Introduction About Lean Way

Download as ppt, pdf0 likes504 views

The document discusses the principles of the 'lean way' in management, emphasizing the importance of standardization, quality, and cooperation to enhance productivity. It cites notable figures such as Frederick Winslow Taylor and W. Edwards Deming to highlight the significance of effective systems and pride in work. It briefly touches on the concept of waste in processes and poses a question about the relationship between lean and agile software development.

1 of 17

Downloaded 61 times

Ad

Recommended

Quotes on 'TEAMWORK' to inspire yourself and others - Sweet TLC Ltd

Quotes on 'TEAMWORK' to inspire yourself and others - Sweet TLC LtdSweet TLC Ltd

?

Teamwork is essential for success. It allows ordinary people to achieve extraordinary results by working together toward a common goal. While conflict is inevitable in a team with diverse ideas and approaches, this variety is needed to find synergistic solutions. A team without a single star player is stronger than one dependent on any individual, as true teamwork requires dividing tasks and doubling efforts. Bringing together good people is not enough - an effective system is also needed to realize their full potential.Five Levels of Communication Infographic

Five Levels of Communication InfographicMaya Townsend

?

The document outlines five levels of communication that are important for successful change:

1. Telling - One-way communication like presentations and emails to inform people of planned changes.

2. Consulting - Gathering feedback on changes through small group meetings and facilitated discussions.

3. Involving - Exploring the implications of changes through interactive group discussions and reflection.

4. Collaborating - Engaging in dialogue through question and answer sessions to build understanding of changes.

5. Empowering - Encouraging understanding, commitment, and behaviors needed to support sustainable changes.Empowerment-TRAINING

Empowerment-TRAININGKanaidi ken

?

The document discusses empowerment and provides guidance for empowering employees. It defines empowerment as giving individuals the knowledge, skills, and opportunity to succeed in a way that leads to organizational success. Some benefits of empowerment include quicker responses to customers and more satisfied employees. Leaders are advised to transfer ownership, create an environment for responsibility, coach development, and learn quickly to empower others.Leadershiptrends

LeadershiptrendsGraham Hart

?

A significant percentage (72%) of organizations in England face a deficit in management and leadership skills, with many global leaders citing this as a major hindrance to adapting to business changes. Effective leadership is increasingly characterized by authenticity, collaboration, and the ability to articulate clear goals, while also being linked to personal well-being and exercise. The document emphasizes the need for a shift towards participative leadership styles to foster teamwork and resilience in response to a complex and fast-changing business environment.The Assembly Line and Mass Production Presentation

The Assembly Line and Mass Production Presentationerinlord

?

The assembly line and mass production transformed industry in the United States through increased efficiency, lower production costs, and higher profits. An assembly line divides the production process into sequential steps with different workers performing specialized tasks, allowing products like Ford's Model T to be mass produced. This innovation utilized unskilled labor, interchangeable parts, and mechanization to build custom products on a large scale, driving down costs and prices while increasing availability to consumers.Taylorism

TaylorismJyotsna Pantula

?

Frederick Winslow Taylor, known as the father of scientific management, developed principles aimed at improving industrial efficiency through methods based on scientific study and time-and-motion analysis. His approach emphasized collaboration between workers and management, systematic selection and training of employees, and the establishment of fair work standards. Despite its historical significance in increasing productivity during the industrial era, Taylorism faced criticism in modern times for de-skilling workers and treating them as replaceable components in a mechanized system.Manufacturing process & assembly of automobile

Manufacturing process & assembly of automobileYashraj Patil

?

The document summarizes the key processes involved in automobile manufacturing, including chassis production, e-coating, surface finishing, pre-assembly, and final assembly. It describes how the chassis is constructed through welding and how the body is coated to prevent corrosion before major components like doors and instrument panels are added. Quality inspection occurs at various stages before cars move to the final assembly line where numerous units further prepare the vehicle for production.Software Dev Process In A Nutshell

Software Dev Process In A NutshellOcean Dong

?

The document discusses software development processes and best practices for iterative processes. It explains that software development is difficult and requires an organized process. Both waterfall and iterative process models are described, with iterative being favored as it allows for periodic planning, quick reaction to changes, and incremental testing and fixing of bugs. The document recommends that developers and testers in iterative processes estimate work, keep estimates updated, improve past work, implement extensibility, and help the whole team succeed in iterations.Review of code review

Review of code reviewOcean Dong

?

Code reviews during phase 1 development provide benefits like learning from others, spreading knowledge, and creating better code, but can fail if people do not prepare, submit incomplete work, repeat the same mistakes, or get into endless arguments. Overall, code reviews are questioned as to whether they achieve their goals.RUP Basics

RUP BasicsOcean Dong

?

The document provides an overview of the Rational Unified Process (RUP). It discusses that RUP is a type of software development process, product, and framework. The document outlines the key concepts of RUP including its history, static concepts such as disciplines, activities, roles and artifacts, and dynamic concepts such as phases and iterations. It notes that RUP is meant to be highly applicable, customizable, and focuses on starting early, embracing change, and adapting quickly through small steps and frequent reviews.Software Design Principles

Software Design PrinciplesOcean Dong

?

The document discusses software design principles for managing complexity and change, including the Open-Closed Principle (OCP), Liskov Substitution Principle (LSP), Dependency Inversion Principle (DIP), and Interface Segregation Principle (ISP). These principles aim to create modules that are open for extension but closed for modification, with subclasses substitutable for their base classes. Dependencies should be on abstractions rather than concretions, and interfaces should be client-specific rather than general. Managing complexity means managing dependencies through high abstraction, single-responsibility classes, and other principles that promote designs that are clean, simple, and elegant.Groovy Intro

Groovy IntroOcean Dong

?

This document introduces the Groovy programming language and summarizes some of its key features. It discusses how Groovy combines the power of Java with the lightweight syntax of dynamic languages like Ruby. Some highlighted features include: dynamic typing, direct property access, powerful string interpolation, simple collection types, operator overloading, switch statements, closures, and more. The document encourages readers to explore Groovy further on its website.A Glance At Scrum

A Glance At ScrumOcean Dong

?

The document discusses the Scrum framework for agile project management. It introduces Scrum and its core concepts, including its artifacts like product backlog, sprints, and daily stand-ups. Scrum uses self-organizing cross-functional teams, short development iterations called sprints, and regular inspection and adaptation to ensure success. The document notes that Scrum aims to help teams succeed through its empirical and iterative process, and that the role of the ScrumMaster is important for implementing Scrum successfully.How To Write Work Mail

How To Write Work MailOcean Dong

?

The document provides tips for writing effective work emails, with the main points being:

- Reveal the main topic as early as possible and keep messages simple and concise

- Use short sentences, numbers, and bullets to break up text

- Include a descriptive title that indicates the issue being discussed

- Follow a clear structure in the email such as requesting help, explaining the problem, and asking for a specific action

- Use a polite tone and be concise while still providing necessary context about the issue or requestContinuous Code Quality Improvement

Continuous Code Quality ImprovementOcean Dong

?

This document discusses continuous code quality improvement through the use of tools like FxCop, NCover, and NDoc, as well as establishing a review process. It provides an overview of each tool, how they are used to check code quality and test coverage, and recommendations for running them on a weekly basis in two phases. The conclusion advocates finding and developing better tools and processes to make code reviews easier and catch mistakes earlier.Stress free email handling

Stress free email handlingOcean Dong

?

The document provides tips for handling emails in a stress-free way by focusing on immediate lightweight handling and on-demand or timed heavyweight handling. It recommends quickly reading and responding to emails within 2 minutes of receipt and saving others as drafts. For important emails, it suggests quick judgement on urgency and keeping memory of follow up needed. Heavy tasks like deleting old emails should be done once or twice daily according to a schedule. The overall goal is to reduce stress by keeping the inbox and drafts empty through regular light scanning and timely heavy tasks.柬埔寨之旅

柬埔寨之旅Ocean Dong

?

该文档是一篇对于柬埔寨旅行的描述,详细列出了行程及主要景点,包括吴哥寺和巴戎寺等重要地标。旅行从上海出发,途经金边和西哈努克港,强调自助游的乐趣与个人反思。作者分享了旅行带来的心灵感悟,推荐柬埔寨作为旅游目的地。Agile Testing

Agile TestingOcean Dong

?

The document discusses an agile testing experiment conducted by BIS to implement immediate scripting and keeping scripts alive. It introduces the concepts of agile testing and describes the benefits of immediate scripting such as producing a richer "done" state with both production code and test suites. Challenges of immediate scripting are also noted such as changing habits and requiring more time than writing test cases. The document then explains how BIS implemented immediate scripting through an easy scripting approach using a domain specific language wrapper and precondition facilities. It further discusses keeping scripts alive through continuous quality checking to ensure old features remain unbroken and allow for regression testing everyday. The challenges of keeping scripts alive at large scale are addressed through a continuous quality checking“Addressing Evolving AI Model Challenges Through Memory and Storage,” a Prese...

“Addressing Evolving AI Model Challenges Through Memory and Storage,” a Prese...Edge AI and Vision Alliance

?

For the full video of this presentation, please visit: https://www.edge-ai-vision.com/2025/06/addressing-evolving-ai-model-challenges-through-memory-and-storage-a-presentation-from-micron/

Wil Florentino, Senior Segment Marketing Manager at Micron, presents the “Addressing Evolving AI Model Challenges Through Memory and Storage” tutorial at the May 2025 Embedded Vision Summit.

In the fast-changing world of artificial intelligence, the industry is deploying more AI compute at the edge. But the growing diversity and data footprint of transformers and models such as large language models and large multimodal models puts a spotlight on memory performance and data storage capacity as key bottlenecks. Enabling the full potential of AI in industries such as manufacturing, automotive, robotics and transportation will require us to find efficient ways to deploy this new generation of complex models.

In this presentation, Florentino explores how memory and storage are responding to this need and solving complex issues in the AI market. He examines the storage capacity and memory bandwidth requirements of edge AI use cases ranging from tiny devices with severe cost and power constraints to edge servers, and he explains how new memory technologies such as LPDDR5, LPCAMM2 and multi-port SSDs are helping system developers to meet these challenges.Enabling BIM / GIS integrations with Other Systems with FME

Enabling BIM / GIS integrations with Other Systems with FMESafe Software

?

Jacobs has successfully utilized FME to tackle the complexities of integrating diverse data sources in a confidential $1 billion campus improvement project. The project aimed to create a comprehensive digital twin by merging Building Information Modeling (BIM) data, Construction Operations Building Information Exchange (COBie) data, and various other data sources into a unified Geographic Information System (GIS) platform. The challenge lay in the disparate nature of these data sources, which were siloed and incompatible with each other, hindering efficient data management and decision-making processes.

To address this, Jacobs leveraged FME to automate the extraction, transformation, and loading (ETL) of data between ArcGIS Indoors and IBM Maximo. This process ensured accurate transfer of maintainable asset and work order data, creating a comprehensive 2D and 3D representation of the campus for Facility Management. FME's server capabilities enabled real-time updates and synchronization between ArcGIS Indoors and Maximo, facilitating automatic updates of asset information and work orders. Additionally, Survey123 forms allowed field personnel to capture and submit data directly from their mobile devices, triggering FME workflows via webhooks for real-time data updates. This seamless integration has significantly enhanced data management, improved decision-making processes, and ensured data consistency across the project lifecycle.Mastering AI Workflows with FME - Peak of Data & AI 2025

Mastering AI Workflows with FME - Peak of Data & AI 2025Safe Software

?

Harness the full potential of AI with FME: From creating high-quality training data to optimizing models and utilizing results, FME supports every step of your AI workflow. Seamlessly integrate a wide range of models, including those for data enhancement, forecasting, image and object recognition, and large language models. Customize AI models to meet your exact needs with FME’s powerful tools for training, optimization, and seamless integrationFIDO Seminar: Evolving Landscape of Post-Quantum Cryptography.pptx

FIDO Seminar: Evolving Landscape of Post-Quantum Cryptography.pptxFIDO Alliance

?

FIDO Seminar: Evolving Landscape of Post-Quantum CryptographyIntegration of Utility Data into 3D BIM Models Using a 3D Solids Modeling Wor...

Integration of Utility Data into 3D BIM Models Using a 3D Solids Modeling Wor...Safe Software

?

Jacobs has developed a 3D utility solids modelling workflow to improve the integration of utility data into 3D Building Information Modeling (BIM) environments. This workflow, a collaborative effort between the New Zealand Geospatial Team and the Australian Data Capture Team, employs FME to convert 2D utility data into detailed 3D representations, supporting enhanced spatial analysis and clash detection.

To enable the automation of this process, Jacobs has also developed a survey data standard that standardizes the capture of existing utilities. This standard ensures consistency in data collection, forming the foundation for the subsequent automated validation and modelling steps. The workflow begins with the acquisition of utility survey data, including attributes such as location, depth, diameter, and material of utility assets like pipes and manholes. This data is validated through a custom-built tool that ensures completeness and logical consistency, including checks for proper connectivity between network components. Following validation, the data is processed using an automated modelling tool to generate 3D solids from 2D geometric representations. These solids are then integrated into BIM models to facilitate compatibility with 3D workflows and enable detailed spatial analyses.

The workflow contributes to improved spatial understanding by visualizing the relationships between utilities and other infrastructure elements. The automation of validation and modeling processes ensures consistent and accurate outputs, minimizing errors and increasing workflow efficiency.

This methodology highlights the application of FME in addressing challenges associated with geospatial data transformation and demonstrates its utility in enhancing data integration within BIM frameworks. By enabling accurate 3D representation of utility networks, the workflow supports improved design collaboration and decision-making in complex infrastructure projectsCrypto Super 500 - 14th Report - June2025.pdf

Crypto Super 500 - 14th Report - June2025.pdfStephen Perrenod

?

This OrionX's 14th semi-annual report on the state of the cryptocurrency mining market. The report focuses on Proof-of-Work cryptocurrencies since those use substantial supercomputer power to mint new coins and encode transactions on their blockchains. Only two make the cut this time, Bitcoin with $18 billion of annual economic value produced and Dogecoin with $1 billion. Bitcoin has now reached the Zettascale with typical hash rates of 0.9 Zettahashes per second. Bitcoin is powered by the world's largest decentralized supercomputer in a continuous winner take all lottery incentive network.vertical-cnc-processing-centers-drillteq-v-200-en.pdf

vertical-cnc-processing-centers-drillteq-v-200-en.pdfAmirStern2

?

?????? CNC ????? ?????? ?? ?????? ?????? ?????? ????? ?????? ?????? ??????? ?????? ??????. ???? ???? ????? ??? ?-x ??????? ??? ??????? ?????, ????? ?"? ??? ?????, ?? ???? ???? ???? setup (??????) ?????? ????? ?? ?????. Viral>Wondershare Filmora 14.5.18.12900 Crack Free Download

Viral>Wondershare Filmora 14.5.18.12900 Crack Free DownloadPuppy jhon

?

? ???COPY & PASTE LINK??? ? ?? https://drfiles.net/

Wondershare Filmora Crack is a user-friendly video editing software designed for both beginners and experienced users.

The State of Web3 Industry- Industry Report

The State of Web3 Industry- Industry ReportLiveplex

?

Web3 is poised for mainstream integration by 2030, with decentralized applications potentially reaching billions of users through improved scalability, user-friendly wallets, and regulatory clarity. Many forecasts project trillions of dollars in tokenized assets by 2030 , integration of AI, IoT, and Web3 (e.g. autonomous agents and decentralized physical infrastructure), and the possible emergence of global interoperability standards. Key challenges going forward include ensuring security at scale, preserving decentralization principles under regulatory oversight, and demonstrating tangible consumer value to sustain adoption beyond speculative cycles.TrustArc Webinar - 2025 Global Privacy Survey

TrustArc Webinar - 2025 Global Privacy SurveyTrustArc

?

How does your privacy program compare to your peers? What challenges are privacy teams tackling and prioritizing in 2025?

In the sixth annual Global Privacy Benchmarks Survey, we asked global privacy professionals and business executives to share their perspectives on privacy inside and outside their organizations. The annual report provides a 360-degree view of various industries' priorities, attitudes, and trends. See how organizational priorities and strategic approaches to data security and privacy are evolving around the globe.

This webinar features an expert panel discussion and data-driven insights to help you navigate the shifting privacy landscape. Whether you are a privacy officer, legal professional, compliance specialist, or security expert, this session will provide actionable takeaways to strengthen your privacy strategy.

This webinar will review:

- The emerging trends in data protection, compliance, and risk

- The top challenges for privacy leaders, practitioners, and organizations in 2025

- The impact of evolving regulations and the crossroads with new technology, like AI

Predictions for the future of privacy in 2025 and beyondENERGY CONSUMPTION CALCULATION IN ENERGY-EFFICIENT AIR CONDITIONER.pdf

ENERGY CONSUMPTION CALCULATION IN ENERGY-EFFICIENT AIR CONDITIONER.pdfMuhammad Rizwan Akram

?

DC Inverter Air Conditioners are revolutionizing the cooling industry by delivering affordable,

energy-efficient, and environmentally sustainable climate control solutions. Unlike conventional

fixed-speed air conditioners, DC inverter systems operate with variable-speed compressors that

modulate cooling output based on demand, significantly reducing energy consumption and

extending the lifespan of the appliance.

These systems are critical in reducing electricity usage, lowering greenhouse gas emissions, and

promoting eco-friendly technologies in residential and commercial sectors. With advancements in

compressor control, refrigerant efficiency, and smart energy management, DC inverter air conditioners

have become a benchmark in sustainable climate control solutionsFIDO Seminar: Targeting Trust: The Future of Identity in the Workforce.pptx

FIDO Seminar: Targeting Trust: The Future of Identity in the Workforce.pptxFIDO Alliance

?

FIDO Seminar: Targeting Trust: The Future of Identity in the WorkforceMore Related Content

More from Ocean Dong (10)

Review of code review

Review of code reviewOcean Dong

?

Code reviews during phase 1 development provide benefits like learning from others, spreading knowledge, and creating better code, but can fail if people do not prepare, submit incomplete work, repeat the same mistakes, or get into endless arguments. Overall, code reviews are questioned as to whether they achieve their goals.RUP Basics

RUP BasicsOcean Dong

?

The document provides an overview of the Rational Unified Process (RUP). It discusses that RUP is a type of software development process, product, and framework. The document outlines the key concepts of RUP including its history, static concepts such as disciplines, activities, roles and artifacts, and dynamic concepts such as phases and iterations. It notes that RUP is meant to be highly applicable, customizable, and focuses on starting early, embracing change, and adapting quickly through small steps and frequent reviews.Software Design Principles

Software Design PrinciplesOcean Dong

?

The document discusses software design principles for managing complexity and change, including the Open-Closed Principle (OCP), Liskov Substitution Principle (LSP), Dependency Inversion Principle (DIP), and Interface Segregation Principle (ISP). These principles aim to create modules that are open for extension but closed for modification, with subclasses substitutable for their base classes. Dependencies should be on abstractions rather than concretions, and interfaces should be client-specific rather than general. Managing complexity means managing dependencies through high abstraction, single-responsibility classes, and other principles that promote designs that are clean, simple, and elegant.Groovy Intro

Groovy IntroOcean Dong

?

This document introduces the Groovy programming language and summarizes some of its key features. It discusses how Groovy combines the power of Java with the lightweight syntax of dynamic languages like Ruby. Some highlighted features include: dynamic typing, direct property access, powerful string interpolation, simple collection types, operator overloading, switch statements, closures, and more. The document encourages readers to explore Groovy further on its website.A Glance At Scrum

A Glance At ScrumOcean Dong

?

The document discusses the Scrum framework for agile project management. It introduces Scrum and its core concepts, including its artifacts like product backlog, sprints, and daily stand-ups. Scrum uses self-organizing cross-functional teams, short development iterations called sprints, and regular inspection and adaptation to ensure success. The document notes that Scrum aims to help teams succeed through its empirical and iterative process, and that the role of the ScrumMaster is important for implementing Scrum successfully.How To Write Work Mail

How To Write Work MailOcean Dong

?

The document provides tips for writing effective work emails, with the main points being:

- Reveal the main topic as early as possible and keep messages simple and concise

- Use short sentences, numbers, and bullets to break up text

- Include a descriptive title that indicates the issue being discussed

- Follow a clear structure in the email such as requesting help, explaining the problem, and asking for a specific action

- Use a polite tone and be concise while still providing necessary context about the issue or requestContinuous Code Quality Improvement

Continuous Code Quality ImprovementOcean Dong

?

This document discusses continuous code quality improvement through the use of tools like FxCop, NCover, and NDoc, as well as establishing a review process. It provides an overview of each tool, how they are used to check code quality and test coverage, and recommendations for running them on a weekly basis in two phases. The conclusion advocates finding and developing better tools and processes to make code reviews easier and catch mistakes earlier.Stress free email handling

Stress free email handlingOcean Dong

?

The document provides tips for handling emails in a stress-free way by focusing on immediate lightweight handling and on-demand or timed heavyweight handling. It recommends quickly reading and responding to emails within 2 minutes of receipt and saving others as drafts. For important emails, it suggests quick judgement on urgency and keeping memory of follow up needed. Heavy tasks like deleting old emails should be done once or twice daily according to a schedule. The overall goal is to reduce stress by keeping the inbox and drafts empty through regular light scanning and timely heavy tasks.柬埔寨之旅

柬埔寨之旅Ocean Dong

?

该文档是一篇对于柬埔寨旅行的描述,详细列出了行程及主要景点,包括吴哥寺和巴戎寺等重要地标。旅行从上海出发,途经金边和西哈努克港,强调自助游的乐趣与个人反思。作者分享了旅行带来的心灵感悟,推荐柬埔寨作为旅游目的地。Agile Testing

Agile TestingOcean Dong

?

The document discusses an agile testing experiment conducted by BIS to implement immediate scripting and keeping scripts alive. It introduces the concepts of agile testing and describes the benefits of immediate scripting such as producing a richer "done" state with both production code and test suites. Challenges of immediate scripting are also noted such as changing habits and requiring more time than writing test cases. The document then explains how BIS implemented immediate scripting through an easy scripting approach using a domain specific language wrapper and precondition facilities. It further discusses keeping scripts alive through continuous quality checking to ensure old features remain unbroken and allow for regression testing everyday. The challenges of keeping scripts alive at large scale are addressed through a continuous quality checkingRecently uploaded (20)

“Addressing Evolving AI Model Challenges Through Memory and Storage,” a Prese...

“Addressing Evolving AI Model Challenges Through Memory and Storage,” a Prese...Edge AI and Vision Alliance

?

For the full video of this presentation, please visit: https://www.edge-ai-vision.com/2025/06/addressing-evolving-ai-model-challenges-through-memory-and-storage-a-presentation-from-micron/

Wil Florentino, Senior Segment Marketing Manager at Micron, presents the “Addressing Evolving AI Model Challenges Through Memory and Storage” tutorial at the May 2025 Embedded Vision Summit.

In the fast-changing world of artificial intelligence, the industry is deploying more AI compute at the edge. But the growing diversity and data footprint of transformers and models such as large language models and large multimodal models puts a spotlight on memory performance and data storage capacity as key bottlenecks. Enabling the full potential of AI in industries such as manufacturing, automotive, robotics and transportation will require us to find efficient ways to deploy this new generation of complex models.

In this presentation, Florentino explores how memory and storage are responding to this need and solving complex issues in the AI market. He examines the storage capacity and memory bandwidth requirements of edge AI use cases ranging from tiny devices with severe cost and power constraints to edge servers, and he explains how new memory technologies such as LPDDR5, LPCAMM2 and multi-port SSDs are helping system developers to meet these challenges.Enabling BIM / GIS integrations with Other Systems with FME

Enabling BIM / GIS integrations with Other Systems with FMESafe Software

?

Jacobs has successfully utilized FME to tackle the complexities of integrating diverse data sources in a confidential $1 billion campus improvement project. The project aimed to create a comprehensive digital twin by merging Building Information Modeling (BIM) data, Construction Operations Building Information Exchange (COBie) data, and various other data sources into a unified Geographic Information System (GIS) platform. The challenge lay in the disparate nature of these data sources, which were siloed and incompatible with each other, hindering efficient data management and decision-making processes.

To address this, Jacobs leveraged FME to automate the extraction, transformation, and loading (ETL) of data between ArcGIS Indoors and IBM Maximo. This process ensured accurate transfer of maintainable asset and work order data, creating a comprehensive 2D and 3D representation of the campus for Facility Management. FME's server capabilities enabled real-time updates and synchronization between ArcGIS Indoors and Maximo, facilitating automatic updates of asset information and work orders. Additionally, Survey123 forms allowed field personnel to capture and submit data directly from their mobile devices, triggering FME workflows via webhooks for real-time data updates. This seamless integration has significantly enhanced data management, improved decision-making processes, and ensured data consistency across the project lifecycle.Mastering AI Workflows with FME - Peak of Data & AI 2025

Mastering AI Workflows with FME - Peak of Data & AI 2025Safe Software

?

Harness the full potential of AI with FME: From creating high-quality training data to optimizing models and utilizing results, FME supports every step of your AI workflow. Seamlessly integrate a wide range of models, including those for data enhancement, forecasting, image and object recognition, and large language models. Customize AI models to meet your exact needs with FME’s powerful tools for training, optimization, and seamless integrationFIDO Seminar: Evolving Landscape of Post-Quantum Cryptography.pptx

FIDO Seminar: Evolving Landscape of Post-Quantum Cryptography.pptxFIDO Alliance

?

FIDO Seminar: Evolving Landscape of Post-Quantum CryptographyIntegration of Utility Data into 3D BIM Models Using a 3D Solids Modeling Wor...

Integration of Utility Data into 3D BIM Models Using a 3D Solids Modeling Wor...Safe Software

?

Jacobs has developed a 3D utility solids modelling workflow to improve the integration of utility data into 3D Building Information Modeling (BIM) environments. This workflow, a collaborative effort between the New Zealand Geospatial Team and the Australian Data Capture Team, employs FME to convert 2D utility data into detailed 3D representations, supporting enhanced spatial analysis and clash detection.

To enable the automation of this process, Jacobs has also developed a survey data standard that standardizes the capture of existing utilities. This standard ensures consistency in data collection, forming the foundation for the subsequent automated validation and modelling steps. The workflow begins with the acquisition of utility survey data, including attributes such as location, depth, diameter, and material of utility assets like pipes and manholes. This data is validated through a custom-built tool that ensures completeness and logical consistency, including checks for proper connectivity between network components. Following validation, the data is processed using an automated modelling tool to generate 3D solids from 2D geometric representations. These solids are then integrated into BIM models to facilitate compatibility with 3D workflows and enable detailed spatial analyses.

The workflow contributes to improved spatial understanding by visualizing the relationships between utilities and other infrastructure elements. The automation of validation and modeling processes ensures consistent and accurate outputs, minimizing errors and increasing workflow efficiency.

This methodology highlights the application of FME in addressing challenges associated with geospatial data transformation and demonstrates its utility in enhancing data integration within BIM frameworks. By enabling accurate 3D representation of utility networks, the workflow supports improved design collaboration and decision-making in complex infrastructure projectsCrypto Super 500 - 14th Report - June2025.pdf

Crypto Super 500 - 14th Report - June2025.pdfStephen Perrenod

?

This OrionX's 14th semi-annual report on the state of the cryptocurrency mining market. The report focuses on Proof-of-Work cryptocurrencies since those use substantial supercomputer power to mint new coins and encode transactions on their blockchains. Only two make the cut this time, Bitcoin with $18 billion of annual economic value produced and Dogecoin with $1 billion. Bitcoin has now reached the Zettascale with typical hash rates of 0.9 Zettahashes per second. Bitcoin is powered by the world's largest decentralized supercomputer in a continuous winner take all lottery incentive network.vertical-cnc-processing-centers-drillteq-v-200-en.pdf

vertical-cnc-processing-centers-drillteq-v-200-en.pdfAmirStern2

?

?????? CNC ????? ?????? ?? ?????? ?????? ?????? ????? ?????? ?????? ??????? ?????? ??????. ???? ???? ????? ??? ?-x ??????? ??? ??????? ?????, ????? ?"? ??? ?????, ?? ???? ???? ???? setup (??????) ?????? ????? ?? ?????. Viral>Wondershare Filmora 14.5.18.12900 Crack Free Download

Viral>Wondershare Filmora 14.5.18.12900 Crack Free DownloadPuppy jhon

?

? ???COPY & PASTE LINK??? ? ?? https://drfiles.net/

Wondershare Filmora Crack is a user-friendly video editing software designed for both beginners and experienced users.

The State of Web3 Industry- Industry Report

The State of Web3 Industry- Industry ReportLiveplex

?

Web3 is poised for mainstream integration by 2030, with decentralized applications potentially reaching billions of users through improved scalability, user-friendly wallets, and regulatory clarity. Many forecasts project trillions of dollars in tokenized assets by 2030 , integration of AI, IoT, and Web3 (e.g. autonomous agents and decentralized physical infrastructure), and the possible emergence of global interoperability standards. Key challenges going forward include ensuring security at scale, preserving decentralization principles under regulatory oversight, and demonstrating tangible consumer value to sustain adoption beyond speculative cycles.TrustArc Webinar - 2025 Global Privacy Survey

TrustArc Webinar - 2025 Global Privacy SurveyTrustArc

?

How does your privacy program compare to your peers? What challenges are privacy teams tackling and prioritizing in 2025?

In the sixth annual Global Privacy Benchmarks Survey, we asked global privacy professionals and business executives to share their perspectives on privacy inside and outside their organizations. The annual report provides a 360-degree view of various industries' priorities, attitudes, and trends. See how organizational priorities and strategic approaches to data security and privacy are evolving around the globe.

This webinar features an expert panel discussion and data-driven insights to help you navigate the shifting privacy landscape. Whether you are a privacy officer, legal professional, compliance specialist, or security expert, this session will provide actionable takeaways to strengthen your privacy strategy.

This webinar will review:

- The emerging trends in data protection, compliance, and risk

- The top challenges for privacy leaders, practitioners, and organizations in 2025

- The impact of evolving regulations and the crossroads with new technology, like AI

Predictions for the future of privacy in 2025 and beyondENERGY CONSUMPTION CALCULATION IN ENERGY-EFFICIENT AIR CONDITIONER.pdf

ENERGY CONSUMPTION CALCULATION IN ENERGY-EFFICIENT AIR CONDITIONER.pdfMuhammad Rizwan Akram

?

DC Inverter Air Conditioners are revolutionizing the cooling industry by delivering affordable,

energy-efficient, and environmentally sustainable climate control solutions. Unlike conventional

fixed-speed air conditioners, DC inverter systems operate with variable-speed compressors that

modulate cooling output based on demand, significantly reducing energy consumption and

extending the lifespan of the appliance.

These systems are critical in reducing electricity usage, lowering greenhouse gas emissions, and

promoting eco-friendly technologies in residential and commercial sectors. With advancements in

compressor control, refrigerant efficiency, and smart energy management, DC inverter air conditioners

have become a benchmark in sustainable climate control solutionsFIDO Seminar: Targeting Trust: The Future of Identity in the Workforce.pptx

FIDO Seminar: Targeting Trust: The Future of Identity in the Workforce.pptxFIDO Alliance

?

FIDO Seminar: Targeting Trust: The Future of Identity in the WorkforceCreating Inclusive Digital Learning with AI: A Smarter, Fairer Future

Creating Inclusive Digital Learning with AI: A Smarter, Fairer FutureImpelsys Inc.

?

Have you ever struggled to read a tiny label on a medicine box or tried to navigate a confusing website? Now imagine if every learning experience felt that way—every single day.

For millions of people living with disabilities, poorly designed content isn’t just frustrating. It’s a barrier to growth. Inclusive learning is about fixing that. And today, AI is helping us build digital learning that’s smarter, kinder, and accessible to everyone.

Accessible learning increases engagement, retention, performance, and inclusivity for everyone. Inclusive design is simply better design.“From Enterprise to Makers: Driving Vision AI Innovation at the Extreme Edge,...

“From Enterprise to Makers: Driving Vision AI Innovation at the Extreme Edge,...Edge AI and Vision Alliance

?

For the full video of this presentation, please visit: https://www.edge-ai-vision.com/2025/06/from-enterprise-to-makers-driving-vision-ai-innovation-at-the-extreme-edge-a-presentation-from-sony-semiconductor-solutions/

Amir Servi, Edge Deep Learning Product Manager at Sony Semiconductor Solutions, presents the “From Enterprise to Makers: Driving Vision AI Innovation at the Extreme Edge” tutorial at the May 2025 Embedded Vision Summit.

Sony’s unique integrated sensor-processor technology is enabling ultra-efficient intelligence directly at the image source, transforming vision AI for enterprises and developers alike. In this presentation, Servi showcases how the AITRIOS platform simplifies vision AI for enterprises with tools for large-scale deployments and model management.

Servi also highlights his company’s collaboration with Ultralytics and Raspberry Pi, which brings YOLO models to the developer community, empowering grassroots innovation. Whether you’re scaling vision AI for industry or experimenting with cutting-edge tools, this presentation will demonstrate how Sony is accelerating high-performance, energy-efficient vision AI for all.Floods in Valencia: Two FME-Powered Stories of Data Resilience

Floods in Valencia: Two FME-Powered Stories of Data ResilienceSafe Software

?

In October 2024, the Spanish region of Valencia faced severe flooding that underscored the critical need for accessible and actionable data. This presentation will explore two innovative use cases where FME facilitated data integration and availability during the crisis. The first case demonstrates how FME was used to process and convert satellite imagery and other geospatial data into formats tailored for rapid analysis by emergency teams. The second case delves into making human mobility data—collected from mobile phone signals—accessible as source-destination matrices, offering key insights into population movements during and after the flooding. These stories highlight how FME's powerful capabilities can bridge the gap between raw data and decision-making, fostering resilience and preparedness in the face of natural disasters. Attendees will gain practical insights into how FME can support crisis management and urban planning in a changing climate.Bridging the divide: A conversation on tariffs today in the book industry - T...

Bridging the divide: A conversation on tariffs today in the book industry - T...BookNet Canada

?

A collaboration-focused conversation on the recently imposed US and Canadian tariffs where speakers shared insights into the current legislative landscape, ongoing advocacy efforts, and recommended next steps. This event was presented in partnership with the Book Industry Study Group.

Link to accompanying resource: https://bnctechforum.ca/sessions/bridging-the-divide-a-conversation-on-tariffs-today-in-the-book-industry/

Presented by BookNet Canada and the Book Industry Study Group on May 29, 2025 with support from the Department of Canadian Heritage.MuleSoft for AgentForce : Topic Center and API Catalog

MuleSoft for AgentForce : Topic Center and API Catalogshyamraj55

?

This presentation dives into how MuleSoft empowers AgentForce with organized API discovery and streamlined integration using Topic Center and the API Catalog. Learn how these tools help structure APIs around business needs, improve reusability, and simplify collaboration across teams. Ideal for developers, architects, and business stakeholders looking to build a connected and scalable API ecosystem within AgentForce.War_And_Cyber_3_Years_Of_Struggle_And_Lessons_For_Global_Security.pdf

War_And_Cyber_3_Years_Of_Struggle_And_Lessons_For_Global_Security.pdfbiswajitbanerjee38

?

Russia is one of the most aggressive nations when it comes to state coordinated cyberattacks?—?and Ukraine has been at the center of their crosshairs for 3 years. This report, provided the State Service of Special Communications and Information Protection of Ukraine contains an incredible amount of cybersecurity insights, showcasing the coordinated aggressive cyberwarfare campaigns of Russia against Ukraine.

It brings to the forefront that understanding your adversary, especially an aggressive nation state, is important for cyber defense. Knowing their motivations, capabilities, and tactics becomes an advantage when allocating resources for maximum impact.

Intelligence shows Russia is on a cyber rampage, leveraging FSB, SVR, and GRU resources to professionally target Ukraine’s critical infrastructures, military, and international diplomacy support efforts.

The number of total incidents against Ukraine, originating from Russia, has steadily increased from 1350 in 2021 to 4315 in 2024, but the number of actual critical incidents has been managed down from a high of 1048 in 2022 to a mere 59 in 2024?—?showcasing how the rapid detection and response to cyberattacks has been impacted by Ukraine’s improved cyber resilience.

Even against a much larger adversary, Ukraine is showcasing outstanding cybersecurity, enabled by strong strategies and sound tactics. There are lessons to learn for any enterprise that could potentially be targeted by aggressive nation states.

Definitely worth the read!FIDO Seminar: Perspectives on Passkeys & Consumer Adoption.pptx

FIDO Seminar: Perspectives on Passkeys & Consumer Adoption.pptxFIDO Alliance

?

FIDO Seminar: Perspectives on Passkeys & Consumer AdoptionSupporting the NextGen 911 Digital Transformation with FME

Supporting the NextGen 911 Digital Transformation with FMESafe Software

?

Next Generation 911 involves the transformation of our 911 system from an old analog one to the new digital internet based architecture. The evolution of NG911 opens up a host of new opportunities to improve the system. This includes everything from device based location, to real time text. This can improve location accuracy dramatically as well as provide live updates from the citizen in need along with real time sensor updates. There is also the opportunity to provide multi-media attachments and medical records if the end user approves. This digital transformation and enhancements all require the support of new NENA and CRTC standards, along with integration across a variety of data streams.

This presentation will focus on how FME has supported NG911 transformations to date, and how we are positioning FME to support the enhanced capabilities to come. This session will be of interest to emergency services, municipalities and anyone who may be interested to know more about how emergency services are being improved to provide more accurate, localized information in order to improve the speed and relevance of emergency response and ultimately save more lives and provide better outcomes for those in need.“Addressing Evolving AI Model Challenges Through Memory and Storage,” a Prese...

“Addressing Evolving AI Model Challenges Through Memory and Storage,” a Prese...Edge AI and Vision Alliance

?

“From Enterprise to Makers: Driving Vision AI Innovation at the Extreme Edge,...

“From Enterprise to Makers: Driving Vision AI Innovation at the Extreme Edge,...Edge AI and Vision Alliance

?

Ad

Introduction About Lean Way

- 1. Ocean Dong ( ocean.dong@infor.com) Introduction about Lean Way

- 2. 2 Nobles

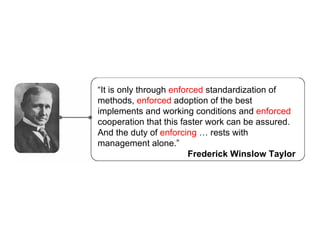

- 3. “ It is only through enforced standardization of methods, enforced adoption of the best implements and working conditions and enforced cooperation that this faster work can be assured. And the duty of enforcing … rests with management alone.” Frederick Winslow Taylor

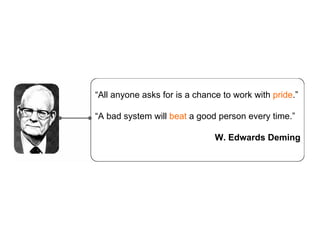

- 4. “ All anyone asks for is a chance to work with pride .” “ A bad system will beat a good person every time.” W. Edwards Deming

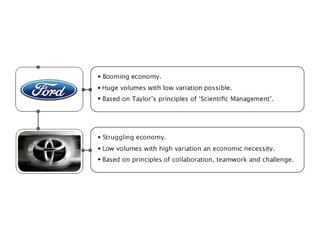

- 5. 2 Companies

- 6. ?

- 7. ?

- 8. So What’s the Lean Way?

- 9. ?

- 11. Build Quality In

- 12. On-Site Management and Authorization

- 13. Waste is everywhere. Can you really see it?

- 14. 7 (+1) Wastes

- 15. Lean Software Development?

- 16. Lean or Agile ?

- 17. Thanks

Editor's Notes

- #4: From mechanical engineer to management consultant 观察到了生产过程的混乱,认识到可以通过对流程的最大程度的分解来控制。 1 )流程分解 2 )标准化 3 )可训练、可重复、可衡量 Taylor's Principles , or frequently disparagingly, as Taylorism . Taylor's scientific management consisted of four principles: Replace rule-of-thumb work methods with methods based on a scientific study of the tasks. Scientifically select, train, and develop each employee rather than passively leaving them to train themselves. Provide "Detailed instruction and supervision of each worker in the performance of that worker's discrete task" (Montgomery 1997: 250). Divide work nearly equally between managers and workers, so that the managers apply scientific management principles to planning the work and the workers actually perform the tasks. Once a good tennis player, win doubles tournament once in the pre US Open

- #5: Deming's message to Japan's chief executives: improving quality will reduce expenses while increasing productivity and market share. JUSE's board of directors established the Deming Prize (December 1950) He was known for his kindness to and consideration for those he worked with, for his robust, if very subtle, humor, and for his interest in music. He sang in a choir, played drums and flute, and published several original pieces of sacred music Largely unknown after being back to US, until 1980s when NBC made a documentary If Japan Can, Why Can’t We Ford got help from Deming from 1981; Management rather than quality control; By 1986, Ford had become the most profitable American auto company and got over GM for the 1 st time Quality = Results of work effort / Total Cost Deming's 14 points No. 10: Eliminate slogans, exhortations, and targets for the work force asking for zero defects and new levels of productivity Appreciation of a system : understanding the overall processes involving suppliers, producers, and customers (or recipients) of goods and services ( explained below ); Knowledge of variation : the range and causes of variation in quality, and use of statistical sampling in measurements; Theory of knowledge : the concepts explaining knowledge and the limits of what can be known (see also: epistemology ); Knowledge of psychology : concepts of human nature.

- #7: Ford: 1908 Model T 1915 500,000 T, 50% increase per year 1965 2,000,000 1980, Japan intruded, Quality revolution started 2006 12.7 B lost Toyota: 1930 founded 1950’s visited by Deming; Taiichi Ohno invented TPS 1991 the whole world learnt from Toyota 2006 passed Ford 2007 passed GM and world’s largest 2007 earned 15.7 B 2008 renamed Toyota Corporation; 45 of 50 Industrial classification

- #11: Pull System 拉动生产强调前一道工序仅在后一道工序提出要求时才开始生产,以此类推,最后一道工序是客 户。可见,在拉动的过程中,信息流动的路径是从客户开始的,经过后道工序到达前道工序。“看板”作为拉动生产的一个重要工具,记录了客户的需求或是后一道 工序对前一道工序的生产需求,它经常被拿来与敏捷开发中的用户故事卡做比较。 Fast Delivery 敏捷开发虽说可能仅需要每几个月才交付一次,但在内部也通过 迭代实现了模拟客户频繁提出需求的过程。每一次迭代都模拟了一次客户提出需求并最终验收的全过程。重点是要尽量按照交付的标准来要求迭代,即使用户不需要 我们真正去交付 维持频繁交付、减少库存还有一个重要的作用就是迫使问题和浪费从隐藏状态浮现出来。比如代码的简单性, 很难想象复杂难懂的代码能支持频繁交付 Zero Inventory

- #12: 有人工参与的自动化( Autonomation ) 强调在第一时间、第一现场发现缺陷,分析根本原因并彻底解决问题,以此实现零缺陷的目标。 “ 有人工参与的自动化”认为质量产生于工序中,而非依赖后期检测,并认为后期检测是一种浪费。 工人被授权在出现问题的时候停止生产线,分析和解决问题,同时 广泛应用自动化的检测设备在生产线上及时发现加工中的缺陷。操作员不能将本工序的缺陷传递到下一个工序,他们要清楚质量的含义,而且有能力验证它 质量主要不在于你投入了多少人组建了一个多么大的后期测试队伍,而在于测试的时机和方式,等所有功能都做完了再测试就太晚了 。我们或许可以通过大量后期测试的投入得到较好的软件“外部质量”,但很可能早已错失了通过改进设计提升软件“内部质量”的时机。糟糕的内部质量在你为软件增加新功能时会暴露无疑。 Immediate Test Immediate Fix (Anchor Light) Automated Quality = Results of work effort / Total Cost

- #13: On-Site Management and Authorization 实施准时化生产的公司认为管理信息和生产数据不应仅保存在电脑中或是高级经理的办公桌里,它们中的绝大部分信息都不值得保密,反而应该公开出来发挥其本身应该发挥的作用。 强调可视化的现场管理,你可以通过简单的观察在 5 分钟内了解生产现场状态 劳动力授权就是将决定权交给那些最熟悉某种特定情况的 人,放权各个小组组织生产 价值产生于生产现场,现场是发现和解决问题的地方也是了解生产现状的最佳场所。精益生产强调“现场态度”,不要听报告,到现场去了解情况

- #14: Lean 就是识别和消除浪费(不产生附加值的活动)的技术 两种类型的浪费 ? 消灭毫无意义的浪费,将不可避免的浪费 减少到最 对于无法避免的浪费,一般要: – 积极对待,配备少而精的人 – 由个人的任务变为团队的任务 – 将工作自动化,区分人和机器的职责 – 工作提前做,频繁做

- #15: Overproduction: extra features Excess inventory: partially completed work 库存 ? 批量和排队(等待) ? 不均衡(周期性) ? 复杂和繁琐 ? 强调符合原则和规定 ? 同时拥有所有权和使用权 ? 归根结底:未完成的工作都涉嫌浪费

- #17: Similar Developed same principles from manufacturing and software development individually Serving User Embrace Change: adaptive rather than predictive people-oriented rather than process-oriented Agile Manifesto : Individuals and interactions over processes and tools Working software over comprehensive documentation Customer collaboration over contract negotiation Responding to change over following a plan

- #18: Ford was one of the first American corporations to seek help from Deming. In 1981, Ford recruited Deming to help jump-start its quality movement. Ford's sales were falling. Between 1979 and 1982, Ford had incurred $3 billion in losses. Deming questioned the company's culture and the way its managers operated. To Ford's surprise, Deming talked not about quality but about management. He told Ford that management actions were responsible for 85% of all problems in developing better cars. In 1986 Ford came out with a profitable line of cars, the Taurus-Sable line. In a letter to Autoweek Magazine , Donald Petersen , then Ford Chairman, said, "We are moving toward building a quality culture at Ford and the many changes that have been taking place here have their roots directly in Dr. Deming's teachings." [15] By 1986, Ford had become the most profitable American auto company. For the first time since the 1920s, its earnings had exceeded those of arch rival General Motors (GM). Ford had come to lead the American automobile industry in improvements. Ford's following years' earnings confirmed that its success was not a fluke, for its earnings continued to exceed GM and Chrysler's.