Eco by teeratorn

Download as pptx, pdf0 likes173 views

DonŌĆÖt DEFORESTATION

1 of 3

Download to read offline

Ad

Recommended

Board report August 07

Board report August 07Robert Tilley

╠²

- Rolled products production was 37,000 cartons under budget due to overspending on casual labor and lower production.

- The Perini line ran at 84.93% efficiency in July, an 11.12% increase over the previous month. However, downtime was incurred due to web breaks, maintenance, changeovers, and other issues.

- Both the Jumbo line and Line 2 had efficiency issues in July due to start-up problems, inconsistent operation, and worn equipment, but scheduling and roster changes are expected to improve performance going forward.True Efficiency Graphs

True Efficiency GraphsRobert Tilley

╠²

The document contains charts showing the true efficiency levels over time for all products produced on three different mills - Mill, Perini, and W2. The charts plot the true efficiency percentage on the y-axis against date on the x-axis, and include a smoothed 7 period moving average line. This appears to be performance data monitoring the true efficiency of production across multiple facilities over the period of July 2003 to December 2003.NRFPRESENTATIONNEWSAIP1finallypresentation13july

NRFPRESENTATIONNEWSAIP1finallypresentation13julyMusa Lonwabo Kwetana

╠²

1. The document discusses the synthesis and labeling of DISIDA (N-2,6-diisopropyl-phenyl carbamoylmethyliminodiacetic acid), which is used as a radiopharmaceutical agent for hepatobiliary imaging.

2. The synthesis of DISIDA involves two steps - first synthesizing an intermediate compound and then reacting it with disodium iminodiacetate to produce DISIDA.

3. Labeling is done by adding 99mTcO4- to a kit containing DISIDA and a reducing agent, and quality control shows the labeled product has over 95% radiochemical purity.Assessment Criteria - Menegatti

Assessment Criteria - MenegattiRobert Tilley

╠²

This document outlines assessment criteria and procedures for assessing competency on an automated production line that produces boxes. It includes 14 separate elements of competency that will be assessed, such as starting and stopping the machine, adjusting various machine components like the accumulator box and discharge belts, and performing maintenance tasks like replacing vacuum cups. For each element, it describes the performance criteria that will be assessed, as well as critical evidence required to demonstrate competency. It establishes assessment conditions such as ensuring all tools and equipment are available and functional and limiting candidates to two attempts.Rob Tilley Overiew

Rob Tilley OveriewRobert Tilley

╠²

This document provides an overview of Rob Tilley's career history and management style. It discusses his focus on safety, developing team skills, understanding the big picture, and keeping the team focused. It also describes his approach as an operations manager and how he reviews projects, provides support, and formulates new plans when results are unexpected. His leadership style encourages discussion and participation in decision making. In his communication, he asks questions, thanks people for their work, and understands others' perspectives. When results are not as wanted, he reaffirms priorities with the team and may manage more closely while avoiding micromanaging.Pp toddler temper tantrums

Pp toddler temper tantrumsMelissa Steinke-Schlachter

╠²

Temper tantrums are common for toddlers between 1-2 years old as they are unable to effectively communicate and become frustrated. The document outlines classic signs of temper tantrums like whining, shouting, and hitting. It recommends preventing tantrums through consistency, positive reinforcement, distraction, and addressing a child's needs before frustration escalates into a full tantrum. Temper tantrums are a normal part of child development and can be managed through patience, consistency in routines, and rewarding good behavior.mud press showers clean

mud press showers cleanRobert Tilley

╠²

The document provides steps for cleaning upper and lower mud press showers. It instructs the user to reduce water flow to the lower shower bar, open the drain tap to release built up material, clean inside the bar with a bottle brush, allow drainage, close the release tap, reopen water flow, and repeat for the upper shower bar. Safety cautions are given to avoid standing directly under taps.BID Final Presentation Creastmead V2.6 crews

BID Final Presentation Creastmead V2.6 crewsRobert Tilley

╠²

The document summarizes the application of the De-Bottlenecking Method (DBM) at a factory to improve production throughput. DBM involves identifying the bottleneck process, ensuring it runs at maximum speed, optimizing upstream and downstream processes, and eliminating downtime. At the factory, DBM was used to:

1) Increase the speed of the bottleneck re-winder from 130 rolls/min to 400 rolls/min through proper set-up.

2) Reduce accumulation to protect the re-winder, increasing overall throughput.

3) Eliminate a "cookie monster" problem causing downtime on the winder.

4) Reduce moisture in recycled mud from 68% to 54% through optimizingHydraulic accumulator

Hydraulic accumulatorShibi Chakravarthy

╠²

The document discusses hydraulic accumulators, which store hydraulic energy as pressure energy to be supplied intermittently for applications requiring bursts of energy. It describes the basic components and working of a hydraulic accumulator, which consists of a cylinder containing a sliding ram that stores energy by lifting a weight as hydraulic fluid enters under pressure. The capacity of an accumulator depends on the pressure, area of the ram, and stroke/lift. Differential accumulators store energy at higher pressures using a smaller ram area and annular space between cylinders.Fct

FctShibi Chakravarthy

╠²

Fluid couplings and torque converters are used to automatically couple and uncouple engines and transmissions. They use a torque converter to multiply torque and transmit power from an engine to a transmission. A torque converter contains an impeller, turbine, and stator that use fluid motion and redirection to multiply torque at lower RPMs to assist with acceleration, with the components equalizing at higher RPMs.SUPERCRITICAL FUEL INJECTION-A PROMISING TECHNOLOGY FOR IMPROVED FUEL EFFICIE...

SUPERCRITICAL FUEL INJECTION-A PROMISING TECHNOLOGY FOR IMPROVED FUEL EFFICIE...saeedahmad7007

╠²

The document discusses transonic combustion, which is a new combustion process that involves injecting fuel into an engine cylinder as a supercritical fluid using a patented fuel injection system. Supercritical fuel mixes rapidly and ignites in multiple locations, resulting in high combustion efficiency. The system allows unthrottled engine operation and stratified charge at part load for improved efficiency. Test results show significant reductions in fuel consumption and emissions. The key aspects of the system involve heating the fuel to a supercritical state before injection to improve mixing and achieving precise ignition timing to utilize most of the heat release.2 stroke cycle engines

2 stroke cycle enginesShibi Chakravarthy

╠²

A two-stroke engine has a compression and combustion stroke in each revolution, while a four-stroke engine has separate intake, compression, combustion, and exhaust strokes. In a two-stroke, oil is mixed with gasoline to lubricate parts. Two-stroke engines are lighter and more powerful but less efficient and produce more pollution than four-stroke engines due to exhausting unburned fuel. The piston acts as both a valve and plunger in two-stroke engines.Pressure die casting

Pressure die castingShibi Chakravarthy

╠²

Pressure die casting is a manufacturing process where molten metal is injected under high pressure into a steel mold cavity. This allows for the rapid solidification of net-shaped metal components with tight tolerances. There are two main types - high pressure die casting for parts requiring close tolerances, and low pressure die casting for larger, less critical parts. Pressure die casting allows for high-volume production of complex parts and good dimensional accuracy.More Related Content

Viewers also liked (11)

NRFPRESENTATIONNEWSAIP1finallypresentation13july

NRFPRESENTATIONNEWSAIP1finallypresentation13julyMusa Lonwabo Kwetana

╠²

1. The document discusses the synthesis and labeling of DISIDA (N-2,6-diisopropyl-phenyl carbamoylmethyliminodiacetic acid), which is used as a radiopharmaceutical agent for hepatobiliary imaging.

2. The synthesis of DISIDA involves two steps - first synthesizing an intermediate compound and then reacting it with disodium iminodiacetate to produce DISIDA.

3. Labeling is done by adding 99mTcO4- to a kit containing DISIDA and a reducing agent, and quality control shows the labeled product has over 95% radiochemical purity.Assessment Criteria - Menegatti

Assessment Criteria - MenegattiRobert Tilley

╠²

This document outlines assessment criteria and procedures for assessing competency on an automated production line that produces boxes. It includes 14 separate elements of competency that will be assessed, such as starting and stopping the machine, adjusting various machine components like the accumulator box and discharge belts, and performing maintenance tasks like replacing vacuum cups. For each element, it describes the performance criteria that will be assessed, as well as critical evidence required to demonstrate competency. It establishes assessment conditions such as ensuring all tools and equipment are available and functional and limiting candidates to two attempts.Rob Tilley Overiew

Rob Tilley OveriewRobert Tilley

╠²

This document provides an overview of Rob Tilley's career history and management style. It discusses his focus on safety, developing team skills, understanding the big picture, and keeping the team focused. It also describes his approach as an operations manager and how he reviews projects, provides support, and formulates new plans when results are unexpected. His leadership style encourages discussion and participation in decision making. In his communication, he asks questions, thanks people for their work, and understands others' perspectives. When results are not as wanted, he reaffirms priorities with the team and may manage more closely while avoiding micromanaging.Pp toddler temper tantrums

Pp toddler temper tantrumsMelissa Steinke-Schlachter

╠²

Temper tantrums are common for toddlers between 1-2 years old as they are unable to effectively communicate and become frustrated. The document outlines classic signs of temper tantrums like whining, shouting, and hitting. It recommends preventing tantrums through consistency, positive reinforcement, distraction, and addressing a child's needs before frustration escalates into a full tantrum. Temper tantrums are a normal part of child development and can be managed through patience, consistency in routines, and rewarding good behavior.mud press showers clean

mud press showers cleanRobert Tilley

╠²

The document provides steps for cleaning upper and lower mud press showers. It instructs the user to reduce water flow to the lower shower bar, open the drain tap to release built up material, clean inside the bar with a bottle brush, allow drainage, close the release tap, reopen water flow, and repeat for the upper shower bar. Safety cautions are given to avoid standing directly under taps.BID Final Presentation Creastmead V2.6 crews

BID Final Presentation Creastmead V2.6 crewsRobert Tilley

╠²

The document summarizes the application of the De-Bottlenecking Method (DBM) at a factory to improve production throughput. DBM involves identifying the bottleneck process, ensuring it runs at maximum speed, optimizing upstream and downstream processes, and eliminating downtime. At the factory, DBM was used to:

1) Increase the speed of the bottleneck re-winder from 130 rolls/min to 400 rolls/min through proper set-up.

2) Reduce accumulation to protect the re-winder, increasing overall throughput.

3) Eliminate a "cookie monster" problem causing downtime on the winder.

4) Reduce moisture in recycled mud from 68% to 54% through optimizingHydraulic accumulator

Hydraulic accumulatorShibi Chakravarthy

╠²

The document discusses hydraulic accumulators, which store hydraulic energy as pressure energy to be supplied intermittently for applications requiring bursts of energy. It describes the basic components and working of a hydraulic accumulator, which consists of a cylinder containing a sliding ram that stores energy by lifting a weight as hydraulic fluid enters under pressure. The capacity of an accumulator depends on the pressure, area of the ram, and stroke/lift. Differential accumulators store energy at higher pressures using a smaller ram area and annular space between cylinders.Fct

FctShibi Chakravarthy

╠²

Fluid couplings and torque converters are used to automatically couple and uncouple engines and transmissions. They use a torque converter to multiply torque and transmit power from an engine to a transmission. A torque converter contains an impeller, turbine, and stator that use fluid motion and redirection to multiply torque at lower RPMs to assist with acceleration, with the components equalizing at higher RPMs.SUPERCRITICAL FUEL INJECTION-A PROMISING TECHNOLOGY FOR IMPROVED FUEL EFFICIE...

SUPERCRITICAL FUEL INJECTION-A PROMISING TECHNOLOGY FOR IMPROVED FUEL EFFICIE...saeedahmad7007

╠²

The document discusses transonic combustion, which is a new combustion process that involves injecting fuel into an engine cylinder as a supercritical fluid using a patented fuel injection system. Supercritical fuel mixes rapidly and ignites in multiple locations, resulting in high combustion efficiency. The system allows unthrottled engine operation and stratified charge at part load for improved efficiency. Test results show significant reductions in fuel consumption and emissions. The key aspects of the system involve heating the fuel to a supercritical state before injection to improve mixing and achieving precise ignition timing to utilize most of the heat release.2 stroke cycle engines

2 stroke cycle enginesShibi Chakravarthy

╠²

A two-stroke engine has a compression and combustion stroke in each revolution, while a four-stroke engine has separate intake, compression, combustion, and exhaust strokes. In a two-stroke, oil is mixed with gasoline to lubricate parts. Two-stroke engines are lighter and more powerful but less efficient and produce more pollution than four-stroke engines due to exhausting unburned fuel. The piston acts as both a valve and plunger in two-stroke engines.Pressure die casting

Pressure die castingShibi Chakravarthy

╠²

Pressure die casting is a manufacturing process where molten metal is injected under high pressure into a steel mold cavity. This allows for the rapid solidification of net-shaped metal components with tight tolerances. There are two main types - high pressure die casting for parts requiring close tolerances, and low pressure die casting for larger, less critical parts. Pressure die casting allows for high-volume production of complex parts and good dimensional accuracy.Eco by teeratorn

- 1. DonŌĆÖt DEFORESTATION ICT ECO KIDS Infographic using PowerP

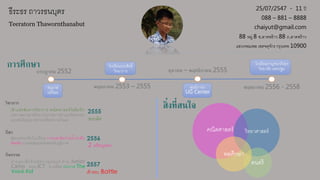

- 3. ÓĖśÓĖĄÓĖŻÓĖ░ÓĖśÓĖŻ ÓĖ¢ÓĖ▓ÓĖ¦ÓĖŻÓĖśÓĖÖÓĖÜÓĖĖÓĖĢÓĖŻ Teeratorn Thawornthanabut 25/07/2547 - 11 ÓĖøÓĖĄ 088 ŌĆō 881 ŌĆō 8888 chaiyut@gmail.com 88 ÓĖ½ÓĖĪÓĖ╣Ó╣ł 8 ÓĖŗ.ÓĖźÓĖ▓ÓĖöÓĖ×ÓĖŻÓ╣ēÓĖ▓ÓĖ¦ 88 ÓĖ¢.ÓĖźÓĖ▓ÓĖöÓĖ×ÓĖŻÓ╣ēÓĖ▓ÓĖ¦ Ó╣üÓĖéÓĖ¦ÓĖćÓĖłÓĖŁÓĖĪÓĖ×ÓĖź Ó╣ĆÓĖéÓĖĢÓĖłÓĖĢÓĖĖÓĖłÓĖ▒ÓĖüÓĖŻ ÓĖüÓĖŻÓĖĖÓĖćÓ╣ĆÓĖŚÓĖ× 10900 ÓĖüÓĖŻÓĖüÓĖÄÓĖ▓ÓĖäÓĖĪ 2552 ÓĖ×ÓĖżÓĖ®ÓĖĀÓĖ▓ÓĖäÓĖĪ 2553 ŌĆō 2555 ÓĖĢÓĖĖÓĖźÓĖ▓ÓĖäÓĖĪ ŌĆō ÓĖ×ÓĖżÓĖ©ÓĖłÓĖ┤ÓĖüÓĖ▓ÓĖóÓĖÖ 2555 ÓĖ×ÓĖżÓĖ®ÓĖĀÓĖ▓ÓĖäÓĖĪ 2556 - 2558ÓĖŁÓĖÖÓĖĖÓĖÜÓĖ▓ÓĖź ÓĖ½ÓĖĪÓĖĄÓĖÖÓ╣ēÓĖŁÓĖó Ó╣éÓĖŻÓĖćÓ╣ĆÓĖŻÓĖĄÓĖóÓĖÖÓĖøÓĖŻÓĖ░ÓĖ¬ÓĖ┤ÓĖŚÓĖśÓĖ┤Ó╣ī ÓĖ¦ÓĖ┤ÓĖŚÓĖóÓĖ▓ÓĖüÓĖ▓ÓĖŻ ÓĖ©ÓĖ╣ÓĖÖÓĖóÓ╣īÓĖĀÓĖ▓ÓĖ®ÓĖ▓ UG Center Ó╣éÓĖŻÓĖćÓ╣ĆÓĖŻÓĖĄÓĖóÓĖÖÓĖüÓĖ▓ÓĖŹÓĖłÓĖÖÓĖ▓ÓĖĀÓĖ┤Ó╣ĆÓĖ®ÓĖü ÓĖ¦ÓĖ┤ÓĖŚÓĖóÓĖ▓ÓĖźÓĖ▒ÓĖó ÓĖÖÓĖäÓĖŻÓĖøÓĖÉÓĖĪ ÓĖüÓĖ▓ÓĖŻÓĖ©ÓĖČÓĖüÓĖ®ÓĖ▓ ÓĖ¦ÓĖ┤ÓĖŖÓĖ▓ÓĖüÓĖ▓ÓĖŻ ÓĖüÓĖĄÓĖ¼ÓĖ▓ ÓĖüÓĖ┤ÓĖłÓĖüÓĖŻÓĖŻÓĖĪ Ó╣ĆÓĖéÓ╣ēÓĖ▓Ó╣üÓĖéÓ╣łÓĖćÓĖéÓĖ▒ÓĖÖÓĖŚÓĖ▓ÓĖćÓĖ¦ÓĖ┤ÓĖŖÓĖ▓ÓĖüÓĖ▓ÓĖŻ ÓĖäÓĖōÓĖ┤ÓĖĢÓĖ©ÓĖ▓ÓĖ¬ÓĖĢÓĖŻÓ╣īÓ╣éÓĖŁÓĖźÓĖ┤ÓĖĪÓĖøÓĖ┤ ÓĖü ÓĖøÓĖŻÓĖ░ÓĖüÓĖ¦ÓĖöÓĖĪÓĖ▓ÓĖŻÓĖóÓĖ▓ÓĖŚÓ╣äÓĖŚÓĖó ÓĖøÓĖŻÓĖ░ÓĖüÓĖ¦ÓĖöÓĖüÓĖ▓ÓĖŻÓĖŁÓ╣łÓĖ▓ÓĖÖÓĖÜÓĖŚÓĖŻÓ╣ēÓĖŁÓĖóÓĖüÓĖŻÓĖŁÓĖć Ó╣üÓĖÜÓĖÜÓĖ¬ÓĖŻÓĖĀÓĖ▒ÓĖŹÓĖŹÓĖ░ ÓĖøÓĖŻÓĖ░ÓĖüÓĖ¦ÓĖöÓ╣ĆÓĖŻÓĖĄÓĖóÓĖćÓĖäÓĖ¦ÓĖ▓ÓĖĪÓĖ¦ÓĖ▒ÓĖÖÓ╣üÓĖĪÓ╣ł ÓĖ¤ÓĖĖÓĖĢÓĖÜÓĖŁÓĖźÓĖŻÓĖ░ÓĖöÓĖ▒ÓĖÜÓ╣éÓĖŻÓĖćÓ╣ĆÓĖŻÓĖĄÓĖóÓĖÖ ÓĖüÓĖ▓ÓĖŻÓ╣üÓĖéÓ╣łÓĖćÓĖéÓĖ▒ÓĖÖÓĖ¦Ó╣łÓĖ▓ÓĖóÓĖÖÓ╣ēÓĖ▓ÓĖŻÓĖ░ÓĖöÓĖ▒ÓĖÜ ÓĖłÓĖ▒ÓĖćÓĖ½ÓĖ¦ÓĖ▒ÓĖö ÓĖüÓĖ▓ÓĖŻÓ╣üÓĖéÓ╣łÓĖćÓĖéÓĖ▒ÓĖÖÓĖĪÓĖ¦ÓĖóÓ╣äÓĖŚÓĖóÓĖŻÓĖ░ÓĖöÓĖ▒ÓĖÜÓĖĀÓĖ╣ÓĖĪÓĖ┤ÓĖĀÓĖ▓ÓĖä ÓĖäÓ╣łÓĖ▓ÓĖóÓĖźÓĖ╣ÓĖüÓ╣ĆÓĖ¬ÓĖĘÓĖŁÓĖłÓĖ▒ÓĖćÓĖ½ÓĖ¦ÓĖ▒ÓĖöÓĖüÓĖ▓ÓĖŹÓĖłÓĖÖÓĖÜÓĖĖÓĖŻÓĖĄ ÓĖäÓ╣łÓĖ▓ÓĖó Junior Camp ÓĖäÓĖōÓĖ░ ICT ÓĖĪ.ÓĖĪÓĖ½ÓĖ┤ÓĖöÓĖź ÓĖøÓĖŻÓĖ░ÓĖüÓĖ¦ÓĖö The Voice Kid 2555 2556 2557 Ó╣ĆÓĖéÓ╣ēÓĖ▓ÓĖŻÓĖŁÓĖÜ Battle ÓĖŖÓĖÖÓĖ░Ó╣ĆÓĖźÓĖ┤ÓĖ© 2 Ó╣ĆÓĖ½ÓĖŻÓĖĄÓĖóÓĖŹÓĖŚÓĖŁÓĖć ÓĖäÓĖōÓĖ┤ÓĖĢÓĖ©ÓĖ▓ÓĖ¬ÓĖĢÓĖŻÓ╣ī ÓĖ¦ÓĖ┤ÓĖŚÓĖóÓĖ▓ÓĖ©ÓĖ▓ÓĖ¬ÓĖĢÓĖŻÓ╣ī ÓĖöÓĖÖÓĖĢÓĖŻÓĖĄ ÓĖ×ÓĖźÓĖ©ÓĖČÓĖüÓĖ®ÓĖ▓ ÓĖ¬ÓĖ┤Ó╣łÓĖćÓĖŚÓĖĄÓ╣łÓĖ¬ÓĖÖÓ╣āÓĖł