BID Final Presentation Creastmead V2.6 crews

- 2. Agenda ŌĆó Introduction ŌĆó De-Bottlenecking Method ŌĆó Summary of what was achieved ŌĆó Question and Answer time

- 3. DBM The De-Bottlenecking Method Rob Tilley

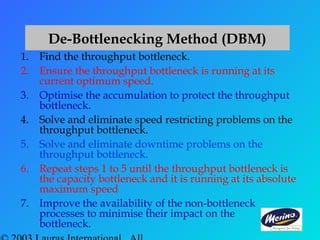

- 4. 1. Find the throughput bottleneck. 2. Ensure the throughput bottleneck is running at its current optimum speed. 3. Optimise the accumulation to protect the throughput bottleneck. 4. Solve and eliminate speed restricting problems on the throughput bottleneck. 5. Solve and eliminate downtime problems on the throughput bottleneck. 6. Repeat steps 1 to 5 until the throughput bottleneck is the capacity bottleneck and it is running at its absolute maximum speed 7. Improve the availability of the non-bottleneck processes to minimise their impact on the bottleneck. De-Bottlenecking Method (DBM)

- 5. Using DBM in the Factory ŌĆó The team was introduced to DBM as the fastest way to determine how to improve performance for each Line/product combination run. Lets Take a look at what they did!

- 6. DBM Step 1 ŌĆ£Determining the throughput bottleneckŌĆØ Rob Tilley

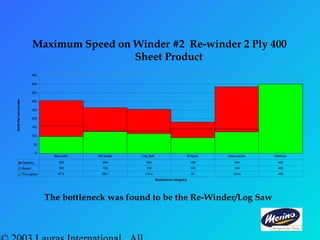

- 7. Maximum Speed on Winder #2 Re-winder 2 Ply 400 Sheet Product The bottleneck was found to be the Re-Winder/Log Saw 0 50 100 150 200 250 300 350 400 450 Equipment catagory RollsPerminuterate Capacity 305 264 254 180 384 400 Speed 160 130 130 140 140 400 Throughput 97.6 126.1 114.4 91 124.6 400 Rew inder Tail Sealer Log Saw Wrapper Case packer Palletiser

- 8. DBM Step 2 ŌĆ£Ensure the Bottleneck is running at its current optimum speedŌĆØ Glen

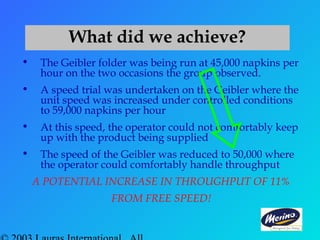

- 10. What did we achieve? ŌĆó The Geibler folder was being run at 45,000 napkins per hour on the two occasions the group observed. ŌĆó A speed trial was undertaken on the Geibler where the unit speed was increased under controlled conditions to 59,000 napkins per hour ŌĆó At this speed, the operator could not comfortably keep up with the product being supplied ŌĆó The speed of the Geibler was reduced to 50,000 where the operator could comfortably handle throughput A POTENTIAL INCREASE IN THROUGHPUT OF 11% FROM FREE SPEED!

- 11. DBM Step 3 ŌĆ£Optimising the state of the accumulationŌĆØ Sal & MAX

- 12. How does optimising accumulation work? ŌĆó The purpose of accumulation is to protect the throughput bottleneck from downtime on other areas of the line. ŌĆó Accumulation should be kept full upstream of the throughput bottleneck and empty downstream of the throughput bottleneck.

- 13. How does optimising accumulation work on the Perini Line now? ŌĆó The Accumulator was ┬Š - Full on most visits out to the Perini Line. ŌĆó The Downstream processes were not draining the Accumulator quick enough to protect the throughput bottleneck. ŌĆó The Re-winder would stop frequently as the Accumulator reached its capacity. ŌĆó The packer and Log saw speed would ŌĆ£bounceŌĆØ back and fourth as the line control would stop the units. Max

- 14. What did we do? ŌĆó Automated Line control is being progressed along the Entire Perini line ŌĆó This will allow all equipment to communicate with each other and maintain optimum speeds without the need for operator input.

- 15. DBM Step 4 ŌĆō Winder #2 ŌĆ£Solve and eliminate speed restricting problems on the throughput bottleneckŌĆØ Wesley Peirce

- 16. What did we find? ŌĆó The maximum speed (Capacity) for winder #2 was stated as 610m/min on 1000 sheet product but it was always running below this. ŌĆó The operators on the line were running to pre- determined set points and procedures and were still unable to obtain optimum speed.

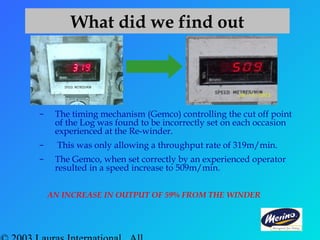

- 17. ŌĆō The timing mechanism (Gemco) controlling the cut off point of the Log was found to be incorrectly set on each occasion experienced at the Re-winder. ŌĆō This was only allowing a throughput rate of 319m/min. ŌĆō The Gemco, when set correctly by an experienced operator resulted in a speed increase to 509m/min. AN INCREASE IN OUTPUT OF 59% FROM THE WINDER What did we find out

- 18. ŌĆó Set up of the Re-winder required a high degree of training and was not instinctive to the operators. ŌĆó Set points on the Gemco unit were not stable at each change over What we found.

- 19. ŌĆó New procedures have been put in place to ensure the expected run speeds are achieved with support from shift leaders ŌĆó Operator training across all shifts will commence to communicate new procedures and expectations. ŌĆó Installation of PLC control on the Re-winder to simplify the set up process. What have we done about it?

- 20. DBM Step 5 Solve and eliminate significant downtime problems on the throughput bottleneck. Martin

- 21. Solving a downtime problem Winder #2 ŌĆ£Cookie MonsterŌĆØ Max (Paul) During Week 3 of the BID, the team moved onto Winder #2.

- 22. What did we find? ŌĆó Less than 20% of all cookies were being removed from the process and rolls were turning over. ŌĆó This caused jam ups and downtime on the line. ŌĆó A full time casual was put in place to manage this problem.

- 23. What did we do? ŌĆó The team took a closer look at the cookie monster problem using PCS and came up with the following results: ŌĆō Took conveyor system back to original specification. ŌĆō Moved the belts further into the Log saw ŌĆō Attached brushes to the Log saw as per original spec ŌĆō Set Guide rails to correct height

- 24. What did we achieve? ŌĆó 100% of all Cookies which fall into acceptable cookie specification are eliminated from the system. ŌĆó All rolls are positioned on their side ŌĆó All cookies are dropped onto their bums and eliminated from the path of travel.

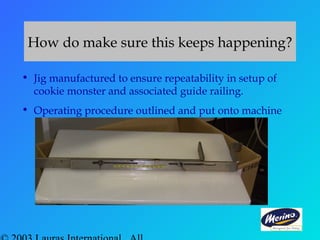

- 25. How do make sure this keeps happening? ŌĆó Jig manufactured to ensure repeatability in setup of cookie monster and associated guide railing. ŌĆó Operating procedure outlined and put onto machine

- 26. DBM Step 7 Solve and eliminate significant downtime problems on the non bottleneck processes to support the Capacity/Throughput bottleneck. Peter

- 27. The Mud Press

- 28. The Mud Press ŌĆó It was discovered that a high percentage of waste in this process was water. ŌĆó Merino currently pay for Mud to be taken away at a standard cost per bin + a tonnage fee.

- 29. What did we find? ŌĆó The presses were not running at optimal pressure and as such the optimal amount of water was not being removed from the mud. ŌĆó The screen wash was leaking a large volume of water directly into the pressed mud and being dumped. ŌĆó The mud bins were exposed to the elements and each time it rained, the rain water was being absorbed by the mud

- 30. What did we do? ŌĆó The group has increased the pressure of the press to optimise the amount of water being removed from the mud. ŌĆó The screen shower has been relocated upstream of the mud press, eliminating all water re entering the pressed mud from the process ŌĆó The group is in the process of obtaining quotes for a permanent shelter to cover the bins and protecting them from rain. ŌĆó Identified and reintroduced the operational procedure for the cleaning of the mud press showers. ŌĆó The group is looking into markets for this mud.

- 31. What did we achieve? ŌĆó The initial testing done on the mud 100% recycled showed a moisture content of 68%. ŌĆó After the completion of all actions on the mud press, the moisture content now stands at 54%. ŌĆó This equates to 2.1 tonnes less water per day leaving the site or $22,000 per year. A 26% reduction in moisture content.