidization nozzle grate or via an ?open“ nozzle grate in case of high impurities / tramp material content ? Co-combustion of various fuels is possible, when considered during boiler design Bubbling Fluidized Bed (2)

- 24. ENVIROTHERM P r o f e s s i o n a l C o m p e t e n c e8 ? Coarse ash classification and re-feed into the BFB combustor in case of ? high amount of ash in the fuel and ? low amount of alkalines in the fuel ash ? Desulphurization is possible via limestone injection ? Operable load range between 50 and 100% ? Application in the lower capacity range ? High reliability due to ? simple and robust design ? good temperature control: avoids agglomerations ? design of coarse ash discharge with sufficient margins Bubbling Fluidized Bed (3)

- 25. ENVIROTHERM P r o f e s s i o n a l C o m p e t e n c e9 Circulating Fluidized Bed (1) Basic Principles of CFB Combustion ? Intense and turbulent mixing of solid fuel, air and flue gas ? Uniform system temperature: no peaks, no agglomerations ? No HP-steam bundles in the ash stream: no bundle erosion ? Low and controlled combustion temperature due to Fluidized Bed Heat Exchanger technology ? Generous residence time: excellent carbon conversion ? Optimum conditions for multiple fuels; variation of fuel shares feasible during operation

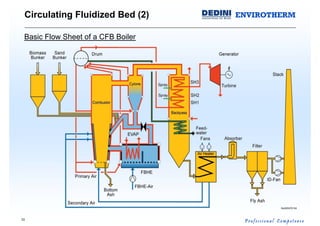

- 26. ENVIROTHERM P r o f e s s i o n a l C o m p e t e n c e10 Circulating Fluidized Bed (2) Basic Flow Sheet of a CFB Boiler

- 27. ENVIROTHERM P r o f e s s i o n a l C o m p e t e n c e11 ? Optimum and stable combustion conditions for lowest emissions ? Efficient sulphur capture in the CFB combustor by limestone injection ? Low NOx emissions due to ? low combustion temperature ? low excess air ratio ? staged combustion ? Partial capture of chlorine and fluorine in the CFB combustor ? High boiler efficiency due to ? low excess air ? high carbon burnout ? no flue gas recirculation Circulating Fluidized Bed (3) Emissions and Efficiency

- 28. ENVIROTHERM P r o f e s s i o n a l C o m p e t e n c e12 Fluidized Beds: Comparison Clean and reliable combustion technologies showing excellent features with respect to emissions, efficiency and future bagasse Feature Bubbling Fluidized Bed Circulating Fluidized Bed Emissions NOx ?? ??? CO ?? ??? Dust ??? ??? SO2 Capture ?? ??? HCl and HF Capture ? ??? Combustor Cross Section ? ??? Complexity of Combustion System ??? ? Particle Residence Time ?? ??? Uniformity of Combustion Temperature ? ??? min. Part Load Capabilty ?? ??? Boiler Efficiency ?? ??? Ability of Firing Varying Fuel Qualities ?? ??? Ability to Cope with "New Bagasse" ?? ??? CAPEX ??? ? OPEX ? ??? Status of Technology ??? ???

- 29. ENVIROTHERM P r o f e s s i o n a l C o m p e t e n c e13 “As a participant in Simtec 2011 ENVIROTHERM is very pleased with the introduction of our technologies into the Brazilian market, and we reaffirm our complete confidence in the potential and performance of the Fluidized Bed Boilers.” “Our partnership with DEDINI reinforces this confidence, and guarantees that all the advantages of the Fluidized Bed Boilers will be fully exploited to the benefit of the Brazilian sugar, ethanol and bioelectricity market.” Werner-Fr. Staab, ENVIROTHERM GmbH

- 30. ENVIROTHERM P r o f e s s i o n a l C o m p e t e n c e14 Obrigado! for your attention Envirotherm GmbH Werner-Fr. Staab Head of Sales (Thermal Processes) Ruhrallee 185 D–45136 Essen Germany werner_staab@envirotherm.de www.envirotherm.de

- 31. Lan?amento 2011 LAN?AMENTO DAS CALDEIRAS COM LEITO FLUIDIZADO &