FANUC Wire Electrical Discharge Machine ROBOCUT brochure Fast, accurate electrical discharge machining

- 1. THE FACTORY AUTOMATION COMPANY ROBOCUT ╬▒-CiC series High-Precision CNC Wire Electrical Discharge Machining Extremely versatile wire EDM WWW.FANUC.EU

- 2. intelligent automation ŌĆō 100% FANUC With three core product groups, FANUC is the only company in its sector to develop and manufacture all its major components in-house. Every detail, both hardware and software, undergoes stringent quality control checks as part of an optimised chain. Fewer parts and lean technology make FANUC solutions reliable, predictable and easy to repair. They are made to run and provide you with the highest uptime on the market. Optimised energy usage ŌĆō intelligent energy management All FANUC products ŌĆō industrial robots, CNC systems and CNC machines ŌĆō share a common servo and control platform, providing seamless connectivity and making full-automation scenarios really simple. Since all products share common parts, spare parts management with FANUC is fairly efficient. Plus, global standards make it very easy to go international with FANUC. Retool in just 0.7 seconds ŌĆō FANUC ROBODRILL, our vertical machining centre, is designed for maximum efficiency. High-precision electric injection moulding ŌĆō with the FANUC ROBOSHOT. The solution for high-speed precision applications, such as assembly, pick and place, inspection and packaging ŌĆō FANUC SCARA series robots. Visual bin picking ŌĆō gives robots the ability to identify and pick loose parts and even bags from a bin. FANUC ROBOCUT wire EDM machine for mould making, tooling and cutting of parts CO2 laser packages for efficient automated laser cutting. Multi-robot welding cells ŌĆō easy automated welding thanks to seamless connectivity and a single user-friendly CNC interface. No need for safety fences ŌĆō FANUC collaborative robots allow easy integration into human workspaces for even more manufacturing efficiency and improved health and safety. Lift up to 2.3 tons ŌĆō choose from over one hundred robots with payload capacities ranging from 1 kg to 2.3 tons. Ultra-fast picking, assembling and sorting ŌĆō FANUCŌĆÖs range of delta robots are ideally suited to high- speed handling processes requiring a great deal of versatility.

- 3. Designed for ultimate performance ŌĆó latest CNC and servomotor technology ŌĆó generator designed for maximum reliability ŌĆó capable of cutting thick and stepped parts ŌĆó multi-workpiece cutting ŌĆó easy-to-use CORE STITCH Function for even longer unmanned machining ŌĆó wire threading in just 10 seconds ŌĆó automatic in-path wire re-threading ŌĆó accurate twin servo wire tension control ROBOCUT ŌĆō fast, accurate, multipurpose EDM Where wire EDM is concerned, accuracy has traditionally come at the cost of speed. ThatŌĆÖs why FANUC has developed a next generation ROBOCUT wire EDM machine. The ╬▒-CiC series comprises two versatile all-rounders. With incredibly long mean times between failures, low maintenance, longevity and excellent uptimes, these future-proof machines are designed to save time and drive down unit costs while ensuring superlative accuracy and cutting. Breakthrough advances of the new ROBOCUT ╬▒-CiC series ŌĆó higher accuracy thanks to new high precision pitch error compensation function ŌĆó hardened and durable workpiece table ŌĆó new cutting technologies ŌĆó new compact design ŌĆó FANUC iH Pro with new display and keyboard design ŌĆó optimised user-friendly screens ŌĆó easy to install, maintain and repair ŌĆó manuals on board designed and built in Japan years of ROBOCUT technology More than

- 4. For the automotive industry Mass producing parts for the automotive industry demands incredibly high levels of reliability and efficiency from machines. These need to deliver repeatable accuracy over extremely long periods of time. ROBOCUT provides incredible accuracy and superior surface finishes on demanding workpieces, such as moulds, that require sophisticated shapes to be cut to very tight tolerances. For the aerospace industry Often aerospace manufacturers need to cut Inconel and other heat resistant alloys. But its material characteristics make this difficult using a conventional milling machine. Wire EDM machines like ROBOCUT, however, cut Inconel, or anything other material that conducts electricity for that matter, effortlessly. And for those applications that require the use of a rotary table, ROBOCUT is available with a proprietary model as well as purpose-designed taper adjustment jig for tapping cutting applications. For the electrical and IT parts industry Extremely high accuracy on tooling, such as moulds, is needed to make high precision and micro parts such as electrical connectors. Incredible levels of repeatability also ensure the same high standards are obtained time and time again. For the medical industry When equipped with a FANUC rotary table, ROBOCUT offers the flexibility to machine the extremely sophisticated shapes required in the manufacture of medical and surgical equipment. ROBOCUT also delivers the high levels of reliability and repeatability required to mass-produce equipment for the medical industry. For mould makers and job shoppers ROBOCUT is a versatile all-rounder that does just about everything. Its low running costs and ability to machine sophisticated parts to incredible degrees of accuracy make it perfect for general machining work. Additionally, its unrivalled CORE STITCH function can be programmed easily on the shop floor without a PC and ensures ultimate reliability for jobs that require long unmanned processing times. The efficient all-rounder for a wide range of industries Every manufacturing industry sector has its own CNC application requirements. Offering versatility across a huge variety of machining tasks, ROBOCUT meets most of them. Boasting a wealth of features designed to help you adapt quickly to new requirements and cutting specifications, ROBOCUT wire-cut EDM machines offer perfect surface quality, excellent repeatability, maximum flexibility for complex shapes, and reliable unmanned operation for extended periods of time. Just what your industry needs.

- 5. Ease of use Thanks to a whole range of smart features such as Simple Adjustment, Set-up Guidance or Custom PMC and Custom Screen, the ROBOCUT ╬▒-CiC series sets a new standard in user- friendliness. Additional options such as QSSR for easy automation with FANUC robots, or ROBOCUT CAMi for easy NC programs and CAD data cutting paths, make work even easier. Minimising downtime An idle machine does nothing for your productivity. That is why we have upgraded every feature of the ROBOCUT ╬▒-CiC series to minimise downtime, including reliable automatic wire threading, the water tank pre-seal mechanism and ROBOCUT-LINKi, the remote production and quality information management tool for preventing downtime. High-performance cutting The ROBOCUT ╬▒-CiC series is your choice for accuracy and surface quality. Its high precision ROBOCUT CCR rotary table ensures maximum precision and versatility, while the ROBOCUT PCD generator takes PCD tool applications to a whole new level. And the AI thermal displacement compensation feature ensures extremely stable cutting. XYZ axis travel: 600x400x310 XYZ axis travel: 400x300x255 More than 33,000 ROBOCUT installed worldwide ╬▒-C600iC ╬▒-C400iC Unbeatable wire EDM versatility A versatile all-rounder, the FANUC ROBOCUT will do all your everyday cutting tasks without you ever needing to change the set up. When you do though, you will find that ROBOCUTŌĆÖs extensive range of options make adapting it extremely straightforward.

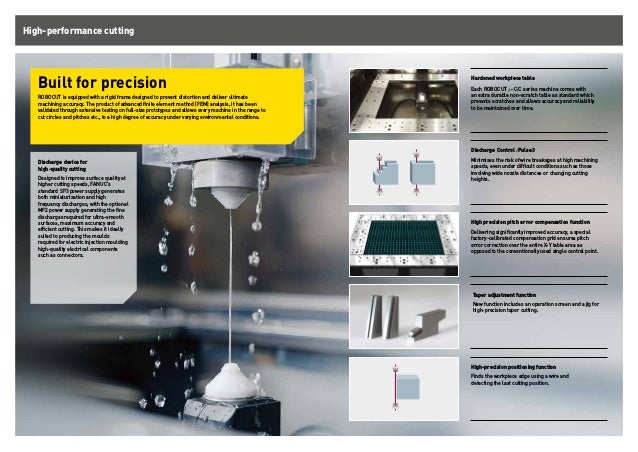

- 6. High-performance cutting Built for precision ROBOCUT is equipped with a rigid frame designed to prevent distortion and deliver ultimate machining accuracy. The product of advanced finite element method (FEM) analysis, it has been validated through extensive testing on full-size prototypes and allows every machine in the range to cut circles and pitches etc., to a high degree of accuracy under varying environmental conditions. Discharge Control iPulse3 Minimises the risk of wire breakages at high machining speeds, even under difficult conditions such as those involving wide nozzle distances or changing cutting heights. Hardened workpiece table Each ROBOCUT ╬▒-CiC series machine comes with an extra durable non-scratch table as standard which prevents scratches and allows accuracy and reliability to be maintained over time. High precision pitch error compensation function Delivering significantly improved accuracy, a special factory-calibrated compensation grid ensures pitch error correction over the entire X-Y table area as opposed to the conventionally used single central point. Taper adjustment function New function includes an operation screen and a jig for high-precision taper cutting. High-precision positioning function Finds the workpiece edge using a wire and detecting the last cutting position. Discharge device for high-quality cutting Designed to improve surface quality at higher cutting speeds, FANUCŌĆÖs standard SF3 power supply generates both miniaturisation and high frequency discharges, with the optional MF2 power supply generating the fine discharges required for ultra-smooth surfaces, maximum accuracy and efficient cutting. This makes it ideally suited to producing the moulds required for electric injection moulding high-quality electrical components such as connectors.

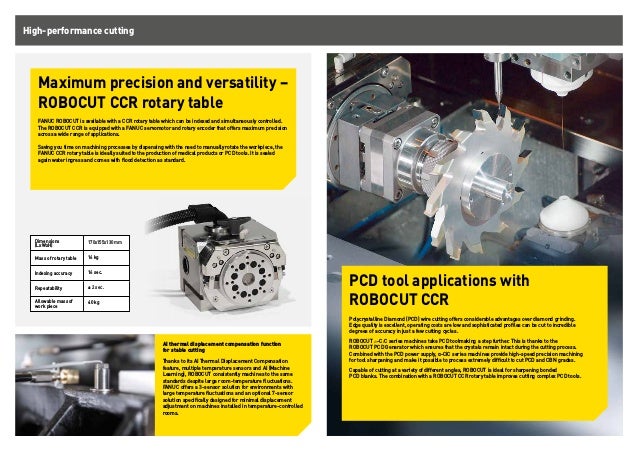

- 7. High-performance cutting Maximum precision and versatility ŌĆō ROBOCUT CCR rotary table FANUC ROBOCUT is available with a CCR rotary table which can be indexed and simultaneously controlled. The ROBOCUT CCR is equipped with a FANUC servomotor and rotary encoder that offers maximum precision across a wide range of applications. Saving you time on machining processes by dispensing with the need to manually rotate the workpiece, the FANUC CCR rotary table is ideally suited to the production of medical products or PCD tools. It is sealed again water ingress and comes with flood detection as standard. PCD tool applications with ROBOCUT CCR Polycrystalline Diamond (PCD) wire cutting offers considerable advantages over diamond grinding. Edge quality is excellent, operating costs are low and sophisticated profiles can be cut to incredible degrees of accuracy in just a few cutting cycles. ROBOCUT ╬▒-CiC series machines take PCD toolmaking a step further. This is thanks to the ROBOCUT PCD Generator which ensures that the crystals remain intact during the cutting process. Combined with the PCD power supply, ╬▒-CiC series machines provide high-speed precision machining for tool sharpening and make it possible to process extremely difficult to cut PCD and CBN grades. Capable of cutting at a variety of different angles, ROBOCUT is ideal for sharpening bonded PCD blanks. The combination with a ROBOCUT CCR rotary table improves cutting complex PCD tools. Dimensions (LxWxH) 170x155x130mm Mass of rotary table 16 kg Indexing accuracy 16 sec. Repeatability ┬▒ 2 sec. Allowable mass of work piece 40 kg AI thermal displacement compensation function for stable cutting Thanks to its AI Thermal Displacement Compensation feature, multiple temperature sensors and AI (Machine Learning), ROBOCUT consistently machines to the same standards despite large room-temperature fluctuations. FANUC offers a 3-sensor solution for environments with large temperature fluctuations and an optional 7-sensor solution specifically designed for minimal displacement adjustment on machines installed in temperature-controlled rooms.

- 8. R Automatic threading in just 10 seconds FANUCŌĆÖs unique AWF3 Automatic Wire Feed threading technology provides fast, reliable automatic threading in just 10 seconds. To ensure reliable threading and re-threading, wires are cut electrically leaving a pointed end that is absolutely straight and burr-free, even on soft wire. Aided by a jet of water, threading the wire is both simple and very fast. Unlike other machines, ROBOCUT does not need to return to the starting point after a wire break. This radically reduces machining times by re-threading automatically in the wire path on workpieces up to ┬Ł 150 mm thick ŌĆō even on challenging micro- machining orders. Two servomotors maintain the wire tension. Made possible by FANUCŌĆÖs digital servo technology, FANUCŌĆÖs twin servo wire tension control ensures consistent cutting by suppressing variations in wire tension. Additional benefits are fewer wire breaks and reduced parts wear. Reliable re-threading in the wire path Consistent wire tension ŌĆō improved overall reliability Built-in efficiency ŌĆó supremely reliable submerged threading and re-threading even on thick workpieces up to 400 mm ŌĆó accurate taper-cut threading up to a height of 50 mm and taper angle of 5 degrees ŌĆó soft wire AWF option to achieve straight burr-free cut ends on soft wire ŌĆó AWF mechanism easy to dismantle, clean and reassemble ŌĆó higher success rate of threading wire by vibrating the wire intentionally through air retry function With 60 hours of wire as standard, the 30 kg spool option and wire cutter more than double the period of continuous operation. hours of unmanned machining 140 Minimising downtime Cutting direction Start point Upper guide Nozzle Wire break point Wire threading point Cutting direction CNC

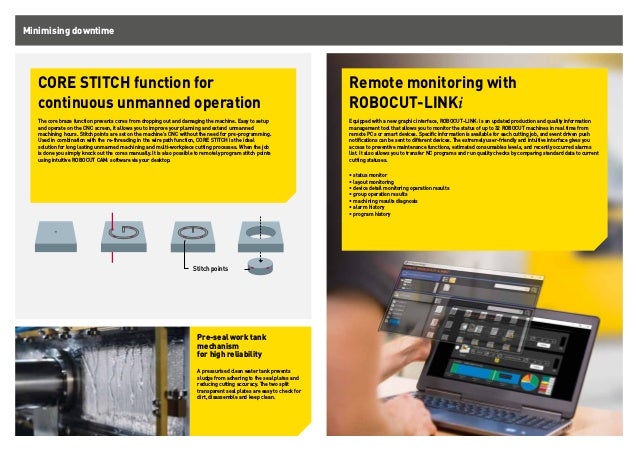

- 9. Minimising downtime CORE STITCH function for continuous unmanned operation The core braze function prevents cores from dropping out and damaging the machine. Easy to setup and operate on the CNC screen, it allows you to improve your planning and extend unmanned machining hours. Stitch points are set on the machineŌĆÖs CNC without the need for pre-programming. Used in combination with the re-threading in the wire path function, CORE STITCH is the ideal solution for long lasting unmanned machining and multi-workpiece cutting processes. When the job is done you simply knock out the cores manually. It is also possible to remotely program stitch points using intuitive ROBOCUT CAMi software via your desktop. Remote monitoring with ROBOCUT-LINKi Equipped with a new graphic interface, ROBOCUT-LINKi is an updated production and quality information management tool that allows you to monitor the status of up to 32 ROBOCUT machines in real time from remote PCs or smart devices. Specific information is available for each cutting job, and event driven push notifications can be sent to different devices. The extremely user-friendly and intuitive interface gives you access to preventive maintenance functions, estimated consumables levels, and recently occurred alarms list. It also allows you to transfer NC programs and run quality checks by comparing standard data to current cutting statuses. ŌĆó status monitor ŌĆó layout monitoring ŌĆó device detail monitoring operation results ŌĆó group operation results ŌĆó machining results diagnosis ŌĆó alarm history ŌĆó program history Pre-seal work tank mechanism for high reliability A pressurised clean water tank prevents sludge from adhering to the seal plates and reducing cutting accuracy. The two split transparent seal plates are easy to check for dirt, disassemble and keep clean. Stitch points

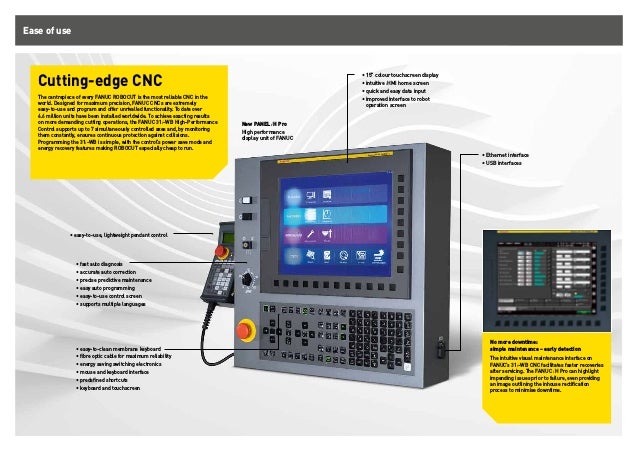

- 10. Ease of use Cutting-edge CNC The centrepiece of every FANUC ROBOCUT is the most reliable CNC in the world. Designed for maximum precision, FANUC CNCs are extremely easy-to-use and program and offer unrivalled functionality. To date over 4.6 million units have been installed worldwide. To achieve exacting results on more demanding cutting operations, the FANUC 31i-WB High-Performance Control supports up to 7 simultaneously controlled axes and, by monitoring them constantly, ensures continuous protection against collisions. Programming the 31i-WB is simple, with the controlŌĆÖs power save mode and energy recovery features making ROBOCUT especially cheap to run. ŌĆó easy-to-clean membrane keyboard ŌĆó fibre optic cable for maximum reliability ŌĆó energy saving switching electronics ŌĆó mouse and keyboard interface ŌĆó predefined shortcuts ŌĆó keyboard and touchscreen ŌĆó fast auto diagnosis ŌĆó accurate auto correction ŌĆó precise predictive maintenance ŌĆó easy auto programming ŌĆó easy-to-use control screen ŌĆó supports multiple languages ŌĆó easy-to-use, lightweight pendant control ŌĆó Ethernet interface ŌĆó USB interfaces ŌĆó 15ŌĆØ colour touchscreen display ŌĆó intuitive iHMI home screen ŌĆó quick and easy data input ŌĆó improved interface to robot operation screen New PANEL iH Pro High performance display unit of FANUC No more downtime: simple maintenance ŌĆō early detection The intuitive visual maintenance interface on FANUCŌĆÖs 31i-WB CNC facilitates faster recoveries after servicing. The FANUC iH Pro can highlight impending issues prior to failure, even providing an image outlining the inhouse rectification process to minimise downtime.

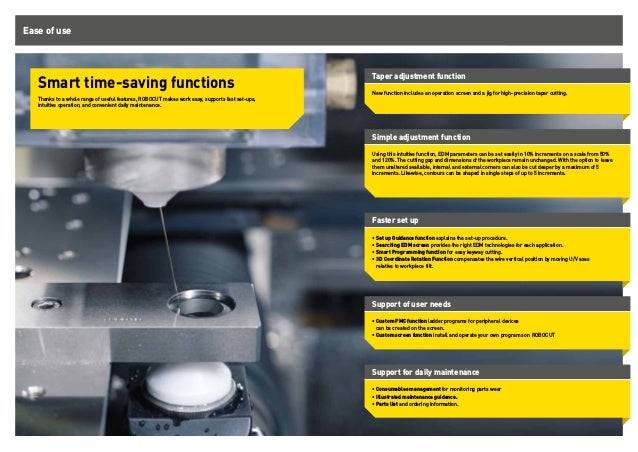

- 11. Ease of use Using this intuitive function, EDM parameters can be set easily in 10% increments on a scale from 50% and 120%. The cutting gap and dimensions of the workpiece remain unchanged. With the option to leave them unaltered available, internal and external corners can also be cut deeper by a maximum of 5 increments. Likewise, contours can be shaped in single steps of up to 5 increments. New function includes an operation screen and a jig for high-precision taper cutting. ŌĆó Set up Guidance function explains the set-up procedure. ŌĆó Searching EDM screen provides the right EDM technologies for each application. ŌĆó Smart Programming function for easy keyway cutting. ŌĆó 3D Coordinate Rotation Function compensates the wire vertical position by moving U/V axes relative to workpiece tilt. ŌĆó Custom PMC function ladder programs for peripheral devices can be created on the screen. ŌĆó Custom screen function install and operate your own programs on ROBOCUT ŌĆó Consumables management for monitoring parts wear ŌĆó Illustrated maintenance guidance. ŌĆó Parts list and ordering information. Simple adjustment function Taper adjustment function Faster set up Support of user needs Support for daily maintenance Smart time-saving functions Thanks to a whole range of useful features, ROBOCUT makes work easy, supports fast set-ups, intuitive operation, and convenient daily maintenance.

- 12. ROBOCUT efficiency highlights ROBOCUT Ease of use NC programming made easy with ROBOCUT-CAMi Programming made easy with ROBOCUT-CAMi The FANUC ROBOCUT-CAMi system makes programming cylindrical, conical and 4-axis machining routines easy. You can mirror ROBOCUT-CAMi software directly to the CNC screen by using the remote desktop func- tion. ROBOCUT-CAMi also offers multiple languages and a number of 2D or 3D data import options such as DXF, IGES and STEP files. Your advantages with ROBOCUT-CAMi ŌĆó ROBOCUT-CAMi software can be mirrored to the CNC screen ŌĆó huge range of post-processing options ŌĆó simple program transfer via Ethernet interface ŌĆó automatic default settings reduce set up times ŌĆó simple programming of involute gearing, top and bottom shapes, coreless cutting ŌĆó flexible programming of CORE STITCH function Simple robot integration via QSSR ROBOCUT has been designed for easy automation and comes with an ergonomically designed work area as well as easy robot access for loading heavier workpieces and hassle-free machine tending. The optional ROBOCUT QSSR feature helps with fast, uncomplicated automation and covers FANUC robots, robot interface, robot stand, safety fence, robot sample program etc. FANUCŌĆÖs comprehensive network of dedicated European partners possesses the technical know-how to provide a solution that is tailored to your specific automation needs. All FANUC products speak the same language and share a common servo and control platform ŌĆō something that makes learning to use them and operating them extremely easy. Additionally, third party automation systems are seamlessly connectable to FANUC machines via the new robot interface Ease of use

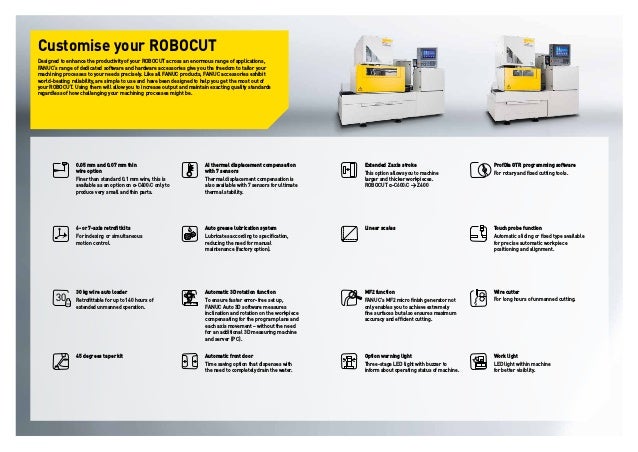

- 13. 30 0.05 mm and 0.07 mm thin wire option Finer than standard 0.1 mm wire, this is available as an option on ╬▒-C400iC only to produce very small and thin parts. AI thermal displacement compensation with 7 sensors Thermal displacement compensation is also available with 7 sensors for ultimate thermal stability. Extended Z axis stroke This option allows you to machine larger and thicker work┬Ł pieces. ROBOCUT ╬▒-C600iC ŌåÆ Z400 ProfDia GTR programming software For rotary and fixed cutting tools. 6- or 7-axis retrofit kits For indexing or simultaneous motion control. Auto grease lubrication system Lubricates according to specification, reducing the need for manual maintenance (factory option). Linear scales Touch probe function Automatic sliding or fixed type available for precise automatic workpiece positioning and alignment. 30 kg wire auto loader Retrofittable for up to 140 hours of extended unmanned operation. Automatic 3D rotation function To ensure faster error-free set up, FANUC Auto 3D software measures inclination and rotation on the workpiece compensating for the program plane and each axis movement╠²ŌĆō without the need for an additional 3D measuring machine and server (PC). MF2 function FANUCŌĆÖs MF2 micro finish generator not only enables you to achieve extremely fine surfaces but also ensures maximum accu┬Ł racy and efficient cutting. Wire cutter For long hours of unmanned cutting. 45 degrees taper kit Automatic front door Time saving option that dispenses with the need to completely drain the water. Option warning light Three-stage LED light with buzzer to inform about operating status of machine. Work light LED light within machine for better visiblity. Customise your ROBOCUT Designed to enhance the productivity of your ROBOCUT across an enormous range of applications, FANUCŌĆśs range of dedicated software and hardware accessories give you the freedom to tailor your machining processes to your needs precisely. Like all FANUC products, FANUC accessories exhibit world-beating reliability, are simple to use and have been designed to help you get the most out of your ROBOCUT. Using them will allow you to increase output and maintain exacting quality standards regardless of how challenging your machining processes might be.

- 14. Designed to save energy ROBOCUTŌĆÖs FANUC-made CNCs, motors, amplifiers, generators and pumps are engineered to deliver the lowest possible energy consumption through the use of intelligent energy management. Every component has been chosen to provide the highest possible performance for the least possible energy. Additional smart features to reduce energy consumption further include power monitoring, sleep mode, LED lighting, inverter pumps and cooling and power regeneration. The energy consumption can be precisely controlled according to various parameters, allowing energy efficiency to be flexibly adjusted, transparently verified, and compared with that of other wire EDM machines. Energy saving function The energy saving function makes it possible to track precisely the amount of energy being consumed during machining or on standby. Power saving interventions such as switching off flushing or filter pumps can also be set, with features such as screen savers, sleep mode, auto start-up by timer and auto power off, all contributing to additional savings. ŌĆó lower energy consumption and costs ŌĆó reduce machine running costs ŌĆó increase the lifetime of the machine Optimised energy usage ŌĆō intelligent energy management

- 15. ╬▒-C600iC Technical Data Standard Maximum workpiece dimensions [mm] Maximum workpiece weight [kg] XY axis table travel [mm] Z axis travel [mm] UV axis travel [mm] Maximum taper angle [ŌĆē┬░ŌĆē/ŌĆēmm] Minimum step increment of the drives [mm] Wire diameter [mm] Maximum wire weight [kg] Machine weight (approx.) [kg] Controller Part program storage size [MB] Acoustic noise level LPA [dB] LPCpeak [dB] Optional Z axis 400 Z axis travel [mm] Maximum workpiece dimensions without automatic door, option Z axis travel [mm] Automatic front door Maximum workpiece dimensions [mm] 45┬░ die guide Maximum taper angle [ŌĆē┬░ŌĆē/ŌĆēmm] 30 kg wire feed unit Maximum wire weight [kg] *) The above floor plan is that of a standard type machine. Contact FANUC if you wish to order options such as 30 kg wire feed unit and Z axis travel 410 mm. Outer dimensions | Floor plan Power input position Compressed air input position * The values in parentheses are when the safety cover is open. ╬▒-C400iC Technical Data Standard Maximum workpiece dimensions [mm] Maximum workpiece weight [kg] XY axis table travel [mm] Z axis travel [mm] UV axis travel [mm] Maximum taper angle [ŌĆē┬░ŌĆē/ŌĆēmm] Minimum step increment of the drives [mm] Wire diameter [mm] Maximum wire weight [kg] Machine weight (approx.) [kg] Controller Part program storage size [MB] Acoustic noise level LPA [dB] LPCpeak [dB] Optional Thin wire Wire diameter [mm] Automatic front door Maximum workpiece dimensions with automatic door, Z axis travel [mm] 45┬░ die guide Maximum taper angle [ŌĆē┬░ŌĆē/ŌĆēmm] 30 kg wire feed unit Maximum wire weight [kg] *) The above floor plan is that of a standard type machine. Contact FANUC if you wish to order options such as 30 kg wire feed unit and thin wire option. Outer dimensions | Floor plan Power input position Compressed air input position * The values in parentheses are when the safety cover is open. 1050 ├Ś 820 ├Ś 300 1000 600 ├Ś 400 310 ┬▒ 100 ├Ś ┬▒100 ┬▒ŌĆē30/150 0,0001 ├ś 0.10 ~ ├ś 0.30 16 About 3600 FANUC 31i-WB 8 64 81 410 1050 ├Ś 820 ├Ś 400 1050 x 775 x 300 ┬▒ŌĆē45/70 30 730 x 630 x 250 500 400 ├Ś 300 255 ┬▒ 60 ├Ś ┬▒ 60 ┬▒ŌĆē30/ŌĆē80 0,0001 ├ś 0.10 ~ ├ś 0.30 16 About 2200 FANUC 31i-WB 8 64 81 ├ś 0.05 ~ ├ś 0.07 730 x 585 x 250 ┬▒ŌĆē45┬░/40 30

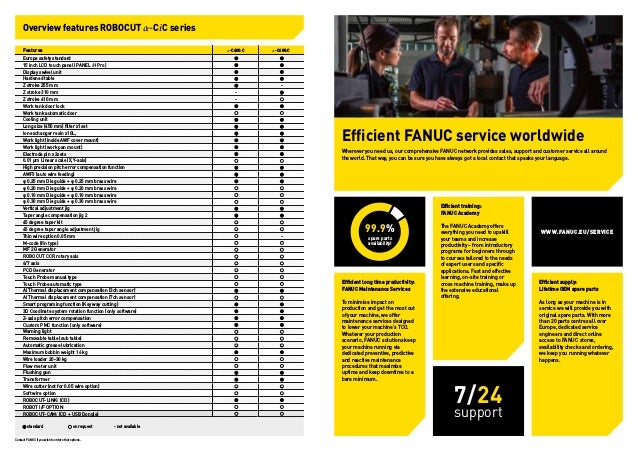

- 16. Overview features ROBOCUT ╬▒-CiC series Efficient supply: Lifetime OEM spare parts As long as your machine is in service we will provide you with original spare parts. With more than 20 parts centres all over Europe, dedicated service engineers and direct online access to FANUC stores, availability checks and ordering, we keep you running whatever happens. Efficient FANUC service worldwide Wherever you need us, our comprehensive FANUC network provides sales, support and customer service all around the world. That way, you can be sure you have always got a local contact that speaks your language. Efficient long time productivity: FANUC Maintenance Services To minimise impact on production and get the most out of your machine, we offer maintenance services designed to lower your machineŌĆÖs TCO. Whatever your production scenario, FANUC solutions keep your machine running via dedicated preventive, predictive and reactive maintenance procedures that maximise uptime and keep downtime to a bare minimum. standard on request - not available Efficient training: FANUC Academy The FANUC Academy offers everything you need to upskill your teams and increase productivity ŌĆō from introductory programs for beginners through to courses tailored to the needs of expert users and specific applications. Fast and effective learning, on-site training or cross machine training, make up the extensive educational offering. spare parts availability! support Features Europe safety standard 15 inch LCD touch panel (PANEL iH Pro) Display swivel unit Hardened table Z stroke 255 mm Z stroke 310 mm Z stroke 410 mm Work tank door lock Work tank automatic door Cooling unit Long size (450 mm) filter x1set Ion exchanger resin x10L, Work light (inside AWF cover mount) Work light (work pan mount) Electrode pin x 2sets 0.01 ╬╝m Linear scale (X,Y-axis) High precision pitch error compensation function AWF3 (auto wire feeding) Žå 0.25 mm Die guide + Žå 0.25 mm brass wire Žå 0.20 mm Die guide + Žå 0.20 mm brass wire Žå 0.10 mm Die guide + Žå 0.10 mm brass wire Žå 0.30 mm Die guide + Žå 0.30 mm brass wire Vertical adjustment jig Taper angle compensation jig 2 45 degree taper kit 45 degree taper angle adjustment jig Thin wire option 0.05 mm M-code (fin type) MF 2 Generator ROBOCUT CCR rotary axis 6/7 axis PCD Generator Touch Probe manual type Touch Probe automatic type AI Thermal displacement compensation (3ch sensor) AI Thermal displacement compensation (7ch sensor) Smart programing function (Key way cutting) 3D Coodinate system rotation function (only software) Z-axis pitch error compensation Custom PMC function (only software) Warning light Removable table (sub table) Automatic grease lubrication Maximum bobbin weight 16 kg Wire loader 20-30 kg Flow meter unit Flushing gun Transformer Wire cutter (not for 0.05 wire option) Soft wire option ROBOCUT-LINKi (CD) ROBOT I/F OPTION ROBOCUT-CAMi (CD + USB Dongle) WWW.FANUC.EU/SERVICE Contact FANUC if you wish to order other options. ╬▒-C400iC - - ╬▒-C600iC - - 7/24 99.9%

- 17. MBR-02766-EN-V1-05/2021 One common servo and control platform ŌĆō Infinite opportunities THATŌĆśs FANUC! WWW.FANUC.EU Technical information subject to change without prior notice. All rights reserved. ┬® 2021 FANUC Europe Corporation FA CNCs, Servo Motors and Lasers ROBOTS Industrial Robots, Accessories and Software ROBOCUT CNC Wire-Cut Electric Discharge Machines ROBODRILL Compact CNC Machining Centres ROBOSHOT Electric CNC Injection Moulding Machines ROBONANO Ultra Precision Machines IoT Industry 4.0 solutions

![╬▒-C600iC Technical Data

Standard

Maximum workpiece dimensions [mm]

Maximum workpiece weight [kg]

XY axis table travel [mm]

Z axis travel [mm]

UV axis travel [mm]

Maximum taper angle [ŌĆē┬░ŌĆē/ŌĆēmm]

Minimum step increment of the drives [mm]

Wire diameter [mm]

Maximum wire weight [kg]

Machine weight (approx.) [kg]

Controller

Part program storage size [MB]

Acoustic noise level

LPA [dB]

LPCpeak [dB]

Optional

Z axis 400

Z axis travel [mm]

Maximum workpiece dimensions without automatic door, option Z axis travel [mm]

Automatic front door

Maximum workpiece dimensions [mm]

45┬░ die guide

Maximum taper angle [ŌĆē┬░ŌĆē/ŌĆēmm]

30 kg wire feed unit

Maximum wire weight [kg]

*)

The above floor plan is that of a standard type machine. Contact FANUC if you wish to order options such as 30 kg wire feed unit and Z axis travel 410 mm.

Outer dimensions | Floor plan

Power input position

Compressed air input position

* The values in parentheses are when the safety cover is open.

╬▒-C400iC Technical Data

Standard

Maximum workpiece dimensions [mm]

Maximum workpiece weight [kg]

XY axis table travel [mm]

Z axis travel [mm]

UV axis travel [mm]

Maximum taper angle [ŌĆē┬░ŌĆē/ŌĆēmm]

Minimum step increment of the drives [mm]

Wire diameter [mm]

Maximum wire weight [kg]

Machine weight (approx.) [kg]

Controller

Part program storage size [MB]

Acoustic noise level

LPA [dB]

LPCpeak [dB]

Optional

Thin wire

Wire diameter [mm]

Automatic front door

Maximum workpiece dimensions with automatic door, Z axis travel [mm]

45┬░ die guide

Maximum taper angle [ŌĆē┬░ŌĆē/ŌĆēmm]

30 kg wire feed unit

Maximum wire weight [kg]

*)

The above floor plan is that of a standard type machine. Contact FANUC if you wish to order options such as 30 kg wire feed unit and thin wire option.

Outer dimensions | Floor plan

Power input position

Compressed air input position

* The values in parentheses are when the safety cover is open.

1050 ├Ś 820 ├Ś 300

1000

600 ├Ś 400

310

┬▒ 100 ├Ś ┬▒100

┬▒ŌĆē30/150

0,0001

├ś 0.10 ~ ├ś 0.30

16

About 3600

FANUC 31i-WB

8

64

81

410

1050 ├Ś 820 ├Ś 400

1050 x 775 x 300

┬▒ŌĆē45/70

30

730 x 630 x 250

500

400 ├Ś 300

255

┬▒ 60 ├Ś ┬▒ 60

┬▒ŌĆē30/ŌĆē80

0,0001

├ś 0.10 ~ ├ś 0.30

16

About 2200

FANUC 31i-WB

8

64

81

├ś 0.05 ~ ├ś 0.07

730 x 585 x 250

┬▒ŌĆē45┬░/40

30](https://image.slidesharecdn.com/mbr-04360-en-220712115121-7688bff5/95/FANUC-Wire-Electrical-Discharge-Machine-ROBOCUT-brochure-Fast-accurate-electrical-discharge-machining-15-638.jpg)