FANUC CNC product overview brochure

- 1. THE FACTORY AUTOMATION COMPANY CNC Controls Product overview

- 2. Highest quality ŌĆō shortest processing time With more than 60 yearsŌĆś experience FANUC offers the widest range of CNC systems in the industry from best value controls with powerful functionality, to high-performance control systems for complex machines ŌĆō all with fast programming and ease of use, guaranteeing the highest quality and short processing times. ThatŌĆśs how we increase your productivity. Your advantages: ŌĆó 100% FANUC quality ŌĆó more than 60 years of experience ŌĆó wide range of displays and panels ŌĆó stand-alone CNCs ŌĆó LCD mounted CNCs ŌĆó highest flexibility for your solutions 50 years MTBF * for 0i-D More than FANUC CNC Controls FANUC Laser Systems FANUC Drive Systems No. 1 in the world FANUC is the leading global manufacturer of factory automation, with more than 60 years experience in the development of computer numerical control equipment. It has more than 4,7 million CNC controls and more than 21,000 laser systems installed worldwide and satisfied customers in every corner of the globe. years of experience 60 100% FANUC

- 3. Unique flexibility Only FANUC offers you CNC controls in two general versions: LCD mounted as compact solution with less space consumption and less hardware or as highly flexible stand-alone solution. Your benefit: full flexibility for your machine design. Versatile field bus systems ŌĆó FANUC I/O Link i ŌĆó PROFINET IO ŌĆó EtherNet/IP ŌĆó FL-net ŌĆó PROFIBUS DP ŌĆó Modbus TCP ŌĆó DeviceNet ŌĆó CC-Link ŌĆó AS-i ŌĆó EtherCAT and POWERLINK (only Digital Servo Adapter - B) Your advantages: ŌĆó perfect matching components ŌĆó all with 100% FANUC quality ŌĆó highest reliability for all parts ŌĆó high compatibility up and downwards for ┬Ł long time planning reliability ŌĆó one strong partner for all components Flexible package solutions FANUC offers all major components for your CNC controlled machine: CNC controls, motors and amplifiers in a tailor made and easy to install package for your specific needs. All components are developed and manufactured in-house. The results are superior functional reliability and the highest levels of machine availability ŌĆō with a mean time between failure of well over fifty years*, contributing to extremely low cost of ownership. *for 0i-D All components 100% FANUC quality Ethernet CNC stand alone Server/PC HSSB Ethernet Display-Bus FSSB-Bus I/O modules Beta I/O Link i drives Servo motor SDU ╬▒i PS power supply ╬▒i SP amplifier ╬▒i SV servo amplifier I/O Link i Bus I/O Link i Bus External measuring system FANUC I/O Link i PROFINET IO EtherNet/IP FL-net PROFIBUS DP Modbus TCP DeviceNet CC-Link AS-i EtherCAT * POWERLINK * *(only Digital Servo Adapter - B) FSSB-Bus Field bus system

- 4. High-performance CNC for complex machine tools CNC Series 30iŌĆē/ŌĆē31iŌĆē/ŌĆē32i-MODEL B Plus The FANUC Series 30iŌĆē/ŌĆē31iŌĆē/ŌĆē32i-MODEL B Plus controls are ideal for highly complex machines with multiple axes, multi-path, and high-speed high- precision machining requirements. The hardware and innovative software provide the highest performance, precision and surface quality. Key features: ŌĆó up to 48 axes, 16 spindle axes and 10 paths * ŌĆó 5-axis machining ŌĆó compound millŌĆē/ŌĆēturn or turnŌĆē/ŌĆēmill machining ŌĆó extended integrated preventive maintenance functions ŌĆó integrated FANUC Dual Check Safety function ŌĆó shop-floor programming via iHMI or MANUAL GUIDE i ŌĆó collision control via 3D Interference Check ŌĆó dynamic compensation functions for highest accuracy ŌĆó High-Speed Smooth Tool Center Point 5-Axis Compensation ŌĆó Learning ControlŌĆē/ŌĆēHigh-Speed-Cycle-Machining ŌĆó integrated high-speed PMC ŌĆó high speed cutting ŌĆó iHMI offering intuitive and extremely user friendly operation ŌĆó customisation functions included ŌĆó packages and kits combine optional functions for specific purposes Applications: ŌĆó milling ŌĆó turning ŌĆó grinding ŌĆó punching ŌĆó laser ŌĆó gear cutting Basic model for multiple control applications CNC Series 0i-MODEL F Plus The CNC Series 0iŌĆē-MODEL F Plus provides the ideal basic solution for multiple control applications. Ready to use, it boasts latest generation hardware and a complete package of standard software. To maximise productivity on more specific applications, it can be easily customised using a range of additional functions. Combining unbeatable value for money with unrivalled performance and reliability, it includes features and functions usually associated with high performance systems. Key features: ŌĆó up to 12 axes, 6 spindle axes and 2 paths ŌĆó up to 2 additional loader paths ŌĆó 4-axis simultaneous and 3+2 axis machining ŌĆó ready to use with integrated software package ŌĆó excellent performance-to-cost ratio ŌĆó integrated FANUC Dual Check Safety function ŌĆó shop-floor programming via iHMI, MANUAL GUIDE i or TURN MATE i ŌĆó functions for simple customisation included ŌĆó integrated high-speed PMC ŌĆó high speed and high quality machining package ŌĆó maximum look-ahead blocks 400 ŌĆó common operability, maintainability, network and PMC function with CNC Series 30i-MODEL B ŌĆó iHMI offering intuitive and extremely user friendly operation Applications: ŌĆó milling ŌĆó turning ŌĆó grinding ŌĆó punching ŌĆó gear cutting Key features: ŌĆó up to 32 axis and 4 path ŌĆó ready to use with integrated software package ŌĆó integrated FANUC Dual Check Safety function ŌĆó additional functions for simple customisation ŌĆó integrated high-speed PMC ŌĆó CAM function ŌĆó perfect combination of pressure and position control CNC for motion control and various applications Power Motion i-MODEL A The FANUC CNC Power Motion i-A is ideal for efficient motion control and a wide range of various applications from positioning up to multi-path axis interpolation. Applications: ŌĆó packing ŌĆó handling ŌĆó wrapping ŌĆó sawing ŌĆó pressing ŌĆó punching ŌĆó bending ŌĆó spinning ŌĆó friction welding Key features: ŌĆó up to 20 axis, 4 spindle axis and 4 path ŌĆó ready to use with integrated software package ŌĆó simple axis setup ŌĆó additional functions for simple customisation ŌĆó up to 5 integrated high speed PMCs ŌĆó integrated FANUC Dual Check Safety function CNC Series 35i-MODEL B The FANUC series 35i-MODEL B control is primarily designed for transfer lines, gantries or multiple milling and drilling stations. Its software options enable high-precision multi-path processing with short processing times. Applications: ŌĆó transfer lines ŌĆó gantries ŌĆó multiple millingŌĆē/ drilling stations CNC designed for transfer lines * Up to 96 axes, 24 spindle axes and 15 paths available with Series 30i-B

- 5. 4096 / 4096 4096 / 4096 4096 / 4096 4096 / 4096 2048 / 2048 2048 / 2048 2048 / 2048 4096 / 4096 4096 / 4096 3 3 3 3 1 1 1 3 3 5 5 5 5 3 3 3 5 5 300 000 300 000 300 000 300 000 100 000 100 000 100 000 300 000 300 000 ŌĆó ŌĆó ŌĆó ŌĆó ŌĆó ŌĆó ŌĆó ŌĆó ŌĆó ŌĆó ŌĆó ŌĆó ŌĆó ŌĆō ŌĆō ŌĆō ŌĆō ŌĆō ŌĆó ŌĆó ŌĆó ŌĆó ŌĆó ŌĆó ŌĆó ŌĆó ŌĆó ŌĆó ŌĆó ŌĆó ŌĆó ŌĆó ŌĆó ŌĆó ŌĆó ŌĆó / ŌĆó ŌĆó / ŌĆó ŌĆó / ŌĆó ŌĆó / ŌĆó ŌĆó / ŌĆó ŌĆó / ŌĆó ŌĆó / ŌĆó ŌĆō ŌĆō ŌĆó ŌĆó ŌĆó ŌĆó ŌĆó ŌĆó ŌĆó ŌĆó ŌĆó ŌĆó ŌĆó ŌĆó ŌĆó ŌĆō ŌĆō ŌĆō ŌĆō ŌĆō ŌĆó ŌĆó ŌĆó ŌĆó ŌĆó ŌĆó ŌĆó ŌĆō ŌĆō ŌĆō / ŌĆó ŌĆō / ŌĆó ŌĆō / ŌĆó ŌĆō / ŌĆó ŌĆó / ŌĆó ŌĆō / ŌĆó ŌĆó / ŌĆō ŌĆó / ŌĆō ŌĆó / ŌĆō ŌĆó / ŌĆó / ŌĆó / ŌĆó ŌĆó / ŌĆó / ŌĆó / ŌĆó ŌĆó / ŌĆó / ŌĆó / ŌĆó ŌĆó / ŌĆó / ŌĆó / ŌĆó ŌĆó / ŌĆó / ŌĆó / ŌĆó ŌĆó / ŌĆó / ŌĆó / ŌĆó ŌĆó / ŌĆó / ŌĆó / ŌĆó ŌĆó / ŌĆó / ŌĆó / ŌĆó ŌĆó / ŌĆó / ŌĆó / ŌĆó ŌĆó ŌĆó ŌĆó ŌĆó ŌĆó / ŌĆó ŌĆó / ŌĆó ŌĆō / ŌĆō ŌĆō ŌĆō ŌĆó / ŌĆó ŌĆó / ŌĆó ŌĆó / ŌĆó ŌĆó / ŌĆó ŌĆō / ŌĆó ŌĆó / ŌĆó ŌĆō / ŌĆō ŌĆó / ŌĆō ŌĆó / ŌĆō ŌĆó / ŌĆó ŌĆó / ŌĆó ŌĆó / ŌĆó ŌĆō ŌĆó / ŌĆō ŌĆō ŌĆō ŌĆō ŌĆō ŌĆó ŌĆó ŌĆō ŌĆō ŌĆō ŌĆō ŌĆō ŌĆō ŌĆō ŌĆó / ŌĆó ŌĆó / ŌĆó ŌĆó / ŌĆó ŌĆó / ŌĆō ŌĆó / ŌĆō ŌĆó / ŌĆō ŌĆó / ŌĆō ŌĆó / ŌĆō ŌĆó / ŌĆō ŌĆó ŌĆó ŌĆó ŌĆó ŌĆó ŌĆó ŌĆō ŌĆō ŌĆō ŌĆó ŌĆó ŌĆó ŌĆó ŌĆō ŌĆó ŌĆō ŌĆō ŌĆō ŌĆó ŌĆó ŌĆó ŌĆó ŌĆó ŌĆó ŌĆō ŌĆō ŌĆō ŌĆó ŌĆō ŌĆó ŌĆō ŌĆō ŌĆō ŌĆō ŌĆō ŌĆō ŌĆó ŌĆō ŌĆó ŌĆō ŌĆō ŌĆō * ŌĆō ŌĆō 30i-B Plus 31i-B5 Plus 31i-B Plus 32i-B Plus 0i-MF Plus 0i-TF Plus 0i-LF Plus 35i-B Power Motion i-A 48 / 28 * 34 / 16 34 / 16 20 / 12 11 / 9 12 / 9 7 20 / 20 32 / 24 64 / 24 26 / 12 26 / 12 12 / 8 9 / 7 10 / 7 7 16 / 16 32 / 24 16 / 4 * 8 / 4 8 / 4 8 / 4 4 / 3 6 / 4 ŌĆō 4 / 4 ŌĆō 24 5 4 4 4 4 4 4 4 10 * 6 6 2 2 2 1 4 4 ŌĆó ŌĆó ŌĆó ŌĆó ŌĆó ŌĆó ŌĆō ŌĆó ŌĆó ŌĆó ŌĆó ŌĆó ŌĆó ŌĆó ŌĆó ŌĆó ŌĆó ŌĆó 10.4 10.4 10.4 10.4 10.4 10.4 10.4 8.4, 10.4, 15ŌĆ£ 8.4, 10.4, 15ŌĆ£ 10.4ŌĆØ, 15ŌĆØ, 19ŌĆØ 10.4ŌĆØ, 15ŌĆØ, 19ŌĆØ 10.4ŌĆØ, 15ŌĆØ, 19ŌĆØ 10.4ŌĆØ, 15ŌĆØ, 19ŌĆØ 10.4ŌĆØ, 15ŌĆØ 10.4ŌĆØ, 15ŌĆØ 10.4ŌĆØ, 15ŌĆØ ŌĆō ŌĆō 10.4ŌĆØ, 15ŌĆØ, 19ŌĆØ, 21,5ŌĆØ 10.4ŌĆØ, 15ŌĆØ, 19ŌĆØ, 21,5ŌĆØ 10.4ŌĆØ, 15ŌĆØ, 19ŌĆØ, 21,5ŌĆØ 10.4ŌĆØ, 15ŌĆØ, 19ŌĆØ, 21,5ŌĆØ 10.4, 15 10.4, 15 10.4, 15 10.4, 15 10.4, 15 ŌĆó ŌĆó ŌĆó ŌĆó 10.4ŌĆØ, 15ŌĆØ, 19ŌĆØ, 21,5ŌĆØ 10.4ŌĆØ, 15ŌĆØ, 19ŌĆØ, 21,5ŌĆØ 10.4ŌĆØ, 15ŌĆØ, 19ŌĆØ, 21.5ŌĆØ ŌĆō ŌĆō ŌĆó ŌĆó ŌĆó ŌĆó ŌĆó ŌĆó ŌĆó ŌĆó ŌĆó ŌĆó ŌĆó ŌĆó ŌĆó ŌĆó ŌĆó ŌĆó ŌĆó ŌĆó 4 MB - 8 MB 4 MB - 8 MB 4 MB - 8 MB 4 MB - 8 MB 2 MB 2 MB 2 MB 32 KB -1 MB 32 KB -1 MB ŌĆó ŌĆó ŌĆó ŌĆó ŌĆó ŌĆó ŌĆó ŌĆó ŌĆó ŌĆó ŌĆó ŌĆó ŌĆó ŌĆó ŌĆó ŌĆó ŌĆó ŌĆó ŌĆó ŌĆó ŌĆó ŌĆó ŌĆó ŌĆó ŌĆó ŌĆó ŌĆó ŌĆó ŌĆó ŌĆó ŌĆó ŌĆó ŌĆó ŌĆó ŌĆó ŌĆó ŌĆó / ŌĆó ŌĆó / ŌĆó ŌĆó / ŌĆó ŌĆó / ŌĆó ŌĆó / ŌĆó ŌĆó / ŌĆó ŌĆó / ŌĆó ŌĆó / ŌĆó ŌĆó / ŌĆó ŌĆó / ŌĆó ŌĆó / ŌĆó ŌĆó / ŌĆó ŌĆó / ŌĆó ŌĆó / ŌĆó ŌĆó / ŌĆó ŌĆó / ŌĆó ŌĆó / ŌĆó ŌĆó / ŌĆó ŌĆó / ŌĆó / ŌĆō / ŌĆó ŌĆó / ŌĆó / ŌĆō / ŌĆó ŌĆó / ŌĆó / ŌĆō / ŌĆó ŌĆó / ŌĆó / ŌĆō / ŌĆó ŌĆó / ŌĆó / ŌĆó / ŌĆó ŌĆó / ŌĆó / ŌĆó / ŌĆó ŌĆó / ŌĆó / ŌĆó / ŌĆó ŌĆó / ŌĆó / ŌĆó / ŌĆó ŌĆó / ŌĆó / ŌĆó / ŌĆó ŌĆó ŌĆó ŌĆó ŌĆó ŌĆó ŌĆó ŌĆó ŌĆó ŌĆó ╬▒i, ╬▓i ╬▒i, ╬▓i ╬▒i, ╬▓i ╬▒i, ╬▓i ╬▒i, ╬▓i ╬▒i, ╬▓i ╬▒i, ╬▓i ╬▒i, ╬▓i ╬▒i, ╬▓i CNC controls overview All panels and screens shown are examples only. Max. controlled axes total / per path Max. feed axes total / per path Max. spindle axes total / per path Max. simultaneously controlled axes / path Max. controlled paths Type of installation LCD version Stand-alone version Operating units LCD panel LCD panel for iHMI PC front-end PC front-end iHMI Touch systems Handheld control unit Machine operators panel Part program memory Integrated from ... to ŌĆ” Additional mass storage device CF-card Additional mass storage device HD-PC-version USB port Ethernet Field bus EtherNet/IP / PROFINET I/O FANUC I/O-Link i / FL-net AS-i / PROFIBUS DP / DeviceNet / CC-Link Modbus TCP Compatible drive systems PMC function Max. number of I/O Max. number of I/O-Link Max. number of PMC channels Maximum steps Block function CNC functions 3D Interference check Dual Check Safety Smart Machine Control Program Restart / Quick Program Restart Nano Interpolation Nano Smoothing Fine Surface Technology AI Advanced Preview / AI Contour Control Macro Executor / C-Executor / FANUC Picture / FOCAS MANUAL GUIDE i / MANUAL GUIDE 0i Tool Functions / Tool Management System Tilted Working Plane / Tool Center Point Control Smooth simultaneous 5-axis machining Error Compensation / Volumetric Error Compensation Technologies Milling Turning Grinding Punching Laser Portable Manual Pulse Generator / iPendant and / or Handy Machine OperatorŌĆśs Panel * Up to 96 axes, 24 spindle axes and 15 paths available with Series 30i-B

- 6. DUAL CHECK SAFETY DUAL CHECK Configure your CNC Each FANUC CNC series offers a diverse range of panels and screen solutions. Your benefit: a wide variety of configuration options for every specific machining solution providing full flexibility for your ideas. The FANUC standard LCD display is available in 2 basic versions: LCD-mounted type embedded in the CNC, physically mounted directly behind the LCD panel or as a separate stand-alone display unit which is connected to the CNC using a fiber optics cable. Standard LCD displays are available in sizes from 8.4ŌĆ£ in diagonal up to 15ŌĆ£, with and without touch panel. LCD displays with touch panel can be used without any additional keyboards and push button panels and can provide small and smart HMI solutions for compact machines. The standard LCD display generates the content of the screens, including customised HMI applications in the CNC. Or choose an LCD display with PC that provides PC CPU and storage capabilities at the display level. Choose the Manual Data Input (MDI) device of your CNC control from a selection of a small size MDI, a standard size MDI, a 68-key MDI or a full keyboard with either English or symbolic key sheets for a variety of applications. Depending on the type, the device has alphanumeric keys to input part programs, operation keys like RESET, PAGE UP, PAGE DOWN, HELP and menu keys to switch between several menu screens. The new Machine Operation Panel (MOP) comes with additional and improved safety options. All the buttons on this control panel are equipped with double wired keys and further safety functions like override switches. An integral ESP button enhances safety in case of emergency. Via the FANUC I/O link i, the operator panel communicates with the CNC system and is thus easily integrated into the FANUC Dual Check Safety system. Like its forerunner, the innovative Safety MOP has exchangable key tops which allow a customised key layout. FANUC iHMI - Simple. Efficient. Intuitive. D IS P L A Y M D I M O P Various cycles ŌĆó turning ŌĆó milling ŌĆó measurement CNC operation screen Simple Easy operation along process flow with integration of three screens: Your benefits: ŌĆó reliable operator safety ŌĆó fewer external safety circuits required ŌĆó overall cost reduction of the safety solution ŌĆó certified to comply to the actual safety standards Friendly Help troubleshooting ŌĆō one-stop problem-solving Graphical Intuitive icons and high-visibility design with animated features FANUC iHMI has been designed to be extremely easy to use. Intuitive menu icons, high-visibility design and animated features take the head-scratching out of complex machining operations, making accessing even the most sophisticated programs and functionalities straightforward. Despite its more intuitive layout, users will nevertheless find that it provides a familiar FANUC user experience. Safety function DCS The certified FANUC Dual Check Safety (DCS) function provides a high level of safety for the operator during operations with protection activated while power is still applied. In case of an abnormal function FANUC DCS quickly shuts off power to protect the operator allowing a quick restart of the machine tool operation. Special functions are available to simplify the creation of the machine documentation, e.g. Test Mode Function for Dual Check Safety.

- 7. Tool Manager Data logger Manual viewer Machine collision avoidance Servo viewer Uniform tool information management for machine ŌĆó up to 1000 tools with tool management option ŌĆó up to 1024 sets of tools with tool life management option ŌĆó up to 1000 tools when the CNC option is invalid ŌĆó tool catalogue data available for about 2000 tools ŌĆó VERICUT format (TLS file) CAM/simulation software is compatible with tool data Model, prevent interference and add to CNC before machining ŌĆó collision status can be confirmed graphically ŌĆó forecast positions for safe, precise collision detection ŌĆó based on CGTech CoŌĆÖs CAS (Collision Avoidance Software) ŌĆó maximum forecast time up to 600 msec. ŌĆó create 3D models of the machine on a PC Investigate cause of problem while machining ŌĆó amount of data per second under 64 KB Data types: ŌĆó position of axes ŌĆó CNC status ŌĆó PMC data ŌĆó macro variable data ŌĆó information of servo/spindle ŌĆó operational information ŌĆó alarm information etc. Measure and display various kinds of data ŌĆó servo and spindle data, e.g. position, speed and torque ŌĆó PMC data ŌĆó CNC status information, e.g. program number, M/S/T codes ŌĆó analyze the axis movement and CNC operation timing ŌĆó optimize the CNC program to reduce cycle times ŌĆó monitor the machineŌĆśs condition by periodical measurements Always refer to the machineŌĆÖs manual ŌĆó add MTBŌĆÖs manuals and classify into an arbitrary group ŌĆó use multiform file formats (HTML,TXT, PDF) ŌĆó display manuals according to NC language setting ŌĆó memory capacity for manuals is limited to 500ŌĆēMB Observe CNC and machine parts and set alert for exchange time ŌĆó specified by usage time, amount of movement, PMC counter etc. ŌĆó add a max. of 100 items as orig. monitoring item ŌĆó min. 1 sec monitoring period ŌĆó time savings of an hour or more ŌĆó easy to add original monitoring item and notification information Tool Manager Uniform tool information management for machine╠² Machine collision avoidance Uniform tool information management for machine╠² Data logger Investigate cause of problem while machining Servo viewer Measure and display various kinds of data Manual viewer Always refer to the machineŌĆÖs manual Maintenance manager Observe CNC and machine parts and set alert for exchange time Maintenance manager

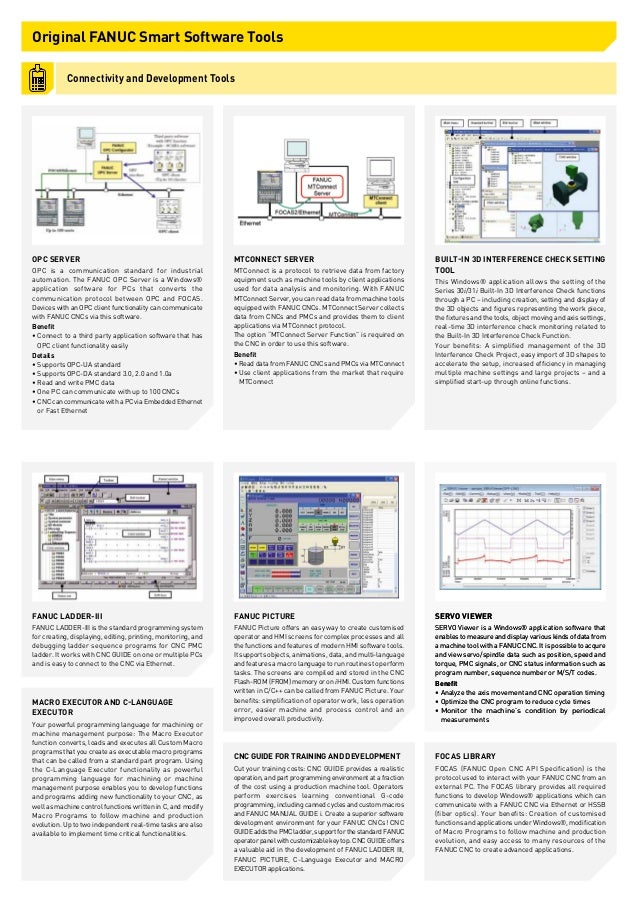

- 8. Original FANUC Smart Software Tools OPC SERVER OPC is a communication standard for industrial automation. The FANUC OPC Server is a Windows┬« application software for PCs that converts the communication protocol between OPC and FOCAS. Devices with an OPC client functionality can communicate with FANUC CNCs via this software. Benefit ŌĆó Connect to a third party application software that has OPC client functionality easily Details ŌĆó Supports OPC-UA standard ŌĆó Supports OPC-DA standard 3.0, 2.0 and 1.0a ŌĆó Read and write PMC data ŌĆó One PC can communicate with up to 100 CNCs ŌĆó CNC can communicate with a PC via Embedded Ethernet or Fast Ethernet FANUC LADDER-III FANUC LADDER-III is the standard programming system for creating, displaying, editing, printing, monitoring, and debugging ladder sequence programs for CNC PMC ladder. It works with CNC GUIDE on one or multiple PCs and is easy to connect to the CNC via Ethernet. MACRO EXECUTOR AND C-LANGUAGE EXECUTOR Your powerful programming language for machining or machine management purpose: The Macro Executor function converts, loads and executes all Custom Macro programs that you create as executable macro programs that can be called from a standard part program. Using the C-Language Executor functionality as powerful programming language for machining or machine management purpose enables you to develop functions and programs adding new functionality to your CNC, as well as machine control functions written in C, and modify Macro Programs to follow machine and production evolution. Up to two independent real-time tasks are also available to implement time critical functionalities. BUILT-IN 3D INTERFERENCE CHECK SETTING TOOL This Windows┬« application allows the setting of the Series 30i/31i Built-In 3D Interference Check functions through a PC ŌĆō including creation, setting and display of the 3D objects and figures representing the work piece, the fixtures and the tools, object moving and axis settings, real-time 3D interference check monitoring related to the Built-In 3D Interference Check Function. Your benefits: A simplified management of the 3D Interference Check Project, easy import of 3D shapes to accelerate the setup, increased efficiency in managing multiple machine settings and large projects ŌĆō and a simplified start-up through online functions. SERVO VIEWER SERVO Viewer is a Windows┬« application software that enables to measure and display various kinds of data from a machine tool with a FANUC CNC. It is possible to acqure and view servo/spindle data such as position, speed and torque, PMC signals, or CNC status information such as program number, sequence number or M/S/T codes. Benefit ŌĆó Analyze the axis movement and CNC operation timing ŌĆó Optimize the CNC program to reduce cycle times ŌĆó Monitor the machineŌĆÖs condition by periodical measurements FOCAS LIBRARY FOCAS (FANUC Open CNC API Specification) is the protocol used to interact with your FANUC CNC from an external PC. The FOCAS library provides all required functions to develop Windows┬« applications which can communicate with a FANUC CNC via Ethernet or HSSB (fiber optics). Your benefits: Creation of customised functions and applications under Windows┬«, modification of Macro Programs to follow machine and production evolution, and easy access to many resources of the FANUC CNC to create advanced applications. MTCONNECT SERVER MTConnect is a protocol to retrieve data from factory equipment such as machine tools by client applications used for data analysis and monitoring. With FANUC MTConnect Server, you can read data from machine tools equipped with FANUC CNCs. MTConnect Server collects data from CNCs and PMCs and provides them to client applications via MTConnect protocol. The option ŌĆ£MTConnect Server FunctionŌĆØ is required on the CNC in order to use this software. Benefit ŌĆó Read data from FANUC CNCs and PMCs via MTConnect ŌĆó Use client applications from the market that require MTConnect FANUC PICTURE FANUC Picture offers an easy way to create customised operator and HMI screens for complex processes and all the functions and features of modern HMI software tools. It supports objects, animations, data, and multi-language and features a macro language to run routines to perform tasks. The screens are compiled and stored in the CNC Flash-ROM (FROM) memory or on iHMI. Custom functions written in C/C++ can be called from FANUC Picture. Your benefits: simplification of operator work, less operation error, easier machine and process control and an improved overall productivity. CNC GUIDE FOR TRAINING AND DEVELOPMENT Cut your training costs: CNC GUIDE provides a realistic operation, and part programming environment at a fraction of the cost using a production machine tool. Operators perform exercises learning conventional G-code programming, including canned cycles and custom macros and FANUC MANUAL GUIDE i. Create a superior software development environment for your FANUC CNCs! CNC GUIDEaddsthePMCladder,supportforthestandardFANUC operatorpanelwithcustomizablekeytop.CNC GUIDEoffers a valuable aid in the development of FANUC LADDER III, FANUC PICTURE, C-Language Executor and MACRO EXECUTOR applications. Connectivity and Development Tools SERVO VIEWER SERVO Viewer is a Windows┬« application software that enables to measure and display various kinds of data from a machine tool with a FANUC CNC. It is possible to acqure and view servo/spindle data such as position, speed and torque, PMC signals, or CNC status information such as program number, sequence number or M/S/T codes. Benefit ŌĆó Analyze the axis movement and CNC operation timing ŌĆó Optimize the CNC program to reduce cycle times ŌĆó Monitor the machineŌĆÖs condition by periodical measurements

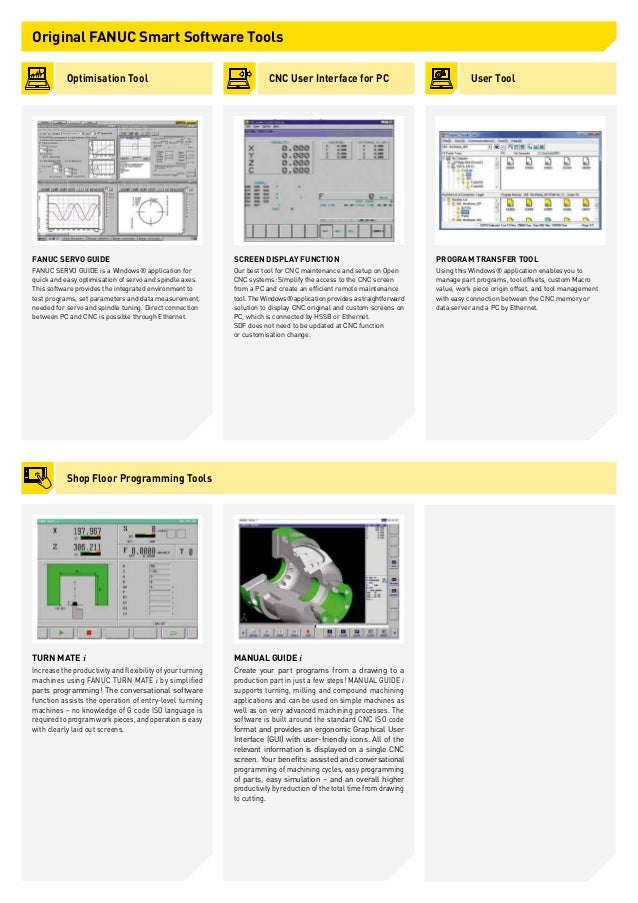

- 9. Original FANUC Smart Software Tools Optimisation Tool CNC User Interface for PC User Tool FANUC SERVO GUIDE FANUC SERVO GUIDE is a Windows┬« application for quick and easy optimisation of servo and spindle axes. This software provides the integrated environment to test programs, set parameters and data measurement, needed for servo and spindle tuning. Direct connection between PC and CNC is possible through Ethernet. PROGRAM TRANSFER TOOL Using this Windows┬« application enables you to manage part programs, tool offsets, custom Macro value, work piece origin offset, and tool management with easy connection between the CNC memory or data server and a PC by Ethernet. SCREEN DISPLAY FUNCTION Our best tool for CNC maintenance and setup on Open CNC systems: Simplify the access to the CNC screen from a PC and create an efficient remote maintenance tool. The Windows┬« application provides a straightforward solution to display CNC original and custom screens on PC, which is connected by HSSB or Ethernet. SDF does not need to be updated at CNC function or customisation change. Shop Floor Programming Tools TURN MATE i Increase the productivity and flexibility of your turning machines using FANUC TURN MATE i by simplified parts programming! The conversational software function assists the operation of entry-level turning machines ŌĆō no knowledge of G code ISO language is required to program work pieces, and operation is easy with clearly laid out screens. MANUAL GUIDE i Create your part programs from a drawing to a production part in just a few steps! MANUAL GUIDE i supports turning, milling and compound machining applications and can be used on simple machines as well as on very advanced machining processes. The software is built around the standard CNC ISO code format and provides an ergonomic Graphical User Interface (GUI) with user-friendly icons. All of the relevant information is displayed on a single CNC screen. Your benefits: assisted and conversational programming of machining cycles, easy programming of parts, easy simulation ŌĆō and an overall higher productivity by reduction of the total time from drawing to cutting.

- 10. Wherever you need us: we are there With the largest global network of local subsidiaries in all continents, we are always there to meet your needs. Fast and efficient ŌĆō 24ŌĆē/ŌĆē7. So you always have a local contact that speaks your language. Our strength: Service and Support Intensive application support and personal customer service are major aspects of the FANUC world ŌĆō from the first step to the last. A very skilled and dedicated service team will help you to build and operate the most efficient machines. Always flexible, always fast, always near. The special FANUC Service packages improves the performance of your machines even further. 2300 service engineers More than 271 subsidiaries worldwide FANUC Academy We help you get the most potential out of your automation through optimising the skills of your employees. Certified FANUC instructors train them in our fully equipped professional training centres, or at your own premises, using standard training modules as well as customised training packages to meet your specific needs. LetŌĆÖs optimise your productivity.

- 11. One common servo and control platform ŌĆō Infinite opportunities THATŌĆśs FANUC! Technical information subject to change without prior notice. All rights reserved. ┬® 2021 FANUC Europe Corporation WWW.FANUC.EU FA CNCs, Servo Motors and Lasers ROBOTS Industrial Robots, Accessories and Software ROBOCUT CNC Wire-Cut Electric Discharge Machines ROBODRILL Compact CNC Machining Centres ROBOSHOT Electric CNC Injection Moulding Machines ROBONANO Ultra Precision Machines IoT Industry 4.0 solutions MBR-00011-EN-V8-11/2021