How to prevent fly contamination in autostripe machine.pptx

- 1. Welcome to our Quality Control Circle Presentation Presented by Team Shofolota

- 2. Vision We envision to sustain and grow as a diversified global conglomerate 2 Crafting Happiness, since 1991

- 3. ’ā╝ Dulal Brothers Ltd. ’ā╝ Mymun Textiles Ltd. ’ā╝ Jinnat Apparels Ltd. ’ā╝ Hamza Washing Ltd. ’ā╝ Flamingo Fashions Ltd. ’ā╝ Color City Ltd. ’ā╝ Jinnat Fashions Ltd. ’ā╝ DB Tex Ltd. ’ā╝ Jinnat Knitwears Ltd. ’ā╝ Textile Testing Service Ltd. ’ā╝ Matin Spinning Mills Ltd. ’ā╝ Thanbee Print World Ltd. ’ā╝ Mawna Fashions Ltd. ’ā╝ Parkway Packaging & Printing Ltd. ’ā╝ Matin Spinning Mills Ltd. ’ā╝ DBL Distribution Ltd. ’ā╝ DBL Ceramics Ltd. Business Units 3

- 4. Buyers of DBL Group 4

- 5. Knitting Unit Profile 5 ’é× Established in 2001 ’é× Floor space: 275000 Sq. Ft. ’é× Total no of knitting mcs: 329 ’é× Production Capacity: 90 tons/day ’é× Products - Single jersey derivatives, Double jersey derivatives, Autostripe, Jacquard fabrics etc.

- 6. Team Profile Team Leader Ashish saha Officer, QAD Dy-Team Leader Saiful Islam Officer, QAD Team Member Shihab Hasan Officer, Production Team Member Gopal Ghosh Officer, Production 6 Team Shofolota Fomation Date: 16 Feb 2014 Meeting Schedule: Wednesday 4 pm

- 7. ŌĆ£Dream it, Follow it & Achieve itŌĆØ Team Motto Team Goal Our goal is to find out main problems of Autostripe knitting machine and solve them. 7

- 8. Major problems of Autostripe knitting machine: ŌĆó Barre & Round Mark ŌĆó Excessive Machine Changeover time ŌĆó Hole, Loop problem ŌĆó Fly Contamination problem ŌĆó Machine Idle time ŌĆó Lycra Out & Lycra Cut problem ŌĆó Yarn Dyed order unavailability ŌĆó Less productivity Problem Identification through Brain Storming 8

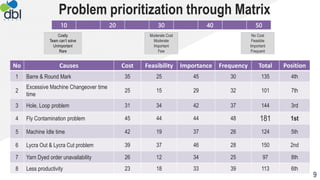

- 9. Problem prioritization through Matrix 10 20 30 40 50 Costly Team canŌĆÖt solve Unimportant Rare Moderate Cost Moderate Important Few No Cost Feasible Important Frequent No Causes Cost Feasibility Importance Frequency Total Position 1 Barre & Round Mark 35 25 45 30 135 4th 2 Excessive Machine Changeover time time 25 15 29 32 101 7th 3 Hole, Loop problem 31 34 42 37 144 3rd 4 Fly Contamination problem 45 44 44 48 181 1st 5 Machine Idle time 42 19 37 26 124 5th 6 Lycra Out & Lycra Cut problem 39 37 46 28 150 2nd 7 Yarn Dyed order unavailability 26 12 34 25 97 8th 8 Less productivity 23 18 33 39 113 6th 9

- 10. Topic ŌĆ£Minimization of Fly Contamination Problem in Autostripe Knitting MachineŌĆØ 10

- 11. Target Setting Month Total autostriped garments (pcs) No. of fly contaminated garments (pcs) No. of fly contaminated garments rejected rejected (pcs) Percentage of fly contaminated garments Percentage of fly contaminated garments rejected July 2018 121564 9247 189 7.61 0.16 August 2018 99037 8614 124 8.70 0.13 September 2018 107764 8395 167 7.79 0.15 Average 109455 8752 160 8.03 % 0.15 % Our Target is to reduce the number of fly contaminated autostriped garments from 8.03% to 6% and fly contaminated garments rejection from 0.15% to 0.10% within December 2018. 11

- 12. Auto stripe knitting machine is a programmable special type of knitting machine where upto 6 colour yarns can be used combined to produce any number of yarn dyed stripe repeat in an orderly manner. It is also known as Auto striper/Engineering striper machine. Auto Stripe Knitting Machine 12

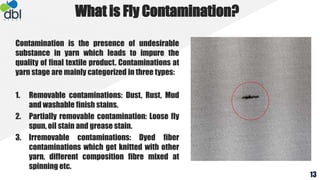

- 13. Contamination is the presence of undesirable substance in yarn which leads to impure the quality of final textile product. Contaminations at yarn stage are mainly categorized in three types: 1. Removable contaminations: Dust, Rust, Mud and washable finish stains. 2. Partially removable contamination: Loose fly spun, oil stain and grease stain. 3. Irremovable contaminations: Dyed fiber contaminations which get knitted with other yarn, different composition fibre mixed at spinning etc. What is Fly Contamination? 13

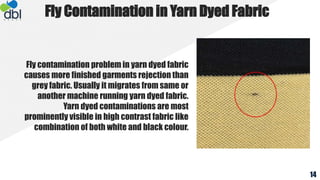

- 14. Fly contamination problem in yarn dyed fabric causes more finished garments rejection than grey fabric. Usually it migrates from same or another machine running yarn dyed fabric. Yarn dyed contaminations are most prominently visible in high contrast fabric like combination of both white and black colour. Fly Contamination in Yarn Dyed Fabric 14

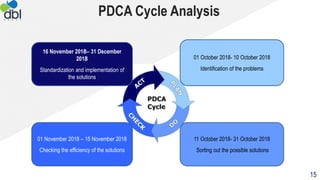

- 15. PDCA Cycle Analysis 01 October 2018- 10 October 2018 Identification of the problems 11 October 2018- 31 October 2018 Sorting out the possible solutions 16 November 2018ŌĆō 31 December 2018 Standardization and implementation of the solutions 01 November 2018 ŌĆō 15 November 2018 Checking the efficiency of the solutions 15

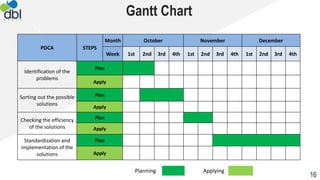

- 16. Gantt Chart Planning Applying PDCA STEPS Month October November December Week 1st 2nd 3rd 4th 1st 2nd 3rd 4th 1st 2nd 3rd 4th Identification of the problems Plan Apply Sorting out the possible solutions Plan Apply Checking the efficiency of the solutions Plan Apply Standardization and implementation of the solutions Plan Apply 16

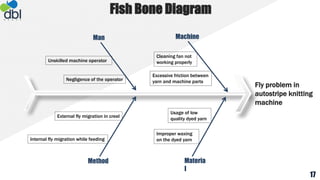

- 17. Fish Bone Diagram Man Machine Method Materia l Internal fly migration while feeding External fly migration in creel Negligence of the operator Unskilled machine operator Excessive friction between yarn and machine parts Fly problem in autostripe knitting machine Usage of low quality dyed yarn Cleaning fan not working properly Improper waxing on the dyed yarn 17

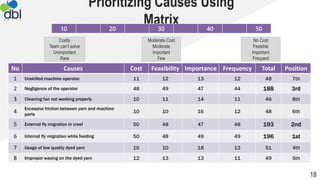

- 18. Prioritizing Causes Using Matrix 10 20 30 40 50 Costly Team canŌĆÖt solve Unimportant Rare Moderate Cost Moderate Important Few No Cost Feasible Important Frequent No Causes Cost Feasibility Importance Frequency Total Position 1 Unskilled machine operator 11 12 13 12 48 7th 2 Negligence of the operator 48 49 47 44 188 3rd 3 Cleaning fan not working properly 10 11 14 11 46 8th 4 Excessive friction between yarn and machine parts 10 10 16 12 48 6th 5 External fly migration in creel 50 48 47 48 193 2nd 6 Internal fly migration while feeding 50 48 49 49 196 1st 7 Usage of low quality dyed yarn 10 10 18 13 51 4th 8 Improper waxing on the dyed yarn 12 13 13 11 49 5th 18

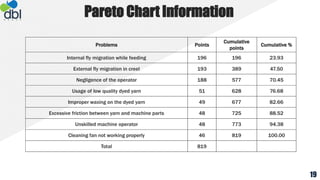

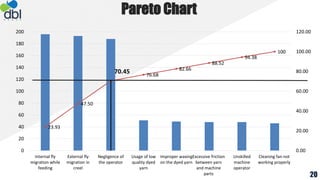

- 19. Pareto Chart Information Problems Points Cumulative points Cumulative % Internal fly migration while feeding 196 196 23.93 External fly migration in creel 193 389 47.50 Negligence of the operator 188 577 70.45 Usage of low quality dyed yarn 51 628 76.68 Improper waxing on the dyed yarn 49 677 82.66 Excessive friction between yarn and machine parts 48 725 88.52 Unskilled machine operator 48 773 94.38 Cleaning fan not working properly 46 819 100.00 Total 819 19

- 20. Pareto Chart 23.93 47.50 70.45 76.68 82.66 88.52 94.38 100 0.00 20.00 40.00 60.00 80.00 100.00 120.00 0 20 40 60 80 100 120 140 160 180 200 Internal fly migration while feeding External fly migration in creel Negligence of the operator Usage of low quality dyed yarn Improper waxing on the dyed yarn Excessive friction between yarn and machine parts Unskilled machine operator Cleaning fan not working properly 20

- 21. 5W1H Analysis 21

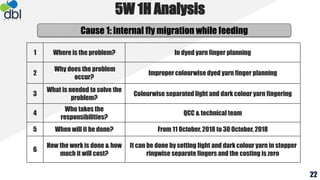

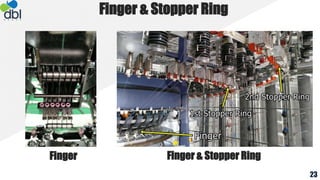

- 22. Cause 1: Internal fly migration while feeding 1 Where is the problem? In dyed yarn finger planning 2 Why does the problem occur? Improper colourwise dyed yarn finger planning 3 What is needed to solve the problem? Colourwise separated light and dark colour yarn fingering 4 Who takes the responsibilities? QCC & technical team 5 When will it be done? From 11 October, 2018 to 30 October, 2018 6 How the work is done & how much it will cost? It can be done by setting light and dark colour yarn in stopper ringwise separate fingers and the costing is zero 5W 1H Analysis 22

- 23. Finger & Stopper Ring Finger Finger & Stopper Ring 23

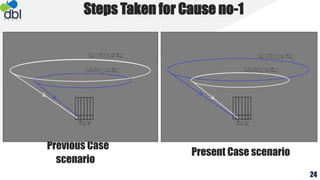

- 24. Steps Taken for Cause no-1 Previous Case scenario Present Case scenario 24

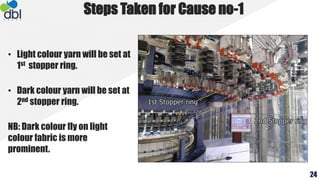

- 25. Steps Taken for Cause no-1 ŌĆó Light colour yarn will be set at 1st stopper ring. ŌĆó Dark colour yarn will be set at 2nd stopper ring. NB: Dark colour fly on light colour fabric is more prominent. 24

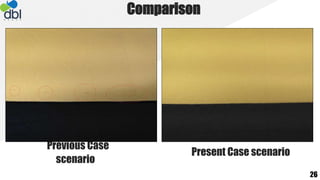

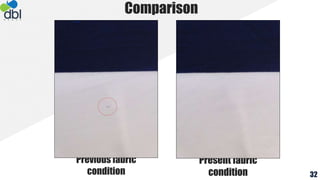

- 26. Comparison Previous Case scenario Present Case scenario 26

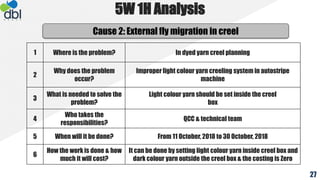

- 27. Cause 2: External fly migration in creel 1 Where is the problem? In dyed yarn creel planning 2 Why does the problem occur? Improper light colour yarn creeling system in autostripe machine 3 What is needed to solve the problem? Light colour yarn should be set inside the creel box 4 Who takes the responsibilities? QCC & technical team 5 When will it be done? From 11 October, 2018 to 30 October, 2018 6 How the work is done & how much it will cost? It can be done by setting light colour yarn inside creel box and dark colour yarn outside the creel box & the costing is Zero 5W 1H Analysis 27

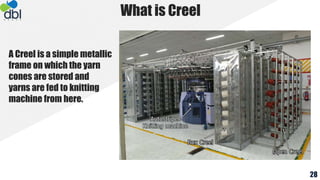

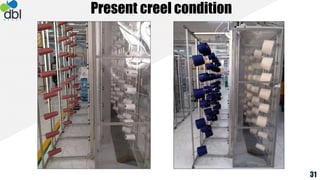

- 28. What is Creel A Creel is a simple metallic frame on which the yarn cones are stored and yarns are fed to knitting machine from here. 28

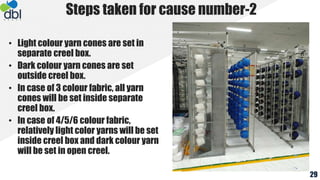

- 29. Steps taken for cause number-2 ŌĆó Light colour yarn cones are set in separate creel box. ŌĆó Dark colour yarn cones are set outside creel box. ŌĆó In case of 3 colour fabric, all yarn cones will be set inside separate creel box. ŌĆó In case of 4/5/6 colour fabric, relatively light color yarns will be set inside creel box and dark colour yarn will be set in open creel. 29

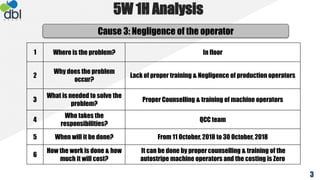

- 33. Cause 3: Negligence of the operator 1 Where is the problem? In floor 2 Why does the problem occur? Lack of proper training & Negligence of production operators 3 What is needed to solve the problem? Proper Counselling & training of machine operators 4 Who takes the responsibilities? QCC team 5 When will it be done? From 11 October, 2018 to 30 October, 2018 6 How the work is done & how much it will cost? It can be done by proper counselling & training of the autostripe machine operators and the costing is Zero 5W 1H Analysis 3

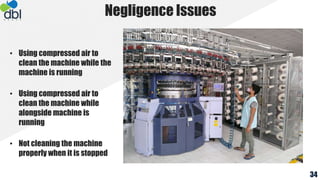

- 34. Negligence Issues ŌĆó Using compressed air to clean the machine while the machine is running ŌĆó Using compressed air to clean the machine while alongside machine is running ŌĆó Not cleaning the machine properly when it is stopped 34

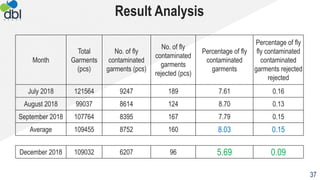

- 37. Result Analysis Month Total Garments (pcs) No. of fly contaminated garments (pcs) No. of fly contaminated garments rejected (pcs) Percentage of fly contaminated garments Percentage of fly fly contaminated contaminated garments rejected rejected July 2018 121564 9247 189 7.61 0.16 August 2018 99037 8614 124 8.70 0.13 September 2018 107764 8395 167 7.79 0.15 Average 109455 8752 160 8.03 0.15 December 2018 109032 6207 96 5.69 0.09 37

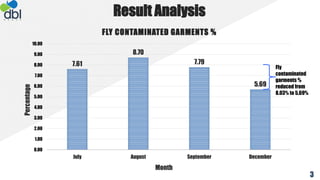

- 38. Result Analysis 7.61 8.70 7.79 5.69 0.00 1.00 2.00 3.00 4.00 5.00 6.00 7.00 8.00 9.00 10.00 July August September December Percentage Month FLY CONTAMINATED GARMENTS % 3 Fly contaminated garments % reduced from 8.03% to 5.69%

- 39. Result Analysis 3 0.16 0.13 0.15 0.09 0.00 0.02 0.04 0.06 0.08 0.10 0.12 0.14 0.16 0.18 July August September December Percentage Month FLY CONTAMINATED REJECTED GARMENTS % Fly contaminated garments rejection % reduced from 0.15% to 0.09%

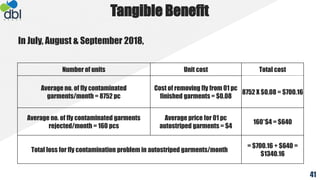

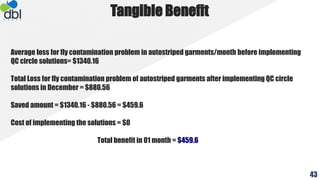

- 41. Tangible Benefit In July, August & September 2018, Number of units Unit cost Total cost Average no. of fly contaminated garments/month = 8752 pc Cost of removing fly from 01 pc finished garments = $0.08 8752 X $0.08 = $700.16 Average no. of fly contaminated garments rejected/month = 160 pcs Average price for 01 pc autostriped garments = $4 160*$4 = $640 Total loss for fly contamination problem in autostriped garments/month = $700.16 + $640 = $1340.16 41

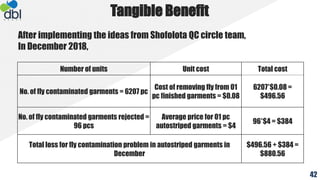

- 42. Tangible Benefit Number of units Unit cost Total cost No. of fly contaminated garments = 6207 pc Cost of removing fly from 01 pc finished garments = $0.08 6207*$0.08 = $496.56 No. of fly contaminated garments rejected = 96 pcs Average price for 01 pc autostriped garments = $4 96*$4 = $384 Total loss for fly contamination problem in autostriped garments in December $496.56 + $384 = $880.56 42 After implementing the ideas from Shofolota QC circle team, In December 2018,

- 43. Tangible Benefit Average loss for fly contamination problem in autostriped garments/month before implementing QC circle solutions= $1340.16 Total Loss for fly contamination problem of autostriped garments after implementing QC circle solutions in December = $880.56 Saved amount = $1340.16 - $880.56 = $459.6 Cost of implementing the solutions = $0 Total benefit in 01 month = $459.6 43

- 44. Approval from Cost & Budget Dept. 44

- 45. Intangible Benefit 45 ’é¦ Increased teamwork ’é¦ Increased team spirit ’é¦ Enhanced self and mutual development ’é¦ Improved self-esteem and motivational needs ’é¦ Improved quality of work-life of employees ’é¦ Improved problem identifying & solving ability

- 47. Standardization ŌĆó Approved by Production and Quality authorized personnel ŌĆó Fully implemented in all Terrot autostripe machines of JAL knitting 47

- 48. Project Summary ŌĆó We found out major problems of autostripe knitting machine ŌĆó We choose one problem and researched for the solutions ŌĆó We developed some solutions and tested them in the floor ŌĆó We compared the results and succeeded to reach our target ŌĆó Finally we made an SOP, authorized it and implemented them in the floor 48 PROJECT SUMMARY

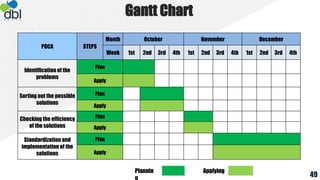

- 49. Gantt Chart Plannin Applying PDCA STEPS Month October November December Week 1st 2nd 3rd 4th 1st 2nd 3rd 4th 1st 2nd 3rd 4th Identification of the problems Plan Apply Sorting out the possible solutions Plan Apply Checking the efficiency of the solutions Plan Apply Standardization and implementation of the solutions Plan Apply 49

- 50. Tools Used ’é¦ Matrix ’é¦ PDCA Cycle ’é¦ Gantt Chart ’é¦ Fish bone analysis ’é¦ Pareto chart ’é¦ 5W1H analysis ’é¦ Bar diagrams 5

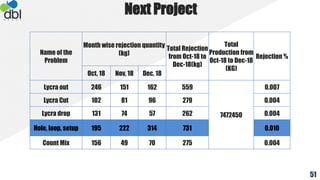

- 51. Next Project 51 Name of the Problem Month wise rejection quantity (kg) Total Rejection from Oct-18 to Dec-18(kg) Total Production from Oct-18 to Dec-18 (KG) Rejection % Oct, 18 Nov, 18 Dec, 18 Lycra out 246 151 162 559 7472450 0.007 Lycra Cut 102 81 96 279 0.004 Lycra drop 131 74 57 262 0.004 Hole, loop, setup 195 222 314 731 0.010 Count Mix 156 49 70 275 0.004

- 52. Our next project will be minimization of hole, loop & setup problem in order to reduce fabric rejection Next Project 52

- 53. THANK YOU

- 54. Any Questions?