Fmms Book Toc

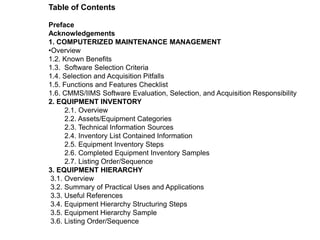

- 2. Table of Contents Preface Acknowledgements 1. COMPUTERIZED MAINTENANCE MANAGEMENT ŌĆóOverview 1.2. Known Benefits 1.3. Software Selection Criteria 1.4. Selection and Acquisition Pitfalls 1.5. Functions and Features Checklist 1.6. CMMS/IIMS Software Evaluation, Selection, and Acquisition Responsibility 2. EQUIPMENT INVENTORY 2.1. Overview 2.2. Assets/Equipment Categories 2.3. Technical Information Sources 2.4. Inventory List Contained Information 2.5. Equipment Inventory Steps 2.6. Completed Equipment Inventory Samples 2.7. Listing Order/Sequence 3. EQUIPMENT HIERARCHY 3.1. Overview 3.2. Summary of Practical Uses and Applications 3.3. Useful References 3.4. Equipment Hierarchy Structuring Steps 3.5. Equipment Hierarchy Sample 3.6. Listing Order/Sequence

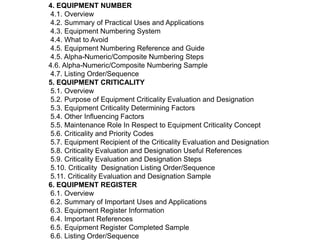

- 3. 4. EQUIPMENT NUMBER 4.1. Overview 4.2. Summary of Practical Uses and Applications 4.3. Equipment Numbering System 4.4. What to Avoid 4.5. Equipment Numbering Reference and Guide 4.5. Alpha-Numeric/Composite Numbering Steps 4.6. Alpha-Numeric/Composite Numbering Sample 4.7. Listing Order/Sequence 5. EQUIPMENT CRITICALITY 5.1. Overview 5.2. Purpose of Equipment Criticality Evaluation and Designation 5.3. Equipment Criticality Determining Factors 5.4. Other Influencing Factors 5.5. Maintenance Role In Respect to Equipment Criticality Concept 5.6. Criticality and Priority Codes 5.7. Equipment Recipient of the Criticality Evaluation and Designation 5.8. Criticality Evaluation and Designation Useful References 5.9. Criticality Evaluation and Designation Steps 5.10. Criticality Designation Listing Order/Sequence 5.11. Criticality Evaluation and Designation Sample 6. EQUIPMENT REGISTER 6.1. Overview 6.2. Summary of Important Uses and Applications 6.3. Equipment Register Information 6.4. Important References 6.5. Equipment Register Completed Sample 6.6. Listing Order/Sequence

- 4. 7. MAINTENANCE INSPECTION TASKS 7.1. Overview 7.2. Basic Elements of a Maintenance Inspection Task 7.3. Maintenance Tasks Delineation 7.4. Maintenance Tasks Economics 7.5. Maintenance Tasks Optimization Process 7.6. Maintenance Tasks Creation Fundamentals 7.7. Maintenance Tasks Writing Style 7.8. Sources and Providers of Maintenance Tasks Information 7.9. Important Reminder 7.10. Maintenance Tasks Analysis and Inventory Worksheet Samples 8. MAINTENANCE JOB CARD 8.1. Overview 8.2. Maintenance Job Card Information Fields 8.3. Maintenance Job Card Format 8.4. Maintenance Job Card Attachments 8.5. Attachment Samples 8.6. Maintenance Job Card Generation, Issuance, Execution, and Closure Process Flo 9. STANDARD TASK PROCEDURES 9.1. Overview 9.2. Basic Inclusions in the Standard Task Procedures 9.3. Standard Task Procedures Sourcing and Scoping Grounds 9.4. Standard Task Procedures Development Process 9.5. Standard Task Procedure Sample 9.6. Operations Standard Task Procedure Sample 9.7. Standard Task Procedure Attachments

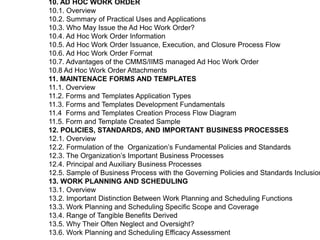

- 5. 10. AD HOC WORK ORDER 10.1. Overview 10.2. Summary of Practical Uses and Applications 10.3. Who May Issue the Ad Hoc Work Order? 10.4. Ad Hoc Work Order Information 10.5. Ad Hoc Work Order Issuance, Execution, and Closure Process Flow 10.6. Ad Hoc Work Order Format 10.7. Advantages of the CMMS/IIMS managed Ad Hoc Work Order 10.8 Ad Hoc Work Order Attachments 11. MAINTENACE FORMS AND TEMPLATES 11.1. Overview 11.2. Forms and Templates Application Types 11.3. Forms and Templates Development Fundamentals 11.4 Forms and Templates Creation Process Flow Diagram 11.5. Form and Template Created Sample 12. POLICIES, STANDARDS, AND IMPORTANT BUSINESS PROCESSES 12.1. Overview 12.2. Formulation of the OrganizationŌĆÖs Fundamental Policies and Standards 12.3. The OrganizationŌĆÖs Important Business Processes 12.4. Principal and Auxiliary Business Processes 12.5. Sample of Business Process with the Governing Policies and Standards Inclusion 13. WORK PLANNING AND SCHEDULING 13.1. Overview 13.2. Important Distinction Between Work Planning and Scheduling Functions 13.3. Work Planning and Scheduling Specific Scope and Coverage 13.4. Range of Tangible Benefits Derived 13.5. Why Their Often Neglect and Oversight? 13.6. Work Planning and Scheduling Efficacy Assessment

- 6. 13.7. Manning Composition 13.8.Required Competencies and Trainings 13.9. Work Planning and Scheduling Tools - of the - Trade 13.10. Work Planning and Scheduling Standard Procedure Sample 13.11. Daily Work Planning and Scheduling ŌĆō Coordination- Worksheet Sample 14. REPORTS 14.1. Overview 14.2. Essential Elements, Qualities, and Features 14.3. Operation and Maintenance (O&M) Reports 14.4. Important O&M and Lead Support GroupsŌĆÖ Reports 14.5. The CMMS/IIMS Distinct Edge 14.6. O&M Report Sample 15. O&M MANNING 15.1. Overview 15.2. Factors Influencing the O&M Organization Structuring Outcome 15.3. O&M Manning Estimation Modalities 15.4. Direct Man-Hours Estimation Sources and Bases 15.5. O&M Manning Bodies Estimation 15.6. Man-Hours Allocation and Utilization Ratio: PM/CM Over Ad Hoc Work Orders 15.7. O&M Organizational and Functional Chart 15.8. O&M Manning Deployment Strategy 15.9. Elements of Labor Economics 15.10. Pitfall to Avoid 16. MAINTENANCE AUDIT 16.1. Overview 16.2. Premier Role of Audit 16.3. Maintenance Audit Focal Objects and Allied Scopes

- 7. 16.4. Audit Practical Methodologies 16.5. Audit Organization 16.6. Audit Planning and Preparation 16.7. Audit Effort and Net-Effect Optimization 16.8. Applied Audit Tactic on Potential Variables and Virtual Constants 16.9. Audit Crediting system 16.10. The Importance of the Parallel audit Exercise with Other Lead Support Departments 16.11. Audit Decorum 17. MAINTENANCE INVENTORY MANAGEMENT 17.1. Overview 17.2. Inventory Control Objectives 17.3. Maintenance Inventory Problem Situations 17.4. Maintenance Inventory Program Development Role and Responsibility 17.5. Maintenance Inventory Control Standard 18. MAINTENANCE CHANGE MANAGEMENT 18.1. Overview 18.2. Change Impact 18.3. Types and Forms of Change Request 18.4. Change Management Business Process 18.5. Change Request Sample 18.6. Counterpart Engineering Change Management Afterword Glossary Index

- 8. About Me Efren G. Ma├▒ez A Mechanical Engineer by profession.I began my serious practice in facility maintenance in 1976.Since then I pursued only 2 major fields of discipline which are the facility maintenance and construction project management. My work mostly brought me to various South East Asian countries which also provided me the fine opportunity of doing close collaborative works with my foreign Asian/Western counterparts.In 1996,I permanently based myself in the Philippines to do freelance facility maintenance and construction project management work. Among my successful professional applications included the transports / construction equipment fleets; Brunei palace, luxury hotel/condominiums ,etc.Also the 2 major geothermal ŌĆōpower generation ŌĆōfacilities owned by a leading MNC where I worked (1998ŌĆō2005)as its main consultant for the overall development and oversight of its maintenance program.My work includes the conduct of lectures and seminars/workshops on O&M program development and implementation processes,audits,technical manning set-up etc. I authored the FACILITY MAINTENANCE MANAGEMENT SYSTEM guidebook -distributed nationwide by CENTRAL BOOKS (centralpod@gmail.com, tel.+632 3723550)