HVAC Complete final.pptx

- 1. HVAC Systems – Understanding the basis Table of Contents 1. Introduction to HVAC Systems 2. HVAC System Types 3. HVAC Piping System 4. HVAC Air Distribution Equipments 5. Fans and Pumps 6. HVAC Instrumentation and Control 7. HVAC System Commissioning

- 2. Introduction to HVAC Systems ‚û¢ This article introduces the heating, ventilating and air-conditioning (HVAC) systems. The primary function of HVAC systems is to provide healthy and comfortable interior conditions for occupants; well- designed, efficient systems do this with minimal non- renewable energy and air, and water pollutant emissions.

- 3. Introduction to HVAC Systems ➢ . ➢ The purpose of HVAC design is both high indoor air quality and energy efficiency. (HVAC) creates a climate that allows for maximum comfort by compensating for changing climatic conditions • offers a number of benefits over a large number of individual packaged cooling units • greater energy efficiency, • better controllability, • cheap maintenance, • longer life.

- 4. ➢ Air Cooled Chiller Advantages • Lower installed cost • Quicker availability • No cooling tower or condenser pump required • Less maintenance • No mechanical room required

- 5. ➢ Water-Cooled Chiller advantages • Higher efficiency • Custom selection in larger sizes • Large tonnage capabilities • Indoor Chiller location • Longer life • Lower maintenance

- 6. ‚û¢Purpose of an air handling system Air Handling System Room With Defined Requirements Supply Air Outlet Air Air Handling Systems

- 7. Objectives In the following slides, we will study the components of air handling systems in order to: 1. Become familiar with the components 2. Know their functions 3. Become aware of possible problems

- 8. + Exhaust air treatment Room/Cabin Central air handling unit Terminal air treatment at production room leve Fresh air treatment (make-up air) Main subsystems

- 9. r Weather louvre Control damper Silence Fan Filter Flow rate controller Humidifier Cooling coil Production Room Overview components + Prefilte r Exhaust Air Grille r Secondary Filter Re-circulated air

- 10. ‚û¢Heating unit ‚û¢Cooling unit dehumidifier ‚û¢Humidifier ‚û¢Filters ‚û¢Ducts ‚û¢ To heat the air to the proper temperature ‚û¢ To cool the air to the required temperature or to remove moisture from the air ‚û¢ To bring the air to the proper humidity, if too low ‚û¢ To eliminate particles of pre- determined dimensions and/or micro-organisms ‚û¢ To transport the air Components (2)

- 11. Filter classes Dust filters Standard Aerosol Fine Coarse ULPA HEPA 10 µ m > Dp > 1 µ m Dp > 10 µ m Dp < 1 µ m F5 - F9 G1 - G4 U 14- 17 H 11 - 13 EN 1822 Standard EN 779 Standard

- 13. Contents ‚û¢Fan Design ‚û¢Fan Performance ‚û¢Fan-duct Systems ‚û¢Duct Construction ‚û¢Air Duct Design Fans and Pumps

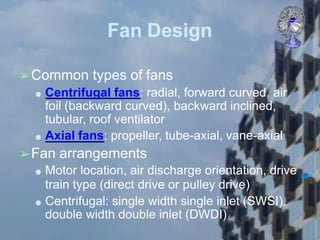

- 14. Fan Design ‚û¢Common types of fans ‚óè Centrifugal fans: radial, forward curved, air foil (backward curved), backward inclined, tubular, roof ventilator ‚óè Axial fans: propeller, tube-axial, vane-axial ‚û¢Fan arrangements ‚óè Motor location, air discharge orientation, drive train type (direct drive or pulley drive) ‚óè Centrifugal: single width single inlet (SWSI), double width double inlet (DWDI)

- 15. Centrifugal and axial fan components AXIAL FANS CENTRIFUGAL FANS Fan Design

- 16. Fan Performance ‚û¢Major issues causing energy losses to a centrifugal fan: ‚óè Circulatory flow between the blades ‚óè Air leakage at the inlet ‚óè Friction between fluid particles and the blade ‚óè Energy loss at the entrance ‚óè Partially filled passage

- 17. Total efficiency curves for centrifugal fans

- 18. Fan-duct Systems Fan-duct System Primary air (conditioned air or makeup airs Secondary air (induced space air, plenum air, or recirculating air) Transfer air (indoor air that moves from an adjacent area)

- 19. Duct Construction ‚û¢Types of air duct ‚óè Supply air duct ‚óè Return air duct ‚óè Outdoor air duct ‚óè Exhaust air ‚û¢Duct sections ‚óè Header or main duct (trunk) ‚óè Branch duct or runout

- 20. Duct Construction ➢Duct material: e.g. UL (Underwriters’ Laboratory) standard ● Class 0: zero flame spread, zero smoke developed • Iron, galvanized steel, aluminum, concrete, masonry, clay tile ● Class 1: flame spread ≤ 25, smoke developed ≤ 50 • Fiberglass, many flexible ducts ● Class 2: flame spread ≤ 50, smoke developed ≤ 100

- 21. DUCT CONSTRUCTION ‚û¢Shapes of air duct ‚óè Rectangular ‚óè More easily fabricated on site, air leakage ‚óè Round Less fluid resistance, better rigidity/strength ‚óè Flat oval ‚óè Flexible

- 22. Rectangular duct Round duct w/ spiral seam Flat oval duct Flexible duct (Source: Wang, S. K., 2001. Handbook of Air Conditioning and Refrigeration)

- 23. Duct Construction ‚û¢Duct specification ‚óè Sheet gauge and thickness of duct material ‚óè Traverse joints & longitudinal seam reinforcements ‚óè Duct hangers & their spacing ‚óè Tapes & adhesive closures ‚óè Fire spread and smoke developed ‚óè Site-fabricated or factory-/pre-fabricated

- 24. Duct Construction ➢Duct heat gain or loss ● Temperature rise or drop ● Duct insulation (mounted or inner-lined) • Reduce heat gain/loss, prevent condensation, sound attentuation • Minimum & recommended thickness ● See ASHRAE standard or local codes ● Temperature rise curves • Depends on air velocity, duct dimensions & insulation

- 25. Duct Construction ➢Dynamic losses ● Result from flow disturbances caused by duct- mounted equipment and fittings • Change airflow path’s direction and/or area • Flow separation & eddies/disturbances ● In dynamic similarity (same Reynolds number & geometrically similar duct fittings), dynamic loss is proportional to their velocity pressure

- 26. Duct Construction ‚û¢Duct fittings ‚óè Elbows ‚óè Converging or diverging tees and wyes ‚óè Entrances and exits ‚óè Enlargements and contractions ‚û¢Means to reduce dynamic losses ‚óè Turning angle, splitter vanes ‚û¢ASHRAE duct fitting database ‚óè Fitting loss coefficients

- 27. Region of eddies and turbulences in a round elbow 5-piece 90o round elbow

- 28. Airflow through a rectangular converging or diverging wye

- 29. Entrance Exit

- 30. Abrupt enlargement Sudden contraction

- 31. Air Duct Design ‚û¢Optimal air duct design ‚óè Optimal duct system layout, space available ‚óè Satisfactory system balance ‚óè Acceptable sound level ‚óè Optimum energy loss and initial cost ‚óè Install only necessary balancing devices (dampers) ‚óè Fire codes, duct construction & insulation ‚û¢Require comprehensive analysis & care for different transport functions

- 32. Air Duct Design ➢Design velocity ● Constraints: space available, beam depth ● Typical guidelines: • Main ducts: air flow usually ≤ 15 m/s; air flow noise must be checked • With more demanding noise criteria (e.g. hotels), max. air velocity: main duct ≤ 10-12.5 m/s, return main duct ≤ 8 m/s, branch ducts ≤ 6 m/s ● Face velocities for air-handling system components

- 33. Air Duct Design ➢Reduce dynamic losses of the critical path ● Maintain optimum air velocity through duct fittings ● Emphasize reduction of dynamic losses nearer to the fan outlet or inlet (high air velocity) ● Proper use of splitter vanes ● Set 2 duct fittings as far apart as possible ➢Air duct leakage ● Duct leakage classification • AISI, SMACNA, ASHRAE standards

- 34. Air Duct Design ‚û¢Fire protection ‚óè Duct material selection ‚óè Vertical ducts (using masonry, concrete or clay) ‚óè When ducts pass through floors & walls ‚óè Use of fire dampers ‚óè Filling the gaps between ducts & bldg structure ‚óè Duct systems for industrial applications ‚û¢Any other fire precautions?

- 35. Air Duct Design ‚û¢ Design procedure (computer-aided or manual) ‚óè ‚óè ‚óè ‚óè ‚óè ‚óè ‚óè ‚óè ‚óè ‚óè Verify local codes & material availability Preliminary duct layout Divide into consecutive duct sections Minimise local loss coefficients of duct fittings Select duct sizing methods Critical total pressure loss of tentative critical path Size branch ducts & balance total pressure at junctions Adjust supply flow rates according to duct heat gain Resize duct sections, recalculate & balance parallel paths Check sound level & add necessary attenuation

- 36. Typical supply duct system with symmetric layout & looping

- 37. Air Duct Design ‚û¢Duct liner ‚óè Lined internally on inner surface of duct wall ‚óè Mainly used for noise attenuation & insulation ‚óè Fiberglass blanket or boards ‚û¢Duct cleaning ‚óè Prevent accumulation of dirt & debris ‚óè Agitation device to loosen the dirt & debris ‚óè Duct vacuum to extract loosened debris ‚óè Sealing of access openings

- 39. HVAC Instrumentation and Control

- 40. HVAC System Commissioning ‚û¢ The key elements of commissioning include: ‚û¢ Installation checks. Check installed equipment to ensure that all associated components and accessories are in place. ‚û¢ Operational checks. Verify and document that systems are performing as expected, and that all sensors and other system control devices are properly calibrated. ‚û¢ Documentation. Confirm that all required documentation has been provided, such as a statement of the design intent and operating protocols for all building systems. ‚û¢ O&M manuals and training. Prepare comprehensive operation and maintenance (O&M) manuals, and provide training for rig operations staff. ‚û¢ Ongoing monitoring. Conduct periodic monitoring after the school is occupied to ensure that equipment and systems continue to perform according to design intent. ‚û¢ Correctly implemented, commissioning is extremely cost-effective, and should improve the delivery process, increase systems reliability, improve energy performance, ensure good indoor environmental quality, and improve operation and maintenance of the facility.