Calibration systems for extruded pipes

Download as pptx, pdf2 likes889 views

This document discusses calibration systems used for extruded plastic tubes. There are two main types of calibration systems - external and internal. External calibrators employ a water-cooled forming tube that the extrudate slides against to harden, while internal calibrators use a tapered, water-cooled mandrel inside the tube. A combination system can provide smooth surfaces both inside and out. Proper sizing is important and factors like calibrator length, mandrel temperature, and vacuum assistance are considered to minimize defects during cooling and hardening of the extrudate.

1 of 14

Download to read offline

Ad

Recommended

Plastics processing

Plastics processingashokb27

?

The document outlines various plastic processing methods including extrusion, injection moulding, blow moulding, vacuum forming, compression moulding, calendering, and rotational moulding. Each method is described in terms of its process, materials used, and types of products produced, emphasizing their unique applications in manufacturing. Key characteristics like speed, waste efficiency, and product quality are highlighted for various techniques, showcasing the versatility of plastic processing.BOPP Presentation for Customers Meet .

BOPP Presentation for Customers Meet .Ashish Kothavade

?

This document discusses additives used in biaxially oriented polypropylene (BOPP) film manufacturing. It describes the BOPP film production process and common film properties required by the market. It then summarizes various additive types used in BOPP films, including antiblock, slip, antistatic, and antioxidant additives. White and pearlescent masterbatch additives for BOPP films are also overviewed along with future trends in BOPP additive technologies.extrusion processing

extrusion processingMuhammad Ahmad

?

Extrusion is a high-volume manufacturing process where plastic material is melted and forced through a die to create a continuous profile. There are various types of extrusion processes depending on the final product, such as sheet/film extrusion, tubing extrusion, and wire coating. Extruders use either single or twin screws to melt, mix, and convey the plastic material. The processing section of the extruder subjects the material to different conditions like melting, mixing, venting and homogenization. Wear of extruder components can reduce efficiency over time. Final products are cut into pellets using various pelletizing systems after exiting the die.Injection Molding (MIT 2.008x Lecture ║▌║▌▀Żs)

Injection Molding (MIT 2.008x Lecture ║▌║▌▀Żs)A. John Hart

?

The document discusses injection molding. It begins with an overview of injection molding and the types of products made through the process. It then covers the fundamentals of polymers used in injection molding, including their properties and how they behave under heat and pressure. The document outlines the key components of injection molding machines and mold tooling, and reviews the injection molding process parameters and how they impact the filling and cooling cycles. It also discusses common defects and guidelines for part design. Advanced topics covered include side-action molding, insert molding, and overmolding.thermal_properties..ppt

thermal_properties..pptRajeshKumarTiwari18

?

Thermal properties play a vital role in evaluating polymer performance and processability. Key thermal properties include heat deflection temperature (HDT), Vicat softening temperature, thermal conductivity, thermal expansion, glass transition temperature (Tg), and melting point (Tm). HDT is the temperature at which a polymer bar deflects under a standard load and is used to compare heat resistance. Vicat softening temperature is when a probe penetrates the polymer surface to a set depth. Thermal conductivity measures how quickly heat transfers through a material. Differential scanning calorimetry (DSC) precisely measures transition temperatures and heat flows associated with phase changes.Components of an Injection Mold

Components of an Injection MoldPatty Rasmussen

?

An injection mold consists of several components that allow molten plastic to be formed into a discrete part shape. The main components include the cavity side, core side, nozzle/sprue bushing, feed system, cavities, cooling system, guide pillars/bushings, ejector system, and ejector plate system. The cavity side is on the stationary side of the press and contains the gate and sprue runner. The core side is on the moving side and contains the core onto which the part forms.Bi-axially oriented Poly polypropylene films

Bi-axially oriented Poly polypropylene films JayaVerma28

?

The document discusses biaxial stretching, a process enhancing the strength of plastic films by stretching them in two directions, and its application to produce Biaxially Oriented Polypropylene (BOPP) films used in various packaging. It details the different production methods, the impact of processing variables on mechanical properties, and the advantages and limitations of BOPP films in terms of clarity, resistance, and recyclability. It concludes with insights into the effects of nucleating agents and processing conditions on the performance of BOPP films.Pipe Extrusion Line

Pipe Extrusion LineWali Khan

?

The document summarizes the key components and processes involved in pipe extrusion lines. Molten plastic is extruded through a die into the shape of a pipe. It is then calibrated to finalize dimensions before cooling. There are different types of dies, including spider-arm and cross-head dies, as well as calibration methods like using water-cooled mandrels, vacuum, or pressure to control the pipe thickness and dimensions. After calibration and cooling, haul-off units pull the pipe for cutting to final lengths.Plastic processing

Plastic processingSushant Kumar

?

Plastics are polymers formed through polymerization reactions that join small organic molecules into long chains. Monomers are the basic building blocks that undergo polymerization to create polymers. There are two main types of polymerization: addition polymerization and condensation polymerization. Addition polymerization involves breaking carbon double bonds in monomers to form chains, producing thermoplastics. Condensation polymerization reacts two different organic molecules to form plastic molecules and byproducts. A variety of additives can be mixed with plastics to modify properties, improve performance, or reduce costs.Topic 5 shaping process for plastics 160214

Topic 5 shaping process for plastics 160214Huai123

?

This document discusses various plastic shaping processes. It begins by describing extrusion, which uses compression to force polymer melts through a die to produce continuous profiles. Extruders consist of a barrel and screw. Sheet and film can be produced via slit-die or blown film extrusion. Injection molding injects molten plastic into a mold cavity at high pressure to form discrete parts. It involves an injection unit and clamping unit. The mold contains the cavity and features to distribute plastic and eject parts.Flashless Forging

Flashless ForgingPeter Columa

?

Flashless forging is a closed die forging process where metal is deformed in a die cavity with little to no excess flash. It is conducted at an elevated temperature between cold and hot forging. The preheated workpiece is compressed in the die until deformation occurs, producing a near-net or net-shaped part. Flashless forging requires tight process control of work volume and die cavity size to ensure proper filling. It is well-suited for producing simple, symmetrical parts and precision forgings from materials like aluminum.Plastics processing Manual (CIPET JAIPUR)

Plastics processing Manual (CIPET JAIPUR)Naresh Dhaker

?

The document provides an extensive overview of plastic injection moulding, including its historical development, types of machines, processes, advantages, limitations, and machine operation sequences. It also discusses material properties for injection moulding, types of clamping systems, and introduces blow moulding and extrusion processes, detailing methods and materials used. Key technical aspects such as screw design, processing temperatures, and equipment specifications are covered, highlighting the manufacturing capabilities in producing plastic components.Fibre Reinforced Plastic manufacturing methods

Fibre Reinforced Plastic manufacturing methodsjeff jose

?

The document discusses various methods of fiberglass reinforced plastic (FRP) processing, including hand lay-up, spray up, pultrusion, filament winding, resin transfer molding, reaction injection molding, and matched die forming. Each method is examined in terms of materials used, advantages, disadvantages, and applications, highlighting differences in production techniques and efficiency. It provides insights into the characteristics of composite parts produced by these methods and their respective economic considerations.The Master Guide To Corrugated Packaging

The Master Guide To Corrugated PackagingPakFactory

?

The document provides a comprehensive overview of corrugated packaging, emphasizing its structure, benefits, and types, distinguishing it from cardboard. It highlights the growing demand for corrugated boxes driven by the e-commerce industry and discusses various paper grades used in their production. Additionally, it covers quality control tests for assessing the strength and durability of corrugated materials.PLASTIC DEFECTS

PLASTIC DEFECTSQualityMolds

?

The document discusses methods to eliminate common plastic defects such as bubbles, voids, sinks, and blisters in injection-molded parts, which can lead to part rejects and poor performance. It outlines causes of these defects, such as trapped air and improper mold venting, and suggests assessment and prevention strategies, including controlling fill rates and using proper materials. Solutions are provided, along with a contact for further assistance in addressing these issues.Delamination in composites

Delamination in compositessoorajndt22

?

Delamination occurs due to the separation of adjacent layers in a composite material. It can be caused by manufacturing defects, stresses that act transverse to the layers, or laminate geometry issues like free edges, notches, cut-outs, poor bonding, or ply drops. Delamination reduces strength and stiffness, causes stress concentrations, and can lead to further growth and compressive failure of the laminate.Lecture 1 manufacturing processes

Lecture 1 manufacturing processesRAJ BAIRWA

?

The lecture on manufacturing processes, presented by Raj Kumar Bairwa, outlines the value-added transformation of raw materials into high-utility products. Manufacturing processes are classified into four main categories: shaping or forming, joining, removal, and regenerative manufacturing. The lecture also distinguishes between production as a comprehensive system that includes various steps leading to product fabrication and manufacturing as the specific conversion of raw materials into final products.Sheet metal forming process Chapter 7

Sheet metal forming process Chapter 7Hosam Hane

?

Okay, here are the steps:

1) UTS of 5052-O aluminum = 280 MPa

2) Thickness, t = 1.8 mm

3) Cutting edge length, L = ”ąD = ”ą * 25 mm = 78.5 mm

4) Using the empirical formula:

Fmax = 7.0 * UTS * t * L

= 7.0 * 280 * 1.8 * 78.5

= 3,400 N

So the estimated maximum punch force required is 3,400 Newtons.AMAN PPT 4985 Assignment-1.pptx

AMAN PPT 4985 Assignment-1.pptxCENTRAL INSTITUTE OF PETROCHEMICALS ENGINEENRING AND TECHNOLOGY

?

This document provides a presentation on IS-4985, the specification for unplasticized PVC pipes for potable water supplies. It discusses the composition and manufacturing process of UPVC pipes. It also outlines the required test report format and specifications for pipe dimensions, visual appearance, opacity, and other tests according to the Indian standard. The presentation was submitted to Mr. Jagan Mehta by Aman Tiwari for their course at CIPET:IPT-Ahmedabad.Shore hardness

Shore hardnessonlinemetallurgy.com

?

The document discusses shore hardness testing, which measures the resistance of materials to indentation. Shore hardness is measured using a durometer indenter that penetrates the sample, with higher numbers indicating greater resistance. The shore scale has two types - Shore A for softer rubbers and Shore D for harder materials. Shore hardness provides an empirical measure of indentation resistance but does not predict other material properties. Mohs hardness characterizes scratch resistance and was created by Friedrich Mohs using minerals to demonstrate increasing hardness.Extrusion

Extrusionkulvindermimit

?

Extrusion is a process that forces metal or plastic through a shaped die opening, plastically deforming the material under compression. Materials commonly extruded include aluminum, copper, steel, and plastics. While tooling costs for extrusion dies are high, the process allows for inexpensive mass production of parts. Extrusion can produce complex shapes with multiple features from a single piece of aluminum, reducing assembly costs. Standard industry tolerances provide adequate precision for most extruded part applications.Polymer Extrusion problems & Defects

Polymer Extrusion problems & DefectsHany G. Amer

?

The document discusses various extrusion problems and defects related to thermoplastics, such as die swell, moisture absorption, trapped air, polymer degradation, and melt fracture. It provides insights into the causes of these issues, remedies to mitigate them, and factors influencing the extrusion process, including die geometry and temperature control. Additionally, it highlights the importance of proper mixing and handling of materials to prevent defects like blistering and lumpiness.Steel Making: Ingot casting

Steel Making: Ingot casting NED University of Engineering and Technology

?

Molten steel is tapped into a ladle and alloying elements are added before being cast into molds. Steel ingots can have square, round, or polygon cross-sections depending on their intended use - squares for rolling, rectangles for flat products, and rounds for tubes. Ingot casting molds are made of cast iron and come in two types - wide end up or narrow end up. As the steel solidifies in the mold, it forms three distinct zones - a thin chill zone against the mold walls, columnar zones of elongated crystals perpendicular to the walls, and an inner equiaxed zone of larger isotropic crystals.Plastics testing standards

Plastics testing standardsjeff jose

?

The document outlines various testing standards for plastics, categorized into analytical, mechanical, thermal, physical, electrical, optical, flammability, chemical resistance, rheological, moisture content, and other testing. Each category lists specific tests along with their corresponding ASTM and ISO standards. This comprehensive list serves as a reference for evaluating different properties and characteristics of plastic materials.Tensile, Impact and Hardness Testing of Mild Steel

Tensile, Impact and Hardness Testing of Mild SteelGulfam Hussain

?

This report details the experimental investigation of the mechanical properties of mild steel through tensile, impact, and hardness testing. Results indicated tensile strength at 1450.833 N/mm?, impact strength at 29.5 J, and hardness at 59.25 HRB. The findings provide insights into the failure modes and suitability of mild steel for engineering applications.Casting Process.ppt

Casting Process.pptAkki7789

?

The document provides an overview of the metal casting process. It discusses the history and basic features of casting, including the types of molds used. The main casting processes are classified as either expandable mold casting (such as sand casting) or permanent mold casting (such as die casting and centrifugal casting). Sand casting uses expendable sand molds, while die casting uses reusable steel dies and forces molten metal into the mold under high pressure. Selection of the appropriate casting process depends on factors like alloy, size, shape, tolerance, and economics of machining versus production costs.Adhesives.pptx

Adhesives.pptxMaqsoodAhmad384555

?

There are three main types of adhesives used in footwear manufacturing: solvent-based adhesives, water-based adhesives, and hot melt adhesives. Solvent-based adhesives typically contain a resin dissolved in a solvent, while water-based adhesives suspend the resin in water. Hot melt adhesives are initially solid and become liquid when heated for application. Common adhesive types include neoprene, polyurethane, latex, and EVA. Proper surface preparation of materials like leather, rubber, and textiles is important for achieving a strong bond.Plastic and Polymers

Plastic and PolymersPrerna Jain

?

This document discusses different types of plastics used in construction, their properties, and applications. It outlines several families of plastics like acrylic, composites, expanded polystyrene, polycarbonate, polyethylene, polypropylene, and polyvinyl chloride. Plastics are described as strong, lightweight materials that are durable, weather resistant, and don't corrode. The document also examines various polymers used in construction and their applications, including flooring, windows, pipes, seals, and insulation. It provides examples of specific plastics like epoxy, polyethylene, polycarbonate, and their construction uses.Latex carpet backing

Latex carpet backingVishal K P

?

Latex is often used as a backing for carpets to improve anchorage of the pile and provide anti-slip characteristics. There are three main methods for applying latex to carpet backs: the lick-roll method, knife-over blanket spreading, and spraying. The lick-roll method involves coating the back of the carpet with latex from a revolving lick roller as it is pulled through an assembly. Knife-over blanket spreading similarly applies latex but uses a spreader instead of a roller. Spraying involves a spray gun that reciprocates above the moving carpet to uniformly coat its back with latex.Epoxy resin composites

Epoxy resin compositesVishal K P

?

Epoxy resins are thermosetting polymers containing at least two epoxide groups. They are prepared through the reaction of bisphenol A and epichlorohydrin to form bisphenol A diglycidyl ethers. Epoxy resins can be cured through reaction with amines, acids, or anhydrides, forming a cross-linked three dimensional network structure. Common applications include surface coatings, composites with fibers like carbon and glass, which provide high strength and stiffness with lighter weight than metals.More Related Content

What's hot (20)

Plastic processing

Plastic processingSushant Kumar

?

Plastics are polymers formed through polymerization reactions that join small organic molecules into long chains. Monomers are the basic building blocks that undergo polymerization to create polymers. There are two main types of polymerization: addition polymerization and condensation polymerization. Addition polymerization involves breaking carbon double bonds in monomers to form chains, producing thermoplastics. Condensation polymerization reacts two different organic molecules to form plastic molecules and byproducts. A variety of additives can be mixed with plastics to modify properties, improve performance, or reduce costs.Topic 5 shaping process for plastics 160214

Topic 5 shaping process for plastics 160214Huai123

?

This document discusses various plastic shaping processes. It begins by describing extrusion, which uses compression to force polymer melts through a die to produce continuous profiles. Extruders consist of a barrel and screw. Sheet and film can be produced via slit-die or blown film extrusion. Injection molding injects molten plastic into a mold cavity at high pressure to form discrete parts. It involves an injection unit and clamping unit. The mold contains the cavity and features to distribute plastic and eject parts.Flashless Forging

Flashless ForgingPeter Columa

?

Flashless forging is a closed die forging process where metal is deformed in a die cavity with little to no excess flash. It is conducted at an elevated temperature between cold and hot forging. The preheated workpiece is compressed in the die until deformation occurs, producing a near-net or net-shaped part. Flashless forging requires tight process control of work volume and die cavity size to ensure proper filling. It is well-suited for producing simple, symmetrical parts and precision forgings from materials like aluminum.Plastics processing Manual (CIPET JAIPUR)

Plastics processing Manual (CIPET JAIPUR)Naresh Dhaker

?

The document provides an extensive overview of plastic injection moulding, including its historical development, types of machines, processes, advantages, limitations, and machine operation sequences. It also discusses material properties for injection moulding, types of clamping systems, and introduces blow moulding and extrusion processes, detailing methods and materials used. Key technical aspects such as screw design, processing temperatures, and equipment specifications are covered, highlighting the manufacturing capabilities in producing plastic components.Fibre Reinforced Plastic manufacturing methods

Fibre Reinforced Plastic manufacturing methodsjeff jose

?

The document discusses various methods of fiberglass reinforced plastic (FRP) processing, including hand lay-up, spray up, pultrusion, filament winding, resin transfer molding, reaction injection molding, and matched die forming. Each method is examined in terms of materials used, advantages, disadvantages, and applications, highlighting differences in production techniques and efficiency. It provides insights into the characteristics of composite parts produced by these methods and their respective economic considerations.The Master Guide To Corrugated Packaging

The Master Guide To Corrugated PackagingPakFactory

?

The document provides a comprehensive overview of corrugated packaging, emphasizing its structure, benefits, and types, distinguishing it from cardboard. It highlights the growing demand for corrugated boxes driven by the e-commerce industry and discusses various paper grades used in their production. Additionally, it covers quality control tests for assessing the strength and durability of corrugated materials.PLASTIC DEFECTS

PLASTIC DEFECTSQualityMolds

?

The document discusses methods to eliminate common plastic defects such as bubbles, voids, sinks, and blisters in injection-molded parts, which can lead to part rejects and poor performance. It outlines causes of these defects, such as trapped air and improper mold venting, and suggests assessment and prevention strategies, including controlling fill rates and using proper materials. Solutions are provided, along with a contact for further assistance in addressing these issues.Delamination in composites

Delamination in compositessoorajndt22

?

Delamination occurs due to the separation of adjacent layers in a composite material. It can be caused by manufacturing defects, stresses that act transverse to the layers, or laminate geometry issues like free edges, notches, cut-outs, poor bonding, or ply drops. Delamination reduces strength and stiffness, causes stress concentrations, and can lead to further growth and compressive failure of the laminate.Lecture 1 manufacturing processes

Lecture 1 manufacturing processesRAJ BAIRWA

?

The lecture on manufacturing processes, presented by Raj Kumar Bairwa, outlines the value-added transformation of raw materials into high-utility products. Manufacturing processes are classified into four main categories: shaping or forming, joining, removal, and regenerative manufacturing. The lecture also distinguishes between production as a comprehensive system that includes various steps leading to product fabrication and manufacturing as the specific conversion of raw materials into final products.Sheet metal forming process Chapter 7

Sheet metal forming process Chapter 7Hosam Hane

?

Okay, here are the steps:

1) UTS of 5052-O aluminum = 280 MPa

2) Thickness, t = 1.8 mm

3) Cutting edge length, L = ”ąD = ”ą * 25 mm = 78.5 mm

4) Using the empirical formula:

Fmax = 7.0 * UTS * t * L

= 7.0 * 280 * 1.8 * 78.5

= 3,400 N

So the estimated maximum punch force required is 3,400 Newtons.AMAN PPT 4985 Assignment-1.pptx

AMAN PPT 4985 Assignment-1.pptxCENTRAL INSTITUTE OF PETROCHEMICALS ENGINEENRING AND TECHNOLOGY

?

This document provides a presentation on IS-4985, the specification for unplasticized PVC pipes for potable water supplies. It discusses the composition and manufacturing process of UPVC pipes. It also outlines the required test report format and specifications for pipe dimensions, visual appearance, opacity, and other tests according to the Indian standard. The presentation was submitted to Mr. Jagan Mehta by Aman Tiwari for their course at CIPET:IPT-Ahmedabad.Shore hardness

Shore hardnessonlinemetallurgy.com

?

The document discusses shore hardness testing, which measures the resistance of materials to indentation. Shore hardness is measured using a durometer indenter that penetrates the sample, with higher numbers indicating greater resistance. The shore scale has two types - Shore A for softer rubbers and Shore D for harder materials. Shore hardness provides an empirical measure of indentation resistance but does not predict other material properties. Mohs hardness characterizes scratch resistance and was created by Friedrich Mohs using minerals to demonstrate increasing hardness.Extrusion

Extrusionkulvindermimit

?

Extrusion is a process that forces metal or plastic through a shaped die opening, plastically deforming the material under compression. Materials commonly extruded include aluminum, copper, steel, and plastics. While tooling costs for extrusion dies are high, the process allows for inexpensive mass production of parts. Extrusion can produce complex shapes with multiple features from a single piece of aluminum, reducing assembly costs. Standard industry tolerances provide adequate precision for most extruded part applications.Polymer Extrusion problems & Defects

Polymer Extrusion problems & DefectsHany G. Amer

?

The document discusses various extrusion problems and defects related to thermoplastics, such as die swell, moisture absorption, trapped air, polymer degradation, and melt fracture. It provides insights into the causes of these issues, remedies to mitigate them, and factors influencing the extrusion process, including die geometry and temperature control. Additionally, it highlights the importance of proper mixing and handling of materials to prevent defects like blistering and lumpiness.Steel Making: Ingot casting

Steel Making: Ingot casting NED University of Engineering and Technology

?

Molten steel is tapped into a ladle and alloying elements are added before being cast into molds. Steel ingots can have square, round, or polygon cross-sections depending on their intended use - squares for rolling, rectangles for flat products, and rounds for tubes. Ingot casting molds are made of cast iron and come in two types - wide end up or narrow end up. As the steel solidifies in the mold, it forms three distinct zones - a thin chill zone against the mold walls, columnar zones of elongated crystals perpendicular to the walls, and an inner equiaxed zone of larger isotropic crystals.Plastics testing standards

Plastics testing standardsjeff jose

?

The document outlines various testing standards for plastics, categorized into analytical, mechanical, thermal, physical, electrical, optical, flammability, chemical resistance, rheological, moisture content, and other testing. Each category lists specific tests along with their corresponding ASTM and ISO standards. This comprehensive list serves as a reference for evaluating different properties and characteristics of plastic materials.Tensile, Impact and Hardness Testing of Mild Steel

Tensile, Impact and Hardness Testing of Mild SteelGulfam Hussain

?

This report details the experimental investigation of the mechanical properties of mild steel through tensile, impact, and hardness testing. Results indicated tensile strength at 1450.833 N/mm?, impact strength at 29.5 J, and hardness at 59.25 HRB. The findings provide insights into the failure modes and suitability of mild steel for engineering applications.Casting Process.ppt

Casting Process.pptAkki7789

?

The document provides an overview of the metal casting process. It discusses the history and basic features of casting, including the types of molds used. The main casting processes are classified as either expandable mold casting (such as sand casting) or permanent mold casting (such as die casting and centrifugal casting). Sand casting uses expendable sand molds, while die casting uses reusable steel dies and forces molten metal into the mold under high pressure. Selection of the appropriate casting process depends on factors like alloy, size, shape, tolerance, and economics of machining versus production costs.Adhesives.pptx

Adhesives.pptxMaqsoodAhmad384555

?

There are three main types of adhesives used in footwear manufacturing: solvent-based adhesives, water-based adhesives, and hot melt adhesives. Solvent-based adhesives typically contain a resin dissolved in a solvent, while water-based adhesives suspend the resin in water. Hot melt adhesives are initially solid and become liquid when heated for application. Common adhesive types include neoprene, polyurethane, latex, and EVA. Proper surface preparation of materials like leather, rubber, and textiles is important for achieving a strong bond.Plastic and Polymers

Plastic and PolymersPrerna Jain

?

This document discusses different types of plastics used in construction, their properties, and applications. It outlines several families of plastics like acrylic, composites, expanded polystyrene, polycarbonate, polyethylene, polypropylene, and polyvinyl chloride. Plastics are described as strong, lightweight materials that are durable, weather resistant, and don't corrode. The document also examines various polymers used in construction and their applications, including flooring, windows, pipes, seals, and insulation. It provides examples of specific plastics like epoxy, polyethylene, polycarbonate, and their construction uses.More from Vishal K P (9)

Latex carpet backing

Latex carpet backingVishal K P

?

Latex is often used as a backing for carpets to improve anchorage of the pile and provide anti-slip characteristics. There are three main methods for applying latex to carpet backs: the lick-roll method, knife-over blanket spreading, and spraying. The lick-roll method involves coating the back of the carpet with latex from a revolving lick roller as it is pulled through an assembly. Knife-over blanket spreading similarly applies latex but uses a spreader instead of a roller. Spraying involves a spray gun that reciprocates above the moving carpet to uniformly coat its back with latex.Epoxy resin composites

Epoxy resin compositesVishal K P

?

Epoxy resins are thermosetting polymers containing at least two epoxide groups. They are prepared through the reaction of bisphenol A and epichlorohydrin to form bisphenol A diglycidyl ethers. Epoxy resins can be cured through reaction with amines, acids, or anhydrides, forming a cross-linked three dimensional network structure. Common applications include surface coatings, composites with fibers like carbon and glass, which provide high strength and stiffness with lighter weight than metals.Poly vinyl carbazole

Poly vinyl carbazoleVishal K P

?

Poly(vinyl carbazole) is known as a photoconductive material whose electrical conductivity increases with light exposure. It has good heat and chemical resistance and softens at 150ĪŃC. The monomer vinyl carbazole is prepared through a reaction of carbazole with acetylene and polymerized using initiators like di-tert-butyl peroxide. Poly(vinyl carbazole) is insoluble in many solvents and difficult to process, requiring high temperatures of 300ĪŃC for injection molding. Its main application is in electrostatic dry copying machines where it is used as the photoconductive layer in xerography.Dyes for fibers

Dyes for fibersVishal K P

?

This document discusses different types of dyes. It begins with an introduction to dyes, noting that they are colored substances that bond to substrates and are often water-soluble. It then covers the main types of dyes including reactive dyes, which form covalent bonds; disperse dyes, which are used for synthetic fibers; azo dyes containing the R-N=N-R' group; sulfur dyes for cotton; and vat dyes which are insoluble but become soluble during the dyeing process. The document provides details on the characteristics and applications of each dye type.Effect of polymer structural factors on the mechanical properties

Effect of polymer structural factors on the mechanical propertiesVishal K P

?

This document discusses how various structural factors affect the mechanical properties of polymers. It examines the effects of molecular weight, cross-linking, crystallinity, polarity, copolymerization, and steric factors. Higher molecular weight, cross-linking density, crystallinity, and polarity generally increase the glass transition temperature and modulus. Crystallinity has a more pronounced effect above the glass transition temperature. Copolymerization can result in properties between the homopolymers or phase separation depending on the type of copolymer. Long flexible side chains decrease properties while branched side chains increase them.Rubber footwears

Rubber footwearsVishal K P

?

This document provides information on the production of rubber footwear. It discusses the traditional hand assembly process and more modern direct moulding and injection moulding techniques. It describes the various materials used such as natural rubber, synthetic rubbers, fillers and chemicals. Specific compound formulations are provided for shoe uppers, soles and industrial boots. The production process involves preparing lasts, assembling parts, varnishing, and vulcanization. Compression moulding and injection moulding of soles and heels are also summarized.Environmental issues related to polymer industries: Local and regional issues

Environmental issues related to polymer industries: Local and regional issuesVishal K P

?

The document discusses environmental issues related to the polymer industry, focusing on the production, use, and disposal of plastics, particularly in India where significant amounts of plastic waste contribute to environmental pollution. It addresses the challenges of municipal solid waste management, including the harmful effects of plastic pollution, leaching of chemicals, and hazardous emissions from incineration. Additionally, the document highlights the role of greenhouse gases and global warming as critical environmental concerns linked to plastic industries.Electrospinning of nanofibers

Electrospinning of nanofibersVishal K P

?

The document details the electrospinning process used to create nanofibers, which are fibers less than 100nm in diameter. It discusses the principles, parameters, advantages, characterizations, and applications of electrospun nanofibers, including their use in sensors, drug delivery systems, and tissue engineering. Key advantages of nanofibers include their high surface area to volume ratio, porosity, and customizable properties.Energy applications of polymer nanocomposites

Energy applications of polymer nanocompositesVishal K P

?

This document discusses the role of polymer nanocomposites in developing sustainable energy storage devices, highlighting their potential to combine high dielectric strength with increased energy density. Applications include lithium-ion batteries, supercapacitors, and fuel cells, where innovations in materials enhance performance and safety. The inclusion of nanofillers in battery electrodes and polymer electrolytes improves efficiency and operational reliability in various energy systems.Ad

Recently uploaded (20)

Water demand - Types , variations and WDS

Water demand - Types , variations and WDSdhanashree78

?

Water demand refers to the volume of water needed or requested by users for various purposes. It encompasses the water required for domestic, industrial, agricultural, public, and other uses. Essentially, it represents the overall need or quantity of water required to meet the demands of different sectors and activities. Development of Portable Biomass Briquetting Machine (S, A & D)-1.pptx

Development of Portable Biomass Briquetting Machine (S, A & D)-1.pptxaniket862935

?

Biomass briquetting Machine Fundamentals of Digital Design_Class_21st May - Copy.pptx

Fundamentals of Digital Design_Class_21st May - Copy.pptxdrdebarshi1993

?

Basics of Number Systems and Logic GatesMachine Learning - Classification Algorithms

Machine Learning - Classification Algorithmsresming1

?

This covers traditional machine learning algorithms for classification. It includes Support vector machines, decision trees, Naive Bayes classifier , neural networks, etc.

It also discusses about model evaluation and selection. It discusses ID3 and C4.5 algorithms. It also describes k-nearest neighbor classifer.Intro║▌║▌▀Żs-June-GDG-Cloud-Munich community gathering@Netlight.pdf

Intro║▌║▌▀Żs-June-GDG-Cloud-Munich community gathering@Netlight.pdfLuiz Carneiro

?

Introduction slides for starting the June GDG Cloud Munich community gathering in Munich, Germany. 20CE601- DESIGN OF STEEL STRUCTURES ,INTRODUCTION AND ALLOWABLE STRESS DESIGN

20CE601- DESIGN OF STEEL STRUCTURES ,INTRODUCTION AND ALLOWABLE STRESS DESIGNgowthamvicky1

?

? Understand concepts of limit state and working stress method of design of structural steel members and various types of connections.

? Determine net area and effective sections in tension members, tension splices, lug angles and gussets.

? Execute design of compression members as per IS codal practice.

? Analyze concepts of design of flexural members.

? Design structural systems such as roof trusses, gantry girders as per provisions of IS 800 ©C 2007 of practice for limit state method.

OUTCOMES:

On successful completion of this course, the students will be able to,

? Analyze different types of bolted and welded connections.

? Develop skills to design tension members, splices, lug angles and gussets.

? Elaborate IS Code design practice of various compression members.

? Design laterally supported and unsupported beams, built-up beams, plate girders and stiffeners.

? Acquire knowledge about components of industrial structures, Gantry girders and roof trusses.

TEXT BOOKS:

1. Bhavikatti S S, Ī░Design of Steel StructuresĪ▒, By Limit State Method as per IS: 800 ©C 2007, IK International Publishing House Pvt. Ltd., 2019.

2. Subramanian N, Ī░Design of Steel StructuresĪ▒, Oxford University Press 2011.

REFERENCE BOOKS:

1. Duggal S K, Ī░Limit State Design of Steel StructuresĪ▒, Tata, McGraw Hill Education Pvt. Ltd., New Delhi, 2017.

2. Shiyekar M R, Ī░Limit State Design in Structural SteelĪ▒, PHI Learning Private Limited, New Delhi, 2013.

3. IS: 800 ©C 2007, IS: 800 ©C 1984, General Construction in Steel ©C Code of Practice, BIS, New Delhi.

Structural steel types ©C Mechanical Properties of structural steel- Indian structural steel products- Steps involved in the Deign Process -Steel Structural systems and their Elements- -Type of Loads on Structures and Load combinations- Code of practices, Loading standards and Specifications - Concept of Allowable Stress Method, and Limit State Design Methods for Steel structures-Relative advantages and Limitations-Strengths and Serviceability Limit states.

Allowable stresses as per IS 800 section 11 -Concepts of Allowable stress design for bending and Shear ©CCheck for Elastic deflection-Calculation of moment carrying capacity ©CDesign of Laterally supported Solid Hot Rolled section beams-Allowable stress deign of Angle Tension and Compression Members and estimation of axial load carrying capacity.

Type of Fasteners- Bolts Pins and welds- Types of simple bolted and welded connections Relative advantages and Limitations-Modes of failure-the concept of Shear lag-efficiency of joints- Axially loaded bolted connections for Plates and Angle Members using bearing type bolts ©CPrying forces and Hanger connection©C Design of Slip critical connections with High strength Friction Grip bolts.- Design of joints for combined shear and Tension- Eccentrically Loaded Bolted Bracket Connections- Welds-symbols and specifications- Effective area of welds-Fillet and but Welded connections-Axially Loaded connections for Plate and angle truss members andCenter Enamel can Provide Aluminum Dome Roofs for diesel tank.docx

Center Enamel can Provide Aluminum Dome Roofs for diesel tank.docxCenterEnamel

?

Center Enamel can Provide Aluminum Dome Roofs for diesel tank.docxHow Binning Affects LED Performance & Consistency.pdf

How Binning Affects LED Performance & Consistency.pdfMina Anis

?

? WhatĪ»s Inside:

? What Is LED Binning?

? The process of sorting LEDs by color temperature, brightness, voltage, and CRI

? Ensures visual and performance consistency across large installations

? Why It Matters:

? Inconsistent binning leads to uneven color and brightness

? Impacts brand perception, customer satisfaction, and warranty claims

? Key Concepts Explained:

? SDCM (Standard Deviation of Color Matching)

? Recommended bin tolerances by application (e.g., 1©C3 SDCM for retail/museums)

? How to read bin codes from LED datasheets

? The difference between ANSI/NEMA standards and proprietary bin maps

? Advanced Practices:

? AI-assisted bin prediction

? Color blending and dynamic calibration

? Customized binning for high-end or global projectsElysiumPro Company Profile 2025-2026.pdf

ElysiumPro Company Profile 2025-2026.pdfinfo751436

?

Description

ElysiumPro | IEEE Final Year Projects | Best Internship Training | Inplant Training in Madurai

Best Final Year project training center

Address:

First Floor, A Block, 'Elysium Campus, 229, Church Rd, Vaigai Colony, Madurai, Tamil Nadu 625020

Plus Code:

W4CX+56 Madurai, Tamil Nadu

+91 9944793398

info@elysiumpro.in

Elysium Group of Companies established ElysiumPro in 2001. Since its inception, it has been the most sought-after destination for final year project development and research papers among the students. Our commitment to providing quality project training & documentation to students has always been exceptional. We deliver the final year engineering projects and technical documents that provide extra edge and industry exposure to land prestigious jobs and reputed institutions for higher studies. Students from all over the country avail of our services for their final year projects. On average, we develop 5000+ projects and research papers per year on varied advanced domains. Python, JAVA, PHP, Android, Matlab, LabView, VLSI, SIMULINK, Power electronics, Power System, Antenna, Machine Learning, Deep Learning, Data Science, Artificial Intelligence, data Mining, Big Data, Cloud Computing, IoT,

Hours of Operation: -

Sunday 10am-1pm

Monday 7.30am-8pm

Tuesday 7.30am-8pm

Wednesday 7.30am-8pm

Thursday 7.30am-8pm

Friday 7.30am-8pm

Saturday 7.30am-8pm

Web Site:

https://elysiumpro.in/

*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*

Youtube Geotagged Video:

https://youtu.be/QULY6XfuMyo

*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*

║▌║▌▀Żshow Images (Google Photos):

https://photos.app.goo.gl/hVwQJtkeptA1JZKd9

*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*

GBP Listing:

https://goo.gl/maps/6d6hko6TsDYyeDrz9

*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*

Serving Areas:

https://www.google.com/maps/d/edit?mid=1-fsZogBiEAcjGP_aDyI0UKKIcwVUWfo&usp=sharing

*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*

Google Site:

https://elysiumpro-project-center.business.site

*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*

Google Sheet: https://docs.google.com/spreadsheets/d/1uXA07zxrUx2FCnBZWH80PpBZQrrX-2q1UBBe_0k3Yeo

*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*

Google Document: https://docs.google.com/document/d/1BU4ZHW_41XJm2lvTq9pWYUpZILAEmF9dWEw7-DBbWoE

*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*

Google ║▌║▌▀Żs: https://docs.google.com/presentation/d/1uF8q6ueJWcAnhKTQsZxLE0Bo9PwgRNwCeuGV_ZgbSyU

*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*-*Montreal Dreamin' 25 - Introduction to the MuleSoft AI Chain (MAC) Project

Montreal Dreamin' 25 - Introduction to the MuleSoft AI Chain (MAC) ProjectAlexandra N. Martinez

?

Montreal Dreamin' 25 - Introduction to the MuleSoft AI Chain (MAC) Project3. What is the principles of Teamwork_Module_V1.0.ppt

3. What is the principles of Teamwork_Module_V1.0.pptengaash9

?

Demonstrate the role of teamwork in the execution of systems engineering.

Describe the principles of successful teams.

WIRELESS COMMUNICATION SECURITY AND ITĪ»S PROTECTION METHODS

WIRELESS COMMUNICATION SECURITY AND ITĪ»S PROTECTION METHODSsamueljackson3773

?

In this paper, the author discusses the concerns of using various wireless communications and how to use

them safely. The author also discusses the future of the wireless industry, wireless communication

security, protection methods, and techniques that could help organizations establish a secure wireless

connection with their employees. The author also discusses other essential factors to learn and note when

manufacturing, selling, or using wireless networks and wireless communication systems. ╔ń─┌├ŃÅŖ╗ß┘Y┴Ž_Chain of Thought .

╔ń─┌├ŃÅŖ╗ß┘Y┴Ž_Chain of Thought .▒Ę┤ĪĄ■│ó┤Ī│¦ųĻ╩Į╗ß╔ń

?

▒Š┘Y┴ŽĪĖTo CoT or not to CoT?Ī╣żŪżŽĪó┤¾ęÄ─ŻčįšZźŌźŪźļż╦ż¬ż▒żļChain of ThoughtŻ©CoTŻ®źūźĒź¾źūź╚ż╬ä┐╣¹ż╦ż─żżżŲįöżĘż»ĮŌšhżĘżŲżżż▐ż╣ĪŻ

CoTżŽżóżķżµżļź┐ź╣ź»ż╦ä┐ż»═“─▄ż╩╩ųĘ©żŪżŽż╩ż»Īó╠žż╦╩²č¦Ą─?šō└ĒĄ─?źóźļź┤źĻź║źÓĄ─ż╩═Ųšōż“░ķż”šnŅ}żŪĖ▀żżä┐╣¹ż“░kō]ż╣żļż│ż╚ż¼īg“Yż½żķ╩ŠżĄżņżŲżżż▐ż╣ĪŻ

ę╗ĘĮżŪĪó│ŻūRżõę╗░Ńų¬ūRż“å¢ż”å¢Ņ}ż╦īØżĘżŲżŽä┐╣¹ż¼Ž▐Č©Ą─żŪżóżļż│ż╚żŌ├„żķż½ż╦ż╩żĻż▐żĘż┐ĪŻ

č}ļjż╩å¢Ņ}ż“Č╬ļAĄ─ż╦ĘųĮŌ?īgąąż╣żļĪĖėŗ╗Łż╚īgąąĪ╣ż╬źūźĒź╗ź╣ż╦ż¬żżżŲĪóCoTż╬ÅŖż▀ż¼╗Ņż½żĄżņżļĄŃżŌūó─┐ź▌źżź¾ź╚żŪż╣ĪŻ

This presentation explores when Chain of Thought (CoT) prompting is truly effective in large language models.

The findings show that CoT significantly improves performance on tasks involving mathematical or logical reasoning, while its impact is limited on general knowledge or commonsense tasks.David Boutry - Mentors Junior Developers

David Boutry - Mentors Junior DevelopersDavid Boutry

?

David Boutry is a Senior Software Engineer in New York with expertise in high-performance data processing and cloud technologies like AWS and Kubernetes. With over eight years in the field, he has led projects that improved system scalability and reduced processing times by 40%. He actively mentors aspiring developers and holds certifications in AWS, Scrum, and Azure.Ad

Calibration systems for extruded pipes

- 1. CALIBRATION SYSTEMS Presented by, Vishal K P. Dept. of PS&RT CUSAT

- 2. Introduction ? Extrudate emerges out from die as semi-molten substance and need to be cooled to harden. ? Calibration systems or Extrusion sizing chills and sizes the extrudate without much defects. ? For tubular films, cold air impingement may be sufficient, but for rigid tubes more positive methods must be employed. ? They are also known as forming boxes, sizing formers, sizing die, etc.

- 3. Two types of calibrators for rigid & semi-rigid tubes: ? External calibrators ? Internal calibrators

- 4. External calibrators ? Employs a water-cooled forming tube in conjunction with internal air pressure. ? It consist of a water jacketed tube, the bore of which is made to the required outer diameter of the pipe + any allowances. ? This assembly is mounted in exact alignment at the front of the extruder die.

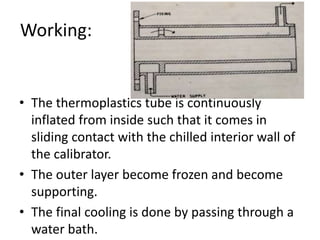

- 5. Working: ? The thermoplastics tube is continuously inflated from inside such that it comes in sliding contact with the chilled interior wall of the calibrator. ? The outer layer become frozen and become supporting. ? The final cooling is done by passing through a water bath.

- 6. Length of the calibrator tube: ? Length must be chosen such that the outer layer of the pipe gets frozen to a sufficient depth for self supporting during cooling. ? The shortest length must be chosen so as to avoid friction, strain and inconvenience.

- 7. Problems: ? Reason: The tubes are inflated by internal pressure, so must be sealed at both ends to prevent air loss. ? Commonly used system to prevent air loss: Floating plug attached to the die mandrel by means of a chain or other flexible members. Air loss through ends of the tube

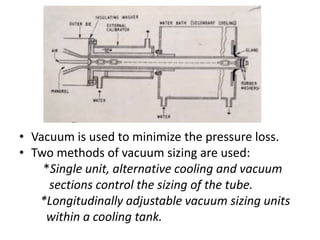

- 8. ? Vacuum is used to minimize the pressure loss. ? Two methods of vacuum sizing are used: *Single unit, alternative cooling and vacuum sections control the sizing of the tube. *Longitudinally adjustable vacuum sizing units within a cooling tank.

- 9. Internal calibrators ? Employs a cooled mandrel and secondary external cooling. ? It consist of a tapered water cooled extension to the mandrel which fixes the diameter of pipe as in external calibration. ? It cools the tube both from inside and outside. ? It has higher rate of cooling hence sizing of the tube.

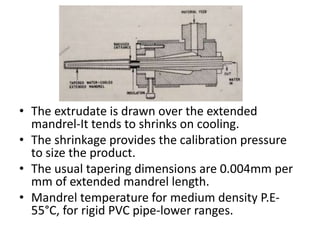

- 10. ? The extrudate is drawn over the extended mandrel-It tends to shrinks on cooling. ? The shrinkage provides the calibration pressure to size the product. ? The usual tapering dimensions are 0.004mm per mm of extended mandrel length. ? Mandrel temperature for medium density P.E- 55ĪŃC, for rigid PVC pipe-lower ranges.

- 11. Drawbacks of Internal and External calibrators ? In external system, the outside of the tube is in sliding contact with smooth cooled metal surface and gives polished surface, but interior remains rough. ? The internal system gives better product and it give a smooth product both from inside and outside. A combined external-internal system can be used to overcome the drawbacks.

- 12. Combined External and Internal calibration ? Here, a short water cooled external calibrator is combined with an extended mandrel which is heated at its upstream end. ? A high finish is given to the tube exterior by contact with external calibrator, and by means of carefully designed internal flow channels.

- 13. References

- 14. THANK YOU

Editor's Notes

- #7: Distortion during cooling