Desh bandhu gangwar

- 1. Bioconversion of Lignocellulosic waste (wheat straw) for the production of biofuelDesh Bandhu Gangwar

- 2. INTRODUCTIONLignocellulosic waste material provide world most abundant renewable resource produced through massive photosynthesis.

- 3. Cellulosic biomass is an alternative energy feed stock because supplies are abundant domestically and globally.

- 4. Ethanol production process only use energy from renewable energy source.The measured residue amount is approximately 39 millions metric tons of biodegradable cellulose.Pretreatment strategies:-mechanical combination -steam explosion -ammonia fiber explosion-acid and alkali pretreatment-biological treatment

- 5. OBJECTIVETo use suitable physical and chemical method for treatment of agro-waste.Bioconversion of agro-waste into fermentable sugars.The production of ethanol.

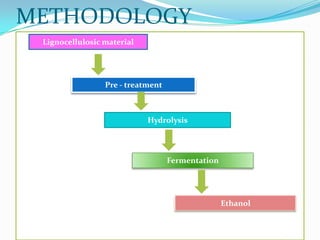

- 6. METHODOLOGYLignocellulosic materialPre - treatmentHydrolysisFermentationEthanol

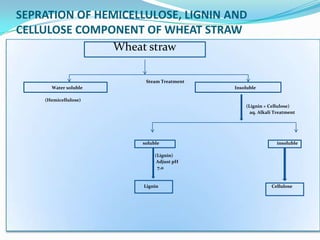

- 7. SEPRATION OF HEMICELLULOSE, LIGNIN AND CELLULOSE COMPONENT OF WHEAT STRAW Wheat straw Steam Treatment Water soluble Insoluble (Hemicellulose) (Lignin + Cellulose) aq. Alkali Treatment soluble insoluble (Lignin) Adjust pH 7.0 Lignin Cellulose

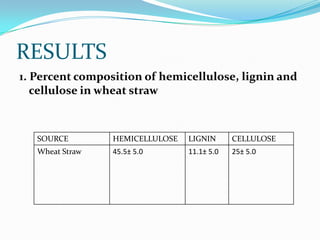

- 8. RESULTS1. Percent composition of hemicellulose, lignin and cellulose in wheat straw

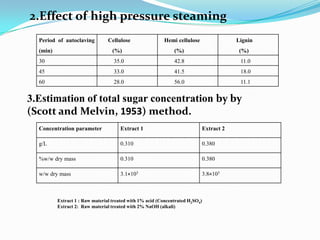

- 9. 2.Effect of high pressure steaming 3.Estimation of total sugar concentration by by (Scott and Melvin, 1953) method.Extract 1 : Raw material treated with 1% acid (Concentrated H2SO4) Extract 2: Raw material treated with 2% NaOH (alkali)

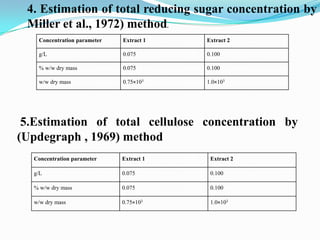

- 10. 4. Estimation of total reducing sugar concentration by Miller et al., 1972) method.. 5.Estimation of total celluloseconcentration by (Updegraph , 1969) method

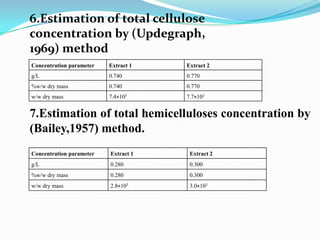

- 11. 6.Estimation of total cellulose concentration by (Updegraph, 1969) method7.Estimation of total hemicelluloses concentration by (Bailey,1957) method.

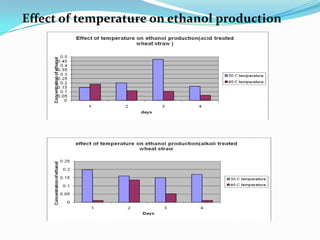

- 12. Effect of temperature on ethanol production

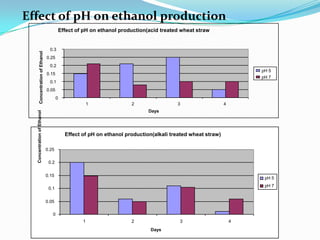

- 13. Concentration of EthanolEffect of pH on ethanol production(acid treated wheat strawEffect of pH on ethanol production(alkali treated wheat straw)0.250.30.20.25Concentration of Ethanol0.150.2pH 5pH 50.15pH 70.1pH 70.10.050.050012341234DaysDaysEffect of pH on ethanol production

- 14. CONCLUSION It was concluded that extract 1 i.e. acid treated wheat straw contain maximum amount of total sugar, reducing sugar and xylose concentration in comparison to extract 2. Extract 1 i.e. acid treated extract gave slightly better production of fermentable sugar.

- 15. The best pH was pH- 5 and the best temperature was 300 C for the production of ethanol. Thank You