How To Build Greener Hopper Dredges - final

- 1. How To Build The Next Generation of Greener Hopper Dredges Vinton Bossert, P.E. Stephen Wright Ethan Wiseman Presentation for: IMarEST New York, NY November 2015

- 2. How To Build Greener Hopper Dredges Dredging Efficiency (Hopper Dredge Design 101) Ō¢║Least Cost vs. Maximum Production

- 3. How To Build Greener Hopper Dredges Dredging Efficiency Ō¢║Least Cost ŌĆó Most Efficient Hull ŌĆó Most Efficient Propulsion System ŌĆó Most Efficient Pumping System ŌĆó Crew Size Matched to Automation ŌĆó Least First Cost ŌĆó Least Maintenance

- 4. How To Build Greener Hopper Dredges Dredging Efficiency Ō¢║Maximum Production ŌĆó Largest Hopper ŌĆó Most Maneuverable ŌĆó Highest Density Excavation ŌĆó Most Efficient Hopper Loading ŌĆó Fastest Loaded Speed to Disposal Site ŌĆó Fastest Unloading ŌĆó Fastest Speed Returning Empty

- 5. How To Build Greener Hopper Dredges Best Available Technologies (BAT) Today ŌĆó Hull Technologies ŌĆó Dredging Technologies ŌĆó Machinery Technologies

- 6. How To Build Greener Hopper Dredges Hull Technologies ŌĆó Minimum Lightship Weight ŌĆó Maximize Hopper Size for Hull Envelope ŌĆó Reduced Freeboard Loadline ŌĆó Hydrodynamic Improvements Around Recessed Hopper Doors & Propulsion ŌĆó Balanced Trim Without Ballast ŌĆó Better Maneuverability ŌĆō Z-Drive Propulsion

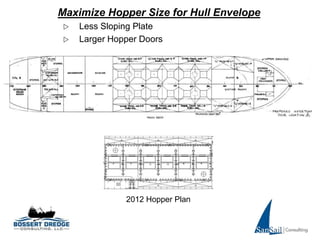

- 7. Maximize Hopper Size for Hull Envelope LtWt + Dwt = Disp Every lb Steel = lb Sand Cannot Carry Older Newer

- 8. Maximize Hopper Size for Hull Envelope ’üĘ Less Sloping Plate ’üĘ Larger Hopper Doors 2012 Hopper Plan

- 9. How To Build Greener Hopper Dredges Better Maneuverability ŌĆō Z-Drive Propulsion Drawing from Thrustmaster of Texas

- 10. How To Build Greener Hopper Dredges Machinery ŌĆó Least Weight, Lowest Cost ŌĆó Tier IV Engines ŌĆó CFD Analysis To Optimize Propulsion ŌĆó Shared Power Systems ŌĆó Environmentally Acceptable Fluids

- 11. How To Build Greener Hopper Dredges Machinery

- 12. How To Build Greener Hopper Dredges ŌĆó CFD Analysis

- 13. How To Build Greener Hopper Dredges Machinery ŌĆó Shared Power Systems ŌĆō Optimum Engine Loading ’üĘ Diesel-Electric - PMS ’üĘ Flexible Arrangement ŌĆō wt, trim, cargo ’üĘ Main Engine Powered Pumps & Generators with CRPP ’üĘ Ease of Construction - modular ’üĘ DC Technology ŌĆō Optimum BSFC ’üĘ Hybrid Energy Storage Systems ’üĘ Cold Ironing ’üĘ Dual Fuel ŌĆō LNG/CNG

- 15. How To Build Greener Hopper Dredges Machinery ŌĆó DC Grid ŌĆó No Synchronization of Generators ŌĆó Minimize Harmonics ŌĆó Gen RPM Matched to Load

- 16. How To Build Greener Hopper Dredges Machinery Ō¢║Power Management System: ŌĆó Optimize number of generators and feeds connected to the bus relative to fuel efficiency and provide a sufficient reserve capacity of power based on user defined presets. ŌĆó Provide proportional load sharing in a symmetrical & asymmetrical plant configurations. ŌĆó Automatically manage Large Loads ŌĆó Automatically control Load Shedding. ŌĆó Automatically Restart Engines Generator/or Storage to restore power following a Black Out Condition. ŌĆó Automatically provide Load Limiting integral to the CPP system.

- 17. How To Build Greener Hopper Dredges Machinery Ō¢║ Dual Fuel ŌĆō LNG/CNG: ŌĆó No Urea Injection, No Sulfer, No Particulates ŌĆó U.S. Reserves are Huge ŌĆó Significant Op Cost Savings - Increase as Oil Price Rises

- 18. Broader Applications for Hybrid Power System ŌĆó Permanent Magnet Motors: Smaller and Lighter compared to Induction Motors and Alternator. ŌĆó Further Improves Efficiency Difference between DE and Conventional system ŌĆó Battery Banks: Battery banks provide Peak Shaving, so Generator Power managed more efficiently.

- 19. How To Build Greener Hopper Dredges Machinery ŌĆó Environmentally Acceptable Fluids ’üĘ Water Fluid Power Applications ’éĪ Hopper Door Operators ’éĪ Hydraulically Operated Valves ’éĪ Draghead Davits/Swell Compensators ’éĪ Draghead Visor Actuators ’éĪ CPP Servo System ’üĘ Engine Coolants ’üĘ Lubricants

- 20. How To Build Greener Hopper Dredges Dredging ŌĆó New Dredge Pumps ŌĆó Over-The-Bow Pumpout Systems ŌĆó Shallow Draft ŌĆó Active Dragheads ŌĆó Large Hopper Doors ŌĆó Automated Dredging Process Control VOSTA LMG Bow Coupling

- 21. How To Build Greener Hopper Dredges Dredging ŌĆó New Dredge Pumps ŌĆó High Efficiency > 87% ŌĆó Better Wear Characteristics ŌĆó Hi Chrome White Iron ŌĆó Diverter Technology ŌĆó Better Suction (NPSH) Characteristics (skewed vanes)

- 22. How To Build Greener Hopper Dredges Dredging ŌĆó New Dredge Pumps

- 23. How To Build Greener Hopper Dredges Dredging ŌĆó Active Dragheads ’üĘ More Pump NPSH is available for Density ’üĘ Jet-assisted ’üĘ Excavating Teeth ’üĘ Adjustable Visor IHCŌĆÖs Wild Dragon┬« Draghead VOSTA LMG Draghead

- 24. How To Build Greener Hopper Dredges Dredging ŌĆó Automated Dredging Process Control ’üĘ Free Up Officers to Optimize Operations ’üĘ Operate 24-7 Without Fatigue ŌĆō One Man Bridge ’üĘ Algorithms Continuously Learn/Adjust/Improve - Maximize Production without Plugging Pipeline ’üĘ Variable Hopper Fill Rate Reduces Overflow Losses ’üĘ Replacement Every 7-10 Years

- 25. Automation ŌĆó Highest Efficiency Gains Optimize Interrelationship of Propulsion, Draghead Visor, and Dredge Pump Speed

- 28. Water Hydraulic Technical Considerations ŌĆó Design Approach ŌĆō Typically lapped spool type designs; Internal Leakage is part of design; rely on internal leakage for lubrication ŌĆó Practical Realities ŌĆō Plunger floats; minimal metal to metal contact, no requirement for high strength/anti corrosive materials ŌĆó Physics ŌĆō Oil allows for higher pressure drops and higher velocities, creating smaller components, but at a price of energy loss ŌĆó Economic Impact ŌĆō Manufactured in volume, price points relatively low given large market size (several $Billion per year) ŌĆó Design Approach ŌĆō Zero Leakage ŌĆō internal leakage damages base materials; water is a cutting agent at high pressure and velocity. Avoidance of internal leakage is key to success ŌĆó Practical Realities ŌĆō Given zero leak requirement, most valves use ŌĆśsoftŌĆÖ packers; lack of lubricity and difficult application environment often requires high strength, more exotic materials such as stainless ŌĆó Physics ŌĆō Water does not compress, makes it more efficient to pump; zero leakage makes it more energy efficient ŌĆó Economic Impact ŌĆō Manufactured in low quantity, price points higher, much smaller market ($100 M) Oil Hydraulics Water Hydraulics Zero Leakage ŌĆō Environmentally Friendly ŌĆō Higher Efficiency ŌĆō Lower Total Cost of Ownership

- 29. Water Hydraulic Fluid Additives ŌĆó Purpose - Many Biodegradable additives aid the use of water as a hydraulic fluid. Water is limited in its ability to lubricate (low viscosity). It also can be a media for biological growth, and it freezes at a relatively high temp. ŌĆó Corrosion Control ŌĆō Synthetic additives bond to the internals of the system and prohibit or slow corrosion ŌĆó Algae Control ŌĆō Algaecides mix with the fluid and prevent growth of biologics which can degrade system performance ŌĆó Lubricity Assistance ŌĆō Other additives are design to add lubricity to the fluid making it slippery and enhancing life of components ŌĆó Freezing Control - Additives such as Propylene glycol (FDA approved food additive) lower the freezing temperature of the water Additives Serve Many Purposes

- 30. Initial Cost - Water Hydraulics vs Oil Hydraulics

- 31. Fluid Cost - Water Hydraulics vs Oil Hydraulics Description Tank Volume EAL Cost WH Cost Reservoir 350 Gal $13,300 $350 Storage Tank 2000 Gal $76,000 $0 Fluid Makeup $38/Gal $1/gal Fluid Contamination 350 Gal $13,300 $350 Notes: ŌĆóWater Hydraulics is filled directly from potable water system. ŌĆóNo clean up cost or fines associated with Water Hydraulics. ŌĆóNo storage or handling costs for Water Hydraulics.

- 34. Dredge MURDENŌĆÖs Water Hydraulic System

- 35. How To Build Greener Hopper Dredges Eliminate Inefficiency ŌĆó Wasted Fuel ŌĆó Environmental Impacts ŌĆó Personal Injuries ŌĆó Unnecessary Exhaust Aftertreatments ŌĆó Unnecessary Fines ŌĆó Over-crewed Vessels ŌĆó Antiquated Practices ŌĆó Legacy Equipment

- 36. DISCUSSION & QUESTIONS Contact Information: Vinton Bossert President ŌĆō Bossert Dredge Consulting vintonbossert@comcast.net (302) 740-1841 Stephen Wright Partner ŌĆō SanSailTEC, LLC swright@sansailtec.com (917) 374-2836 Ethan Wiseman Naval Architect & Marine Engineer ethan.wiseman@gmail.com (516) 640-0554