Igen visit innovÃĄciÃģs program

- 1. ni.com

- 3. 3ni.com HosszÚ tÃĄvÚ nÃķvekedÃĐs ÃrbevÃĐtel: 1.24 Mrd $ 2014-ben GlobÃĄlis mÅąkÃķdÃĐs: kb. 7,100 munkavÃĄllalÃģ; mÅąkÃķdÃĐs kÃķzel 50 orszÃĄgban SzÃĐles ÞgyfÃĐlkÃķr: tÃķbb mint 35,000 vÃĄllalat kiszolgÃĄlÃĄsa ÃĐvente SokszÃnÅąsÃĐg: iparÃĄgon kÃvÞli bevÃĐtel az ÃĄrbevÃĐtel tÃķbb mint 15%-a KultÚra: a vilÃĄg legjobb 25 munkÃĄltatÃģja kÃķzÃķtt szerepel a Great Place to Work Institute szerint (2014-ben 15. helyen)

- 4. 4ni.com A mÃĐrnÃķki munka hatÃĄsa Az ÃĐletminÅsÃĐg ÃĐs biztonsÃĄg javÃtÃĄsaIdÅ, munka ÃĐs kÃķltsÃĐg megtakarÃtÃĄs

- 5. 5ni.com Mindennapi mÃĐrnÃķki kihÃvÃĄsok TÃķbbet kevesebbel Egyre Ãķsszetettebb termÃĐkek a gyorsabb piacra jutÃĄs ÃĐrdekÃĐben Alkalmazkodni a vÃĄltozÃģ felhasznÃĄlÃĄsi kÃķvetelmÃĐnyekhez MeglÃĐvÅ beruhÃĄzÃĄsok vÃĐdelme EnergiafelhasznÃĄlÃĄs minimalizÃĄlÃĄsa

- 6. 6ni.com A rendszerek fokozÃģdÃģ °ėīĮģūąčąôąðģæūąģŲÃĄēõēđ

- 7. 7ni.com MissziÃģnk Olyan rendszereket biztosÃtunk a mÃĐrnÃķkÃķk ÃĐs tudÃģsok szÃĄmÃĄra, amelyek nÃķvelik a termelÃĐkenysÃĐget, ÃĐs felgyorsÃtjÃĄk az innovÃĄciÃģt ÃĐs tudomÃĄnyos felfedezÃĐseket.

- 8. 8ni.com

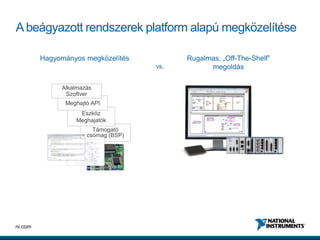

- 9. 9ni.com AbeÃĄgyazott rendszerek platform alapÚ megkÃķzelÃtÃĐse HagyomÃĄnyos megkÃķzelÃtÃĐs Rugalmas, âOff-The-Shelfâ megoldÃĄsvs. TÃĄmogatÃģ csomag (BSP) EszkÃķz MeghajatÃģk MeghajtÃģ API AlkalmazÃĄs Szoftver

- 10. 10ni.com Kik a vÃĄsÃĄrlÃģink? HaladÃģ gyÃĄripar LÃĐgierÅ ÃĐs lÃĐgvÃĐdelem FogyasztÃģi elektronika Energia KÃķzlekedÃĐs VezetÃĐk nÃĐlkÞli eszkÃķzÃķk OktatÃĄs

- 11. 11ni.com A Subaru NI termÃĐkek hasznÃĄlatÃĄval a kÃĐzi tesztelÃĐshez kÃĐpest 94%-kal csÃķkkentette a termÃĐktesztelÃĐsi idÅt.

- 12. 12ni.com Az Airbus tizedÃĐre csÃķkkentette a fejlesztÃĐsi idÅt az NI megoldÃĄsainak kÃķszÃķnhetÅen.

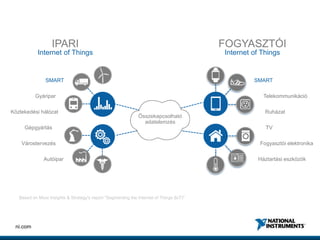

- 13. 13ni.com Based on Moor Insights & Strategy's report "Segmenting the Internet of Things (IoT)" SMART GyÃĄripar KÃķzlekedÃĐsi hÃĄlÃģzat GÃĐpgyÃĄrtÃĄs VÃĄrostervezÃĐs AutÃģipar SMART TelekommunikÃĄciÃģ RuhÃĄzat TV FogyasztÃģi elektronika HÃĄztartÃĄsi eszkÃķzÃķk ÃsszekapcsolhatÃģ adatelemzÃĐs IPARI Internet of Things FOGYASZTÃI Internet of Things

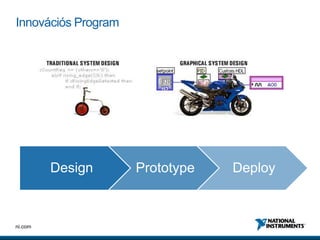

- 15. 15ni.com InnovÃĄciÃģs Program â H1nstra Instruments

- 16. 16ni.com InnovÃĄciÃģs Program â Kinek / kinek nem?

- 17. 17ni.com InnovÃĄciÃģs Program â Kinek / kinek nem?

- 18. 18ni.com InnovÃĄciÃģs Program â Kinek / kinek nem?

- 19. 19ni.com InnovÃĄciÃģs Program â Kinek / kinek nem?

- 20. 20ni.com InnovÃĄciÃģs Program â Kinek / kinek nem?

- 21. ni.com

- 22. ni.com

Editor's Notes

- #3: VideÃģ elindÃtÃĄsa/megÃĄllÃtÃĄsa diavetÃtÃĐs sorÃĄn: kattints a fekete nÃĐgyzetre. LÃĐpÃĐs a kÃķvetkezÅ diÃĄra: kattints a fehÃĐr rÃĐszre. A videÃģ hossza: 1.37 A videÃģ a kÃķvetkezÅ helyen is elÃĐrhetÅ: P:\C&E\Public\NI videok\NI videok\corporate video_hunsub.mp4

- #4: 2014-ben 15. helyezÃĐsÞnkkel olyan cÃĐgeket elÅztÞnk meg, mint az eBay vagy a Coca-Cola. NI has a strong track record of sustainable growth a profitability because we are managed for the long term. We believe that the best way to serve our customers is to ensure a successful stable company which our customers can rely on for products that will be of consistent quality over time, and provide customer service for the decades that our products will be used. This sustainable ethic is reflected in our growth, our breadth and our diversity. We also reflect it in our culture of being a consistently great place to work throughout our offices worldwide.

- #5: We all know the immense impact that engineers have. They are increasing wealth by saving companies and people time and money, and improving the quality of life and safety for all of us.

- #6: As they are doing this, they are faced many challenges on a daily basis, including building systems using disparate tools, integrating existing equipment with new hardware, and adapting to changing requirements over time. These days, they have fewer resources, and less time to get solutions completed.

- #7: These challenges are being compounded by increasing complexity of systems today and the rapid pace of technology change. Only a decade ago, a mobile phone testing application would be about transmitting and receiving signals. Today, itâs a much more comprehensive device capable of serving almost limitless applications defined by software and therefore requiring a much more robust approach to design and test.

- #9: Olyan rendszereket biztosÃtunk mÃĐrnÃķkÃķk ÃĐs tudÃģsok szÃĄmÃĄra, amelyek felgyorsÃtjÃĄk a termelÃĐkenysÃĐget, az innovÃĄciÃģt ÃĐs a tudomÃĄnyos felfedezÃĐseket.

- #10: Some of these challenges come to light very early in a projects life cycle. At the beginning of a project, engineers face the inevitable question of âShould I build it from scratch, or should I buy something off the shelf such as a PLC or a single board computer. Each of these choices comes with advantages, but they have some down-sides as well. If, for example, you decided that you were going to build the device from scratch you would benefit from the fact that you are getting a custom hardware and software solution. With a build solution you get maximum flexibility as well as the exact feature set that you are looking for, but the designs can take a lot of time and resources. Alternatively if you were going to buy something off the shelf then you can bypass some of those investments, but you have more limited functionality. So now letâs take a deeper look at each of these options. When building an embedded system, you will inevitably have to answer the question of build or buy. Each has it advantages, but which one is the right one to choose? ----- Meeting Notes (9/3/14 14:31) ----- Is the traditional design approach image ok? If so, should the title be altered to match the image (i.e. traditional instrumentation)?

- #11: Ez csupÃĄn nÃĐhÃĄny pÃĐlda. Az NI gyakorlatilag minden iparÃĄgban jelen van. Az NI vÃĄsÃĄrlÃģi tÃķbbszÃĄzezer termÃĐket gyÃĄrtottak a piacra ÃĐs szÃĄmos technolÃģgiai akadÃĄlyt kÞzdÃķttek le annak ÃĐrdekÃĐben, hogy megkÃķnnyÃtsÃĐk a mindennapokat. Ha be tudod kapcsolni, Ãķssze tudod valamivel kÃķtni, vezetheted vagy elindÃthatod, akkor nagy az esÃĐlye annak, hogy az NI kÃķzvetlenÞl vagy kÃķzvetetten, de hozzÃĄjÃĄrult a termÃĐk elkÃĐszÃtÃĐsÃĐhez. SzÃĄmos iparÃĄg mÃĐrnÃķkeivel dolgozunk egyÞtt, ezÃĐrt az NI egy nagyon kÞlÃķnleges helyzetben van.

- #12: Having a solution that was flexible was critical to Subaru when they were looking for a platform to test their first hybrid vehicle. They needed comprehensive testing of driver and passenger safety under various conditions. Using open hardware with reconfigurable I/O, Subaru engineers can simply change parameters during testing to make an HIL system simulate various complex test scenarios that would destroy an expensive prototype motor. They were able to test scenarios that would have been nearly impossible to create in real-world testing in a fraction of the time and cost. Learn more about how Subaru used the NI platform at ni.com/subarutest Quote that was deleted: âWe significantly reduced overall test time and optimized time to market, with all the test patterns running automatically in only 118 hours; a 94 percent reduction in test time compared to manual testing.ââMr. Tomohiro Morita,ĖýFUJI Heavy Industries, Ltd.Ėý

- #13: Airbus: Adding intelligence to the tools and shopfloor systems helped simplify the process and improve efficiency for the production of airplanes of by managing and checking the tasks the operator is completing. http://sine.ni.com/cs/app/doc/p/id/cs-16246

- #14: One example of this is the Internet of Things. This is a trend we are seeing impact just about every industry, from consumer products to factory automation. While we test just about everything on the consumer side, the Industrial Internet of Things is where we are seeing our approach have a significant impact because of our ability to simplify the development of smart, highly connected systems as well as our ability to help engineers capture and gain insight from vast amounts of analog data. Every day, we hear about the explosion of connected devices promised in the Internet of Things (IoT). With an antenna and sensors on every consumer and industrial device, the opportunities to improve our lives and businesses are endless. But, this revolution will only happen if it can be done economically, and a big part of that challenge is keeping the cost of test low enough to maintain appropriate unit pricing on the "things" of the IoT. As it stands right now, adding RF/wireless and sensor test to existing test systems can be extremely expensive and time consuming; it might literally prevent a product concept from becoming profitable. Test organizations in both the semiconductor and consumer electronic spaces need to consider alternate approaches to automated test built on open standards and the latest technology to meet these challenges.