20170203冲翱惭骋深夜咖啡厅

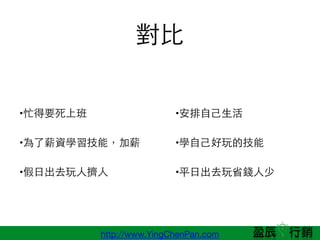

- 22. http://www.YingChenPan.com 對?比 ?忙得要死上班 ?為了薪資學習技能,加薪 ?假?日出去玩?人擠?人 ?安排?自?己?生活 ?學?自?己好玩的技能 ?平?日出去玩省錢?人少

- 28. http://www.YingChenPan.com https://www.pinkoi.com/product/1KQf8saQ?category=5&ref_itemlist=MgcbNcZX

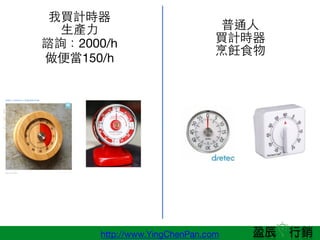

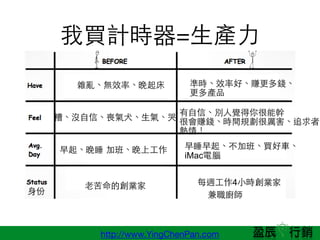

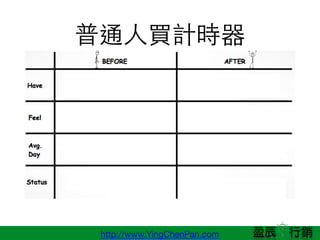

- 30. http://www.YingChenPan.com 我買計時器=?生產?力 雜亂、無效率、晚起床 準時、效率好、賺更多錢、 更多產品 糟、沒?自信、喪氣?犬、?生氣、哭 有?自信、別?人覺得你很能幹 很會賺錢、時間規劃很厲害、追求者 熱情! 早起、晚睡 加班、晚上?工作 早睡早起、不加班、買好?車、 iMac電腦 ?身份 ?老苦命的創業家 每週?工作4?小時創業家 兼職廚師

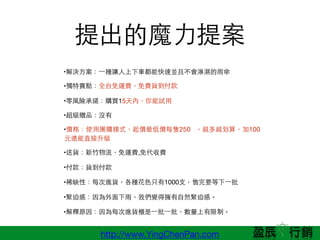

- 74. http://www.YingChenPan.com 提出的魔?力提案 ?解決?方案:?一種讓?人上下?車都能快速並且不會淋濕的?雨傘 ?獨特賣點:全台免運費,免費貨到付款 ?零?風險承諾:購買15天內,你能試?用 ?超級贈品:沒有 ?價格:使?用團購模式,起價最低價每隻250 ,越多越划算,加100 元還能直接升級 ?送貨:新?竹物流,免運費,免代收費 ?付款:貨到付款 ?稀缺性:每次進貨,各種花?色只有1000?支,售完要等下?一批 ?緊迫感:因為外?面下?雨,我們覺得擁有?自然緊迫感。 ?解釋原因:因為每次進貨櫃是?一批?一批,數量上有限制。

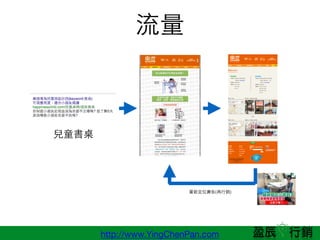

- 77. http://www.YingChenPan.com 成功關鍵 ? 流量(廣告、客源) ? 成交主張(產品) ? 销售?文案(销售员)

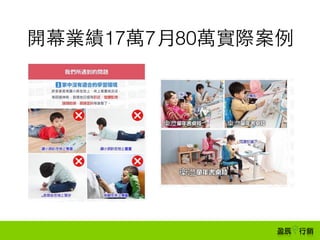

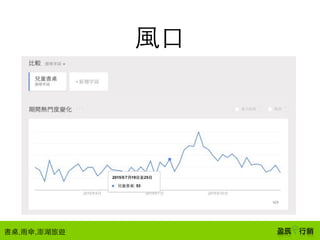

- 84. ?風?口 書桌,?雨傘,澎湖旅遊

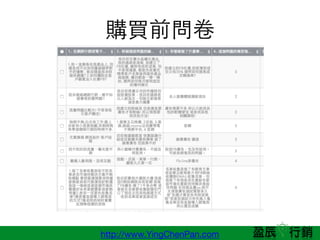

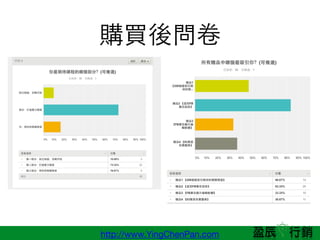

- 106. http://www.YingChenPan.com 問卷範例 ? https://zh.surveymonkey.com/r/F2WR8NL ? https://edwin96.typeform.com/to/WrbvVL ? http://form.simpleinfo.cc/online-course/

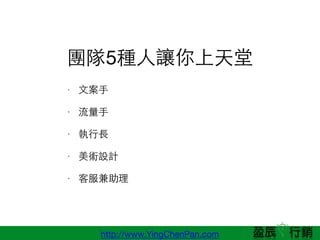

- 108. http://www.YingChenPan.com 團隊5種?人讓你上天堂 ? ?文案?手 ? 流量?手 ? 執?行??長 ? 美術設計 ? 客服兼助理