1 of 1

Download to read offline

Ad

Recommended

DAC Annexair Composite Panel 2-2013

DAC Annexair Composite Panel 2-2013DAC Sales

╠²

The document describes a new Thermo-Composite unit for rooftops that features thermal-break panel and framing construction for improved insulation and resistance to corrosion. It has a foam core panel with recycled content that is lightweight yet fire resistant. The unit uses extruded aluminum profiles only on the perimeter for a hygienic construction. It provides advantages over standard units like lighter weight, lifetime warranty against corrosion, and no possibility of rusting or sweating. The unit also features improved electrical components and piping for water source heat pumps.DAC Annexair Overview 2-2013

DAC Annexair Overview 2-2013DAC Sales

╠²

This document discusses new innovations in rooftop units, including variable speed compressor technology, V3 technology, and a new thermo-composite unit. Variable speed compressors provide higher efficiency at part loads and eliminate hot gas bypass. V3 technology uses variable speed compressors and condenser fans for even greater efficiency. A new thermo-composite unit features a lightweight insulated panel construction for improved performance and lifecycle costs. Examples of completed projects utilizing these technologies are also provided.Aluminium composite panels(acp)

Aluminium composite panels(acp)Parivesh Sharma

╠²

Aluminium composite panels (ACPs) consist of two thin aluminium sheets bonded to a non-aluminium core. ACPs have benefits over other panel materials like being lightweight, durable, and able to be painted in a wide range of colors. They are commonly used for building exteriors and interiors, signage, ceilings, and more. ACPs offer advantages like beauty, affordability, ease of installation, weather resistance, and low maintenance. Famous structures that have used ACPs include SpaceShip Earth and the German National Library due to ACPs' cost-effectiveness, durability, and design flexibility.Ma╠üy trie╠é╠üt ro╠üt tu╠ø╠Ż ─æo╠Ż╠éng yg4

Ma╠üy trie╠é╠üt ro╠üt tu╠ø╠Ż ─æo╠Ż╠éng yg4Stock company Hoa Viet

╠²

M├Īy chiß║┐t r├│t tß╗▒ ─æß╗Öng YG4/1 c├│ chß╗®c n─āng chuyß╗ān lß╗Ź, ─æ├│ng nß║»p v├Ā xß║┐p lß╗Ź vß╗øi n─āng suß║źt tß╗½ 30 ─æß║┐n 60 lß╗Ź/ph├║t t├╣y thuß╗Öc v├Āo dung t├Łch. Thiß║┐t bß╗ŗ t├Łch hß╗Żp c├Īc t├Łnh n─āng nhŲ░ bß║Żng ─æiß╗üu khiß╗ān cß║Żm ß╗®ng, tß╗▒ ─æß╗Öng dß╗½ng khi hß║┐t lß╗Ź, v├Ā ─æiß╗üu chß╗ēnh lß╗▒c vß║Ęn nß║»p ─æß╗ā ─æß║Żm bß║Żo ─æß╗Ö chß║Ęt. Vß╗ü linh kiß╗ćn, m├Īy sß╗Ł dß╗źng nhiß╗üu bß╗Ö phß║Łn chß║źt lŲ░ß╗Żng tß╗½ c├Īc nh├Ā sß║Żn xuß║źt nß╗Ģi tiß║┐ng ß╗¤ Trung Quß╗æc, Nhß║Łt Bß║Żn v├Ā ─É├Āi Loan.M├Īy ru╠ø╠ēa chai lo╠Ż tu╠ø╠Ż ─æo╠Ż╠éng

M├Īy ru╠ø╠ēa chai lo╠Ż tu╠ø╠Ż ─æo╠Ż╠éngStock company Hoa Viet

╠²

M├Īy rß╗Ła chai lß╗Ź tß╗▒ ─æß╗Öng ghp-0210 c├│ khß║Ż n─āng rß╗Ła nhiß╗üu loß║Īi lß╗Ź vß╗øi h├¼nh dß║Īng ─æa dß║Īng, th├Łch hß╗Żp cho doanh nghiß╗ćp sß║Żn xuß║źt rŲ░ß╗Żu. Thiß║┐t bß╗ŗ hoß║Īt ─æß╗Öng vß╗øi n─āng suß║źt 2000 lß╗Ź/h v├Ā ─æŲ░ß╗Żc trang bß╗ŗ nhiß╗üu bß╗Ö phß║Łn hiß╗ćn ─æß║Īi ─æß╗ā tß╗æi Ų░u h├│a quy tr├¼nh rß╗Ła. Ngo├Āi ra, m├Īy c├▓n t├Łch hß╗Żp hß╗ć thß╗æng ─æiß╗üu khiß╗ān PLC v├Ā m├Ān h├¼nh cß║Żm ß╗®ng cho trß║Żi nghiß╗ćm sß╗Ł dß╗źng dß╗ģ d├Āng.Tu╠ē sa╠é╠üy chai lo╠Ż hai cu╠ø╠ēa ─æo╠éi ct

Tu╠ē sa╠é╠üy chai lo╠Ż hai cu╠ø╠ēa ─æo╠éi ctStock company Hoa Viet

╠²

Tß╗¦ sß║źy chai lß╗Ź hai cß╗Ła ─æ├┤i CT-C-I l├Ā thiß║┐t bß╗ŗ sß║źy kh├┤ v├Ā diß╗ćt khuß║®n hiß╗ću quß║Ż, thiß║┐t kß║┐ theo ti├¬u chuß║®n GMP. Thiß║┐t bß╗ŗ sß╗Ł dß╗źng phŲ░ŲĪng ph├Īp th├┤ng gi├│ tuß║¦n ho├Ān, vß╗øi khß║Ż n─āng sß║źy tß╗æi ─æa 120 kg/lß║¦n v├Ā phß║Īm vi nhiß╗ćt ─æß╗Ö tß╗½ nhiß╗ćt ─æß╗Ö ph├▓ng ─æß║┐n 180 ─æß╗Ö C. Tß╗¦ c├│ k├Łch thŲ░ß╗øc khoang sß║źy 705├Ś950├Ś1400 mm v├Ā t├Łch hß╗Żp nhiß╗üu t├Łnh n─āng nhŲ░ ─æiß╗üu khiß╗ān nhiß╗ćt ─æß╗Ö th├┤ng minh.Ma╠üy thu╠ø╠ē ─æo╠Ż╠é ki╠ün cu╠ēa thuo╠é╠üc mfy1

Ma╠üy thu╠ø╠ē ─æo╠Ż╠é ki╠ün cu╠ēa thuo╠é╠üc mfy1Stock company Hoa Viet

╠²

M├Īy thß╗Ł ─æß╗Ö k├Łn MFY-01 l├Ā thiß║┐t bß╗ŗ kiß╗ām tra ─æß╗Ö k├Łn cß╗¦a c├Īc sß║Żn phß║®m ─æ├│ng g├│i nhŲ░ t├║i, chai v├Ā ß╗æng trong c├Īc ng├Ānh thß╗▒c phß║®m, dŲ░ß╗Żc phß║®m v├Ā y tß║┐. Thiß║┐t bß╗ŗ sß╗Ł dß╗źng hß╗ć thß╗æng c├Āi ─æß║Ęt sß╗æ ho├Ī, c├│ t├Łnh n─āng tß╗▒ ─æß╗Öng duy tr├¼ ├Īp suß║źt v├Ā hß╗Ś trß╗Ż qu├Ī tr├¼nh th├Ł nghiß╗ćm bß║▒ng phß║¦n mß╗üm chuy├¬n dß╗źng. N├│ hoß║Īt ─æß╗Öng dß╗▒a tr├¬n nguy├¬n l├Į tß║Īo ├Īp suß║źt kh├Īc biß╗ćt ─æß╗ā kiß╗ām tra t├Łnh n─āng ─æ├│ng k├Łn cß╗¦a mß║½u thß╗Ł.Tu╠ē sa╠é╠üy ti╠ānh 1 cu╠ø╠ēa ─æo╠éi ct c-i

Tu╠ē sa╠é╠üy ti╠ānh 1 cu╠ø╠ēa ─æo╠éi ct c-iStock company Hoa Viet

╠²

Tß╗¦ sß║źy t─®nh mß╗Öt cß╗Ła ─æ├┤i CT-C-I l├Ā thiß║┐t bß╗ŗ sß║źy kh├┤ ─æŲ░ß╗Żc thiß║┐t kß║┐ theo ti├¬u chuß║®n GMP, ph├╣ hß╗Żp cho sß║źy kh├┤ v├Ā diß╗ćt khuß║®n c├Īc loß║Īi nguy├¬n liß╗ću v├Ā thuß╗æc. Thiß║┐t bß╗ŗ n├Āy c├│ hß╗ć thß╗æng quß║Īt gi├│ th├┤ng minh, qu├Ī tr├¼nh ─æiß╗üu chß╗ēnh nhiß╗ćt ─æß╗Ö ß╗Ģn ─æß╗ŗnh v├Ā hai khoang sß║źy, c├╣ng nhiß╗üu t├Łnh n─āng kh├Īc gi├║p ─æß║Żm bß║Żo hiß╗ću quß║Ż v├Ā an to├Ān trong qu├Ī tr├¼nh sß║źy. C├Īc th├┤ng sß╗æ kß╗╣ thuß║Łt nhŲ░ c├┤ng suß║źt, k├Łch thŲ░ß╗øc v├Ā vß║Łt liß╗ću ─æŲ░ß╗Żc chß╗ē r├Ą ─æß╗ā ─æ├Īp ß╗®ng nhu cß║¦u sß╗Ł dß╗źng.No╠é╠Ći na╠é╠üu ho╠é╠Ć kf 50 l

No╠é╠Ći na╠é╠üu ho╠é╠Ć kf 50 lStock company Hoa Viet

╠²

Nß╗ōi nß║źu hß╗ō KF-50L c├│ dung t├Łch 50L, ├Īp lß╗▒c hoß║Īt ─æß╗Öng Ōēż0.25mpa, v├Ā sß╗Ł dß╗źng phŲ░ŲĪng thß╗®c gia nhiß╗ćt bß║▒ng hŲĪi ─æß╗ā ─æun n├│ng c├Īc nguy├¬n liß╗ću dß║Īng lß╗Ång, chß╗¦ yß║┐u trong sß║Żn xuß║źt thuß╗æc, thß╗▒c phß║®m v├Ā h├│a chß║źt. Thiß║┐t bß╗ŗ bao gß╗ōm nhiß╗üu bß╗Ö phß║Łn chß║źt lŲ░ß╗Żng cao, ─æŲ░ß╗Żc sß║Żn xuß║źt tß╗½ inox 304, c├│ khß║Ż n─āng xoay 180 ─æß╗Ö v├Ā t├Łch hß╗Żp hß╗ć thß╗æng ─æiß╗üu khiß╗ān th├┤ng minh. C├┤ng suß║źt m├Īy trß╗Ön l├Ā 0.75kw v├Ā tß╗æc ─æß╗Ö trß╗Ön c├│ thß╗ā ─æiß╗üu chß╗ēnh tß╗½ 8 ─æß║┐n 40 v├▓ng/ph├║t.No╠é╠Ći bao ho╠ø╠ē byc 800

No╠é╠Ći bao ho╠ø╠ē byc 800Stock company Hoa Viet

╠²

M├Īy bao vi├¬n BYC-800 l├Ā thiß║┐t bß╗ŗ d├╣ng ─æß╗ā bao vi├¬n thuß╗æc v├Ā thß╗▒c phß║®m, vß╗øi Ų░u ─æiß╗ām dß╗ģ thao t├Īc v├Ā tiß║┐t kiß╗ćm phß╗ź liß╗ću. N├│ sß╗Ł dß╗źng c├┤ng nghß╗ć phun sŲ░ŲĪng v├Ā ─æiß╗üu chß╗ēnh nhiß╗ćt ─æß╗ā tß║Īo ra lß╗øp vß╗Å mß╗ŗn m├Āng cho vi├¬n thuß╗æc, ─æß╗ōng thß╗Øi c├│ khß║Ż n─āng sß║Żn xuß║źt 30-50 kg mß╗Śi lß║¦n. Thiß║┐t bß╗ŗ bao gß╗ōm nhiß╗üu th├Ānh phß║¦n nhŲ░ m├Īy chß╗¦, hß╗ć thß╗æng ─æiß╗üu chß╗ēnh nhiß╗ćt v├Ā s├║ng phun, ph├╣ hß╗Żp vß╗øi nhiß╗üu y├¬u cß║¦u kh├Īc nhau cß╗¦a kh├Īch h├Āng.No╠é╠Ći bao ho╠ø╠ē by800 1000

No╠é╠Ći bao ho╠ø╠ē by800 1000Stock company Hoa Viet

╠²

Nß╗ōi bao hß╗¤ BY-800/1000 l├Ā thiß║┐t bß╗ŗ ─æŲĪn giß║Żn, dß╗ģ bß║Żo tr├¼, l├Į tŲ░ß╗¤ng cho viß╗ćc bao vi├¬n trong sß║Żn xuß║źt thuß╗æc v├Ā thß╗▒c phß║®m, ─æ├Īp ß╗®ng ti├¬u chuß║®n GMP. Thiß║┐t bß╗ŗ n├Āy c├│ hai phi├¬n bß║Żn vß╗øi ─æŲ░ß╗Øng k├Łnh 800mm v├Ā 1000mm, n─āng suß║źt tß╗½ 30-70 kg/lß║¦n, vß╗øi khß║Ż n─āng bao v├Ā ─æ├Īnh b├│ng vi├¬n, hß║Īt hiß╗ću quß║Ż. N├│ gi├║p tß║Īo ra sß║Żn phß║®m c├│ bß╗ü ngo├Āi hß║źp dß║½n, chß╗æng ├┤xi h├│a v├Ā ß║®m Ų░ß╗øt.Ma╠üy sa╠üt ha╠Żt la╠å╠üc yk160

Ma╠üy sa╠üt ha╠Żt la╠å╠üc yk160Stock company Hoa Viet

╠²

M├Īy s├Īt hß║Īt lß║»c YK160 ─æŲ░ß╗Żc sß╗Ł dß╗źng ─æß╗ā nghiß╗ün hß╗Śn hß╗Żp th├Ānh hß║Īt trong c├Īc ng├Ānh thuß╗æc, h├│a chß║źt, thß╗▒c phß║®m, gß╗æm sß╗® v├Ā nhß╗▒a. N├│ hoß║Īt ─æß╗Öng bß║▒ng c├Īch rung lß║»c ß╗æng l─ān, cho n─āng suß║źt 200~300kg/h vß╗øi c├┤ng suß║źt ─æß╗Öng cŲĪ 2.2kw. Tß║źt cß║Ż bß╗Ö phß║Łn tiß║┐p x├║c ─æß╗üu l├Ām bß║▒ng inox SUS304 v├Ā m├Īy c├│ k├Łch thŲ░ß╗øc 950*750*1240 mm.Ma╠üy sa╠Ćng rung xzs

Ma╠üy sa╠Ćng rung xzsStock company Hoa Viet

╠²

M├Īy s├Āng rung XZS l├Ā thiß║┐t bß╗ŗ hiß╗ćn ─æß║Īi sß╗Ł dß╗źng c├┤ng nghß╗ć ti├¬n tiß║┐n vß╗øi chß║źt liß╗ću inox v├Ā bß╗Ö phß║Łn chß╗æng rung bß║▒ng cao su, gi├║p giß║Żm tiß║┐ng ß╗ōn v├Ā tiß║┐t kiß╗ćm ─æiß╗ćn n─āng. N├│ ─æŲ░ß╗Żc thiß║┐t kß║┐ ─æß╗ā s├Āng lß╗Źc c├Īc vß║Łt liß╗ću dß║Īng hß║Īt v├Ā bß╗Öt trong c├Īc ng├Ānh y dŲ░ß╗Żc, thß╗▒c phß║®m v├Ā h├│a chß║źt, ─æ├Īp ß╗®ng ti├¬u chuß║®n GMP. Thiß║┐t bß╗ŗ c├│ hiß╗ću suß║źt cao, dß╗ģ d├Āng bß║Żo tr├¼ v├Ā ─æŲ░ß╗Żc ngŲ░ß╗Øi ti├¬u d├╣ng ─æ├Īnh gi├Ī cao sau khi ra mß║»t thß╗ŗ trŲ░ß╗Øng.Ma╠üy pha di╠Żch (xay keo) jm 130

Ma╠üy pha di╠Żch (xay keo) jm 130Stock company Hoa Viet

╠²

M├Īy pha dß╗ŗch JM-130 hoß║Īt ─æß╗Öng dß╗▒a tr├¬n nguy├¬n l├Į lß╗▒c cß║»t v├Ā ma s├Īt, nghiß╗ün nhß╗Å c├Īc nguy├¬n liß╗ću lß╗Ång hoß║Ęc sß╗ćt ─æß╗ā tß║Īo ra sß║Żn phß║®m ho├Ān thiß╗ćn. M├Īy c├│ nhiß╗üu cß║źu tr├║c v├Ā linh kiß╗ćn bß║▒ng inox, ─æŲ░ß╗Żc sß╗Ł dß╗źng trong nhiß╗üu ng├Ānh c├┤ng nghiß╗ćp nhŲ░ thß╗▒c phß║®m, h├│a chß║źt, y dŲ░ß╗Żc v├Ā mß╗╣ phß║®m. C├Īc th├┤ng sß╗æ kß╗╣ thuß║Łt cho thß║źy hai model JM-130 v├Ā JM-85 vß╗øi c├┤ng suß║źt v├Ā sß║Żn lŲ░ß╗Żng kh├Īc nhau, ph├╣ hß╗Żp vß╗øi nhu cß║¦u sß║Żn xuß║źt.Ma╠üy nha╠Ćo hai tru╠Żc sch 200 l

Ma╠üy nha╠Ćo hai tru╠Żc sch 200 lStock company Hoa Viet

╠²

M├Īy nh├Āo hai trß╗źc SCH-200L c├│ dung t├Łch 200L, c├┤ng suß║źt trß╗Ön 5.5kw v├Ā vß║Łn tß╗æc trß╗Ön 24 v├▓ng/ph├║t, ─æŲ░ß╗Żc sß╗Ł dß╗źng ─æß╗ā trß╗Ön ─æß╗üu c├Īc nguy├¬n liß╗ću dß║Īng bß╗Öt, Ų░ß╗øt v├Ā cao trong ng├Ānh thß╗▒c phß║®m v├Ā dŲ░ß╗Żc phß║®m. Thiß║┐t kß║┐ cß╗¦a m├Īy bao gß╗ōm th├ón h├¼nh chß╗» W, trß╗źc trß╗Ön linh hoß║Īt, v├Ā hß╗ć thß╗æng ─æ├│ng k├Łn hiß╗ću quß║Ż ─æß╗ā tr├Īnh ├┤ nhiß╗ģm, trong khi bß╗Ö ─æiß╗üu khiß╗ān ─æiß╗ćn cho ph├®p t├╣y chß╗ēnh thß╗Øi gian v├Ā g├│c ─æß╗Ģ nguy├¬n liß╗ću. Vß║Łt liß╗ću chß║┐ tß║Īo gß╗ōm inox chß║źt lŲ░ß╗Żng cao v├Ā th├®p cŲ░ß╗Øng lß╗▒c, ─æß║Żm bß║Żo ─æß╗Ö bß╗ün v├Ā hiß╗ću suß║źt l├Ām viß╗ćc ß╗Ģn ─æß╗ŗnh.May dong nang tu dong njp 1200

May dong nang tu dong njp 1200Stock company Hoa Viet

╠²

M├Īy ─æ├│ng vi├¬n nang tß╗▒ ─æß╗Öng NJP-1200 l├Ā thiß║┐t bß╗ŗ ─æ├│ng c├Īc loß║Īi bß╗Öt, hß║Īt hoß║Ęc vi├¬n nhß╗Å v├Āo trong vß╗Å nang trß╗æng vß╗øi khß║Ż n─āng tß╗▒ ─æß╗Öng ho├Ān th├Ānh c├Īc kh├óu chuyß╗ān nang, ph├ón nang v├Ā ─æ├│ng thuß╗æc. Thiß║┐t bß╗ŗ c├│ thiß║┐t kß║┐ cß║Żi tiß║┐n ─æß║Żm bß║Żo ─æß╗Ö ch├Łnh x├Īc v├Ā an to├Ān, vß╗øi c├┤ng suß║źt sß║Żn xuß║źt 72,000 vi├¬n/h v├Ā sai sß╗æ trong khoß║Żng ┬▒3.5%. NJP-1200 th├Łch hß╗Żp cho viß╗ćc ─æ├│ng vi├¬n c├Īc sß║Żn phß║®m thuß╗æc ─æ├┤ng y v├Ā t├óy y, l├Ā lß╗▒a chß╗Źn l├Į tŲ░ß╗¤ng cho c├Īc nh├Ā m├Īy sß║Żn xuß║źt vi├¬n nang cß╗®ng.Ma╠üy ─æo╠üng tu╠üi thuo╠é╠üc bo╠Ż╠ét dxdf60 d

Ma╠üy ─æo╠üng tu╠üi thuo╠é╠üc bo╠Ż╠ét dxdf60 dStock company Hoa Viet

╠²

M├Īy ─æ├│ng t├║i thuß╗æc bß╗Öt DXDF60E c├│ cß║źu tr├║c dß║Łp 4 m├®p vß╗øi t├Łnh n─āng hiß╗ān thß╗ŗ ─æa ng├┤n ngß╗» v├Ā ─æiß╗üu khiß╗ān th├┤ng minh gi├║p tß╗▒ ─æß╗Öng dß╗½ng khi c├│ sß╗▒ cß╗æ. N├│ c├│ khß║Ż n─āng ─æiß╗üu chß╗ēnh nhiß╗ćt ─æß╗Ö, tß╗æc ─æß╗Ö ─æ├│ng g├│i tß╗½ 40-60 t├║i/ph├║t v├Ā dß╗ģ d├Āng thay ─æß╗Ģi k├Łch thŲ░ß╗øc t├║i. Thiß║┐t bß╗ŗ bao gß╗ōm nhiß╗üu bß╗Ö phß║Łn ─æŲ░ß╗Żc sß║Żn xuß║źt tß╗½ c├Īc nh├Ā cung cß║źp uy t├Łn, ─æß║Żm bß║Żo hiß╗ću quß║Ż c├┤ng viß╗ćc v├Ā khß║Ż n─āng bß║Żo tr├¼ tß╗æt.Ma╠üy ─æo╠üng nang tu╠ø╠Ż ─æo╠Ż╠éng njp 400

Ma╠üy ─æo╠üng nang tu╠ø╠Ż ─æo╠Ż╠éng njp 400Stock company Hoa Viet

╠²

M├Īy ─æ├│ng nang tß╗▒ ─æß╗Öng NJP-400 c├│ ─æß║Ęc ─æiß╗ām tiß║┐t kiß╗ćm n─āng lŲ░ß╗Żng, dß╗ģ d├Āng l├Ām sß║Īch v├Ā ─æŲ░ß╗Żc sß╗Ł dß╗źng rß╗Öng r├Żi tß║Īi Trung Quß╗æc. Thiß║┐t bß╗ŗ sß╗Ł dß╗źng c├┤ng nghß╗ć ti├¬n tiß║┐n tß╗½ Siemens, vß╗øi khß║Ż n─āng tß╗▒ ─æß╗Öng dß╗½ng khi thiß║┐u nguy├¬n liß╗ću v├Ā hiß╗ān thß╗ŗ th├┤ng tin vß╗ü sß║Żn lŲ░ß╗Żng. Th├┤ng sß╗æ kß╗╣ thuß║Łt bao gß╗ōm sß║Żn lŲ░ß╗Żng 400 hß║Īt/ph├║t v├Ā tß╗Ģng c├┤ng suß║źt 3.32kw.Ma╠üy ─æo╠üng nang ba╠ün tu╠ø╠Ż ─æo╠Ż╠éng

Ma╠üy ─æo╠üng nang ba╠ün tu╠ø╠Ż ─æo╠Ż╠éngStock company Hoa Viet

╠²

M├Īy ─æ├│ng nang b├Īn tß╗▒ ─æß╗Öng sß╗Ł dß╗źng chuyß╗ān ─æß╗Öng giß╗»a b├Īnh r─āng ─æß╗ā nghiß╗ün nguy├¬n liß╗ću th├Ānh vß╗źn, ─æß╗ōng thß╗Øi thu hß╗ōi bß╗źi qua t├║i vß║Żi. Thiß║┐t bß╗ŗ ─æß║Īt ti├¬u chuß║®n GMP, ─æŲ░ß╗Żc chß║┐ tß║Īo tß╗½ inox v├Ā ph├╣ hß╗Żp vß╗øi nhiß╗üu loß║Īi vi├¬n nang, vß╗øi n─āng suß║źt tß╗½ 10-20.000 vi├¬n/ph├║t. C├Īc th├┤ng sß╗æ kß╗╣ thuß║Łt ch├Łnh bao gß╗ōm tß╗Ģng c├┤ng suß║źt 3.31kw v├Ā k├Łch thŲ░ß╗øc 1890├Ś880├Ś1700mm.Ma╠üy ─æe╠é╠üm vie╠én tcc 8 h

Máy đếm viên tcc 8 hStock company Hoa Viet

╠²

M├Īy ─æß║┐m vi├¬n ─æiß╗ćn tß╗Ł TCC-8 l├Ā thiß║┐t bß╗ŗ ─æß║┐m vi├¬n ─æ├│ng lß╗Ź tß╗▒ ─æß╗Öng, sß╗Ł dß╗źng c├┤ng nghß╗ć vi m├Īy t├Łnh v├Ā hß╗ć thß╗æng rung ─æß╗ā ─æŲ░a nguy├¬n liß╗ću v├Āo vß╗øi ─æß╗Ö ch├Łnh x├Īc cao. Thiß║┐t bß╗ŗ th├Łch hß╗Żp cho nhiß╗üu loß║Īi thuß╗æc vi├¬n v├Ā hß║Īt giß╗æng n├┤ng sß║Żn, vß╗øi tß╗æc ─æß╗Ö ─æß║┐m l├¬n tß╗øi 4000 vi├¬n/ph├║t v├Ā dß╗ģ d├Āng thao t├Īc nhß╗Ø giao diß╗ćn th├ón thiß╗ćn. N├│ c├│ k├Łch thŲ░ß╗øc nhß╗Å gß╗Źn v├Ā nhiß╗üu t├Łnh n─āng bß║Żo vß╗ć nhŲ░ cß║Żnh b├Īo sß╗▒ cß╗æ v├Ā tß╗▒ ─æß╗Öng dß╗½ng m├Īy khi hß║┐t lß╗Ź.Ma╠üy bao vie╠én bo╠Żc ─æu╠øo╠ø╠Ćng bg75

Ma╠üy bao vie╠én bo╠Żc ─æu╠øo╠ø╠Ćng bg75Stock company Hoa Viet

╠²

M├Īy bao vi├¬n bß╗Źc ─æŲ░ß╗Øng BG75 ─æŲ░ß╗Żc sß╗Ł dß╗źng trong sß║Żn xuß║źt thuß╗æc v├Ā thß╗▒c phß║®m, c├│ hiß╗ću suß║źt cao v├Ā an to├Ān, vß╗øi nhiß╗üu t├Łnh n─āng tß╗▒ ─æß╗Öng. To├Ān bß╗Ö qu├Ī tr├¼nh bao vi├¬n ─æŲ░ß╗Żc ─æiß╗üu khiß╗ān bß║▒ng hß╗ć thß╗æng m├Īy t├Łnh, ─æß║Żm bß║Żo kh├┤ng c├│ bß╗źi v├Ā chß║źt lß╗Ång bß║»n l├¬n. Thiß║┐t bß╗ŗ n├Āy c├▓n c├│ khß║Ż n─āng bao vi├¬n li├¬n tß╗źc, tiß║┐t kiß╗ćm thß╗Øi gian v├Ā n─āng lŲ░ß╗Żng.Lß╗▒a chß╗Źn HAVC

Lß╗▒a chß╗Źn HAVCStock company Hoa Viet

╠²

This document provides an overview and objectives of a training module on heating, ventilation and air conditioning (HVAC) systems for pharmaceutical manufacturing facilities. It discusses various HVAC design considerations and components including air filtration levels, airflow patterns, temperature and humidity control, dust control, and protecting the environment from exhaust air and fumes. The role of HVAC in preventing cross-contamination between production areas is also covered.So s├Īnh Asian GMP v├Ā WHO GMP

So s├Īnh Asian GMP v├Ā WHO GMPStock company Hoa Viet

╠²

T├Āi liß╗ću so s├Īnh c├Īc ─æiß╗ām tŲ░ŲĪng ─æß╗ōng v├Ā kh├Īc biß╗ćt giß╗»a WHO GMP v├Ā ASEAN GMP, n├¬u r├Ą y├¬u cß║¦u vß╗ü nh├ón sß╗▒, cŲĪ sß╗¤ sß║Żn xuß║źt, thiß║┐t bß╗ŗ v├Ā quy tr├¼nh li├¬n quan ─æß║┐n chß║źt lŲ░ß╗Żng trong ng├Ānh dŲ░ß╗Żc. WHO GMP cung cß║źp c├Īc hŲ░ß╗øng dß║½n chi tiß║┐t hŲĪn v├Ā quy tr├¼nh tß╗▒ thanh tra nghi├¬m ngß║Ęt hŲĪn so vß╗øi ASEAN GMP. T├Āi liß╗ću c┼®ng nhß║źn mß║Īnh sß╗▒ cß║¦n thiß║┐t phß║Żi tu├ón thß╗¦ quy ─æß╗ŗnh cß╗¦a WHO ─æß╗ā ─æß║Żm bß║Żo giß║źy chß╗®ng nhß║Łn GMP c├│ gi├Ī trß╗ŗ quß╗æc tß║┐.Clean room standards

Clean room standardsStock company Hoa Viet

╠²

This document discusses different standards for classifying cleanrooms according to airborne particle concentrations. It describes the obsolete Federal Standard 209 classification system used in the US which categorizes cleanrooms from Class 1 to Class 10,000 based on particle counts per cubic foot. It then outlines the ISO 14644 international cleanroom standards which use particle counts per cubic meter and have classifications from ISO 1 to ISO 9. The document provides tables comparing particle concentration limits between the two systems. It also discusses pharmaceutical cleanroom classifications used in the European Union and US which are based on maximum permitted particle counts for different operations.Panel PU

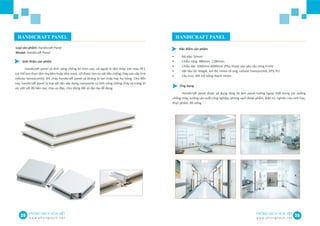

Panel PU Stock company Hoa Viet

╠²

C├öNG TY TNHH PH├ÆNG Sß║ĀCH HOA VIß╗åT

Add: Sß╗æ107 Nguyß╗ģn TrŲ░ß╗Øng Tß╗Ö, H├Ā Nß╗Öi / Tel/Fax: 04 - 6291- 8853

Hotline: 0903-412-416 /Email: sales@phongsach.net Website: www.phongsach.net Panel EPs

Panel EPsStock company Hoa Viet

╠²

C├öNG TY TNHH PH├ÆNG Sß║ĀCH HOA VIß╗åT

Add: Sß╗æ107 Nguyß╗ģn TrŲ░ß╗Øng Tß╗Ö, H├Ā Nß╗Öi / Tel/Fax: 04 - 6291- 8853

Hotline: 0903-412-416 /Email: sales@phongsach.net Website: www.phongsach.net More Related Content

More from Stock company Hoa Viet (20)

Tu╠ē sa╠é╠üy ti╠ānh 1 cu╠ø╠ēa ─æo╠éi ct c-i

Tu╠ē sa╠é╠üy ti╠ānh 1 cu╠ø╠ēa ─æo╠éi ct c-iStock company Hoa Viet

╠²

Tß╗¦ sß║źy t─®nh mß╗Öt cß╗Ła ─æ├┤i CT-C-I l├Ā thiß║┐t bß╗ŗ sß║źy kh├┤ ─æŲ░ß╗Żc thiß║┐t kß║┐ theo ti├¬u chuß║®n GMP, ph├╣ hß╗Żp cho sß║źy kh├┤ v├Ā diß╗ćt khuß║®n c├Īc loß║Īi nguy├¬n liß╗ću v├Ā thuß╗æc. Thiß║┐t bß╗ŗ n├Āy c├│ hß╗ć thß╗æng quß║Īt gi├│ th├┤ng minh, qu├Ī tr├¼nh ─æiß╗üu chß╗ēnh nhiß╗ćt ─æß╗Ö ß╗Ģn ─æß╗ŗnh v├Ā hai khoang sß║źy, c├╣ng nhiß╗üu t├Łnh n─āng kh├Īc gi├║p ─æß║Żm bß║Żo hiß╗ću quß║Ż v├Ā an to├Ān trong qu├Ī tr├¼nh sß║źy. C├Īc th├┤ng sß╗æ kß╗╣ thuß║Łt nhŲ░ c├┤ng suß║źt, k├Łch thŲ░ß╗øc v├Ā vß║Łt liß╗ću ─æŲ░ß╗Żc chß╗ē r├Ą ─æß╗ā ─æ├Īp ß╗®ng nhu cß║¦u sß╗Ł dß╗źng.No╠é╠Ći na╠é╠üu ho╠é╠Ć kf 50 l

No╠é╠Ći na╠é╠üu ho╠é╠Ć kf 50 lStock company Hoa Viet

╠²

Nß╗ōi nß║źu hß╗ō KF-50L c├│ dung t├Łch 50L, ├Īp lß╗▒c hoß║Īt ─æß╗Öng Ōēż0.25mpa, v├Ā sß╗Ł dß╗źng phŲ░ŲĪng thß╗®c gia nhiß╗ćt bß║▒ng hŲĪi ─æß╗ā ─æun n├│ng c├Īc nguy├¬n liß╗ću dß║Īng lß╗Ång, chß╗¦ yß║┐u trong sß║Żn xuß║źt thuß╗æc, thß╗▒c phß║®m v├Ā h├│a chß║źt. Thiß║┐t bß╗ŗ bao gß╗ōm nhiß╗üu bß╗Ö phß║Łn chß║źt lŲ░ß╗Żng cao, ─æŲ░ß╗Żc sß║Żn xuß║źt tß╗½ inox 304, c├│ khß║Ż n─āng xoay 180 ─æß╗Ö v├Ā t├Łch hß╗Żp hß╗ć thß╗æng ─æiß╗üu khiß╗ān th├┤ng minh. C├┤ng suß║źt m├Īy trß╗Ön l├Ā 0.75kw v├Ā tß╗æc ─æß╗Ö trß╗Ön c├│ thß╗ā ─æiß╗üu chß╗ēnh tß╗½ 8 ─æß║┐n 40 v├▓ng/ph├║t.No╠é╠Ći bao ho╠ø╠ē byc 800

No╠é╠Ći bao ho╠ø╠ē byc 800Stock company Hoa Viet

╠²

M├Īy bao vi├¬n BYC-800 l├Ā thiß║┐t bß╗ŗ d├╣ng ─æß╗ā bao vi├¬n thuß╗æc v├Ā thß╗▒c phß║®m, vß╗øi Ų░u ─æiß╗ām dß╗ģ thao t├Īc v├Ā tiß║┐t kiß╗ćm phß╗ź liß╗ću. N├│ sß╗Ł dß╗źng c├┤ng nghß╗ć phun sŲ░ŲĪng v├Ā ─æiß╗üu chß╗ēnh nhiß╗ćt ─æß╗ā tß║Īo ra lß╗øp vß╗Å mß╗ŗn m├Āng cho vi├¬n thuß╗æc, ─æß╗ōng thß╗Øi c├│ khß║Ż n─āng sß║Żn xuß║źt 30-50 kg mß╗Śi lß║¦n. Thiß║┐t bß╗ŗ bao gß╗ōm nhiß╗üu th├Ānh phß║¦n nhŲ░ m├Īy chß╗¦, hß╗ć thß╗æng ─æiß╗üu chß╗ēnh nhiß╗ćt v├Ā s├║ng phun, ph├╣ hß╗Żp vß╗øi nhiß╗üu y├¬u cß║¦u kh├Īc nhau cß╗¦a kh├Īch h├Āng.No╠é╠Ći bao ho╠ø╠ē by800 1000

No╠é╠Ći bao ho╠ø╠ē by800 1000Stock company Hoa Viet

╠²

Nß╗ōi bao hß╗¤ BY-800/1000 l├Ā thiß║┐t bß╗ŗ ─æŲĪn giß║Żn, dß╗ģ bß║Żo tr├¼, l├Į tŲ░ß╗¤ng cho viß╗ćc bao vi├¬n trong sß║Żn xuß║źt thuß╗æc v├Ā thß╗▒c phß║®m, ─æ├Īp ß╗®ng ti├¬u chuß║®n GMP. Thiß║┐t bß╗ŗ n├Āy c├│ hai phi├¬n bß║Żn vß╗øi ─æŲ░ß╗Øng k├Łnh 800mm v├Ā 1000mm, n─āng suß║źt tß╗½ 30-70 kg/lß║¦n, vß╗øi khß║Ż n─āng bao v├Ā ─æ├Īnh b├│ng vi├¬n, hß║Īt hiß╗ću quß║Ż. N├│ gi├║p tß║Īo ra sß║Żn phß║®m c├│ bß╗ü ngo├Āi hß║źp dß║½n, chß╗æng ├┤xi h├│a v├Ā ß║®m Ų░ß╗øt.Ma╠üy sa╠üt ha╠Żt la╠å╠üc yk160

Ma╠üy sa╠üt ha╠Żt la╠å╠üc yk160Stock company Hoa Viet

╠²

M├Īy s├Īt hß║Īt lß║»c YK160 ─æŲ░ß╗Żc sß╗Ł dß╗źng ─æß╗ā nghiß╗ün hß╗Śn hß╗Żp th├Ānh hß║Īt trong c├Īc ng├Ānh thuß╗æc, h├│a chß║źt, thß╗▒c phß║®m, gß╗æm sß╗® v├Ā nhß╗▒a. N├│ hoß║Īt ─æß╗Öng bß║▒ng c├Īch rung lß║»c ß╗æng l─ān, cho n─āng suß║źt 200~300kg/h vß╗øi c├┤ng suß║źt ─æß╗Öng cŲĪ 2.2kw. Tß║źt cß║Ż bß╗Ö phß║Łn tiß║┐p x├║c ─æß╗üu l├Ām bß║▒ng inox SUS304 v├Ā m├Īy c├│ k├Łch thŲ░ß╗øc 950*750*1240 mm.Ma╠üy sa╠Ćng rung xzs

Ma╠üy sa╠Ćng rung xzsStock company Hoa Viet

╠²

M├Īy s├Āng rung XZS l├Ā thiß║┐t bß╗ŗ hiß╗ćn ─æß║Īi sß╗Ł dß╗źng c├┤ng nghß╗ć ti├¬n tiß║┐n vß╗øi chß║źt liß╗ću inox v├Ā bß╗Ö phß║Łn chß╗æng rung bß║▒ng cao su, gi├║p giß║Żm tiß║┐ng ß╗ōn v├Ā tiß║┐t kiß╗ćm ─æiß╗ćn n─āng. N├│ ─æŲ░ß╗Żc thiß║┐t kß║┐ ─æß╗ā s├Āng lß╗Źc c├Īc vß║Łt liß╗ću dß║Īng hß║Īt v├Ā bß╗Öt trong c├Īc ng├Ānh y dŲ░ß╗Żc, thß╗▒c phß║®m v├Ā h├│a chß║źt, ─æ├Īp ß╗®ng ti├¬u chuß║®n GMP. Thiß║┐t bß╗ŗ c├│ hiß╗ću suß║źt cao, dß╗ģ d├Āng bß║Żo tr├¼ v├Ā ─æŲ░ß╗Żc ngŲ░ß╗Øi ti├¬u d├╣ng ─æ├Īnh gi├Ī cao sau khi ra mß║»t thß╗ŗ trŲ░ß╗Øng.Ma╠üy pha di╠Żch (xay keo) jm 130

Ma╠üy pha di╠Żch (xay keo) jm 130Stock company Hoa Viet

╠²

M├Īy pha dß╗ŗch JM-130 hoß║Īt ─æß╗Öng dß╗▒a tr├¬n nguy├¬n l├Į lß╗▒c cß║»t v├Ā ma s├Īt, nghiß╗ün nhß╗Å c├Īc nguy├¬n liß╗ću lß╗Ång hoß║Ęc sß╗ćt ─æß╗ā tß║Īo ra sß║Żn phß║®m ho├Ān thiß╗ćn. M├Īy c├│ nhiß╗üu cß║źu tr├║c v├Ā linh kiß╗ćn bß║▒ng inox, ─æŲ░ß╗Żc sß╗Ł dß╗źng trong nhiß╗üu ng├Ānh c├┤ng nghiß╗ćp nhŲ░ thß╗▒c phß║®m, h├│a chß║źt, y dŲ░ß╗Żc v├Ā mß╗╣ phß║®m. C├Īc th├┤ng sß╗æ kß╗╣ thuß║Łt cho thß║źy hai model JM-130 v├Ā JM-85 vß╗øi c├┤ng suß║źt v├Ā sß║Żn lŲ░ß╗Żng kh├Īc nhau, ph├╣ hß╗Żp vß╗øi nhu cß║¦u sß║Żn xuß║źt.Ma╠üy nha╠Ćo hai tru╠Żc sch 200 l

Ma╠üy nha╠Ćo hai tru╠Żc sch 200 lStock company Hoa Viet

╠²

M├Īy nh├Āo hai trß╗źc SCH-200L c├│ dung t├Łch 200L, c├┤ng suß║źt trß╗Ön 5.5kw v├Ā vß║Łn tß╗æc trß╗Ön 24 v├▓ng/ph├║t, ─æŲ░ß╗Żc sß╗Ł dß╗źng ─æß╗ā trß╗Ön ─æß╗üu c├Īc nguy├¬n liß╗ću dß║Īng bß╗Öt, Ų░ß╗øt v├Ā cao trong ng├Ānh thß╗▒c phß║®m v├Ā dŲ░ß╗Żc phß║®m. Thiß║┐t kß║┐ cß╗¦a m├Īy bao gß╗ōm th├ón h├¼nh chß╗» W, trß╗źc trß╗Ön linh hoß║Īt, v├Ā hß╗ć thß╗æng ─æ├│ng k├Łn hiß╗ću quß║Ż ─æß╗ā tr├Īnh ├┤ nhiß╗ģm, trong khi bß╗Ö ─æiß╗üu khiß╗ān ─æiß╗ćn cho ph├®p t├╣y chß╗ēnh thß╗Øi gian v├Ā g├│c ─æß╗Ģ nguy├¬n liß╗ću. Vß║Łt liß╗ću chß║┐ tß║Īo gß╗ōm inox chß║źt lŲ░ß╗Żng cao v├Ā th├®p cŲ░ß╗Øng lß╗▒c, ─æß║Żm bß║Żo ─æß╗Ö bß╗ün v├Ā hiß╗ću suß║źt l├Ām viß╗ćc ß╗Ģn ─æß╗ŗnh.May dong nang tu dong njp 1200

May dong nang tu dong njp 1200Stock company Hoa Viet

╠²

M├Īy ─æ├│ng vi├¬n nang tß╗▒ ─æß╗Öng NJP-1200 l├Ā thiß║┐t bß╗ŗ ─æ├│ng c├Īc loß║Īi bß╗Öt, hß║Īt hoß║Ęc vi├¬n nhß╗Å v├Āo trong vß╗Å nang trß╗æng vß╗øi khß║Ż n─āng tß╗▒ ─æß╗Öng ho├Ān th├Ānh c├Īc kh├óu chuyß╗ān nang, ph├ón nang v├Ā ─æ├│ng thuß╗æc. Thiß║┐t bß╗ŗ c├│ thiß║┐t kß║┐ cß║Żi tiß║┐n ─æß║Żm bß║Żo ─æß╗Ö ch├Łnh x├Īc v├Ā an to├Ān, vß╗øi c├┤ng suß║źt sß║Żn xuß║źt 72,000 vi├¬n/h v├Ā sai sß╗æ trong khoß║Żng ┬▒3.5%. NJP-1200 th├Łch hß╗Żp cho viß╗ćc ─æ├│ng vi├¬n c├Īc sß║Żn phß║®m thuß╗æc ─æ├┤ng y v├Ā t├óy y, l├Ā lß╗▒a chß╗Źn l├Į tŲ░ß╗¤ng cho c├Īc nh├Ā m├Īy sß║Żn xuß║źt vi├¬n nang cß╗®ng.Ma╠üy ─æo╠üng tu╠üi thuo╠é╠üc bo╠Ż╠ét dxdf60 d

Ma╠üy ─æo╠üng tu╠üi thuo╠é╠üc bo╠Ż╠ét dxdf60 dStock company Hoa Viet

╠²

M├Īy ─æ├│ng t├║i thuß╗æc bß╗Öt DXDF60E c├│ cß║źu tr├║c dß║Łp 4 m├®p vß╗øi t├Łnh n─āng hiß╗ān thß╗ŗ ─æa ng├┤n ngß╗» v├Ā ─æiß╗üu khiß╗ān th├┤ng minh gi├║p tß╗▒ ─æß╗Öng dß╗½ng khi c├│ sß╗▒ cß╗æ. N├│ c├│ khß║Ż n─āng ─æiß╗üu chß╗ēnh nhiß╗ćt ─æß╗Ö, tß╗æc ─æß╗Ö ─æ├│ng g├│i tß╗½ 40-60 t├║i/ph├║t v├Ā dß╗ģ d├Āng thay ─æß╗Ģi k├Łch thŲ░ß╗øc t├║i. Thiß║┐t bß╗ŗ bao gß╗ōm nhiß╗üu bß╗Ö phß║Łn ─æŲ░ß╗Żc sß║Żn xuß║źt tß╗½ c├Īc nh├Ā cung cß║źp uy t├Łn, ─æß║Żm bß║Żo hiß╗ću quß║Ż c├┤ng viß╗ćc v├Ā khß║Ż n─āng bß║Żo tr├¼ tß╗æt.Ma╠üy ─æo╠üng nang tu╠ø╠Ż ─æo╠Ż╠éng njp 400

Ma╠üy ─æo╠üng nang tu╠ø╠Ż ─æo╠Ż╠éng njp 400Stock company Hoa Viet

╠²

M├Īy ─æ├│ng nang tß╗▒ ─æß╗Öng NJP-400 c├│ ─æß║Ęc ─æiß╗ām tiß║┐t kiß╗ćm n─āng lŲ░ß╗Żng, dß╗ģ d├Āng l├Ām sß║Īch v├Ā ─æŲ░ß╗Żc sß╗Ł dß╗źng rß╗Öng r├Żi tß║Īi Trung Quß╗æc. Thiß║┐t bß╗ŗ sß╗Ł dß╗źng c├┤ng nghß╗ć ti├¬n tiß║┐n tß╗½ Siemens, vß╗øi khß║Ż n─āng tß╗▒ ─æß╗Öng dß╗½ng khi thiß║┐u nguy├¬n liß╗ću v├Ā hiß╗ān thß╗ŗ th├┤ng tin vß╗ü sß║Żn lŲ░ß╗Żng. Th├┤ng sß╗æ kß╗╣ thuß║Łt bao gß╗ōm sß║Żn lŲ░ß╗Żng 400 hß║Īt/ph├║t v├Ā tß╗Ģng c├┤ng suß║źt 3.32kw.Ma╠üy ─æo╠üng nang ba╠ün tu╠ø╠Ż ─æo╠Ż╠éng

Ma╠üy ─æo╠üng nang ba╠ün tu╠ø╠Ż ─æo╠Ż╠éngStock company Hoa Viet

╠²

M├Īy ─æ├│ng nang b├Īn tß╗▒ ─æß╗Öng sß╗Ł dß╗źng chuyß╗ān ─æß╗Öng giß╗»a b├Īnh r─āng ─æß╗ā nghiß╗ün nguy├¬n liß╗ću th├Ānh vß╗źn, ─æß╗ōng thß╗Øi thu hß╗ōi bß╗źi qua t├║i vß║Żi. Thiß║┐t bß╗ŗ ─æß║Īt ti├¬u chuß║®n GMP, ─æŲ░ß╗Żc chß║┐ tß║Īo tß╗½ inox v├Ā ph├╣ hß╗Żp vß╗øi nhiß╗üu loß║Īi vi├¬n nang, vß╗øi n─āng suß║źt tß╗½ 10-20.000 vi├¬n/ph├║t. C├Īc th├┤ng sß╗æ kß╗╣ thuß║Łt ch├Łnh bao gß╗ōm tß╗Ģng c├┤ng suß║źt 3.31kw v├Ā k├Łch thŲ░ß╗øc 1890├Ś880├Ś1700mm.Ma╠üy ─æe╠é╠üm vie╠én tcc 8 h

Máy đếm viên tcc 8 hStock company Hoa Viet

╠²

M├Īy ─æß║┐m vi├¬n ─æiß╗ćn tß╗Ł TCC-8 l├Ā thiß║┐t bß╗ŗ ─æß║┐m vi├¬n ─æ├│ng lß╗Ź tß╗▒ ─æß╗Öng, sß╗Ł dß╗źng c├┤ng nghß╗ć vi m├Īy t├Łnh v├Ā hß╗ć thß╗æng rung ─æß╗ā ─æŲ░a nguy├¬n liß╗ću v├Āo vß╗øi ─æß╗Ö ch├Łnh x├Īc cao. Thiß║┐t bß╗ŗ th├Łch hß╗Żp cho nhiß╗üu loß║Īi thuß╗æc vi├¬n v├Ā hß║Īt giß╗æng n├┤ng sß║Żn, vß╗øi tß╗æc ─æß╗Ö ─æß║┐m l├¬n tß╗øi 4000 vi├¬n/ph├║t v├Ā dß╗ģ d├Āng thao t├Īc nhß╗Ø giao diß╗ćn th├ón thiß╗ćn. N├│ c├│ k├Łch thŲ░ß╗øc nhß╗Å gß╗Źn v├Ā nhiß╗üu t├Łnh n─āng bß║Żo vß╗ć nhŲ░ cß║Żnh b├Īo sß╗▒ cß╗æ v├Ā tß╗▒ ─æß╗Öng dß╗½ng m├Īy khi hß║┐t lß╗Ź.Ma╠üy bao vie╠én bo╠Żc ─æu╠øo╠ø╠Ćng bg75

Ma╠üy bao vie╠én bo╠Żc ─æu╠øo╠ø╠Ćng bg75Stock company Hoa Viet

╠²

M├Īy bao vi├¬n bß╗Źc ─æŲ░ß╗Øng BG75 ─æŲ░ß╗Żc sß╗Ł dß╗źng trong sß║Żn xuß║źt thuß╗æc v├Ā thß╗▒c phß║®m, c├│ hiß╗ću suß║źt cao v├Ā an to├Ān, vß╗øi nhiß╗üu t├Łnh n─āng tß╗▒ ─æß╗Öng. To├Ān bß╗Ö qu├Ī tr├¼nh bao vi├¬n ─æŲ░ß╗Żc ─æiß╗üu khiß╗ān bß║▒ng hß╗ć thß╗æng m├Īy t├Łnh, ─æß║Żm bß║Żo kh├┤ng c├│ bß╗źi v├Ā chß║źt lß╗Ång bß║»n l├¬n. Thiß║┐t bß╗ŗ n├Āy c├▓n c├│ khß║Ż n─āng bao vi├¬n li├¬n tß╗źc, tiß║┐t kiß╗ćm thß╗Øi gian v├Ā n─āng lŲ░ß╗Żng.Lß╗▒a chß╗Źn HAVC

Lß╗▒a chß╗Źn HAVCStock company Hoa Viet

╠²

This document provides an overview and objectives of a training module on heating, ventilation and air conditioning (HVAC) systems for pharmaceutical manufacturing facilities. It discusses various HVAC design considerations and components including air filtration levels, airflow patterns, temperature and humidity control, dust control, and protecting the environment from exhaust air and fumes. The role of HVAC in preventing cross-contamination between production areas is also covered.So s├Īnh Asian GMP v├Ā WHO GMP

So s├Īnh Asian GMP v├Ā WHO GMPStock company Hoa Viet

╠²

T├Āi liß╗ću so s├Īnh c├Īc ─æiß╗ām tŲ░ŲĪng ─æß╗ōng v├Ā kh├Īc biß╗ćt giß╗»a WHO GMP v├Ā ASEAN GMP, n├¬u r├Ą y├¬u cß║¦u vß╗ü nh├ón sß╗▒, cŲĪ sß╗¤ sß║Żn xuß║źt, thiß║┐t bß╗ŗ v├Ā quy tr├¼nh li├¬n quan ─æß║┐n chß║źt lŲ░ß╗Żng trong ng├Ānh dŲ░ß╗Żc. WHO GMP cung cß║źp c├Īc hŲ░ß╗øng dß║½n chi tiß║┐t hŲĪn v├Ā quy tr├¼nh tß╗▒ thanh tra nghi├¬m ngß║Ęt hŲĪn so vß╗øi ASEAN GMP. T├Āi liß╗ću c┼®ng nhß║źn mß║Īnh sß╗▒ cß║¦n thiß║┐t phß║Żi tu├ón thß╗¦ quy ─æß╗ŗnh cß╗¦a WHO ─æß╗ā ─æß║Żm bß║Żo giß║źy chß╗®ng nhß║Łn GMP c├│ gi├Ī trß╗ŗ quß╗æc tß║┐.Clean room standards

Clean room standardsStock company Hoa Viet

╠²

This document discusses different standards for classifying cleanrooms according to airborne particle concentrations. It describes the obsolete Federal Standard 209 classification system used in the US which categorizes cleanrooms from Class 1 to Class 10,000 based on particle counts per cubic foot. It then outlines the ISO 14644 international cleanroom standards which use particle counts per cubic meter and have classifications from ISO 1 to ISO 9. The document provides tables comparing particle concentration limits between the two systems. It also discusses pharmaceutical cleanroom classifications used in the European Union and US which are based on maximum permitted particle counts for different operations.Panel PU

Panel PU Stock company Hoa Viet

╠²

C├öNG TY TNHH PH├ÆNG Sß║ĀCH HOA VIß╗åT

Add: Sß╗æ107 Nguyß╗ģn TrŲ░ß╗Øng Tß╗Ö, H├Ā Nß╗Öi / Tel/Fax: 04 - 6291- 8853

Hotline: 0903-412-416 /Email: sales@phongsach.net Website: www.phongsach.net Panel EPs

Panel EPsStock company Hoa Viet

╠²

C├öNG TY TNHH PH├ÆNG Sß║ĀCH HOA VIß╗åT

Add: Sß╗æ107 Nguyß╗ģn TrŲ░ß╗Øng Tß╗Ö, H├Ā Nß╗Öi / Tel/Fax: 04 - 6291- 8853

Hotline: 0903-412-416 /Email: sales@phongsach.net Website: www.phongsach.net