164_TP.pptx

- 1. TQM International Pvt. Ltd. 709, Vipul Business Park, 7th Floor, Sector â 48, Main Sohna Road, Gurgaon â 122018, Phone No. 0124 â 4968989 ÂĐ by TQMI Copying of this document and giving it to others and the use or communication of the concepts thereof, are forbidden without express liability. Offenders are liable to the payment of damages. All rights are reserved in the event of the grant of a patent or the registration of a utility model or design. Introduction to the concepts of Quality Circles 164_TP.PPT/1 E-1/L0306-ISSUE1 SKR

- 2. Workforce in the organization who play an important role, in the transformation of the organization, has to be associated closely with the organization. Participative methods in the workplace are one way to improve both the work environment for employees and productivity & quality for the organization. The simple way to do this, is implementation of âQuality Circle concepts in the organizationâ The Need

- 3. Quality Circle âĒ This concept originated from Japan during 1960s. âĒ Dr. K. Ishikawa is the father of this concept. âĒ This concept is based on the assumption that: - Employees are the expert in their work areas. - The people who carry out the job every day are qualified to identify areas for continuous improvements.

- 4. Who can implement this concept âĒ Any organization offering any type of goods or services. âĒ Besides manufacturing organisation, - Banks. - Offices. - Software companies. - Laboratories. can also apply this concept successfully.

- 5. Philosophy Quality circle is: âĒ people building providing self-motivation, happiness in improving environment without momentary benefits. âĒ a progressive attitude on the part of management, their willingness to make adjustments in their style and culture. ContdâĶ

- 6. Philosophy (contdâĶ) âĒ Respecting people, which leads to success which make decisions concerning their work. which makes capabilities being looked as assets. âĒ Creating congenial work environment.

- 7. What is Quality Circle (QC) ? Quality circle is âĒ A small group. âĒ Meets regularly. âĒ Identifies problem in their work area. âĒ Solves the problem. âĒ Makes continuous improvement.

- 8. Small Group This small group carries on continuously as a part of company- wide quality activities for : âĒ Self- development and mutual development, âĒ Control and improvement within the work areas, âĒ Utilization of quality control techniques with all the members participating.

- 9. Quality Circle is VOLUNTARY âĒ Forms voluntarily. âĒ Meets voluntarily. âĒ Identifies problems voluntarily. âĒ Selects problems voluntarily. âĒ Analyse problem voluntarily. âĒ Resolves problems voluntarily. All activities are done voluntarily.

- 10. Why Quality Circles ? âĒ To achieve continuous improvement and development of/in the organization. âĒ To respect humanity and build a learning workshop (organization) which is meaningful to work in. âĒ To catalyze attitudinal changes. âĒ To Reduce defects/ pitfalls/ problems and to improve quality.

- 11. Objectives âĒ To create job satisfaction. âĒ To improve capabilities of individuals by self development. âĒ To inculcate a feelings of team work and team building. âĒ To Improve management - employee relationship. âĒ To encourage the employees for participative cost reduction.

- 12. Quality circle is not âĒ Suggestion scheme. âĒ Quality control. âĒ Task force or a committee. âĒ Solution for personal problems. âĒ Demand Scheme. âĒ Solution to all problems. âĒ For monetary benefit. âĒ A short term project.

- 13. Journey of a Quality circle Implementation and standardization of the changes. Making a presentation to the top management and get concurrence. Checking results. Trial of countermeasure. Foreseeing the probable resistance. Determination of the root causes of the problem. Determination of target. Collection of data on selected problem and Analysis. Preparation of Activity Plan. Registration of QC with the coordinator. Identification and selection of problem. Circle formation (Team selection).

- 14. Structure of Quality Circle Organization structure consisting of Top management, steering committee, leaders and members. Top Management (Corporate coordinator) QC Leader Members Department level Steering committee

- 15. Introduction of QC concept in the organization âĒ Conduct conceptual training programmes to Top management. âĒ Select Managers/ Leaders/ Coordinators from all departments âĒ Conduct special/ detailed training programmes. âĒ Conduct a preliminary survey in the organization about the QC concept. âĒ Discuss the findings with the top management and make strategy accordingly. âĒ Conduct awareness programme to all employees on QC concept. âĒ Start the first QC at the managerial level to set a precedent.

- 16. How QC works? âĒ Cannot be large - no time to participate, - may make the QC ineffective. âĒ Always try to form a QC with persons within a shift. âĒ QC is preliminary for the improvement of the employees but this is done by bringing improvement to the workplace also. Conduct meeting during working hours. If not possible meet after working hours, after all, it is voluntary.

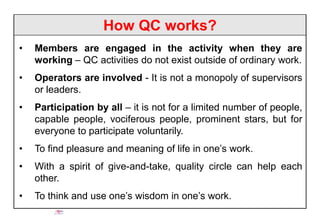

- 17. How QC works? âĒ Members are engaged in the activity when they are working â QC activities do not exist outside of ordinary work. âĒ Operators are involved - It is not a monopoly of supervisors or leaders. âĒ Participation by all â it is not for a limited number of people, capable people, vociferous people, prominent stars, but for everyone to participate voluntarily. âĒ To find pleasure and meaning of life in oneâs work. âĒ With a spirit of give-and-take, quality circle can help each other. âĒ To think and use oneâs wisdom in oneâs work.

- 18. The role of workers in Quality Circle âĒ Study the quality circle activities. âĒ Get in touch with other quality circle outside oneâs own company and bring this experience back to the circle as a subject of discussion. âĒ Find a specific theme to work on and start analyzing a problem. âĒ Discuss among the circle members how they will carry out their circle activities. âĒ Study and apply the various techniques. âĒ Report oneâs experience to sub-ordinates in the form of case study and discuss it with them.

- 19. The Role of Leader in Quality Circle âĒ To integrate the circle. âĒ To orient and direct circle activities. âĒ To facilitate cooperation among the members by getting everyone involved, speaking out and sharing responsibility. âĒ To create favourable human relationship. âĒ To train the members on the application of engineering and QC techniques. âĒ To adjust relationships with other circles and other levels and functions of the organization.

- 20. Four elements of group activities QC is characterized by the following 4 elements: âĒ Members work closely together and run group activities on their own initiative. âĒ Members interact sufficiently to influence each other. âĒ Members know each other well. They can talk openly without trying to guard oneâs own position. âĒ Members gather to share common objectives.

- 21. An ideal group activity requires the following 3 points attitude: âĒ Individuals are respected. Members participate in the group activities on equal terms. âĒ Initiative and independence of each member is respected. âĒ Information is shared by all the members for maximum benefit.

- 22. How to ensure longevity âĒ To be problem-conscious. âĒ To enhance peopleâs awareness in 3 areas â Quality, problem, improvement. âĒ To understand why the activities should be carried out voluntarily. âĒ To find pleasure in the QC activities. âĒ To give training. âĒ To secure management involvement. âĒ To run QC effectively. âĒ To organize a system to promote QC activities.

- 23. QC uses the following simple problem solving tools âĒ Brain Storming. âĒ Graphs. âĒ Flow diagram. âĒ Pareto analysis. âĒ Cause and effect diagram.

- 24. Problems affecting QC implementation âĒ Sudden/ by force formation of circles. âĒ QC members/ leaders transfer. âĒ Lack of periodical refreshment training on QC. âĒ Resistance from trade unions. âĒ Delay or non-implementation of circle recommendations. âĒ Improper recording system during circle meetings, presentation and activities. âĒ Theme taken is very tough. ContdâĶ

- 25. Problem affecting QC implementation (contdâĶ) âĒ Members in QC belong to different shifts. âĒ Lack of interest among departmental leaders/ facilitators. âĒ Circle leaders are not allowing other members to participate equally. âĒ Lack of knowledge on concept and activities of QC for all levels of management and workers. âĒ Giving less priority for QC activities than Production activities. ContdâĶ

- 26. Problem affecting QC implementation (contdâĶ) âĒ Top management thinking that QC activities are responsibility of middle management and workers only. âĒ Fear and misunderstanding among Middle/ Junior management, thinking that if QC members could solve problems, they will be neglected by top management. âĒ Expecting short term/ immediate success of QC.

- 27. How to maintain the concept of QC Workshop on QC with the objective of âĒ proper understanding of the concept and philosophy. âĒ To prepare the concerned for playing their roles effectively for the successful functioning of QC. âĒ Proper understanding and application of simple statistical Quality control tools and techniques. ContdâĶ

- 28. How to maintain the concept of QC (contdâĶ) Training âĒ Exposure for - Top management - Senior management executives âĒ Orientation training for - Facilitators as teacher, guide, catalyst, coordinator, guard against pitfalls.

- 29. Motivation âĒ Launching & inauguration of each circle through a form of function in a traditional way. âĒ Presentation by circles before Top management. âĒ Presentation by circles in sister concerns, ancillaries, outside seminars etc. âĒ Wearing badges, issuing certificates for members & leaders of circles to give separate identity. âĒ Annual get-together of members with Top management. âĒ Publishing QC activities in in-house journals. âĒ Continuous encouragement by facilitators. âĒ Providing snacks and tea during circle meetings. How to maintain the concept of QC (contdâĶ)

- 30. A system of Function to Invigorate and Perpetuate Quality Circle Awareness âĒ Problem-consciousness of management and staff. âĒ Quality-consciousness of a Quality Circle. âĒ Problem-consciousness of a Quality Circle. âĒ Improvement-consciousness of a Quality Circle. âĒ Quality Circleâs understanding of the importance of voluntary action.

- 31. A system of Function to Invigorate and Perpetuate Quality Circle (contdâĶ) Education and training âĒ Self-development within a circle. âĒ Training provided by management and staff. - Collective training. - practical training through problem-solving. âĒ Quality Circle concept is taught.

- 32. A system of Function to Invigorate and Perpetuate Quality Circle (contdâĶ) Interest of supervisors (the role of management) âĒ Interest and understanding of top management. - to create an environment, - to formulate policies concerning Quality Circles, - to praise and encourage Quality Circles. âĒ Interest and understanding of supervisors and staff - leadership, dissemination, advertising, - to find effective ways of promotion.

- 33. A system of Function to Invigorate and Perpetuate Quality Circle (contdâĶ) Effective management of Quality Circles âĒ To convert people to belief in Quality Circles. âĒ To understand the essence and objectives of Quality Circles To find effective ways of holding Quality Circles meeting - outside the company, - inside the company, in the workshop. ContdâĶ

- 34. A system of Function to Invigorate and Perpetuate Quality Circle (contdâĶ) âĒ To hold Quality Circles leaders meeting to study effective ways of managing Quality Circles. - guidance of management and staff, - voluntarily organise and manage leaders meeting. âĒ Guidance and support of supervisors and staff. âĒ Organization for promotion - coordination with management and staff. - organization of sub-Circles or mini-Circles.

- 35. A system of Function to Invigorate and Perpetuate Quality Circle (contdâĶ) âĒ Measures to prevent mannerism - Staff and supervisors. - Quality Circle members. âĒ Commendation and reward - Company. - Quality Circle headquarters. âĒ The role of Quality Circle headquarters - Advertisement of Quality Circles. - To set a guideline of Quality Circle activities. - To organize national conferences.

- 36. Delay in issue of observation memos: The Public Works Department of Maharashtra is divided into six regions each headed by a Chief Engineer. Each regional Chief Engineer is assisted by a Superintending Engineer, Vigilance & Quality Circle who with the help of two Executive Engineer and about 6 Deputy Engineers carries out inspection of the ongoing projects. The samples of the construction material being used on project are collected and independently tested in the Regional Testing Laboratories to ascertain the level of acceptance. The findings of the inspections are communicated to the field engineers in the form of âobservation memoâ. It is contemplated that the Execution Engineer in charge of the project ensures immediate compliance of the remarks raised in the observation memo and carries out corrective measures in the ongoing project as well as preventive measures for the future works.

- 37. However, very often the observation memos are issued after much delay defeating the very purpose of the observation memo. This problem was identified by the âOMKARâ Quality Circle formed in the office of Superintending Engineer, Vigilance & Quality Control Circle, Navi Mumbai. The members used various tools and methodology, identified the various root causes that led to this problem and finally solved the problem with requisite fool proofing. ContdâĶ

- 38. By solving this problem, it became possible to improve the quality of work in the field which ultimately brightened the image of the Department. The formation of Quality Circle also benefited employees by providing. a) A systematic style of education that helped them grow. b) Freedom to modify their work habits. c) Opportunity to use their brain for development of the Department; and d) Opportunity to work as a team. e) The employees were also motivated to improve work culture, self improvement recognition and creativity in work.

- 39. Preventing accidents on highways: It was observed that the accident rate on Sion-Panvel Highway passing through New Mumbai had gone up sharply. The Circle members collected the data from the respective police stations and identified the important causes of accidents by using Pareto Analysis. They segregated the causes under Man, Machine, Material & Method . The Circle members found out solutions to the problem such as closing of central verge at all locations except junction, frequent lane marking, installation of Caution boards, Providing lay-byes for buses etc. The data collection of accidents for a period three months after implementation of solutions near Shirvane and Turbhe revealed that the cause of accident had been eliminated and no more accidents occurred at those locations had been eliminated and no more accidents accoured at those locations again. This way the Circle members ensured the effectiveness of the solution implemented. They made presentation to their steering committee for obtaining sanction to other solutions involving more funds.