hull inspection class

Download as PPTX, PDF1 like2,251 views

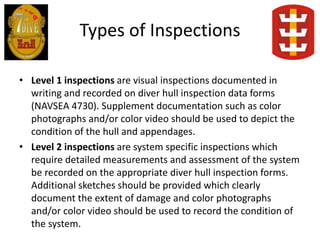

As a member of a hull inspection team, you will conduct visual inspections of a ship's hull and document any issues found. Level 1 inspections note damage in writing while Level 2 inspections require detailed measurements. Inspections check components like the bow thruster, keel cooler, rudders, sea chest, drive shaft, and zinc anodes for damage, debris, or corrosion. Measurements and damage descriptions are recorded according to standard procedures. Any unidentified objects like mines are carefully marked and reported. Inspection findings are documented on forms after completing the dive.

1 of 20

Downloaded 24 times

Recommended

Plumbness & Roundness of storage tanks

Plumbness & Roundness of storage tanksWeld Maniac

Ã˝

The document discusses methods for measuring the plumbness and roundness of storage tank shells during construction and maintenance. Plumbness is measured using a total station to determine the verticality of each shell course, while roundness is measured to check how circular each course is. Measurements are taken at regular intervals and positions around the tank circumference and shell height. The document provides acceptance criteria from API standards, specifying maximum allowable deviations for plumbness and roundness based on tank size.Lesson 14 Precise Piloting

Lesson 14 Precise PilotingGuilherme Azevedo

Ã˝

This document provides an overview of key concepts for ship handling and piloting, including:

1. Describing characteristics like turning circles, advance, transfer, and tactical diameters.

2. Demonstrating how to calculate turn bearings, danger bearings, and determine position relative to track.

3. Explaining terms like standard tactical diameter and standard rudder.Robots for Industrial Inspection

Robots for Industrial Inspectionmarshallbutler

Ã˝

Newton Robotics delivers custom robotic solutions based on advanced machine vision technology. As a solutions provider, Newton Robotics is uniquely organized and staffed to include both development and manufacturing capabilities, based on our multi-disciplinary approach. Polyinform_pipelines inspection_english

Polyinform_pipelines inspection_englishPolyinform

Ã˝

The document describes a new contactless pipeline inspection technology called KMD-01M. It uses magnetometers to detect defects in pipelines from the surface without disrupting operations. The technology is based on nanofilm sensors that can detect weak magnetic fields from defects. It can identify a variety of defect types and has inspected over 10,000 km of pipelines accurately. The system offers advantages over traditional inspection methods like lower costs and ability to inspect underwater or inaccessible areas.Under water welding.smnr

Under water welding.smnrChuchu Beera

Ã˝

The document discusses underwater welding. It begins by explaining that underwater welding involves processes that join steel on offshore structures, pipelines, and ships underwater. It then covers the principles of underwater welding, classifications of wet and dry underwater welding, advantages and disadvantages of each method, risks and safety considerations, and applications of underwater welding such as offshore construction and ship repair. It concludes by discussing future developments in automation and new techniques like friction welding.Typical Quality Management System Based On Iso 9001 2008

Typical Quality Management System Based On Iso 9001 2008Isidro Sid Calayag

Ã˝

This document outlines the key elements of a quality management system (QMS) based on ISO 9001:2008. It discusses the objectives of implementing a QMS, including achieving organizational success and meeting requirements. The QMS focuses on customer focus, leadership, involvement of people, process approach, and continual improvement. It addresses management responsibility, resource management, product realization, measurement and improvement to ensure a process-based approach that meets customer needs and enhances supplier relationships.Energy Oil Gas Presentation

Energy Oil Gas Presentationjlai

Ã˝

This document summarizes a company that provides computer-based measurement and automation solutions. Some key points:

- The company has over $570M in annual revenue, over 3,800 employees operating in 40+ countries.

- They leverage mainstream technologies like PCs, networks, and software to provide virtual instrumentation and cost-effective automation solutions.

- Their products and applications span various industries like oil & gas, manufacturing, and utilities.The use of imagery in monitoring existing sub surface structures

The use of imagery in monitoring existing sub surface structuresPeter McCready

Ã˝

Applications and Research in Hydrographic Surveying:

A report examining the use of imagery to monitor sub surface structures.

Produced in fulfilment of MSc Geospatial & Mapping Sciences at the University of Glasgow (2015).“Securing underwater wireless communication networks” 2

“Securing underwater wireless communication networks” 2Naveena N

Ã˝

This document summarizes a seminar presentation on securing underwater wireless communication networks. It discusses the existing challenges with underwater wireless networks including high bit error rates, propagation delays, and low bandwidth. It proposes three schemes for securing such networks: secure time synchronization to enable power saving; secure localization for location information and data tagging; and secure routing to reject paths with malicious nodes. The techniques aim to provide secure data transmission and are based on mechanisms like time synchronization, localization using time/signal information, and routing protocols.Underwater Welding

Underwater WeldingKaran Prajapati

Ã˝

It is the welding process done under the water with the help of two methods : Dry Welding and Wet Welding. The presentation provides basic knowledge on the underwater welding and it's respective techniques.Underwater concrete

Underwater concretesanthinishanthu

Ã˝

This document discusses underwater concrete, including its production, placement methods, and quality control. It notes that underwater concrete must have proper mix design and flowability to consolidate under its own weight without vibration. The main placement methods described are tremie, pump, toggle bags, and bagwork. Quality control includes monitoring placement rate and volume. Common issues with underwater concrete include cement washout, laitance, and segregation, which mix design and proper placement seek to prevent.Autonomous Underwater Vehicle (AUVs)

Autonomous Underwater Vehicle (AUVs)MM.H.Saboo Siddik Polytechnic

Ã˝

An autonomous underwater vehicle (AUV) is a robot which travels underwater without requiring input from an operator. AUVs constitute part of a larger group of undersea systems known as unmanned underwater vehicles, a classification that includes non-autonomous remotely operated underwater vehicles (ROVs) – controlled and powered from the surface by an operator/pilot via an umbilical or using remote control. In military applications AUVs are more often referred to simply as unmanned undersea vehicles (UUVs).Korea and norway maritime opportunities and challenges in the high north

Korea and norway maritime opportunities and challenges in the high northInnovation Norway

Ã˝

1) NTNU is a leading Norwegian university focused on science and technology with over 20,000 students. It has strong maritime and marine engineering programs.

2) NTNU conducts extensive research on Arctic challenges like ship design, drilling, and transportation that is important for both Norway and Korea's maritime industries.

3) NTNU collaborates closely with Korean universities like KAIST and has opportunities for further research cooperation in areas like Arctic infrastructure and floating structures in ice.OPTICLINE C200 C1000 BY JENOPTIK

OPTICLINE C200 C1000 BY JENOPTIKHommel Etamic (Jenoptik)

Ã˝

Medicion de contorno y forma de piezas tipo flecha, cigüeñales, arbol de levas, partes de transmicion,etc.

Somos lideres mundiales en este segmento!!!!Calibration of MMDs to meet QMS

Calibration of MMDs to meet QMSAmsavel Vel

Ã˝

This presentation is on basic requirement on Claibtration to meet Quality management system in the manufacturing area.Norsok standards for oil and gas

Norsok standards for oil and gasmarco garofanello

Ã˝

The document outlines various NORSOK standards for equipment and operations used in the oil and gas industry. There are multiple standards listed for subsea production systems, diving and underwater operations, drilling facilities, instrumentation, materials, piping systems, electrical systems, safety, and other areas. The NORSOK standards are intended for use in offshore and onshore petroleum facilities and operations. The website www.standard.no/petroleum provides updated information on the NORSOK standards.Emm unit i

Emm unit iGopinath Guru

Ã˝

Metrology is the science of measurement. It has three main tasks: defining measurement units, realizing measurement units through scientific methods, and establishing traceability in documenting measurement accuracy. Metrology is essential in scientific research and various industries. It covers establishing standards, developing measurement methods, analyzing errors, and ensuring instrument accuracy. Metrology helps plan lives and enable commercial exchanges with confidence as measurements can be seen everywhere.Zigbee based water quality monitoring system using solar power

Zigbee based water quality monitoring system using solar powereSAT Journals

Ã˝

Abstract Now a days technology is advancing especially wireless sensor network have numerous application in remote sensing and

controlling. So by this technology various environmental parameters can be monitored. Idea comes into the mind to monitor the

quality of water because water is one of the important factors for living organism. There are various wireless models such as Wi-

Fi, Bluetooth, Wi-Max. Here Zigbee is used as wireless sensor network for monitoring the quality of water because, of its low

cost, low power consumption and easy to operate. Rapid development in industry and human activities affects the quality of water.

Maintaining the good quality of water is a critical problem. But, by using this new wireless technology the task of monitoring

become simple. In this system various sensors are used for monitoring the parameters for water samples as quality of water

depends upon number of parameters such as pH, turbidity, dissolved oxygen and many more. The main parameters for this system

are pH and turbidity, for that pH sensor and turbidity sensor are used. This whole system is powered by solar energy.

Keywords: pH Sensor, Turbidity Sensor, ZigbeeCorrosion monitoring in petroleum refineries

Corrosion monitoring in petroleum refineriesK R SONI

Ã˝

In petroleum refineries, corrosion of equipment takes place all through its operating life. It is essential to monitor the corrosion damage so that timely corrective actions like maintenance / repairs / rehabilitation of equipment can be undertaken before it causes unsafe plant operations.

The techniques employed for systematic corrosion monitoring of refinery equipment have been described in this presentation.Quality management in construction

Quality management in constructionIsidro Sid Calayag

Ã˝

Using ISO 9001:2008 helps ensure that customers get consistent, good quality products and services, which in turn brings many business benefits.Calibration of Coordinate Measuring Machines (CMM)

Calibration of Coordinate Measuring Machines (CMM)Hassan Habib

Ã˝

This presentation is made in an effort to impart information regarding the techniques used for the calibration of coordinate measuring machines. These versatile machines are today being used for the inspection of very precise and accurate mechanical components manufactured by keeping in view advanced geometrical dimensioning and tolerancing techniques.Plant Maintenance

Plant MaintenanceAnand Subramaniam

Ã˝

The document discusses plant maintenance strategies and terminology. It outlines various types of maintenance including corrective, preventative, and predictive maintenance. It emphasizes the importance of aligning maintenance goals with business goals to improve processes, asset performance, and uptime. Various maintenance planning, control, and terminology are defined to effectively manage strategic assets.Underwater welding

Underwater weldingShobhit Ishan

Ã˝

The document discusses underwater welding technology. It describes how underwater welding was first developed by the British Admiralty and then special waterproof electrodes were created. It discusses the different types of underwater welding including wet welding, dry welding using hyperbaric chambers, and different habitat sizes. It outlines the challenges of underwater welding including costs and equipment needs. It also discusses the welding processes, necessary equipment, safety considerations, and developing automation trends in the field.Cost of quality

Cost of qualityHassan Asif

Ã˝

The document discusses cost of quality and its categories. It explains that cost of quality refers to the costs incurred to prevent non-conformance and the costs associated with poor quality. There are two main categories - costs of achieving good quality like prevention and appraisal costs, and costs of poor quality like internal and external failure costs. Measuring these costs helps identify opportunities to improve quality and reduce costs. It provides an example of measuring quality costs at a motor company over four years which showed prevention costs increasing and overall quality costs decreasing as quality improved.Gamma BP Profile

Gamma BP ProfileGulam Jailani Kassim Ali

Ã˝

Gamma BP Pte. Ltd. is a subsidiary of PT Gamma Buana Persada that provides inspection services to the oil and gas industries in Southeast Asia. It offers advanced and conventional NDT inspections, rope access inspections, lifting gear inspections, load testing, OCTG inspections, welding engineering services, and manpower supplies from its locations in Singapore and Indonesia.ISO Clause No 7 Production Realization

ISO Clause No 7 Production RealizationMANOJ KUMAR MAHARANA

Ã˝

All about ISO clause No-7 i.e. production Realization

7.1 Planning of Product Realization

7.2 Customer Related Processes

7.4 Purchasing

7.5.1 Control of production & service provision

7.5.2 Validation of processes for production and service provision

7.5.3 Identification & Traceability

7.5.4 Customer Property

7.5.5 Preservation of Product

7.6 Control of monitoring & measuring devices

Types of maintenance

Types of maintenanceAbhik Rathod

Ã˝

This document discusses different types of maintenance for assets including aircraft. It defines maintenance as work carried out to preserve assets and enable continued use over their design life. The main types of maintenance discussed are: breakdown, preventive (periodic and predictive), and corrective. Periodic maintenance involves regular inspection and servicing, while predictive uses condition monitoring. Aircraft maintenance checks ranging from light A/B checks every 500-800 hours to comprehensive D checks every 5 years are also outlined. Nondestructive testing methods like liquid penetrant and eddy current are used during aircraft maintenance inspections.Steel boat (8m)

Steel boat (8m)hydrologyproject0

Ã˝

This document specifies requirements for an 8-meter steel boat to be used for hydrological measurements. The boat must be durable and able to operate safely in shallow water. It requires a cabin that can accommodate staff and equipment, as well as an open deck space for measurements. The boat must be fitted with outboard engines, safety equipment, and accessories for effective deployment. Optional configurations include an instrument well inside the boat for transducers.Motor launch

Motor launchhydrologyproject0

Ã˝

The document specifies requirements for a motor launch that will be used to conduct hydrological measurements. It must:

- Operate reliably and safely in rivers, canals, and reservoirs, including very shallow water.

- Be constructed of steel with durable coatings for protection against corrosion.

- Have a cabin that can accommodate equipment, staff, and hydrological measurement devices.

- Be powered by two 50kW diesel engines and controlled remotely from the cabin.

- Include features like a transducer trunk pipe for echosounders and current meters.Cswip 11-01 - plant inspection- Week 2 cours

Cswip 11-01 - plant inspection- Week 2 coursRafik Guerbous

Ã˝

This document provides an overview of the content covered in Week 2 of the CSWIP Plant Inspector Level 1 course, including:

1. An introduction to pressure equipment, defining key characteristics like stored energy and factors of safety.

2. Summaries of sections on pressure vessel inspection, outlining the roles of inspectors in verifying integrity, design aspects like corrosion allowance, and code compliance.

3. Details on visual and dimensional examinations performed on pressure vessels, including examination points for vessel exteriors and interiors and dimensional checking procedures.More Related Content

Viewers also liked (19)

“Securing underwater wireless communication networks” 2

“Securing underwater wireless communication networks” 2Naveena N

Ã˝

This document summarizes a seminar presentation on securing underwater wireless communication networks. It discusses the existing challenges with underwater wireless networks including high bit error rates, propagation delays, and low bandwidth. It proposes three schemes for securing such networks: secure time synchronization to enable power saving; secure localization for location information and data tagging; and secure routing to reject paths with malicious nodes. The techniques aim to provide secure data transmission and are based on mechanisms like time synchronization, localization using time/signal information, and routing protocols.Underwater Welding

Underwater WeldingKaran Prajapati

Ã˝

It is the welding process done under the water with the help of two methods : Dry Welding and Wet Welding. The presentation provides basic knowledge on the underwater welding and it's respective techniques.Underwater concrete

Underwater concretesanthinishanthu

Ã˝

This document discusses underwater concrete, including its production, placement methods, and quality control. It notes that underwater concrete must have proper mix design and flowability to consolidate under its own weight without vibration. The main placement methods described are tremie, pump, toggle bags, and bagwork. Quality control includes monitoring placement rate and volume. Common issues with underwater concrete include cement washout, laitance, and segregation, which mix design and proper placement seek to prevent.Autonomous Underwater Vehicle (AUVs)

Autonomous Underwater Vehicle (AUVs)MM.H.Saboo Siddik Polytechnic

Ã˝

An autonomous underwater vehicle (AUV) is a robot which travels underwater without requiring input from an operator. AUVs constitute part of a larger group of undersea systems known as unmanned underwater vehicles, a classification that includes non-autonomous remotely operated underwater vehicles (ROVs) – controlled and powered from the surface by an operator/pilot via an umbilical or using remote control. In military applications AUVs are more often referred to simply as unmanned undersea vehicles (UUVs).Korea and norway maritime opportunities and challenges in the high north

Korea and norway maritime opportunities and challenges in the high northInnovation Norway

Ã˝

1) NTNU is a leading Norwegian university focused on science and technology with over 20,000 students. It has strong maritime and marine engineering programs.

2) NTNU conducts extensive research on Arctic challenges like ship design, drilling, and transportation that is important for both Norway and Korea's maritime industries.

3) NTNU collaborates closely with Korean universities like KAIST and has opportunities for further research cooperation in areas like Arctic infrastructure and floating structures in ice.OPTICLINE C200 C1000 BY JENOPTIK

OPTICLINE C200 C1000 BY JENOPTIKHommel Etamic (Jenoptik)

Ã˝

Medicion de contorno y forma de piezas tipo flecha, cigüeñales, arbol de levas, partes de transmicion,etc.

Somos lideres mundiales en este segmento!!!!Calibration of MMDs to meet QMS

Calibration of MMDs to meet QMSAmsavel Vel

Ã˝

This presentation is on basic requirement on Claibtration to meet Quality management system in the manufacturing area.Norsok standards for oil and gas

Norsok standards for oil and gasmarco garofanello

Ã˝

The document outlines various NORSOK standards for equipment and operations used in the oil and gas industry. There are multiple standards listed for subsea production systems, diving and underwater operations, drilling facilities, instrumentation, materials, piping systems, electrical systems, safety, and other areas. The NORSOK standards are intended for use in offshore and onshore petroleum facilities and operations. The website www.standard.no/petroleum provides updated information on the NORSOK standards.Emm unit i

Emm unit iGopinath Guru

Ã˝

Metrology is the science of measurement. It has three main tasks: defining measurement units, realizing measurement units through scientific methods, and establishing traceability in documenting measurement accuracy. Metrology is essential in scientific research and various industries. It covers establishing standards, developing measurement methods, analyzing errors, and ensuring instrument accuracy. Metrology helps plan lives and enable commercial exchanges with confidence as measurements can be seen everywhere.Zigbee based water quality monitoring system using solar power

Zigbee based water quality monitoring system using solar powereSAT Journals

Ã˝

Abstract Now a days technology is advancing especially wireless sensor network have numerous application in remote sensing and

controlling. So by this technology various environmental parameters can be monitored. Idea comes into the mind to monitor the

quality of water because water is one of the important factors for living organism. There are various wireless models such as Wi-

Fi, Bluetooth, Wi-Max. Here Zigbee is used as wireless sensor network for monitoring the quality of water because, of its low

cost, low power consumption and easy to operate. Rapid development in industry and human activities affects the quality of water.

Maintaining the good quality of water is a critical problem. But, by using this new wireless technology the task of monitoring

become simple. In this system various sensors are used for monitoring the parameters for water samples as quality of water

depends upon number of parameters such as pH, turbidity, dissolved oxygen and many more. The main parameters for this system

are pH and turbidity, for that pH sensor and turbidity sensor are used. This whole system is powered by solar energy.

Keywords: pH Sensor, Turbidity Sensor, ZigbeeCorrosion monitoring in petroleum refineries

Corrosion monitoring in petroleum refineriesK R SONI

Ã˝

In petroleum refineries, corrosion of equipment takes place all through its operating life. It is essential to monitor the corrosion damage so that timely corrective actions like maintenance / repairs / rehabilitation of equipment can be undertaken before it causes unsafe plant operations.

The techniques employed for systematic corrosion monitoring of refinery equipment have been described in this presentation.Quality management in construction

Quality management in constructionIsidro Sid Calayag

Ã˝

Using ISO 9001:2008 helps ensure that customers get consistent, good quality products and services, which in turn brings many business benefits.Calibration of Coordinate Measuring Machines (CMM)

Calibration of Coordinate Measuring Machines (CMM)Hassan Habib

Ã˝

This presentation is made in an effort to impart information regarding the techniques used for the calibration of coordinate measuring machines. These versatile machines are today being used for the inspection of very precise and accurate mechanical components manufactured by keeping in view advanced geometrical dimensioning and tolerancing techniques.Plant Maintenance

Plant MaintenanceAnand Subramaniam

Ã˝

The document discusses plant maintenance strategies and terminology. It outlines various types of maintenance including corrective, preventative, and predictive maintenance. It emphasizes the importance of aligning maintenance goals with business goals to improve processes, asset performance, and uptime. Various maintenance planning, control, and terminology are defined to effectively manage strategic assets.Underwater welding

Underwater weldingShobhit Ishan

Ã˝

The document discusses underwater welding technology. It describes how underwater welding was first developed by the British Admiralty and then special waterproof electrodes were created. It discusses the different types of underwater welding including wet welding, dry welding using hyperbaric chambers, and different habitat sizes. It outlines the challenges of underwater welding including costs and equipment needs. It also discusses the welding processes, necessary equipment, safety considerations, and developing automation trends in the field.Cost of quality

Cost of qualityHassan Asif

Ã˝

The document discusses cost of quality and its categories. It explains that cost of quality refers to the costs incurred to prevent non-conformance and the costs associated with poor quality. There are two main categories - costs of achieving good quality like prevention and appraisal costs, and costs of poor quality like internal and external failure costs. Measuring these costs helps identify opportunities to improve quality and reduce costs. It provides an example of measuring quality costs at a motor company over four years which showed prevention costs increasing and overall quality costs decreasing as quality improved.Gamma BP Profile

Gamma BP ProfileGulam Jailani Kassim Ali

Ã˝

Gamma BP Pte. Ltd. is a subsidiary of PT Gamma Buana Persada that provides inspection services to the oil and gas industries in Southeast Asia. It offers advanced and conventional NDT inspections, rope access inspections, lifting gear inspections, load testing, OCTG inspections, welding engineering services, and manpower supplies from its locations in Singapore and Indonesia.ISO Clause No 7 Production Realization

ISO Clause No 7 Production RealizationMANOJ KUMAR MAHARANA

Ã˝

All about ISO clause No-7 i.e. production Realization

7.1 Planning of Product Realization

7.2 Customer Related Processes

7.4 Purchasing

7.5.1 Control of production & service provision

7.5.2 Validation of processes for production and service provision

7.5.3 Identification & Traceability

7.5.4 Customer Property

7.5.5 Preservation of Product

7.6 Control of monitoring & measuring devices

Types of maintenance

Types of maintenanceAbhik Rathod

Ã˝

This document discusses different types of maintenance for assets including aircraft. It defines maintenance as work carried out to preserve assets and enable continued use over their design life. The main types of maintenance discussed are: breakdown, preventive (periodic and predictive), and corrective. Periodic maintenance involves regular inspection and servicing, while predictive uses condition monitoring. Aircraft maintenance checks ranging from light A/B checks every 500-800 hours to comprehensive D checks every 5 years are also outlined. Nondestructive testing methods like liquid penetrant and eddy current are used during aircraft maintenance inspections.Similar to hull inspection class (20)

Steel boat (8m)

Steel boat (8m)hydrologyproject0

Ã˝

This document specifies requirements for an 8-meter steel boat to be used for hydrological measurements. The boat must be durable and able to operate safely in shallow water. It requires a cabin that can accommodate staff and equipment, as well as an open deck space for measurements. The boat must be fitted with outboard engines, safety equipment, and accessories for effective deployment. Optional configurations include an instrument well inside the boat for transducers.Motor launch

Motor launchhydrologyproject0

Ã˝

The document specifies requirements for a motor launch that will be used to conduct hydrological measurements. It must:

- Operate reliably and safely in rivers, canals, and reservoirs, including very shallow water.

- Be constructed of steel with durable coatings for protection against corrosion.

- Have a cabin that can accommodate equipment, staff, and hydrological measurement devices.

- Be powered by two 50kW diesel engines and controlled remotely from the cabin.

- Include features like a transducer trunk pipe for echosounders and current meters.Cswip 11-01 - plant inspection- Week 2 cours

Cswip 11-01 - plant inspection- Week 2 coursRafik Guerbous

Ã˝

This document provides an overview of the content covered in Week 2 of the CSWIP Plant Inspector Level 1 course, including:

1. An introduction to pressure equipment, defining key characteristics like stored energy and factors of safety.

2. Summaries of sections on pressure vessel inspection, outlining the roles of inspectors in verifying integrity, design aspects like corrosion allowance, and code compliance.

3. Details on visual and dimensional examinations performed on pressure vessels, including examination points for vessel exteriors and interiors and dimensional checking procedures.Aluminium boat (6m)

Aluminium boat (6m)hydrologyproject0

Ã˝

The document specifies requirements for an aluminum boat to be used for hydrological measurements. The boat must be capable of operating safely and reliably in shallow water. It must have a cabin, deck space, and be outfitted with equipment like anchors, life jackets, and fire extinguishers. Optional configurations include fitting the boat with an instrument well inside for transducers. The boat will be approximately 6 meters long, 2.5 meters wide, have a 0.5 meter draft and be propelled by two 30kW outboard engines.STANDARD ANCHORING AND ANCHORING PROCEDURES

STANDARD ANCHORING AND ANCHORING PROCEDURESssuser81322e

Ã˝

STANDARD PROCEDURES FOR ANCHORING AND ANCHORING Hull inspection

Hull inspectionHIMTFaculty

Ã˝

The document outlines areas and procedures for inspecting ships for defects, damages, and corrosion. It describes how to inspect different parts of the ship to check for buckling, indents, fatigue cracks, coating breakdown, and corrosion. It also discusses documenting inspection findings in reports, including what details to include for different types of defects. The purpose is to systematically check the ship's structure according to regulations and maintenance planning.What should i expect from a marine survey

What should i expect from a marine surveyDonald Mccann

Ã˝

A marine survey report provides an objective assessment of a boat's condition and value. The surveyor conducts a visual inspection and some non-destructive testing to evaluate the hull, deck, mechanical and electrical systems. The report will identify any issues found and make recommendations. It also estimates the boat's current market value. The survey helps buyers and sellers accurately price a boat. It also ensures the boat meets safety standards for insurance purposes. Overall, the survey provides an impartial evaluation of the boat's condition from a professional perspective.Navtec rigging service guidelines

Navtec rigging service guidelinesDavid de Haro Malo de Molina

Ã˝

The document provides guidelines for routine inspection and maintenance of mast and rigging systems to maximize their lifespan. It discusses factors that affect the longevity of rod and wire rigging, including sailing conditions, loads, care/maintenance, and environmental factors. For rod rigging, it recommends a Level C inspection every 40,000-60,000 miles or 6 years, which includes inspecting rod heads and replacing any cracked rods or turnbuckle screws. Wire rigging should also be inspected regularly for corrosion or cracks in the fittings or wire. Proper cleaning, alignment and replacement of damaged parts can extend the usable life of rigging components.Frp boat (7m)

Frp boat (7m)hydrologyproject0

Ã˝

The document specifies requirements for a fiberglass reinforced plastic (FRP) boat to be used for hydrological measurements. The boat must be capable of operating safely and reliably in shallow water. It should have a sturdy hull, floatation chambers, and be unsinkable with adequate stability. The boat will include a cabin with seating and windows, work space on the deck, and will be powered by two outboard engines operated by a remote control system. It may optionally include an instrument well inside the boat for transducers.SEAM-5-GRP2-REPORT.pptx

SEAM-5-GRP2-REPORT.pptxAllenDizon3

Ã˝

Discuss different conventional hatch including the structural components, testing methods and watertight and weather tight of the hatch cover.

A cargo hatch or deck hatch or hatchway is type of door used on ships and boats to cover the opening to the cargo hold or other lower part of the ship. To make the cargo hold waterproof, most cargo holds have cargo hatch. Hatch covers of ships are designed to be efficient and cost-effective, as an initial investment and during service, and at the same time should suit the demands of the various types of cargo vessels. With the many changing trends of cargo transportation, it would be expected that the design and structure of cargo holds would change to meet the needs of modern shipping. This is clearly evident with container tonnage and the vehicle decks of the Roll-on, Roll-off (Ro-Ro) vessels. However, the changes in the carriage of general cargoes have been comparatively small. This is possible because most merchandise will suit the more popular container or similar unit load movement.

Hold structures have tended to go towards square corners to reduce broken stowage (BS), and suit palletization, pre-slung loads and the use of the fork lift truck inside the holds. Stowage by such vehicles are aided by flush decks in way of the turn of the bilge, as opposed to the angle turn in the sides of the holds of older tonnage.

Some specialist cargoes, like steel coils , still suit conventional holds and clearly would not be compatible inside containers, because of the shape and weight of each item. As with large case goods or castings, which tend to transport better by means of conventional stowage in the more conventional type vessel. Such merchandise is clearly edging towards heavy-lift type loads and these heavier loads are covered in detail here, alongside the designated heavy-lift ship and project cargoes.

The objective of this chapter is to provide an overall picture of an industry sector which is an essential part of cargo handling and general shipping practice. It does not have such a high profile...

FW Tank Cleaning (1).pptx

FW Tank Cleaning (1).pptxAnubhav Soni

Ã˝

The document discusses fire water storage tank inspection and maintenance. It covers topics like classification of storage tanks, design aspects, materials used, objectives of tank inspection, internal and external inspection procedures and intervals, areas prone to corrosion, and precautions during inspection. The document provides detailed guidance on planning and conducting thorough inspections of fire water storage tanks to evaluate integrity and safety.Intervention Engineering IWS Methodology

Intervention Engineering IWS MethodologySarolta Pudney

Ã˝

The document discusses ROV inspection methods for various hull components including:

- The hull shell plating can be inspected via free flying for an overview or attached to the hull for better video quality but limited field of view. High definition video and lighting is used to assess marine growth and coatings.

- ICCP anodes and zinc reference cells on cathodic protection systems can be visually inspected for damage and high pressure water used to clean them.

- Sea chests can be inspected using high definition cameras through gratings to assess coatings, marine growth, and anodes, with cleaning used to remove marine growth.

- Overboard discharges can be inspected externally and internally using various cameras and aShip construction project

Ship construction projectMummina Sekhar

Ã˝

The document outlines the key steps in the ship building process, including design, steel cutting, block assembly, painting, block erection, launching, and sea trials. It first defines important ship parts like the bow, stern, keel, and rigging. The main steps are designing the hull, outfitting, and machinery; cutting steel plates using plasma or hydraulic presses; welding plates into blocks; painting the blocks; erecting blocks according to the design; launching via slipway, float out, or lift; and conducting sea trials to test performance.Sample-Survey-Sea-Ray-200.pdf

Sample-Survey-Sea-Ray-200.pdfTriMarinesurvey

Ã˝

This marine survey report summarizes the condition of a 30-foot 1992 Sea Ray 300 Sundancer boat. The survey found moisture issues in the foredeck that require further investigation and repair. It also recommends replacing the cracked portlights in the V-berth. Overall the boat appears to be in good condition for its age, though some routine maintenance is needed.Marine-Shipbuilding-and-Onboard-Systems.ppt

Marine-Shipbuilding-and-Onboard-Systems.pptdevmarineacademy

Ã˝

This document provides information on ship design and construction terminology and concepts. It discusses factors to consider in ship design like purpose, operating environment, size and construction material. It also covers stability, watertight integrity, subdivision, rig design and engine selection. Specific stability concepts like center of buoyancy, center of gravity and downflooding are defined. Construction methods for different materials like steel, aluminum and wood are also outlined.Frp catamaran (8m)

Frp catamaran (8m) hydrologyproject0

Ã˝

The document specifies requirements for an 8-meter long fiberglass catamaran boat to be used for hydrological measurements. It must operate reliably in shallow water and withstand impacts. The boat will have a 3-meter cabin with seating and storage. It will be powered by two 40HP outboard engines and control systems. Safety equipment like life jackets, fire extinguishers and anchors will be included. Optional features include an instrument well for transducers. The boat is intended for reliable operation making hydrological measurements over 10 years in rivers, canals and reservoirs.mh_saad_resume (2) - Copy

mh_saad_resume (2) - Copymohamed saad

Ã˝

This document contains contact information and a resume for Mohamed Saad Abd El Sabour Ahmed Helaly. It lists his address, phone numbers, email, personal details such as nationality and date of birth, education history including graduating from Alexandria University's Faculty of Law in 2002, technical skills including Microsoft Office and various operating systems, and professional experience conducting subsea inspections for oil and gas companies from 2013 to 2015.Global arc

Global arcValentin Bañaco

Ã˝

The document provides information about the bulk carrier Global Arc, including its ship particulars, ports of call, cargo details, and history of incidents onboard. It also includes pictures of the ship and equipment, as well as guidelines for lashing preparations, crane inspections, and safety criteria at various ports. The summaries focus on key details about the ship and operations.hull inspection class

- 1. Perform as a Member of a Hull Inspection Team 052-238-1650 By: SGT GARCIA

- 2. Table of Contents • References • Task, Conditions, and Standards • Types of Inspections • Cleaning and Inspection Tools • Major Components • Performance Steps

- 3. References • FM 20-11: Military Diving • NAVSEA S0600-AA-PRO-010, NAVSEA S0600- AA-PRO-160, NAVSEA S0600-AA-PRO-170: Underwater Ship Husbandry Manuals • NSTM S9086-CQ-STM-010: Waterborne Underwater Hull Cleaning of Navy Ships

- 4. Task, Conditions, and Standards • Task: Perform as a Member of a Hull Inspection Team (052-238-1650) • Conditions: As a diver in a field environment, you are given orders to conduct a hull inspection, the appropriate diving equipment, an underwater photographic and video set, and an underwater construction tool kit. • Standards: Perform as a member of a hull inspection team, noting all variations from the ship drawings and utilizing underwater camera systems and measurement devices.

- 5. Types of Inspections • Level 1 inspections are visual inspections documented in writing and recorded on diver hull inspection data forms (NAVSEA 4730). Supplement documentation such as color photographs and/or color video should be used to depict the condition of the hull and appendages. • Level 2 inspections are system specific inspections which require detailed measurements and assessment of the system be recorded on the appropriate diver hull inspection forms. Additional sketches should be provided which clearly document the extent of damage and color photographs and/or color video should be used to record the condition of the system.

- 6. Cleaning and Inspection Tools • Putty Knife • Wire Brush • Brush • Hull Scrubber • Green scratch pads • Pressure Washer • Calipers • Machinist Ruler • Camera

- 7. Major Components Bow Thruster •On all Boats, your going to need to inspect both sides for damage and over growth •Look at the fins and propeller (screw) for bent or broken pieces •Check to make sure the propeller is free of any debris i.e. rope and large growth.

- 8. Major Components Keel Cooler •The keel coolers are underwater radiators for the ships engines. •These need to be inspected thoroughly to make sure there are no signs of damage that could cause a leak •They need to be cleaned and cleared of all debris and growth

- 9. Major Components •The rudders and rear propellers need to be inspected for damage •Thoroughly inspect each propeller fin for major damage. i.e. “dog eared” •Look for tangled rope in the joint areas and make sure all moving pieces have free operation. Rudders and screws

- 10. Major Components Sea Chest •Size, shape and location may change on all the different models of boats but they all have the same operations, to allow a large amount of water to flow in to the ships ballast, also it helps cool the engines •Make sure the grate is free and clear of debris and overgrowth, check to make sure the bolts are all there.

- 11. Major Components •The drive shaft is a long cylindrical shaft that transfers power from the engine to the propeller •This should be kept clean of growth. •Fishing line and net has a tendency to get wrapped around it and work its way into the packing areas - Packing area - Drive Shaft

- 12. Major Components Can you count how many anodes are in this picture? In 10 sec? 19 •Anodes can come in all shapes and sizes •Be sure to check all anodes for corrosion •Give an estimated percentage of the remaining anode Zinc Anodes

- 13. Performance Steps 1. Assemble the diving equipment a. Verify the camera system has adequate available memory and battery life b. Review the diagrams of the ship and the previous hull inspection form c. Ensure that measuring devices are available, such as a machinist ruler and calipers

- 14. Performance Steps 2. Conduct a Level 1 or Level 2 inspection a. Annotate the measurements Note: Measurements should be annotated according to NAVSEA S0060-AA-PRO-170, Table 17-3.1 b. Apply common terms associated with any common damage Note: Terms of damage should be applied according to NAVSEA S0600-AA-PRO-10 c. Record the condition of the hull

- 16. Terms of Damage a. Crack. A linear rupture of material under stress. Cracks may form anywhere on a surface, but are usually found near an edge or joint. Cracks have depth, length, and width and are not simply a surface defect. b. Dent. A hollow area made by a blow or collision. There is no loss of material with a dent. c. Gouge. A scooped out, shallow area or groove in the material caused by contact or collision with a hard object. This is common on softer material such as sonar dome rubber windows and shaft coatings, but may also be found on hull plating. d. Scratch. A narrow surface defect that can be felt, but which has no depth into the material. Typically, scratches can be buffed out.

- 17. Terms of Damage e. Surface indication. Any inconsistency of the surface that looks like a scratch or “hair line crack” but cannot be felt or buffed out. f. Tear. Pulled apart or separated by force, common on the leading edge of a bilge keel or a sonar dome rubber window. g. Delamination. Separation between layers, common on shaft coatings and sonar domes. Delaminations may be obvious with entire sections of material lost or may be hidden as a subsurface failure. Subsurface delaminations may appear as bulges. h. Discontinuity. Any imperfection (e.g., surface indication or crack) in the material that has been confirmed with an approved non- destructive test procedure using qualified personnel.

- 18. Performance Steps 3. Identify objects not on the diagram of the ship, such as mines. a. Search for mines. 1) Ensure that you do not expose any mines to movement, light, or high magnetic signatures because they can be detonated in a variety of ways. 2) Use extreme caution when searching, and do not touch or move any mines. b. Mark the location of a mine. 1) Use a grease pencil , and mark the depth of the mine on the hull above the water line with an arrow pointing towards the location of the mine. 2) Record the approximate height, width, and depth of a mine and any words, symbols of color markings

- 19. Performance Steps 4. Use the running log, photographs, video, and diver’s notes to fill out the hull inspection forms after completing the dive.

- 20. Questions?

Editor's Notes

- #8: Bow thruster