110615 pyi - work out -dfp-report 080211

Download as ppt, pdf1 like577 views

This document summarizes a Kaizen workshop held by Team 3 to improve the Workout Plus shoe. The team identified ways to simplify the shoe design including standardizing eyelets, changing quarter logos to printing, and matching lining colors. Their proposals are estimated to save 4 manufacturing positions, reduce cutting dies and tools, lower overhead costs, and decrease assembly time by 22 seconds per pair. The next steps are to trial samples, make costing proposals, and implement changes in production if approved.

1 of 24

Download to read offline

Ad

Recommended

Tìm hiểu Smed và qco ( bkls team)

Tìm hiểu Smed và qco ( bkls team)Nguyễn Thành Đạt

╠²

Single Minute Exchange of Dies (SMED) l├á mß╗Öt phã░ãíng ph├íp nhß║▒m giß║úm thß╗Øi gian chuyß╗ân ─æß╗òi thiß║┐t bß╗ï giß╗»a c├íc sß║ún phß║®m, qua ─æ├│ n├óng cao hiß╗çu suß║Ñt v├á kiß╗âm so├ít c├┤ng viß╗çc trong sß║ún xuß║Ñt. Phã░ãíng ph├íp n├áy ph├ón biß╗çt giß╗»a chuyß╗ân ─æß╗òi trong (phß║úi thß╗▒c hiß╗çn khi thiß║┐t bß╗ï dß╗½ng) v├á chuyß╗ân ─æß╗òi ngo├ái (c├│ thß╗â thß╗▒c hiß╗çn khi thiß║┐t bß╗ï ─æang chß║íy) ─æß╗â tß╗æi ã░u h├│a qu├í tr├¼nh. C├íc bã░ß╗øc ├íp dß╗Ñng SMED bao gß╗ôm ─æo lã░ß╗Øng, x├íc ─æß╗ïnh v├á cß║úi tiß║┐n c├íc hoß║ít ─æß╗Öng chuyß╗ân ─æß╗òi nhß║▒m giß║úm l├úng ph├¡ v├á n├óng cao hiß╗çu quß║ú sß║ún xuß║Ñt.Zedo Vs DFP - A Quick Guide about Ad-ServersKarthik Ramanujam

╠²

Le document semble contenir un message de remerciement. Il n'y a pas d'autres informations sp├®cifiques fournies. Le contenu est principalement compos├® de symboles et de points, sans d├®tails suppl├®mentaires.DoubleClick for Publishers (DFP) Basic Guide

DoubleClick for Publishers (DFP) Basic GuideBidGear Inc.

╠²

DoubleClick for Publishers (DFP) is an ad serving platform aiding publishers in organizing and selling advertising inventory efficiently, offering both a paid premium version for high-traffic sites and a free version for smaller publishers. Key features include managing multiple ad tags, passbacks for unsold impressions, and a powerful reporting system for ad optimization. The document outlines how to set up, create orders, line items, and manage ad partners to maximize revenue from various advertiser types.Building best in-class quality in footwear manufacturing

Building best in-class quality in footwear manufacturingTony Lopez

╠²

The document provides an overview of Tony Lopez's experience and strategies for building best-in-class quality in footwear manufacturing. It details his 28 years of experience in quality roles across various industries. As Director of Quality & Process Engineering at New Balance, his mission was to build a world-class quality mindset and continuous improvement culture. Key strategies included training programs to develop problem-solving skills, building quality awareness, and establishing metrics to drive data-driven improvements. Examples demonstrate focusing investigations on root causes rather than blame, and cross-functional collaboration to resolve complex issues.Six sigma project report

Six sigma project reportmahtabsiddiqui

╠²

The document outlines the establishment of a quality improvement team at Apex Footwear Ltd. to address high rejection rates of shoe uppers in their sewing line 1. Specifically, the team aims to reduce rejections from the current 12% rate to the industry average of 1%.

The charter provides background on the company and production process. It identifies key tasks for the team, including analyzing past rejection data, identifying causes of rejections, and developing and implementing solutions. Metrics include designing solutions to address root causes and reducing rejections to meet goals.WQD2011 - KAIZEN - SRF Oversear Ltd - Set up time reduction in loom during st...

WQD2011 - KAIZEN - SRF Oversear Ltd - Set up time reduction in loom during st...Dubai Quality Group

╠²

A kaizen initiative at Textile SRF Overseas Limited focused on reducing loom setup time from 70 minutes to 10 minutes during style changes, improving efficiency and productivity. The project led to an annual production increase of 141mt and cost savings of $141,306. The successful strategies implemented in this project have been horizontally deployed across four additional units globally.Global qa conference updated

Global qa conference updatedJohnny Chan

╠²

This document summarizes the key points from a seminar on quality and productivity. It discusses the customer mission of delivering excellent quality products on time and on budget. It outlines Next's expectations for suppliers to meet customer expectations. It also discusses challenges like price pressures and how improvements can be made through techniques like lean manufacturing, reducing waste, and improving internal processes and training.HOP Yick BD Ltd SMED

HOP Yick BD Ltd SMEDEngr. Mahmudul Khaleque

╠²

This document contains analysis of operations for producing a moulded padded bra over multiple days. It found that learning curve issues where the primary root cause of inefficiency, accounting for over 70% of additional time. Other significant factors included delays in material preparation, machine maintenance issues, and lack of standard operating procedures. Overall, actual time was over triple the expected time due to various issues related to new product introduction and process training.Applying Lean Six Sigma to improve garment production processes-A case study

Applying Lean Six Sigma to improve garment production processes-A case studyBOHR International Journal of Operations Management Research and Practices

╠²

This research paper explores the application of Lean Six Sigma techniques to enhance garment production processes in a Vietnamese company facing issues with high waste, long lead times, and high defect rates. By implementing the DMAIC methodology, the study successfully reduced the production lead time by 89.21%, cycle time by 36%, and defect rate by 37.45%, significantly improving productivity and on-time delivery. The findings underscore the effectiveness of Lean Six Sigma in driving operational efficiency and competitiveness in the garment industry.Finishing Charters

Finishing Chartersnushpe

╠²

1. The document outlines an improvement project to implement 5S activities in the finishing department to increase output and decrease time spent looking for items.

2. The project team will conduct training, create checklists, label safety items, remove unnecessary items, and implement sorting and set in order.

3. The scope includes all 5S activities and standardizing work to reduce inconsistencies between operators and lost capacity.Kierra Sanders Final Presentation Fall2014

Kierra Sanders Final Presentation Fall2014Kierra Sanders

╠²

Kierra Sanders completed her 1st term co-op at Southern Polytechnic State University at Plant 13 of Shaw Industries. During her time there, she worked on several projects including a safety and ergonomics risk assessment of the coater line, an 8C waste reduction green belt project, a roll length audit, and training in various plant departments. She gained hands-on experience in manufacturing, developed workplace relationships, and applied classroom tools and skills. Kierra concluded her co-op experience appreciated the opportunity provided by Shaw Industries and looking forward to future co-op terms.Awd Pump Project Report Out

Awd Pump Project Report OutTodd Parrish

╠²

The document outlines a project to reduce processing times for an AWD product line by 50% or more. Key aspects of the project include analyzing and mapping current processes, identifying defects, developing solutions to address top defects, and implementing changes with the goal of avoiding additional costs from a anticipated 50-100% increase in product volume. The project team developed solutions such as eliminating redundant data entry of serial numbers, reducing unnecessary inventory transfers, and standardizing order cutoff times. Process mapping and time studies were used to measure improvements.Increasing the productivity and efficiency of a sewing line in an apparel man...

Increasing the productivity and efficiency of a sewing line in an apparel man...Mazedul Islam Soyeb

╠²

This document presents a project aimed at increasing the productivity and efficiency of a sewing line in the apparel manufacturing industry by incorporating working aids into sewing machines. The project outlines the objectives, methodologies, and literature related to productivity improvements in garment production, highlighting the significance of effective working aids in enhancing production quality and efficiency. It also includes detailed data collection and analysis on operations before and after the implementation of the working aids.Report on apparel internship at orient craft limited

Report on apparel internship at orient craft limitedUniversity of Southern California

╠²

This document provides a summary of an apparel internship at Orient Craft Limited, a garment manufacturing company. It describes the company profile and various departments involved in production planning and quality control. It then discusses three specific production lines that were having issues with alterations. For each line, it identifies the problem causing alterations, the time and cost of alterations, and the solution implemented to reduce defects and alterations. These solutions included using specialized equipment, adding training, and modifying sewing techniques. Data is presented showing reductions in the number of alterations on each line after implementing the recommended changes.2012W32_Toolsharing_Bangalore

2012W32_Toolsharing_BangaloreDeepak Parackal

╠²

1) The document discusses improvements made across various product segments at a tool sharing company including harness export, local harness, connectors, and devices.

2) Metrics are shown tracking delivery performance improvements across different time periods after implementing changes like footfall monitoring, cell design changes, and kanban systems.

3) Specific kaizens are described to improve processes like material movement, testing, assembly, and training qualification that reduced costs and lead times. Standard work and visual management were introduced.Lean Six Sigma Projects

Lean Six Sigma ProjectsJulian Kalac P.Eng

╠²

This document describes several Lean Six Sigma projects aimed at improving efficiency and reducing costs. It summarizes multiple projects including reducing packaging scrap, improving productivity in packaging and coil winding operations, reducing injection molding setup times, and implementing a warehouse management system. One project improved productivity from 240 to 331 packs per hour and reduced setup time from 30 minutes to under 5 minutes, realizing annual savings of $300,000.Lean Improvement Case Study 3

Lean Improvement Case Study 3actionmaster007

╠²

The document summarizes several Lean projects implemented at a manufacturing facility to improve production processes. Key outcomes included establishing standard work procedures, improving material flow through production by organizing logical work cells and implementing a Kanban system, and reducing work in progress and lead times. Other projects optimized the packaging area layout and implemented a two-bin material replenishment system between stores and production. Overall the projects significantly reduced process times, inventory, and improved productivity.Marc Rambaud supporting documents

Marc Rambaud supporting documents Marc Rambaud

╠²

Marc Rambaud is a design consultant who specializes in managing innovation projects from concept to production across various contexts and industries. He has experience in areas like branding, engineering, business planning, and more. Some of the projects he has worked on include designing medical equipment cases, developing furniture lines, and creating urban lighting designs. Marc takes a human-centered approach and uses design thinking methodologies to help clients solve problems and bring new products to market.(Student assignment) riordan manufacturing process improvement final

(Student assignment) riordan manufacturing process improvement finalCharles James

╠²

The document outlines Riordan Manufacturing's process improvement efforts for electric fan production using DMAIC (Define, Measure, Analyze, Improve, Control). It defines the current process for make-to-stock and custom fans, identifies bottlenecks, and proposes a new process and project plans. The new process separates make-to-stock and custom fan production. It also implements tools like flow charts and tree diagrams to identify issues and responsibilities. Gantt charts show the project plans and deliverables for the new make-to-stock and custom fan processes.Improving Productivity by Lean

Improving Productivity by LeanANITHA BALA

╠²

The document discusses the implementation of lean manufacturing in the Indian apparel industry to enhance productivity while minimizing waste. It outlines the challenges faced, strategies employed, and results after focusing on critical areas such as overproduction, defects, and waiting times, highlighting significant improvements in productivity and quality without additional investments. The findings recommend continuous adherence to lean principles like the traffic light system and 5S housekeeping to sustain these gains.MARINEW Resume

MARINEW Resumemari muthu

╠²

- The document contains the resume of M. Marimuthu, who is currently a Senior Engineer at Grupo Antolin India Pvt Ltd with over 14 years of experience in engineering, projects, and new product development.

- His responsibilities have included new product development, engineering change management, tool room management, machine commissioning, process improvements, and programming.

- He holds a B.Tech in Mechanical Engineering and additional qualifications in areas such as CNC programming, robot programming, quality standards, and computer skills.Industrial engineering

Industrial engineeringPradeep Poornishankar

╠²

The document discusses implementing lean manufacturing principles in the apparel industry to reduce waste and improve efficiency. It compares traditional sewing line layouts to lean layouts that incorporate single-piece flow and line balancing. Key lean tools covered include standard work, visual management, continuous improvement, and eliminating overproduction and waiting times to reduce lead times.Tejas krishna_apparel_internship_report

Tejas krishna_apparel_internship_reportNational Institute of Fashion technology

╠²

Tejas M P completed an internship at Everblue Apparels Ltd in Doddaballapur to fulfill the requirements of a Masters in Fashion Technology degree. The internship report provides an overview of the various departments at Everblue including design, merchandising, sampling, CAD, planning, fabric store, trims, cutting, embroidery, sewing, washing, quality assurance, finishing, and ETP. It also details several projects completed by Tejas during the internship aimed at reducing production losses, minimizing non-value added time, improving work processes, and reducing labor costs. The report provides information on the operations, objectives, and outcomes of the internship projects.Invest NI Lean Conference 2016 | Case Study: Interface | Creating a lean thin...

Invest NI Lean Conference 2016 | Case Study: Interface | Creating a lean thin...Invest Northern Ireland

╠²

The document outlines the lean journey of a European manufacturing organization from 2014-2016. It describes initial problems like lack of investment in people and resistance to change. First steps included structuring roles, providing formal training to shift managers and team leaders, and empowering employees. Early projects focused on improving yarn flow and reducing changeover times. Subsequent efforts sustained changes through daily management reviews, waste walks, and continued training. Looking forward, the organization aimed to maintain continuous improvement projects on each shift and expand lean methods to service departments.time study in Arvind garment

time study in Arvind garment Chandra Shekhar Kumar

╠²

The document provides details about an internship report on time study carried out at Arvind Limited. It summarizes the key processes at Arvind including washing, dry processing, laser fading, whiskering, hand sanding, and crinkling and curing. Time studies were conducted for each process to calculate standard allowed minutes based on basic time and performance ratings. Recommendations are provided to improve efficiency and reduce unnecessary time for each process.How to Improve Productivity

How to Improve ProductivitySunjib Anwar; MBA,SCSS

╠²

Effective ways to improve productivity in garment production include:

1. Conducting motion studies and correcting faulty motions to reduce operation cycle times and improve labor productivity up to 100%.

2. Checking hourly operator capacity to keep operators productive and identify ways to reduce cycle times.

3. Using the best possible line layouts to reduce transportation time and improve line productivity.Ci training doc

Ci training docnmjohnson84

╠²

This document outlines the goals and principles of a continuous improvement event. It encourages participants to listen with an open mind, respect each other's ideas, and provide constructive feedback to help the team improve. The document explains that change is necessary to meet customers' evolving needs and remain successful. It defines value-added and non-value added processes, highlighting seven types of waste. The goal of continuous improvement is to continuously improve processes by understanding customer requirements and removing waste.Dore%2520dore%5 B1%5 D[1]

Dore%2520dore%5 B1%5 D[1]Gagan306

╠²

The document discusses implementing a cellular design process at Dore Dore, a hosiery manufacturer. Currently, production involves high inventory costs and unsold items. The company wants to adopt cellular design for better production and utilization. Analysis shows cellular design can decrease throughput time and increase efficiency in the knitwear division. For hosiery, calculations show adopting cellular design by skipping embroidery can increase factory machine utilization from 58% to 92%, reducing costs. It is recommended the company implement a quick response process layout in hosiery for higher efficiency and lower inventory levels.Ecrs ina

Ecrs inaTaufik Azzikra

╠²

Dokumen ini menjelaskan pentingnya metode ECRS (eliminate, combine, rearrange, simplify) dan Kaizen dalam meningkatkan efisiensi dan pengurangan biaya dalam proses produksi. Selain itu, diperkenalkan juga metode analisis masalah seperti 5W1H dan 5Why untuk memecahkan masalah secara efektif dengan melakukan observasi langsung di lokasi kerja. Manajemen yang baik mencakup pelatihan, penyelesaian masalah di lokasi, dan pengembangan visi untuk perbaikan berkelanjutan.20111104 qcc-daredevil-(reduce wrinkle 2b)-report

20111104 qcc-daredevil-(reduce wrinkle 2b)-reportTaufik Azzikra

╠²

This document summarizes a quality control circle (QCC) workshop from November 7 to December 7, 2011 that aimed to reduce wrinkle defects in a classic leather shoe model produced in Area 2B. The team of 8 members from different departments developed a project plan and tracked their progress. Their goal was to reduce the defect rate of 6.1% to the target of 3% or lower, which could save the company an estimated $1,518 per order through reduced costs from lowering prices on defective shoes. They applied the CEDAC problem-solving method and created a Gantt chart to manage their activities.More Related Content

Similar to 110615 pyi - work out -dfp-report 080211 (20)

Applying Lean Six Sigma to improve garment production processes-A case study

Applying Lean Six Sigma to improve garment production processes-A case studyBOHR International Journal of Operations Management Research and Practices

╠²

This research paper explores the application of Lean Six Sigma techniques to enhance garment production processes in a Vietnamese company facing issues with high waste, long lead times, and high defect rates. By implementing the DMAIC methodology, the study successfully reduced the production lead time by 89.21%, cycle time by 36%, and defect rate by 37.45%, significantly improving productivity and on-time delivery. The findings underscore the effectiveness of Lean Six Sigma in driving operational efficiency and competitiveness in the garment industry.Finishing Charters

Finishing Chartersnushpe

╠²

1. The document outlines an improvement project to implement 5S activities in the finishing department to increase output and decrease time spent looking for items.

2. The project team will conduct training, create checklists, label safety items, remove unnecessary items, and implement sorting and set in order.

3. The scope includes all 5S activities and standardizing work to reduce inconsistencies between operators and lost capacity.Kierra Sanders Final Presentation Fall2014

Kierra Sanders Final Presentation Fall2014Kierra Sanders

╠²

Kierra Sanders completed her 1st term co-op at Southern Polytechnic State University at Plant 13 of Shaw Industries. During her time there, she worked on several projects including a safety and ergonomics risk assessment of the coater line, an 8C waste reduction green belt project, a roll length audit, and training in various plant departments. She gained hands-on experience in manufacturing, developed workplace relationships, and applied classroom tools and skills. Kierra concluded her co-op experience appreciated the opportunity provided by Shaw Industries and looking forward to future co-op terms.Awd Pump Project Report Out

Awd Pump Project Report OutTodd Parrish

╠²

The document outlines a project to reduce processing times for an AWD product line by 50% or more. Key aspects of the project include analyzing and mapping current processes, identifying defects, developing solutions to address top defects, and implementing changes with the goal of avoiding additional costs from a anticipated 50-100% increase in product volume. The project team developed solutions such as eliminating redundant data entry of serial numbers, reducing unnecessary inventory transfers, and standardizing order cutoff times. Process mapping and time studies were used to measure improvements.Increasing the productivity and efficiency of a sewing line in an apparel man...

Increasing the productivity and efficiency of a sewing line in an apparel man...Mazedul Islam Soyeb

╠²

This document presents a project aimed at increasing the productivity and efficiency of a sewing line in the apparel manufacturing industry by incorporating working aids into sewing machines. The project outlines the objectives, methodologies, and literature related to productivity improvements in garment production, highlighting the significance of effective working aids in enhancing production quality and efficiency. It also includes detailed data collection and analysis on operations before and after the implementation of the working aids.Report on apparel internship at orient craft limited

Report on apparel internship at orient craft limitedUniversity of Southern California

╠²

This document provides a summary of an apparel internship at Orient Craft Limited, a garment manufacturing company. It describes the company profile and various departments involved in production planning and quality control. It then discusses three specific production lines that were having issues with alterations. For each line, it identifies the problem causing alterations, the time and cost of alterations, and the solution implemented to reduce defects and alterations. These solutions included using specialized equipment, adding training, and modifying sewing techniques. Data is presented showing reductions in the number of alterations on each line after implementing the recommended changes.2012W32_Toolsharing_Bangalore

2012W32_Toolsharing_BangaloreDeepak Parackal

╠²

1) The document discusses improvements made across various product segments at a tool sharing company including harness export, local harness, connectors, and devices.

2) Metrics are shown tracking delivery performance improvements across different time periods after implementing changes like footfall monitoring, cell design changes, and kanban systems.

3) Specific kaizens are described to improve processes like material movement, testing, assembly, and training qualification that reduced costs and lead times. Standard work and visual management were introduced.Lean Six Sigma Projects

Lean Six Sigma ProjectsJulian Kalac P.Eng

╠²

This document describes several Lean Six Sigma projects aimed at improving efficiency and reducing costs. It summarizes multiple projects including reducing packaging scrap, improving productivity in packaging and coil winding operations, reducing injection molding setup times, and implementing a warehouse management system. One project improved productivity from 240 to 331 packs per hour and reduced setup time from 30 minutes to under 5 minutes, realizing annual savings of $300,000.Lean Improvement Case Study 3

Lean Improvement Case Study 3actionmaster007

╠²

The document summarizes several Lean projects implemented at a manufacturing facility to improve production processes. Key outcomes included establishing standard work procedures, improving material flow through production by organizing logical work cells and implementing a Kanban system, and reducing work in progress and lead times. Other projects optimized the packaging area layout and implemented a two-bin material replenishment system between stores and production. Overall the projects significantly reduced process times, inventory, and improved productivity.Marc Rambaud supporting documents

Marc Rambaud supporting documents Marc Rambaud

╠²

Marc Rambaud is a design consultant who specializes in managing innovation projects from concept to production across various contexts and industries. He has experience in areas like branding, engineering, business planning, and more. Some of the projects he has worked on include designing medical equipment cases, developing furniture lines, and creating urban lighting designs. Marc takes a human-centered approach and uses design thinking methodologies to help clients solve problems and bring new products to market.(Student assignment) riordan manufacturing process improvement final

(Student assignment) riordan manufacturing process improvement finalCharles James

╠²

The document outlines Riordan Manufacturing's process improvement efforts for electric fan production using DMAIC (Define, Measure, Analyze, Improve, Control). It defines the current process for make-to-stock and custom fans, identifies bottlenecks, and proposes a new process and project plans. The new process separates make-to-stock and custom fan production. It also implements tools like flow charts and tree diagrams to identify issues and responsibilities. Gantt charts show the project plans and deliverables for the new make-to-stock and custom fan processes.Improving Productivity by Lean

Improving Productivity by LeanANITHA BALA

╠²

The document discusses the implementation of lean manufacturing in the Indian apparel industry to enhance productivity while minimizing waste. It outlines the challenges faced, strategies employed, and results after focusing on critical areas such as overproduction, defects, and waiting times, highlighting significant improvements in productivity and quality without additional investments. The findings recommend continuous adherence to lean principles like the traffic light system and 5S housekeeping to sustain these gains.MARINEW Resume

MARINEW Resumemari muthu

╠²

- The document contains the resume of M. Marimuthu, who is currently a Senior Engineer at Grupo Antolin India Pvt Ltd with over 14 years of experience in engineering, projects, and new product development.

- His responsibilities have included new product development, engineering change management, tool room management, machine commissioning, process improvements, and programming.

- He holds a B.Tech in Mechanical Engineering and additional qualifications in areas such as CNC programming, robot programming, quality standards, and computer skills.Industrial engineering

Industrial engineeringPradeep Poornishankar

╠²

The document discusses implementing lean manufacturing principles in the apparel industry to reduce waste and improve efficiency. It compares traditional sewing line layouts to lean layouts that incorporate single-piece flow and line balancing. Key lean tools covered include standard work, visual management, continuous improvement, and eliminating overproduction and waiting times to reduce lead times.Tejas krishna_apparel_internship_report

Tejas krishna_apparel_internship_reportNational Institute of Fashion technology

╠²

Tejas M P completed an internship at Everblue Apparels Ltd in Doddaballapur to fulfill the requirements of a Masters in Fashion Technology degree. The internship report provides an overview of the various departments at Everblue including design, merchandising, sampling, CAD, planning, fabric store, trims, cutting, embroidery, sewing, washing, quality assurance, finishing, and ETP. It also details several projects completed by Tejas during the internship aimed at reducing production losses, minimizing non-value added time, improving work processes, and reducing labor costs. The report provides information on the operations, objectives, and outcomes of the internship projects.Invest NI Lean Conference 2016 | Case Study: Interface | Creating a lean thin...

Invest NI Lean Conference 2016 | Case Study: Interface | Creating a lean thin...Invest Northern Ireland

╠²

The document outlines the lean journey of a European manufacturing organization from 2014-2016. It describes initial problems like lack of investment in people and resistance to change. First steps included structuring roles, providing formal training to shift managers and team leaders, and empowering employees. Early projects focused on improving yarn flow and reducing changeover times. Subsequent efforts sustained changes through daily management reviews, waste walks, and continued training. Looking forward, the organization aimed to maintain continuous improvement projects on each shift and expand lean methods to service departments.time study in Arvind garment

time study in Arvind garment Chandra Shekhar Kumar

╠²

The document provides details about an internship report on time study carried out at Arvind Limited. It summarizes the key processes at Arvind including washing, dry processing, laser fading, whiskering, hand sanding, and crinkling and curing. Time studies were conducted for each process to calculate standard allowed minutes based on basic time and performance ratings. Recommendations are provided to improve efficiency and reduce unnecessary time for each process.How to Improve Productivity

How to Improve ProductivitySunjib Anwar; MBA,SCSS

╠²

Effective ways to improve productivity in garment production include:

1. Conducting motion studies and correcting faulty motions to reduce operation cycle times and improve labor productivity up to 100%.

2. Checking hourly operator capacity to keep operators productive and identify ways to reduce cycle times.

3. Using the best possible line layouts to reduce transportation time and improve line productivity.Ci training doc

Ci training docnmjohnson84

╠²

This document outlines the goals and principles of a continuous improvement event. It encourages participants to listen with an open mind, respect each other's ideas, and provide constructive feedback to help the team improve. The document explains that change is necessary to meet customers' evolving needs and remain successful. It defines value-added and non-value added processes, highlighting seven types of waste. The goal of continuous improvement is to continuously improve processes by understanding customer requirements and removing waste.Dore%2520dore%5 B1%5 D[1]

Dore%2520dore%5 B1%5 D[1]Gagan306

╠²

The document discusses implementing a cellular design process at Dore Dore, a hosiery manufacturer. Currently, production involves high inventory costs and unsold items. The company wants to adopt cellular design for better production and utilization. Analysis shows cellular design can decrease throughput time and increase efficiency in the knitwear division. For hosiery, calculations show adopting cellular design by skipping embroidery can increase factory machine utilization from 58% to 92%, reducing costs. It is recommended the company implement a quick response process layout in hosiery for higher efficiency and lower inventory levels.Applying Lean Six Sigma to improve garment production processes-A case study

Applying Lean Six Sigma to improve garment production processes-A case studyBOHR International Journal of Operations Management Research and Practices

╠²

Increasing the productivity and efficiency of a sewing line in an apparel man...

Increasing the productivity and efficiency of a sewing line in an apparel man...Mazedul Islam Soyeb

╠²

Invest NI Lean Conference 2016 | Case Study: Interface | Creating a lean thin...

Invest NI Lean Conference 2016 | Case Study: Interface | Creating a lean thin...Invest Northern Ireland

╠²

More from Taufik Azzikra (8)

Ecrs ina

Ecrs inaTaufik Azzikra

╠²

Dokumen ini menjelaskan pentingnya metode ECRS (eliminate, combine, rearrange, simplify) dan Kaizen dalam meningkatkan efisiensi dan pengurangan biaya dalam proses produksi. Selain itu, diperkenalkan juga metode analisis masalah seperti 5W1H dan 5Why untuk memecahkan masalah secara efektif dengan melakukan observasi langsung di lokasi kerja. Manajemen yang baik mencakup pelatihan, penyelesaian masalah di lokasi, dan pengembangan visi untuk perbaikan berkelanjutan.20111104 qcc-daredevil-(reduce wrinkle 2b)-report

20111104 qcc-daredevil-(reduce wrinkle 2b)-reportTaufik Azzikra

╠²

This document summarizes a quality control circle (QCC) workshop from November 7 to December 7, 2011 that aimed to reduce wrinkle defects in a classic leather shoe model produced in Area 2B. The team of 8 members from different departments developed a project plan and tracked their progress. Their goal was to reduce the defect rate of 6.1% to the target of 3% or lower, which could save the company an estimated $1,518 per order through reduced costs from lowering prices on defective shoes. They applied the CEDAC problem-solving method and created a Gantt chart to manage their activities.20110814 skiving machine - tpm - report

20110814 skiving machine - tpm - report Taufik Azzikra

╠²

The document summarizes work done by Team 2 to improve the Skiving Machine. It lists team members and details activities from August 2nd to September 10th 2011, including cleaning the machine, adding guards, replacing missing parts, and lubricating. Pictures show before and after conditions. The team addressed safety issues and made the machine easier to operate.040711 computer stitching - qco - report 061411

040711 computer stitching - qco - report 061411Taufik Azzikra

╠²

Team 2 worked to reduce the changeover time for computer stitching from April to June 2011. Their initial changeover time was 416 seconds. Through identifying waste, streamlining processes, and implementing improvements like preparing tools and materials in advance, they reduced the changeover time to 211 seconds by April 14th and 173 seconds by June 10th, a 58% improvement from baseline. They documented their activities, ideas, implementations, and results to track their progress toward targets.QCO (Quick Change Over)

QCO (Quick Change Over)Taufik Azzikra

╠²

Dokumen ini membahas tentang pelatihan Quick Changeover (QCO) di PGD Training Center, Sukabumi, yang bertujuan untuk mengurangi kerugian perusahaan melalui pengoptimalan proses pergantian model sepatu. Dijalaskan definisi terkait waktu pergantian, faktor yang mempengaruhi QCO, serta langkah-langkah pelaksanaan yang meliputi persiapan, pelaksanaan, dan evaluasi setelah QCO. Selain itu, struktur tim yang terlibat dalam proses ini juga diuraikan, mencakup tugas dan tanggung jawab masing-masing anggota.Total Productive Maintenance (TPM)

Total Productive Maintenance (TPM)Taufik Azzikra

╠²

TPM adalah strategi Jepang yang berfokus pada efisiensi mesin untuk meningkatkan keuntungan perusahaan. TPM mencakup perawatan ketika kerusakan, upaya pencegahan, dan perbaikan untuk mencapai tujuan nol kerusakan, kecelakaan, dan kemacetan. Pengukuran seperti MTBF dan MTTR digunakan untuk memantau kinerja mesin.Tpm (translate)

Tpm (translate)Taufik Azzikra

╠²

Dokumen ini menjelaskan tentang focused equipment improvement (FEI) yang merupakan filosofi perusahaan untuk memaksimalkan efektivitas peralatan melalui pemahaman dan kolaborasi antara semua anggota tim. FEI terdiri dari lima tiang, yang meliputi perawatan awal, pelatihan sistematis, dan manajemen perbaikan, dengan tujuan mencapai nol cedera, nol downtime, dan pengurangan biaya perawatan. Selain itu, dokumen ini juga membahas berbagai kerugian peralatan dan metode untuk mengatasi serta meningkatkan kinerja peralatan.Total productive maintenance (tpm)

Total productive maintenance (tpm)Taufik Azzikra

╠²

Total Productive Maintenance (TPM) adalah strategi kaizen yang bertujuan meningkatkan efisiensi mesin dengan melibatkan seluruh departemen dan karyawan. Keuntungan dari penerapan TPM termasuk pengurangan waktu shutdown dan peningkatan kualitas serta efisiensi peralatan. Selain itu, terdapat enam tiang utama dalam TPM yang mendukung perawatan dan pengelolaan mesin secara efektif.Ad

Recently uploaded (20)

Webinar: Why Odoo is a game-changer for Service Companies

Webinar: Why Odoo is a game-changer for Service Companiesdear digital

╠²

Watch the webinar: https://youtu.be/49xUiOHJwa4

Running a service business? Then you know how messy operations can get.

YouÔÇÖre not selling products. YouÔÇÖre selling time, expertise, and client satisfaction. That means your tools need to handle projects, people, planning, and billing - all in one place.

ThatÔÇÖs exactly where Odoo shines. Unlike traditional ERP systems, Odoo is built to support the unique workflows of service companies. From managing projects and tracking time to invoicing, signing contracts, and handling support tickets: Odoo brings everything together. No more jumping between a plethora of spreadsheets, tools, and inboxes.

With over 45 modules, Odoo grows with your business. Need CRM today, Helpdesk tomorrow? No worries, itÔÇÖs all connected. Plus, itÔÇÖs fully customizable to match the way your company works.

Wondering if itÔÇÖs a fit?

Join our 1-hour webinar where our Odoo expert Julien will walk you through the power of Odoo for service companies, complete with real-life examples from companies like yours!

What youÔÇÖll learn:

 How Odoo streamlines the entire service lifecycle

 Key modules for service businesses: Project, Timesheets, CRM, Invoicing & more

 How reporting works within Odoo

 What makes Odoo different from other ERP systems

 When Odoo is a fit for your company (and when it's not)

 A demo where we guide you through the possibilities step-by-step

AX to Dynamics 365 Finance and Operations in USA.pdf

AX to Dynamics 365 Finance and Operations in USA.pdfTrident information system

╠²

Upgrading from Microsoft Dynamics AX to Dynamics 365 Finance & Supply Chain Management (D365 F&O) is not just a technology upgradeÔÇöitÔÇÖs a strategic move to transform your business. At Trident Information Systems, a trusted Microsoft Gold Partner, we specialize in Upgrade AX to D365 F&O implementations. With decades of ERP expertise, we ensure your migration journey is smooth, efficient, and delivers maximum ROI. Whether youÔÇÖre transitioning from AX to D365 F&O, we are here to make your digital transformation seamless and impactful.

Rushi Manche | Blockchain Tech Company Co-Founder

Rushi Manche | Blockchain Tech Company Co-FounderRushi Manche

╠²

Rushi Manche has received recognition for his academic, entrepreneurial, and public service achievements at the state, national, and international levels. His contributions span a variety of disciplines, including finance, technology, and education.Hire the Best Crypto Recovery Experts for Fast Recovery in 2025: Puran Crypto...

Hire the Best Crypto Recovery Experts for Fast Recovery in 2025: Puran Crypto...henryywalker3

╠²

In 2025, crypto recovery is critical, with $140 billion in Bitcoin and other assets stranded. Puran Crypto Recovery, with a 94% success rate, is the best expert for fast, secure recovery. Their CCMB technology, success-based fees, and legal compliance ensure effective results, as seen in $1.2ÔÇô$4.2 million recoveries. Act within 48 hours, gather evidence, and contact Puran at www.puranonline.com or purancryptorecovery@contactpuran.co.site. While recovery is complex, PuranÔÇÖs expertise offers hope, though preventionÔÇövia hardware wallets and vigilanceÔÇöremains key.MOOJAY Wireless Keyboard & Mouse Ergonomic Combo ÔÇô Comfort, Silence, and Styl...

MOOJAY Wireless Keyboard & Mouse Ergonomic Combo ÔÇô Comfort, Silence, and Styl...Topmate

╠²

Upgrade your workspace with the MOOJAY Wireless Keyboard and Mouse Ergonomic Combo ÔÇô a full-sized, rechargeable set designed for comfort and quiet performance. With a 2.4G wireless connection, silent typing, ergonomic wrist rest, and a convenient phone holder, this combo is perfect for both work and home setups. Compatible with Windows, Mac, laptops, and PCs, it offers seamless performance, modern design, and enhanced productivity.Noah Loul Shares 5 Key Impacts of AI Agents on the Sales Industry

Noah Loul Shares 5 Key Impacts of AI Agents on the Sales IndustryNoah Loul

╠²

Noah Loul is the CEO of AI Agents by B2B Rocket, a company dedicated to transforming how sales teams operate using AI. With a clear and practical approach, Noah Loul is creating tools that help businesses respond quickly, qualify leads more effectively, and close more deals. He believes technology should support people, not replace them, and his work helps sales teams accomplish more with less effort. Noah Loul shares five straightforward ways AI agents are changing the way sales teams work and helping businesses boost their sales.PTJ Contracted Manufacturer's Repsentative V.1.pdf

PTJ Contracted Manufacturer's Repsentative V.1.pdfvictoryuipworks

╠²

TFT LCD, display integration, touch panel, AD board, Marketing Assignment presentation of good marketing techniques how to impleme...

Marketing Assignment presentation of good marketing techniques how to impleme...Priya Raj

╠²

Marketing presentationOleksandr Osypenko: ðúð┐ÐÇð░ð▓ð╗Ðûð¢ð¢ÐÅ Ðçð░Ðüð¥ð╝ Ðéð░ ÐÇðÁÐüÐâÐÇÐüð░ð╝ð© (UA)

Oleksandr Osypenko: ðúð┐ÐÇð░ð▓ð╗Ðûð¢ð¢ÐÅ Ðçð░Ðüð¥ð╝ Ðéð░ ÐÇðÁÐüÐâÐÇÐüð░ð╝ð© (UA)Lviv Startup Club

╠²

Oleksandr Osypenko: ðúð┐ÐÇð░ð▓ð╗Ðûð¢ð¢ÐÅ Ðçð░Ðüð¥ð╝ Ðéð░ ÐÇðÁÐüÐâÐÇÐüð░ð╝ð© (UA)

LemBS PMP Prep Course

Website ÔÇô https://lembs.com/pmpcourse

Youtube ÔÇô https://www.youtube.com/startuplviv

FB ÔÇô https://www.facebook.com/pmdayconferenceIT Companies in Magarpatta: A Thriving Hub of Technology and Innovation

IT Companies in Magarpatta: A Thriving Hub of Technology and Innovationprernarathi90

╠²

IT Firms in Magarpatta have transformed the region into one of PuneÔÇÖs most vibrant and sought-after technology destinations. Located in Hadapsar, Magarpatta City is a privately managed, self-sustained township that blends residential, commercial, and IT infrastructure with green and eco-friendly planning. The presence of leading software companies, excellent connectivity, and world-class amenities make it a hotspot for IT professionals and businesses alike.

Integrating Customer Journey Insights into Your Business Process Management S...

Integrating Customer Journey Insights into Your Business Process Management S...RUPAL AGARWAL

╠²

Discover how aligning customer journey insights with your business process management (BPM) strategy can unlock greater efficiency, improve customer satisfaction, and drive innovation. This presentation explores key methods, tools, and real-world applications for transforming BPM through a customer-centric lens.Power of the Many Masterclasses - 2nd draft .pptx

Power of the Many Masterclasses - 2nd draft .pptxAlexBausch2

╠²

Masterclass on digitalisation of Energy SystemsRecruitment Policy Sample, Recruitment Policy PDF

Recruitment Policy Sample, Recruitment Policy PDFSeemaAgrawal43

╠²

A recruitment policy outlines the guidelines and principles an organization follows when hiring new employees. It ensures consistency, fairness, and transparency in the recruitment process, setting clear expectations for job roles, qualifications, and selection criteria. This policy helps attract the right talent, fosters a diverse workforce, and supports the organization's overall goals.

The APCO Geopolitical Radar Q3 2025 Edition

The APCO Geopolitical Radar Q3 2025 EditionAPCO

╠²

Welcome to the APCO Geopolitical Radar (AGR), an overview of geopolitical risks posed to corporations operating globally. AGR reflects our understanding of the regional risks facing businesses and how these risks come together at a global level. It is intended as a baseline from which to develop strategies that navigate and mitigate these risks. This report looks at emerging issues for Q3 2025 and was published in April 2025. Our regional insights represent the best thinking of APCO corporate advisory practitioners. With more than 1,300 people across more than 30 global locations, our analysis draws on decades of experience and insights serving corporations that operate globally.

The APCO Geopolitical Radar Q3 2025 EditionPower of the Many: Digital Energy Masterclass

Power of the Many: Digital Energy Masterclassmariana491193

╠²

Masterclass on digitalisation of Energy SystemsEasy Solar Calculator for Homeowners : ksquare energy

Easy Solar Calculator for Homeowners : ksquare energyKsquare Energy Pvt. Ltd.

╠²

"Easy Solar Calculator for Homeowners" is a simple online tool that helps you estimate how much money and energy you can save by switching to solar. Just enter your monthly electricity usage and roof details, and get a personalized report on solar panel costs, savings, and payback time - all in minutes!Tesia Dobrydnia - A Leader In Her Industry

Tesia Dobrydnia - A Leader In Her IndustryTesia Dobrydnia

╠²

Tesia Dobrydnia brings her many talents to her career as a chemical engineer in the oil and gas industry. With the same enthusiasm she puts into her work, she engages in hobbies and activities including watching movies and television shows, reading, backpacking, and snowboarding. She is a Relief Senior Engineer for Chevron and has been employed by the company since 2007. Tesia is considered a leader in her industry and is known to for her grasp of relief design standards. Ad

110615 pyi - work out -dfp-report 080211

- 1. TEAM 3 DFM/ DFP Kaizen Workshop ÔÇô SS12 Product name: WORKOUT PLUS Team Members: UJANG Y M.Taufik Lili Saptaji Suherlan Yusuf Dwi Silvi Rani F Start: June 16th 2011 Update :August 1st 2011

- 2. Contents ´ü▒ Project Overview ´ü▒ Team Charter ´ü▒ Lean Tools (Fishbone Diagram) ´ü▒ RACI ´ü▒ Gantt Chart ´ü▒ Activities Progress ´ü▒ Activities Pictures ´ü▒ Best Practice ´ü▒ Current Result ´ü▒ Next Steps

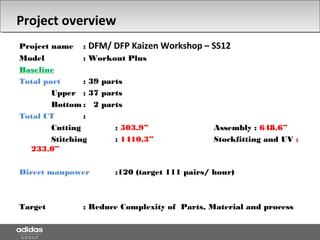

- 3. Project overview Project name : DFM/ DFP Kaizen Workshop ÔÇô SS12 Model : Workout Plus Baseline Total part : 39 parts Upper : 37 parts Bottom : 2 parts Total CT : Cutting : 503.9ÔÇØ Assembly : 648.6ÔÇØ Stitching : 1410.3ÔÇØ Stockfitting and UV : 233.0ÔÇØ Direct manpower :120 (target 111 pairs/ hour) Target : Reduce Complexity of Parts, Material and process

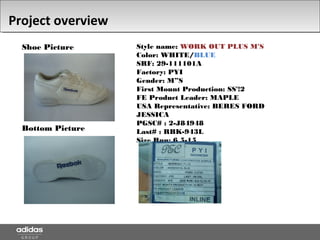

- 4. Project overview Shoe Picture Bottom Picture Style name: WORK OUT PLUS M'S Color: WHITE/BLUE SRF: 29-111101A Factory: PYI Gender: MÔÇØS First Mount Production: SS'!2 FE Product Leader: MAPLE USA Representative: BERES FORD JESSICA PGSC# : 2-J84948 Last# : RBK-943L Size Run: 6.5-15

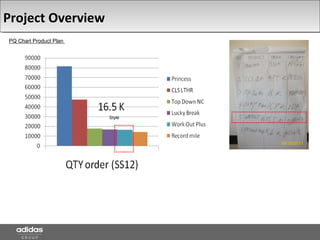

- 5. Project Overview Style PQ Chart Product Plan 06/15/2011

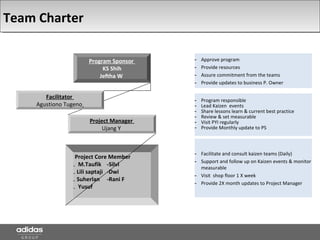

- 6. Team Charter - Approve program - Provide resources - Assure commitment from the teams - Provide updates to business P. Owner Program Sponsor KS Shih Jeftha W Project Manager Ujang Y Project Core Member - M.Taufik -Silvi - Lili saptaji -Dwi - Suherlan -Rani F - Yusuf - Program responsible - Lead Kaizen events - Share lessons learn & current best practice - Review & set measurable - Visit PYI regularly - Provide Monthly update to PS - Facilitate and consult kaizen teams (Daily) - Support and follow up on Kaizen events & monitor measurable - Visit shop floor 1 X week - Provide 2X month updates to Project Manager Facilitator Agustiono Tugeno

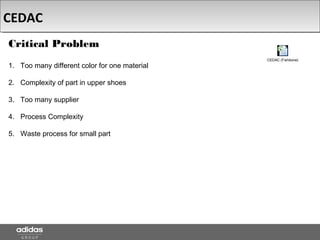

- 7. CEDAC CEDAC (Fishbone) Critical Problem 1. Too many different color for one material 2. Complexity of part in upper shoes 3. Too many supplier 4. Process Complexity 5. Waste process for small part

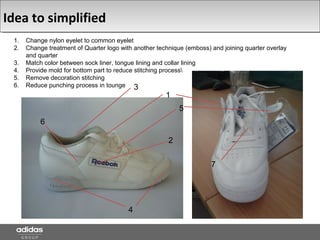

- 8. Idea to simplified 1. Change nylon eyelet to common eyelet 2. Change treatment of Quarter logo with another technique (emboss) and joining quarter overlay and quarter 3. Match color between sock liner, tongue lining and collar lining 4. Provide mold for bottom part to reduce stitching process 5. Remove decoration stitching 6. Reduce punching process in tounge 1 2 3 4 5 6 7

- 9. RACI Chart

- 10. Gantt Chart Gant Chart Workout plus

- 11. Activities Progress Propose : Presentation of waste identified Attendance : Team 3 Location : Training room Date/Time : June 14th , 2011 Description : Explain Cause and Effect of waste according 8 waste principles in daily job Propose : Brainstorming Session Attendance : Team 3 Location : Training room Date/Time : June 15th , 2011 Description : Brainstorming idea to improve the current design

- 12. Activities Progress Propose : Presentation to PYI senior managers Attendance : Team 3 Location : Training room Date/Time : June 15th , 2011 Description : Explain Cause and Effect idea implementation Propose : Project review meeting with Mark Ma Attendance : Team 3 Location : Meeting Room 1st floor Date/Time : June 24h , 2011 Description : Review Project and Brainstorming season 2

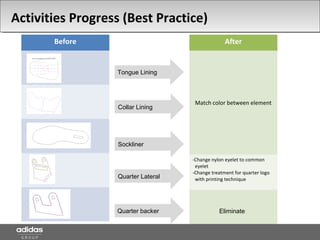

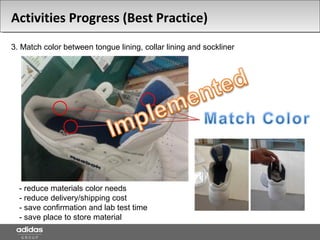

- 13. After Match color between element -Change nylon eyelet to common eyelet -Change treatment for quarter logo with printing technique Before Quarter Lateral Tongue Lining Collar Lining Sockliner EliminateQuarter backer Activities Progress (Best Practice)

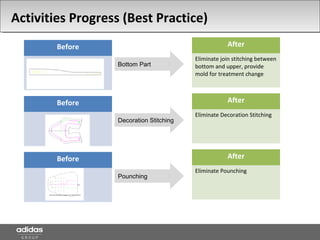

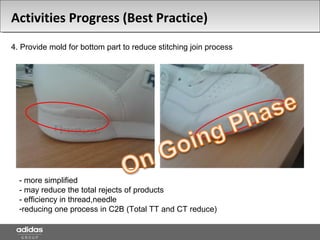

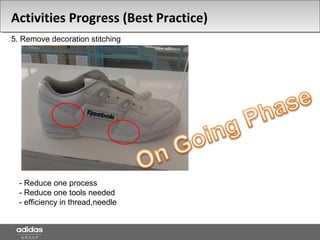

- 14. Before After Eliminate join stitching between bottom and upper, provide mold for treatment change Activities Progress (Best Practice) Bottom Part Before After Eliminate Decoration Stitching Decoration Stitching Before After Eliminate Pounching Pounching

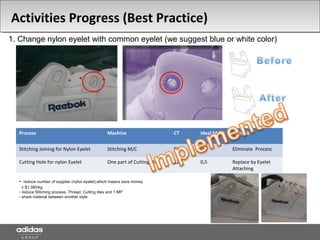

- 15. 1. Change nylon eyelet with common eyelet (we suggest blue or white color) - reduce number of supplier (nylon eyelet),which means save money + $1.380/kg - reduce Stitching process, Thread, Cutting dies and 1 MP - share material between another style Activities Progress (Best Practice) Process Machine CT Ideal Man Remark Stitching Joining for Nylon Eyelet Stitching M/C 06 0,3 Eliminate Process Cutting Hole for nylon Eyelet One part of Cutting Dies 12 0,5 Replace by Eyelet Attaching

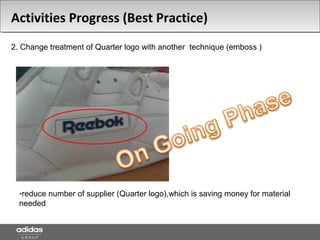

- 16. 2. Change treatment of Quarter logo with another technique (emboss ) -reduce number of supplier (Quarter logo),which is saving money for material needed Activities Progress (Best Practice)

- 17. 3. Match color between tongue lining, collar lining and sockliner - reduce materials color needs - reduce delivery/shipping cost - save confirmation and lab test time - save place to store material Activities Progress (Best Practice)

- 18. 4. Provide mold for bottom part to reduce stitching join process - more simplified - may reduce the total rejects of products - efficiency in thread,needle -reducing one process in C2B (Total TT and CT reduce) Activities Progress (Best Practice)

- 19. 5. Remove decoration stitching - Reduce one process - Reduce one tools needed - efficiency in thread,needle Activities Progress (Best Practice)

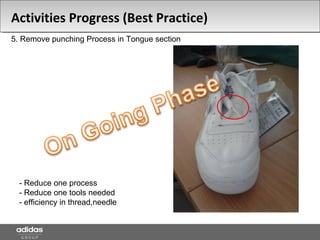

- 20. 5. Remove punching Process in Tongue section - Reduce one process - Reduce one tools needed - efficiency in thread,needle Activities Progress (Best Practice)

- 21. Best Practice Statement Reduce Complexity of Part ,Material and Process: a. Manpower saving: idea#1 : -1 person by stitching process of joining nylon eyelet idea#2 : -1 person by stitching process of joining quarter logo idea#3 : 0 Idea#4 : 1 person by stitching process of joining bottom and upper part idea#5 : 1 person by decoration stitching idea#6 : 0 Calculation : Total Manpower Saving : 4 MP Labor cost 1 operator/month =100USD 100USD x 4 = 400 USD/month = 2000 USD/SS Total CT and TT Reduce = joining nylon eyelet = 30ÔÇØ/Pair joining quarter logo = 04ÔÇØ/Pair joining bottom and upper part = 15ÔÇØ/Pair joining quarter backer and lateral = 08ÔÇØ/Pair b. Overhead: idea#1 : 0 idea#2 : reduce one number of supplier idea#3 : reduce shipping cost, streamline the material needs, idea#4 : total TT and CT reduce in C2B idea#5 : material saving for quarter backer minor reduce : reduce stitching machine maintenance, electricity, save place to storage, save lab test and confirmation time may reduce total number of defect Calculation Not Included (On Going Phase) c. Machine and tools reduce : idea #1 : little cutting dies for nylon eyelet hole = idea#2 : Cutting dies for make a hole in quarter logo section idea#3 : 0 idea#4 : 0 idea#5 : eliminate one tool and process reduce minor reduce : needle and stitching machine efficiency electricity, save place to storage, save lab test and confirmation time may reduce total number of defect efficiency of cutting dies using Cutting Dies = 17.64 USD x 2 Cutting dies = 35.28 USD Tool for Decoration Stitching Process = 9.2 USD Approx for minor reducement = 28 USD Total CT reduce = 22ÔÇØ/Pair

- 22. Next Step (refer to Gantt Chart) Calculation Data Trial On Sample Room Make A Proposal Propose To Costing Dept Propose To Customer Implement On Production

- 23. Group Picture

Editor's Notes

- #6: This potential saving will be achieve at the condition as above, manpower reduction 136 and B-grade at assembling line down to be 5%