FUV CV

- 1. CURRICULUM VITAE OBJECTIVE: I am looking to get involved with a company that can offer upward mobility to those employees that prove their value by hard work and diligent effort. I would like to get more involved in the manufacturing field of this company as Mechanical Engineer. PERSONAL DETAILS: Name : Fermin U. Vosotros Profession : License Mechanical Engineer Marital Status : widower Email- ID : ferminvtrs@yahoo.com Mailing Address : Purok Red Leah, Acmac Iligan City Date of birth : November 22, 1959 Phone : Globe +639472446620 : STC +966554926010(Saudi, Riyadh) : +6309472446620 {roaming number) Nationality : Filipino EMPLOYMENT: November 22, 2011-present Riyadh Cement Corporation Kingdom of Saudi Arabia POSITION: Production Shift Supervisor  Directly accountable to the Department Manager  Primary responsible for directing, coordinating, supervising and controlling Kiln Line no.1 and Line no.2, Raw grinding mill Line no.1 and Line no.2 and Cement Mills Line no.1 and Line no.2 operations. a. Ensures that quality standards are met and that production output is within the Business Plan/budget. b. Conducts and performs routine inspection check in every shift of all equipment and auxiliaries, take note and records any abnormalities observed and immediately inform concerned department for immediate correction. c. Actively participates in Root cause analysis (RCA) together with other concern employees for all production and quality related problems, equipment/machinery breakdown including accidents, serious near miss and environmental incidents and ensures that action plans to prevent recurrence are effectively implemented. d. Records production output and makes Plant daily operation reports. Iligan Cement Corporation (Lafarge Philippines) Kiwalan, Iligan City A. POSITION: Cement Mill Shift Supervisor (2005-2008) Job Summary: This job is responsible for directing, coordinating, supervising and controlling Finish Mill grinding operations for both Finish Mill nos. 1 & 2 (ICC/MPCC) at the lowest possible cost and in accordance with the established specifications as to quantity and quality. This job specifically directs the activities of personnel in performing grinding of cement and maintenance works.

- 2. Typical Duties and Responsibilities: Within limits of established company policies, systems and procedures, this job is responsible for and has commensurate authority in carrying out the following: 1. Conducts Daily Safety Program in every start of each shift. Refer to Finish Mill Shift Supervisor’s Daily Safety Program. 2. Ensures that quality standards are met as to Blaine, residue and free lime, and that production output is within the Business Plan/Budget. 3. Prepares status report if necessary on failure of mechanical/electrical equipment and submits to the Finish Mill Manager for further action and disposition. 4. Arranges and initiates ball mill charging and ball grading, mill sounding, liners and diaphragm inspection and other related mill optimization works. 5. Performs other related duties as may be required by the position and/or as directed by superior. B. POSITION: Quarry / Crusher operations supervisor (1999-2005)  Accountable to the Motor pool /crusher and Quarry Manager  Primary responsible for directing, coordinating, supervising and controlling crusher and Quarry operations, a. Ensure availability of mobile equipment and Operators are conducting pre-operational inspection of the mobile prior to depart. b. Carry out survey to see that safe work method, health and safety requirements are being observed. c. Ensures that raw materials delivered met with quality standards and the productions outputs are within Business plan/budget. d. Records production outputs and make daily/weekly and monthly reports. e. Conducts and performs routine inspection check in every shift of all equipment and auxiliaries, take note and records any abnormalities observed and immediately inform concerned department for immediate correction. f. Plan/estimates drilling and blasting activity and ensure that safe work method are being observed C. POSITION: Production Process Supervisor ( 1998 – 1999 )  Directly accountable to the Department Manager  Primary responsible for directing, coordinating, supervising and controlling Kiln, Dryer, Raw grinding mill and Cooling tower operations. e. Ensures that quality standards are met and that production output is within the Business Plan/budget. f. Conducts and performs routine inspection check in every shift of all equipment and auxiliaries, take note and records any abnormalities observed and immediately inform concerned department for immediate correction. g. Actively participates in Root cause analysis (RCA) together with other concern employees for all production and quality related problems, equipment/machinery breakdown including accidents, serious near miss and environmental incidents and ensures that action plans to prevent recurrence are effectively implemented. h. Plans periodic long and short shutdown schedule, plans bricklaying activities, ensure availability of materials, spares parts of all equipment and auxiliaries, records production output and make daily, weekly and production output reports. D. POSITION: Kiln Operator ( 1989 – 1998 ) Job Summary: This job is responsible for operating Rotary Kiln including its auxiliaries to burn homogenized Raw Meal into cement clinker, maintaining optimum rates of kiln feed, complete fuel combustion and other variable factors to achieve desired clinker quantity, quality and full economy. These auxiliaries include AQC and its EP, Pre-heater, Kiln EP, CPAG Raw Meal Silos and Coal Plant.

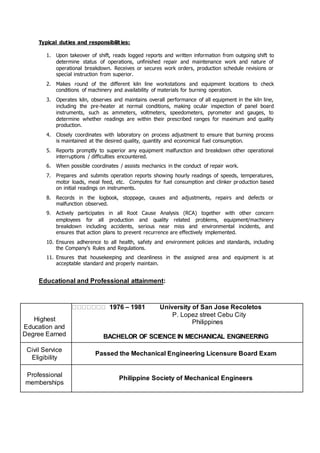

- 3. Typical duties and responsibilities: 1. Upon takeover of shift, reads logged reports and written information from outgoing shift to determine status of operations, unfinished repair and maintenance work and nature of operational breakdown. Receives or secures work orders, production schedule revisions or special instruction from superior. 2. Makes round of the different kiln line workstations and equipment locations to check conditions of machinery and availability of materials for burning operation. 3. Operates kiln, observes and maintains overall performance of all equipment in the kiln line, including the pre-heater at normal conditions, making ocular inspection of panel board instruments, such as ammeters, voltmeters, speedometers, pyrometer and gauges, to determine whether readings are within their prescribed ranges for maximum and quality production. 4. Closely coordinates with laboratory on process adjustment to ensure that burning process is maintained at the desired quality, quantity and economical fuel consumption. 5. Reports promptly to superior any equipment malfunction and breakdown other operational interruptions / difficulties encountered. 6. When possible coordinates / assists mechanics in the conduct of repair work. 7. Prepares and submits operation reports showing hourly readings of speeds, temperatures, motor loads, meal feed, etc. Computes for fuel consumption and clinker production based on initial readings on instruments. 8. Records in the logbook, stoppage, causes and adjustments, repairs and defects or malfunction observed. 9. Actively participates in all Root Cause Analysis (RCA) together with other concern employees for all production and quality related problems, equipment/machinery breakdown including accidents, serious near miss and environmental incidents, and ensures that action plans to prevent recurrence are effectively implemented. 10. Ensures adherence to all health, safety and environment policies and standards, including the Company’s Rules and Regulations. 11. Ensures that housekeeping and cleanliness in the assigned area and equipment is at acceptable standard and properly maintain. Educational and Professional attainment: Highest Education and Degree Earned – 1981 University of San Jose Recoletos P. Lopez street Cebu City Philippines BACHELOR OF SCIENCE IN MECHANICAL ENGINEERING Civil Service Eligibility Passed the Mechanical Engineering Licensure Board Exam Professional memberships Philippine Society of Mechanical Engineers

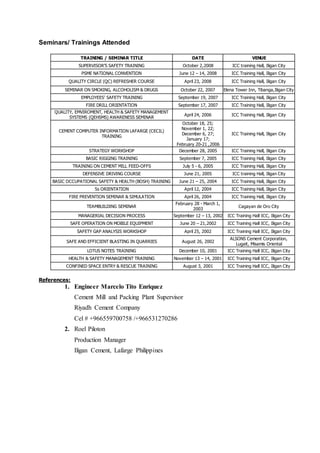

- 4. Seminars/ Trainings Attended TRAINING / SEMINAR TITLE DATE VENUE SUPERVISOR’S SAFETY TRAINING October 2,2008 ICC training Hall, Iligan City PSME NATIONAL CONVENTION June 12 – 14, 2008 ICC Training Hall, Iligan City QUALITY CIRCLE (QC) REFRESHER COURSE April 23, 2008 ICC Training Hall, Iligan City SEMINAR ON SMOKING, ALCOHOLISM & DRUGS October 22, 2007 Elena Tower Inn, Tibanga,Iligan City EMPLOYEES’ SAFETY TRAINING September 19, 2007 ICC Training Hall, Iligan City FIRE DRILL ORIENTATION September 17, 2007 ICC Training Hall, Iligan City QUALITY, EMVIROMENT, HEALTH & SAFETY MANAGEMENT SYSTEMS (QEHSMS) AWARENESS SEMINAR April 24, 2006 ICC Training Hall, Iligan City CEMENT COMPUTER INFORMATION LAFARGE (CECIL) TRAINING October 18, 25; November 1, 22; December 6, 27; January 17; February 20-21 ,2006 ICC Training Hall, Iligan City STRATEGY WORKSHOP December 28, 2005 ICC Training Hall, Iligan City BASIC RIGGING TRAINING September 7, 2005 ICC Training Hall, Iligan City TRAINING ON CEMENT MILL FEED-OFFS July 5 - 6, 2005 ICC Training Hall, Iligan City DEFENSIVE DRIVING COURSE June 21, 2005 ICC training Hall, Iligan City BASIC OCCUPATIONAL SAFETY & HEALTH (BOSH) TRAINING June 21 – 25, 2004 ICC Training Hall, Iligan City 5s ORIENTATION April 12, 2004 ICC Training Hall, Iligan City FIRE PREVENTION SEMINAR & SIMULATION April 26, 2004 ICC Training Hall, Iligan City TEAMBUILDING SEMINAR February 28 - March 1, 2003 Cagayan de Oro City MANAGERIAL DECISION PROCESS September 12 – 13, 2002 ICC Training Hall ICC, Iligan City SAFE OPERATION ON MOBILE EQUIPMENT June 20 – 21,2002 ICC Training Hall ICC, Iligan City SAFETY GAP ANALYSIS WORKSHOP April 25, 2002 ICC Training Hall ICC, Iligan City SAFE AND EFFICIENT BLASTING IN QUARRIES August 26, 2002 ALSONS Cement Corporation, Lugait, Misamis Oriental LOTUS NOTES TRAINING December 10, 2001 ICC Training Hall ICC, Iligan City HEALTH & SAFETY MANAGEMENT TRAINING November 13 – 14, 2001 ICC Training Hall ICC, Iligan City CONFINED SPACE ENTRY & RESCUE TRAINING August 3, 2001 ICC Training Hall ICC, Iligan City References: 1. Engineer Marcelo Tito Enriquez Cement Mill and Packing Plant Supervisor Riyadh Cement Company Cel # +966559700758 /+966531270286 2. Roel Piloton Production Manager Iligan Cement, Lafarge Philippines

![CV latest[256478]](https://cdn.slidesharecdn.com/ss_thumbnails/94248987-39fc-495a-8c4e-4c9bb24883d5-160924055856-thumbnail.jpg?width=560&fit=bounds)