Fermentation project

- 1. Optimization of bakerâs yeast production in a Steam-in-Place Stirred tank Bioreactor By V.Yerrapu Nataraja Sekhar Reddy

- 2. Objectives OBJECTIVES: ïTo study the effect of media composition on cell growth ïTo study the effect of two different types of impellers: Rushton and paddle type on cell growth ïTo study the effect of scale of operation on growth and to perform scale up fermentation in bioreactor

- 3. Saccharomyces cerevisiae ïSaccharomyces cerevisiae is simple unicellular organism belonging to the Kingdom Fungi ïIn Greek it is called sugar fungus because many products of these fungi are sugar derived ïIt is a budding yeast

- 4. As model organism: ïshort generation time (doubling time) 1.25â2 hours ïA well defined genetic system ï Highly versatile DNA transformation system ïCan easily freeze and store at 4šC for later use ïRemarkably inexpensive compared to higher eukaryote organisms.

- 5. Commercial applications: ïBeverages ïFor providing CO2 to underwater aquatic plants ïBaking bread ïSingle cell protein

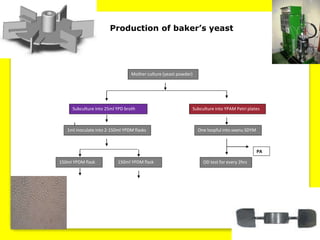

- 6. Mother culture (yeast powder) Production of bakerâs yeast Subculture into 25ml YPD broth Subculture into YPAM Petri plates 1ml inoculate into 2-150ml YPDM flasks One loopful into seenu SDYM 150ml YPDM flask 150ml YPDM flask PA OD test for every 2hrs

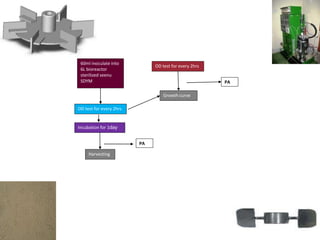

- 7. 60ml inoculate into 6L bioreactor sterilized seenu SDYM OD test for every 2hrs Growth curve OD test for every 2hrs Incubation for 1day Harvesting PA PA

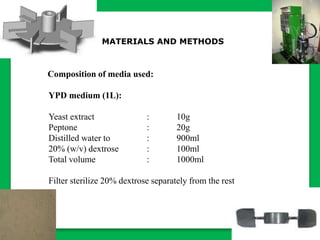

- 8. MATERIALS AND METHODS Composition of media used: YPD medium (1L): Yeast extract : 10g Peptone : 20g Distilled water to : 900ml 20% (w/v) dextrose : 100ml Total volume : 1000ml Filter sterilize 20% dextrose separately from the rest

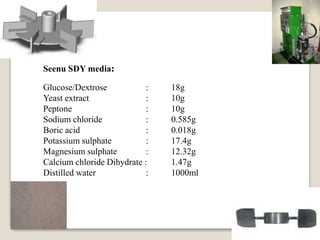

- 9. Glucose/Dextrose : 18g Yeast extract : 10g Peptone : 10g Sodium chloride : 0.585g Boric acid : 0.018g Potassium sulphate : 17.4g Magnesium sulphate : 12.32g Calcium chloride Dihydrate : 1.47g Distilled water : 1000ml Seenu SDY media:

- 10. Media formulation Media formulated as for following requirements- ïSelection of necessary ingredients ïLow cost ïEasily available ïminimum yield of undesired products ïminimal problems during media preparation and sterilization

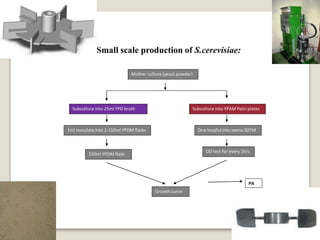

- 11. Small scale production of S.cerevisiae: Mother culture (yeast powder) Subculture into 25ml YPD broth Subculture into YPAM Petri plates 1ml inoculate into 2-150ml YPDM flasks One loopful into seenu SDYM 150ml YPDM flask OD test for every 2hrs Growth curve PA

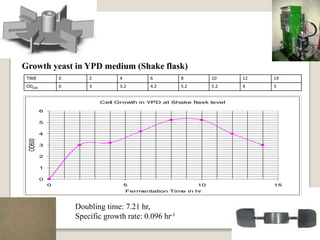

- 12. Growth yeast in YPD medium (Shake flask) Doubling time: 7.21 hr, Specific growth rate: 0.096 hr-1 TIME 0 2 4 6 8 10 12 14 OD600 0 3 3.2 4.2 5.2 5.2 4 3 Cell Growth in YPD at Shake flask level 0 1 2 3 4 5 6 0 5 10 15 Fermentation Time in hr OD600

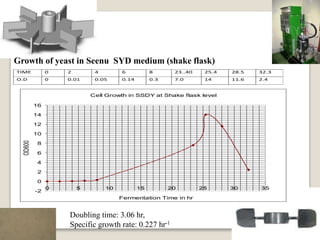

- 13. Growth of yeast in Seenu SYD medium (shake flask) TIME 0 2 4 6 8 23..40 25.4 28.5 32.3 O.D 0 0.01 0.05 0.14 0.3 7.0 14 11.6 2.4 Cell Growth in SSDY at Shake flask level -2 0 2 4 6 8 10 12 14 16 0 5 10 15 20 25 30 35 Fermentation Time in hr OD600 Doubling time: 3.06 hr, Specific growth rate: 0.227 hr-1

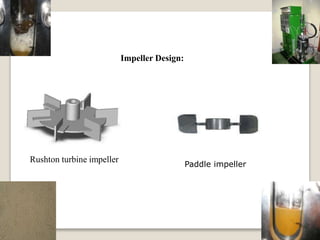

- 14. Impeller Design: Rushton turbine impeller Paddle impeller

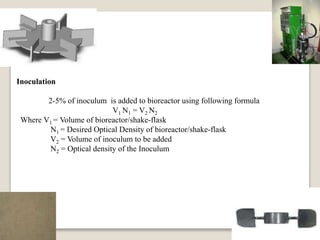

- 15. Inoculation 2-5% of inoculum is added to bioreactor using following formula V1 N1 = V2 N2 Where V1 = Volume of bioreactor/shake-flask N1 = Desired Optical Density of bioreactor/shake-flask V2 = Volume of inoculum to be added N2 = Optical density of the Inoculum

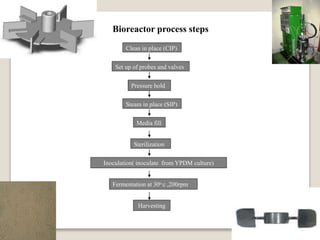

- 16. Bioreactor process steps Clean in place (CIP) Set up of probes and valves Pressure hold Steam in place (SIP) Media fill Sterilization Inoculation( inoculate from YPDM culture) Fermentation at 30o c ,200rpm Harvesting

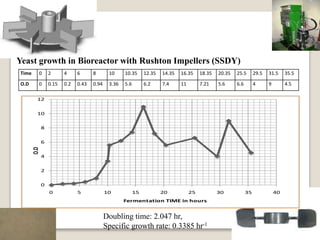

- 17. 0 2 4 6 8 10 12 0 5 10 15 20 25 30 35 40 O.D Fermentation TIME in hours Yeast growth in Bioreactor with Rushton Impellers (SSDY) Time 0 2 4 6 8 10 10.35 12.35 14.35 16.35 18.35 20.35 25.5 29.5 31.5 35.5 O.D 0 0.15 0.2 0.43 0.94 3.36 5.6 6.2 7.4 11 7.21 5.6 6.6 4 9 4.5 Doubling time: 2.047 hr, Specific growth rate: 0.3385 hr-1

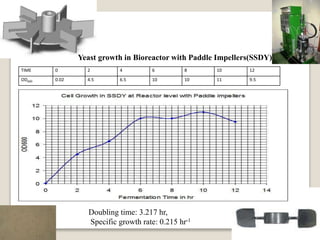

- 18. TIME 0 2 4 6 8 10 12 OD600 0.02 4.5 6.5 10 10 11 9.5 Yeast growth in Bioreactor with Paddle Impellers(SSDY) Doubling time: 3.217 hr, Specific growth rate: 0.215 hr-1

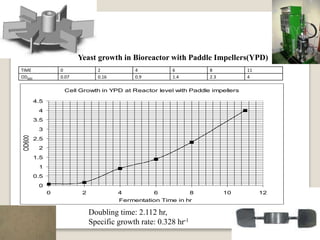

- 19. Yeast growth in Bioreactor with Paddle Impellers(YPD) Doubling time: 2.112 hr, Specific growth rate: 0.328 hr-1 TIME 0 2 4 6 8 11 OD600 0.07 0.16 0.9 1.4 2.3 4 Cell Growth in YPD at Reactor level with Paddle impellers 0 0.5 1 1.5 2 2.5 3 3.5 4 4.5 0 2 4 6 8 10 12 Fermentation Time in hr OD600

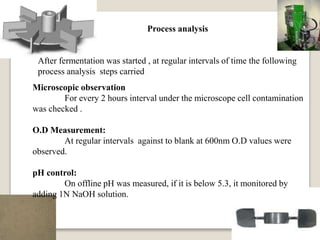

- 20. Process analysis After fermentation was started , at regular intervals of time the following process analysis steps carried Microscopic observation For every 2 hours interval under the microscope cell contamination was checked . O.D Measurement: At regular intervals against to blank at 600nm O.D values were observed. pH control: On offline pH was measured, if it is below 5.3, it monitored by adding 1N NaOH solution.

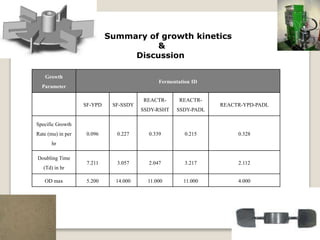

- 21. Summary of growth kinetics & Discussion Growth Parameter Fermentation ID SF-YPD SF-SSDY REACTR- SSDY-RSHT REACTR- SSDY-PADL REACTR-YPD-PADL Specific Growth Rate (mu) in per hr 0.096 0.227 0.339 0.215 0.328 Doubling Time (Td) in hr 7.211 3.057 2.047 3.217 2.112 OD max 5.200 14.000 11.000 11.000 4.000

- 22. CONCLUSIONS EFFECT OF MEDIA COMPOSITION: SSDY media was given more growth than YPD media EFFECT OF IMPELLER DESIGNE: Rushton Turbine impeller gave maximum cell density than Paddle impeller under same conditions EFFECT OF SCALE OF OPERATION: Cells doubled much faster in reactor (2.11 hrs) compared to shake flask (7.21 hrs)