Introduction - Well completion

7 likes1,582 views

This document discusses learning by sharing (LBS) and offshore stimulation. It mentions that LBS involves learning from many different sources. Offshore stimulation is also briefly referenced.

1 of 86

Downloaded 79 times

Ad

Recommended

3. sequances of drilling operations

3. sequances of drilling operationsElsayed Amer

╠²

The document outlines the procedures and equipment involved in oil and gas well drilling, including site preparation, hole drilling, and casing installation. It details the roles of various components such as conductor pipes, mud systems, cementing processes, and various drilling logs. Additionally, it provides insights into the operational sequences and specifications essential for efficient drilling operations.Completion equipment part 1

Completion equipment part 1Elsayed Amer

╠²

This document discusses various components used in well completion and intervention, including landing nipples, perforated joints, flow couplings, blast joints, and wireline entry guides. It provides information on the applications and design of each component, with diagrams to illustrate their uses and configurations in the subsurface completion string. Manufacturers of some components are also mentioned. The document is authored by Eng. El Sayed Amer and appears to be presentation materials on well completion equipment and techniques.Well test-procedures-manual

Well test-procedures-manualNarendra Kumar Dewangan

╠²

This document provides procedures for well test operations. It describes various types of well tests including drawdown, build-up, and deliverability tests. It outlines responsibilities for company and contractor personnel involved in well testing. Safety barriers for well tests include well test fluid, mechanical barriers, casing overpressure valves, and more. Test string equipment, surface equipment, data acquisition methods, sampling procedures, and other well testing steps are also covered. The document aims to provide uniform guidelines for Agip's well testing operations worldwide.Well intervention

Well interventionTouseef Rehman

╠²

This document discusses well intervention techniques using coiled tubing. It describes coiled tubing as continuously-milled tubular product that is straightened before insertion into the wellbore. The main types of well intervention discussed are pumping, slickline, snubbing, workover, and coiled tubing. It provides details on the components and functions of a coiled tubing unit, including the reel, injector head, control cabin, power pack, blowout preventer, stripper, and bottom hole assembly.Fundamentals of Petroleum Engineering Module 6

Fundamentals of Petroleum Engineering Module 6Aijaz Ali Mooro

╠²

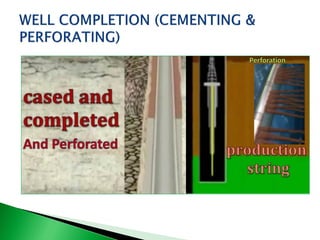

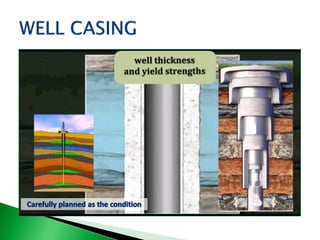

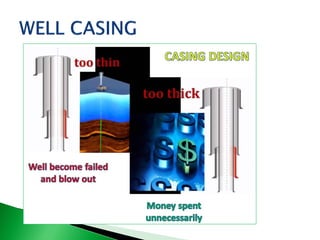

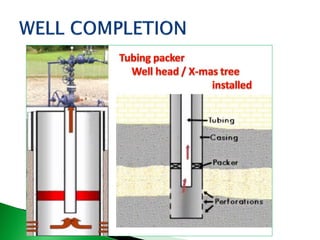

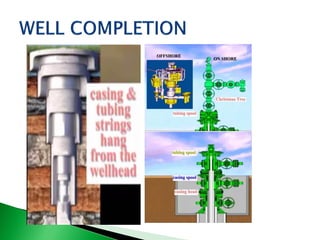

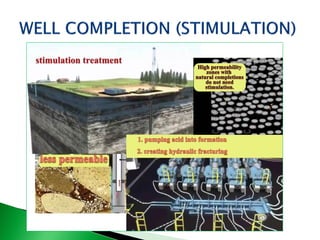

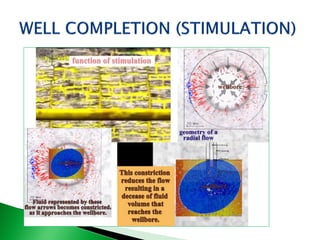

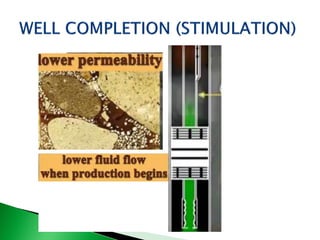

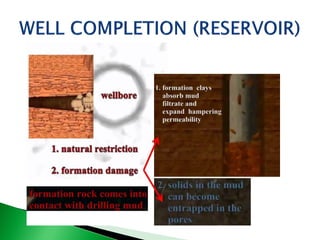

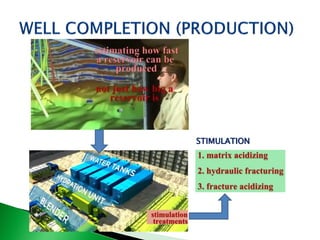

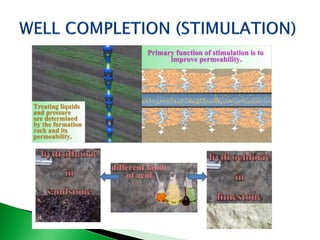

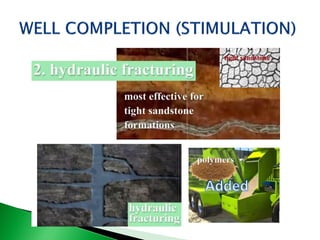

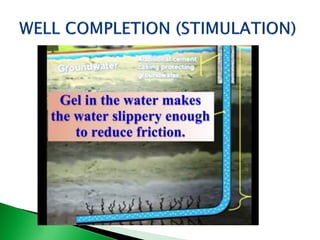

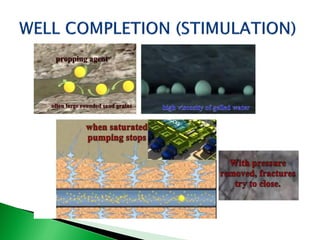

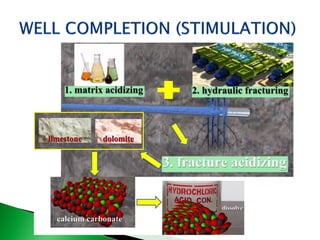

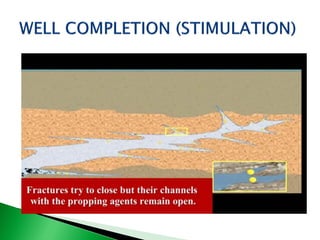

This document provides an overview of well completion and stimulation. It discusses the key steps in well completion including setting production casing, installing tubing and a Christmas tree. It also covers types of well completions, factors influencing selection, perforating, and well stimulation techniques like acidizing and fracturing to improve flow from low permeability formations. The overall goal of well completion is to prepare an oil or gas well so it can safely and controllably produce petroleum.Well Workover

Well Workover Christian Akhilome

╠²

The document discusses workover operations in oil and gas wells, which are conducted to enhance well performance through various interventions such as well killing, recompletion, and installation of down-hole production equipment. It highlights the reasons for workovers, including mechanical and reservoir-related issues, as well as the importance of maintaining the well to optimize its profitability and output. Techniques like stimulation and artificial lift are also mentioned as part of the overall workover process.Completion equipment packer part #2

Completion equipment packer part #2Elsayed Amer

╠²

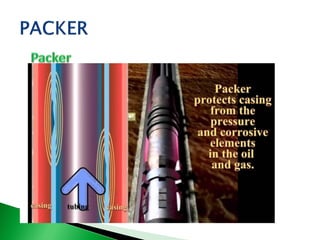

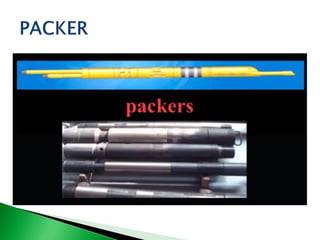

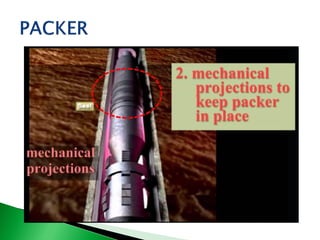

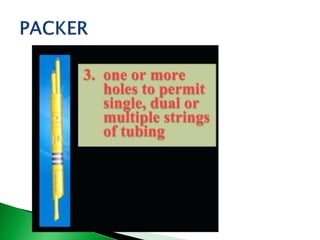

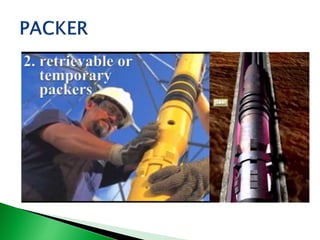

The document discusses various types of production packers used in well completion and intervention work. It describes packers that can be set mechanically, hydraulically, or electrically and covers single bore, dual bore, sump, and ESP packers. The purposes of packers include isolating zones, facilitating gas lift, preventing fluid flow, and testing or abandoning wells. Packer setting mechanisms, components, and installation procedures are also outlined.Well control equipment

Well control equipmentSARWAR SALAM

╠²

This document discusses well control equipment used in drilling operations. It describes blowout preventers (BOPs) which are used to close the well and control kicks before they become blowouts. There are different types of BOPs including annular preventers, ram preventers, and rotational preventers. Other important well control equipment includes an accumulator unit to operate BOPs hydraulically, inside BOPs, choke and kill lines, and a wellhead with casing heads to support tubulars and control fluid flow. Components should be function tested at least weekly to verify operations and actuation times should be recorded.Well completion

Well completionPETROLEUM AND NATURAL GAS ENGINEERING OF MEHRAN UET

╠²

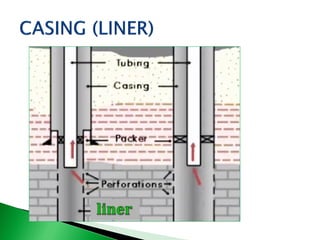

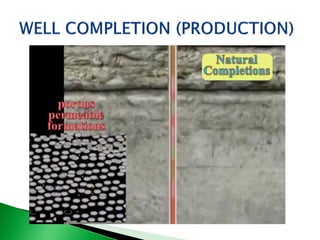

This document discusses different types of well completion methods including open hole completion and cased hole completion. Open hole completion involves setting the production casing just above the pay zone and leaving the bottom hole uncased, allowing maximum exposure but inability to isolate zones. Cased hole completion involves cementing and perforating the production casing/liner selectively, allowing isolation of zones but risk of formation damage. Common cased hole methods are liner completions, selective perforations of casing, and cemented production tubing. Flow methods include casing flow, tubing and annulus flow, and single/multiple tubing flows.Drilling Problems.pdf

Drilling Problems.pdfTinaMarey

╠²

The document discusses various drilling problems that can occur such as pipe sticking, loss of circulation, hole deviation, and more. It describes the causes and solutions for different types of pipe sticking problems including differential pressure sticking and mechanical sticking due to cuttings accumulation, borehole instability, or key seating. The document also covers loss of circulation issues and explains common lost circulation zones and causes. Planning and understanding potential problems is key to successfully reaching the target zone.Well completion 1 wleg

Well completion 1 wlegElsayed Amer

╠²

This document discusses well completion design, selection, and operations. It provides an overview of the sequence of well drilling and completion. It describes common casing programs and marks the starting point of completion. It also details the metals commonly used in completion equipment and describes various downhole completion tools like tubing hangers, packers, and wireline entry guides.Tubing string

Tubing stringElsayed Amer

╠²

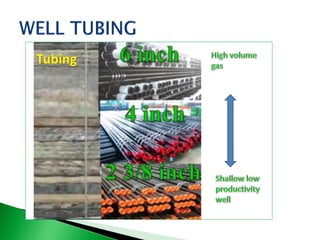

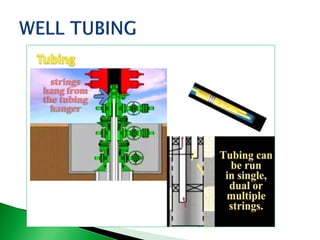

Production tubing is installed in oil and gas wells to allow hydrocarbons to flow from the reservoir to the surface while protecting the casing from reservoir fluids. Tubing is specified based on its size, length, grade, and connection type. Common tubing sizes range from 2-3/8" to 4-1/2" in diameter. Tubing joints are typically 20-48 feet in length. Tubing grade depends on the application and is chosen based on strength, corrosion resistance, and availability. Connections can be either upset or non-upset threaded types.Side sliding door ssd

Side sliding door ssdElsayed Amer

╠²

This document provides information about side sliding doors (SSDs), including:

1) SSDs are also known as sliding sleeves that provide controlled communication between the tubing and casing annulus.

2) SSDs can be used for applications like fluid displacement, well killing, gas lifting, and chemical injection by opening or closing ports between the annulus and tubing.

3) SSD sleeves can be shifted using wireline methods, coiled tubing methods, pressure darts, or differential pressure application to the annulus.Well completion techniques

Well completion techniquesvelMurugan260

╠²

This document discusses well completion testing and work over. It defines well completion as preparing a well for production by installing necessary equipment to allow safe and controlled hydrocarbon flow to the surface. The document describes open hole and cased hole well completions, including their advantages and disadvantages. It also discusses different types of well completions like liner completions, perforated liner completions, and production casing completions. Finally, it briefly covers different flow configurations like casing flow, tubing and annulus flow, and tubing flow.Completion equipment packer part #1

Completion equipment packer part #1Elsayed Amer

╠²

This document contains information about Eng. El Sayed Amer, a petroleum engineer who has worked for Weatherford Drilling International and as a process and production engineer for SUCO and RWE DEA. It discusses production packers, which are subsurface tools used to provide a seal between the tubing and casing. Production packers can protect the casing from corrosion, provide better well control, isolate pay zones, and prevent fluid movement between zones. They are classified as either permanent or retrievable based on whether they can be removed from the well without destruction. The document focuses on the characteristics and advantages and disadvantages of permanent and retrievable production packers.Well completion equipment 2. landing nipples

Well completion equipment 2. landing nipplesElsayed Amer

╠²

A landing nipple is a short length of pipe with a cut profile on the inside used to allow a lock mandrel to locate and lock into for various purposes like plugging the tubing. There are selective and no-go types, with no-go containing a restriction preventing passage. Landing nipples are used for removing surface equipment, pressure testing, setting packers, installing downhole tools, and landing pressure recorders. They consist of a lock mandrel, equalizing sub, and flow control device. Major manufacturers include Baker, CAMCO, Halliburton, and Weatherford.WELL COMPLETIONS.pptx

WELL COMPLETIONS.pptxDagogoGreenFurosigha

╠²

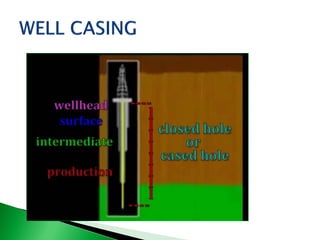

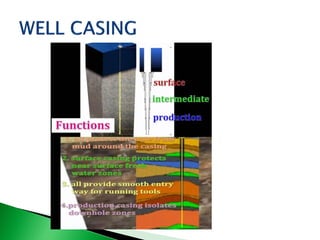

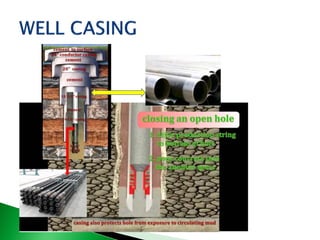

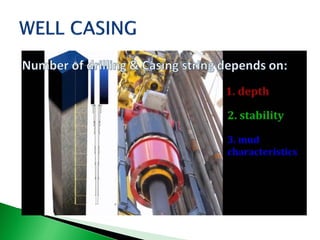

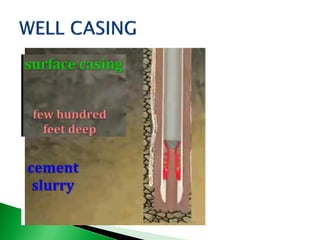

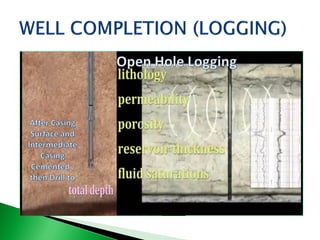

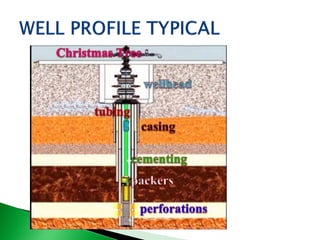

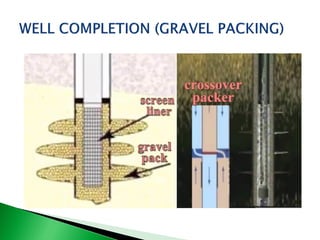

The document discusses well completion processes. It describes the different types of well casing installed during completion, including conductor, surface, intermediate, production, and liner casing. It also discusses functions of casing like strengthening the wellbore and preventing fluid migration. The document outlines various completion methods like open hole, cemented liners, gravel packs, and describes how zones are produced. It classifies completions based on reservoir interface, production method (natural flow, artificial lift like rod pumps and ESPs), and number of zones. The artificial lift methods support production when natural reservoir pressure declines.Sequence of well completion part 1

Sequence of well completion part 1Elsayed Amer

╠²

This document provides information about well completion processes and equipment. It discusses steps like well clean up, mud displacement, perforating, and describes completion equipment such as packers, landing nipples, perforated joints, and side pocket mandrels. The document is a reference for engineers, providing technical details on well completion design, operations, and component functions.perforated joint, flow coupling and blast joint

perforated joint, flow coupling and blast jointElsayed Amer

╠²

This document discusses perforated joints, flow couplings, and blast joints used in downhole equipment. A perforated joint is installed above a no-go and provides flow bypass when gauges are installed. It must have a total cross-sectional area of holes equivalent to the tubing internal diameter. Flow couplings are installed where turbulence is expected, such as above and below crossovers or nipples, and have thicker walls to prevent early erosion failures. Blast joints are placed near perforations and have heavy, blast-resistant coatings to protect from extreme erosional forces opposite open perforations.A Brief Introduction to Coiled Tubing: What is it? What to do with it?, pumps...

A Brief Introduction to Coiled Tubing: What is it? What to do with it?, pumps...tmhsweb

╠²

This document provides an overview of coiled tubing, including its history, equipment, and applications. It discusses how coiled tubing originated from military projects during World War II and was first used in the oilfield in 1962. The key components of a coiled tubing unit are described, including the injector, reel, control house, and other equipment. Common applications of coiled tubing in the oil and gas industry involve well intervention operations such as drilling, logging, perforating, and more. A comparison is made between addressing blockages in wells and arteries.introduction to completions and workovers (2)

introduction to completions and workovers (2)Dr. Arzu Javadova

╠²

This document provides an overview of workovers and completions in the oil and gas industry, detailing various completion methods, advantages and disadvantages, and reasons for workovers. It discusses both open hole and cased hole completions, secondary recovery methods, and common reasons for mechanical issues that necessitate workovers. Additionally, it addresses formation damage during drilling and completion processes and highlights the importance of reservoir characteristics for successful hydrocarbon production.Well head and christmas tress 2019.

Well head and christmas tress 2019.Vihar Pothukuchi

╠²

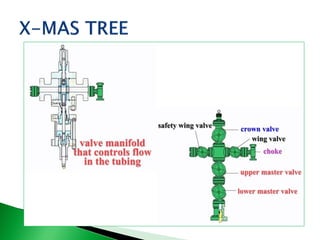

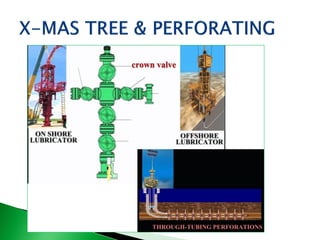

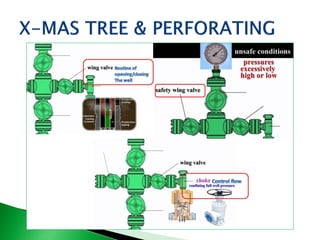

The document discusses Christmas trees and wellheads used in oil and gas extraction. It defines a Christmas tree as an assembly of valves, spools, and fittings used to control the flow of oil, gas, and other fluids from a well. A wellhead provides structural support and pressure containment for casing strings. It interfaces with the reservoir and provides a path for well fluids. The document describes the components and functions of Christmas trees and wellheads, and notes they work together to bring oil and gas to the surface from underground reservoirs.Well Integrity.pptx

Well Integrity.pptxAnjanKumar960785

╠²

Well integrity is critical for oil and gas wells to prevent uncontrolled release of hydrocarbons. The document discusses well integrity failures, management, and standards. It defines well integrity and outlines its importance. Failures are common, with 35-50% of existing wells having issues. Well integrity management involves design, construction, monitoring, and abandonment phases. Standards provide guidelines on barriers, casing pressure, and integrity best practices to reduce risks over a well's lifecycle. Maintaining well barriers and addressing integrity proactively are keys to successful management.140717 artificial lift

140717 artificial liftAli Okasha

╠²

The document discusses artificial lift, which refers to methods used to raise oil and gas from wells when the natural reservoir pressure has declined. It describes several types of artificial lift systems including beam pumping (also called sucker rod pumping), electric submersible pumps, gas lift, and plunger lift. Beam pumping is the most common type and involves using the up and down motion of a pump jack at the surface to actuate a downhole pump via sucker rods. Over 1 million oil wells worldwide use some type of artificial lift, with more than 750,000 relying on beam/sucker rod pumping. The document provides details on how beam pumping systems work and factors to consider when selecting artificial lift methods.Subsurface safety valves

Subsurface safety valvesAkhilesh Maurya

╠²

This document summarizes a minor project report on subsurface safety valves. It discusses the history and operation of safety valves, which provide protection against uncontrolled flow from oil and gas wells. Safety valves have evolved from simple downhole devices in the 1940s to complex systems integral to offshore well completions worldwide. There are two main types - surface operated and subsurface operated valves. Surface operated valves are further divided into pressure differential and pressure operated types, while subsurface operated valves include wireline retrievable and tubing mounted varieties. The project aims to develop an understanding of safety valve applications and parameters that affect their performance and efficiency.Well intervention

Well interventionMohammed Ismail

╠²

This document discusses well intervention using coiled tubing. It defines coiled tubing and its main components, which include an injector head, coiled tubing reel, control unit, power pack unit, and bottom-hole assembly. Coiled tubing can be used for various applications like wellbore cleanout, milling, logging, perforating, drilling deviated wells, fluid conveyance, and tool conveyance. It has advantages over conventional drilling like not requiring connections and allowing faster tripping in and out. However, coiled tubing also has disadvantages like fatigue life limits and reduced bore diameter.Chapter 2 surface equipment (1)

Chapter 2 surface equipment (1)Dr. Arzu Javadova

╠²

The document discusses various types of surface equipment used in oil and gas production operations, including:

1. Production trees (single and dual string), gate valves, tubing hangers, production chokes, and surface safety systems.

2. Components of these systems like tubing spools, tubing hangers, back pressure valves, lubricators, and production chokes.

3. Specialized equipment for different well types/applications such as coiled tubing, pumping, and frac stacks.Sucker Rod Pump (SRP)

Sucker Rod Pump (SRP)Rakesh Kumar

╠²

Sucker rod pumps are a type of artificial lift used in oil wells that involves components both above and below ground. The surface pumping unit is connected via sucker rods to the subsurface pump located downhole. The pumping cycle involves the plunger moving up and down inside the barrel, using the traveling or standing valves to draw fluid into the barrel on the upstroke and push it up on the downstroke. Sucker rod pumps are suitable for shallow wells producing 10-1000 bbl/day but become less effective at greater depths or in wells with high gas levels.Garmin BaseCamp & Google Earth (From Tracking to Monitoring)

Garmin BaseCamp & Google Earth (From Tracking to Monitoring)Andi Anriansyah

╠²

This document provides an overview of using Garmin BaseCamp and Google Earth software to import GPS tracking data, create maps and monitor project progress. It discusses downloading and installing both programs, navigating their interfaces, importing GPS data files and KML files, editing and analyzing point, path, polygon and image data, measuring distances, and using the tools to create a monitoring project in Google Earth to track structure development over time. Step-by-step instructions are provided for tasks like overlaying maps, digitizing layout lines, importing GPS tracks and photos, and estimating areas to visualize and measure progress.Rock Mass Classification

Rock Mass ClassificationAndi Anriansyah

╠²

The document provides an overview of rock mass classification systems used in engineering geology, emphasizing concepts related to the properties and behavior of rocks under different conditions. It discusses major classification systems, factors influencing rock stability, and methods like the Rock Mass Rating (RMR) and Geological Strength Index (GSI) to evaluate rock mass quality. Additionally, it covers geological processes, the impact of earthquakes, and the usefulness of geology in environmental protection and construction planning.More Related Content

What's hot (20)

Well completion

Well completionPETROLEUM AND NATURAL GAS ENGINEERING OF MEHRAN UET

╠²

This document discusses different types of well completion methods including open hole completion and cased hole completion. Open hole completion involves setting the production casing just above the pay zone and leaving the bottom hole uncased, allowing maximum exposure but inability to isolate zones. Cased hole completion involves cementing and perforating the production casing/liner selectively, allowing isolation of zones but risk of formation damage. Common cased hole methods are liner completions, selective perforations of casing, and cemented production tubing. Flow methods include casing flow, tubing and annulus flow, and single/multiple tubing flows.Drilling Problems.pdf

Drilling Problems.pdfTinaMarey

╠²

The document discusses various drilling problems that can occur such as pipe sticking, loss of circulation, hole deviation, and more. It describes the causes and solutions for different types of pipe sticking problems including differential pressure sticking and mechanical sticking due to cuttings accumulation, borehole instability, or key seating. The document also covers loss of circulation issues and explains common lost circulation zones and causes. Planning and understanding potential problems is key to successfully reaching the target zone.Well completion 1 wleg

Well completion 1 wlegElsayed Amer

╠²

This document discusses well completion design, selection, and operations. It provides an overview of the sequence of well drilling and completion. It describes common casing programs and marks the starting point of completion. It also details the metals commonly used in completion equipment and describes various downhole completion tools like tubing hangers, packers, and wireline entry guides.Tubing string

Tubing stringElsayed Amer

╠²

Production tubing is installed in oil and gas wells to allow hydrocarbons to flow from the reservoir to the surface while protecting the casing from reservoir fluids. Tubing is specified based on its size, length, grade, and connection type. Common tubing sizes range from 2-3/8" to 4-1/2" in diameter. Tubing joints are typically 20-48 feet in length. Tubing grade depends on the application and is chosen based on strength, corrosion resistance, and availability. Connections can be either upset or non-upset threaded types.Side sliding door ssd

Side sliding door ssdElsayed Amer

╠²

This document provides information about side sliding doors (SSDs), including:

1) SSDs are also known as sliding sleeves that provide controlled communication between the tubing and casing annulus.

2) SSDs can be used for applications like fluid displacement, well killing, gas lifting, and chemical injection by opening or closing ports between the annulus and tubing.

3) SSD sleeves can be shifted using wireline methods, coiled tubing methods, pressure darts, or differential pressure application to the annulus.Well completion techniques

Well completion techniquesvelMurugan260

╠²

This document discusses well completion testing and work over. It defines well completion as preparing a well for production by installing necessary equipment to allow safe and controlled hydrocarbon flow to the surface. The document describes open hole and cased hole well completions, including their advantages and disadvantages. It also discusses different types of well completions like liner completions, perforated liner completions, and production casing completions. Finally, it briefly covers different flow configurations like casing flow, tubing and annulus flow, and tubing flow.Completion equipment packer part #1

Completion equipment packer part #1Elsayed Amer

╠²

This document contains information about Eng. El Sayed Amer, a petroleum engineer who has worked for Weatherford Drilling International and as a process and production engineer for SUCO and RWE DEA. It discusses production packers, which are subsurface tools used to provide a seal between the tubing and casing. Production packers can protect the casing from corrosion, provide better well control, isolate pay zones, and prevent fluid movement between zones. They are classified as either permanent or retrievable based on whether they can be removed from the well without destruction. The document focuses on the characteristics and advantages and disadvantages of permanent and retrievable production packers.Well completion equipment 2. landing nipples

Well completion equipment 2. landing nipplesElsayed Amer

╠²

A landing nipple is a short length of pipe with a cut profile on the inside used to allow a lock mandrel to locate and lock into for various purposes like plugging the tubing. There are selective and no-go types, with no-go containing a restriction preventing passage. Landing nipples are used for removing surface equipment, pressure testing, setting packers, installing downhole tools, and landing pressure recorders. They consist of a lock mandrel, equalizing sub, and flow control device. Major manufacturers include Baker, CAMCO, Halliburton, and Weatherford.WELL COMPLETIONS.pptx

WELL COMPLETIONS.pptxDagogoGreenFurosigha

╠²

The document discusses well completion processes. It describes the different types of well casing installed during completion, including conductor, surface, intermediate, production, and liner casing. It also discusses functions of casing like strengthening the wellbore and preventing fluid migration. The document outlines various completion methods like open hole, cemented liners, gravel packs, and describes how zones are produced. It classifies completions based on reservoir interface, production method (natural flow, artificial lift like rod pumps and ESPs), and number of zones. The artificial lift methods support production when natural reservoir pressure declines.Sequence of well completion part 1

Sequence of well completion part 1Elsayed Amer

╠²

This document provides information about well completion processes and equipment. It discusses steps like well clean up, mud displacement, perforating, and describes completion equipment such as packers, landing nipples, perforated joints, and side pocket mandrels. The document is a reference for engineers, providing technical details on well completion design, operations, and component functions.perforated joint, flow coupling and blast joint

perforated joint, flow coupling and blast jointElsayed Amer

╠²

This document discusses perforated joints, flow couplings, and blast joints used in downhole equipment. A perforated joint is installed above a no-go and provides flow bypass when gauges are installed. It must have a total cross-sectional area of holes equivalent to the tubing internal diameter. Flow couplings are installed where turbulence is expected, such as above and below crossovers or nipples, and have thicker walls to prevent early erosion failures. Blast joints are placed near perforations and have heavy, blast-resistant coatings to protect from extreme erosional forces opposite open perforations.A Brief Introduction to Coiled Tubing: What is it? What to do with it?, pumps...

A Brief Introduction to Coiled Tubing: What is it? What to do with it?, pumps...tmhsweb

╠²

This document provides an overview of coiled tubing, including its history, equipment, and applications. It discusses how coiled tubing originated from military projects during World War II and was first used in the oilfield in 1962. The key components of a coiled tubing unit are described, including the injector, reel, control house, and other equipment. Common applications of coiled tubing in the oil and gas industry involve well intervention operations such as drilling, logging, perforating, and more. A comparison is made between addressing blockages in wells and arteries.introduction to completions and workovers (2)

introduction to completions and workovers (2)Dr. Arzu Javadova

╠²

This document provides an overview of workovers and completions in the oil and gas industry, detailing various completion methods, advantages and disadvantages, and reasons for workovers. It discusses both open hole and cased hole completions, secondary recovery methods, and common reasons for mechanical issues that necessitate workovers. Additionally, it addresses formation damage during drilling and completion processes and highlights the importance of reservoir characteristics for successful hydrocarbon production.Well head and christmas tress 2019.

Well head and christmas tress 2019.Vihar Pothukuchi

╠²

The document discusses Christmas trees and wellheads used in oil and gas extraction. It defines a Christmas tree as an assembly of valves, spools, and fittings used to control the flow of oil, gas, and other fluids from a well. A wellhead provides structural support and pressure containment for casing strings. It interfaces with the reservoir and provides a path for well fluids. The document describes the components and functions of Christmas trees and wellheads, and notes they work together to bring oil and gas to the surface from underground reservoirs.Well Integrity.pptx

Well Integrity.pptxAnjanKumar960785

╠²

Well integrity is critical for oil and gas wells to prevent uncontrolled release of hydrocarbons. The document discusses well integrity failures, management, and standards. It defines well integrity and outlines its importance. Failures are common, with 35-50% of existing wells having issues. Well integrity management involves design, construction, monitoring, and abandonment phases. Standards provide guidelines on barriers, casing pressure, and integrity best practices to reduce risks over a well's lifecycle. Maintaining well barriers and addressing integrity proactively are keys to successful management.140717 artificial lift

140717 artificial liftAli Okasha

╠²

The document discusses artificial lift, which refers to methods used to raise oil and gas from wells when the natural reservoir pressure has declined. It describes several types of artificial lift systems including beam pumping (also called sucker rod pumping), electric submersible pumps, gas lift, and plunger lift. Beam pumping is the most common type and involves using the up and down motion of a pump jack at the surface to actuate a downhole pump via sucker rods. Over 1 million oil wells worldwide use some type of artificial lift, with more than 750,000 relying on beam/sucker rod pumping. The document provides details on how beam pumping systems work and factors to consider when selecting artificial lift methods.Subsurface safety valves

Subsurface safety valvesAkhilesh Maurya

╠²

This document summarizes a minor project report on subsurface safety valves. It discusses the history and operation of safety valves, which provide protection against uncontrolled flow from oil and gas wells. Safety valves have evolved from simple downhole devices in the 1940s to complex systems integral to offshore well completions worldwide. There are two main types - surface operated and subsurface operated valves. Surface operated valves are further divided into pressure differential and pressure operated types, while subsurface operated valves include wireline retrievable and tubing mounted varieties. The project aims to develop an understanding of safety valve applications and parameters that affect their performance and efficiency.Well intervention

Well interventionMohammed Ismail

╠²

This document discusses well intervention using coiled tubing. It defines coiled tubing and its main components, which include an injector head, coiled tubing reel, control unit, power pack unit, and bottom-hole assembly. Coiled tubing can be used for various applications like wellbore cleanout, milling, logging, perforating, drilling deviated wells, fluid conveyance, and tool conveyance. It has advantages over conventional drilling like not requiring connections and allowing faster tripping in and out. However, coiled tubing also has disadvantages like fatigue life limits and reduced bore diameter.Chapter 2 surface equipment (1)

Chapter 2 surface equipment (1)Dr. Arzu Javadova

╠²

The document discusses various types of surface equipment used in oil and gas production operations, including:

1. Production trees (single and dual string), gate valves, tubing hangers, production chokes, and surface safety systems.

2. Components of these systems like tubing spools, tubing hangers, back pressure valves, lubricators, and production chokes.

3. Specialized equipment for different well types/applications such as coiled tubing, pumping, and frac stacks.Sucker Rod Pump (SRP)

Sucker Rod Pump (SRP)Rakesh Kumar

╠²

Sucker rod pumps are a type of artificial lift used in oil wells that involves components both above and below ground. The surface pumping unit is connected via sucker rods to the subsurface pump located downhole. The pumping cycle involves the plunger moving up and down inside the barrel, using the traveling or standing valves to draw fluid into the barrel on the upstroke and push it up on the downstroke. Sucker rod pumps are suitable for shallow wells producing 10-1000 bbl/day but become less effective at greater depths or in wells with high gas levels.More from Andi Anriansyah (20)

Garmin BaseCamp & Google Earth (From Tracking to Monitoring)

Garmin BaseCamp & Google Earth (From Tracking to Monitoring)Andi Anriansyah

╠²

This document provides an overview of using Garmin BaseCamp and Google Earth software to import GPS tracking data, create maps and monitor project progress. It discusses downloading and installing both programs, navigating their interfaces, importing GPS data files and KML files, editing and analyzing point, path, polygon and image data, measuring distances, and using the tools to create a monitoring project in Google Earth to track structure development over time. Step-by-step instructions are provided for tasks like overlaying maps, digitizing layout lines, importing GPS tracks and photos, and estimating areas to visualize and measure progress.Rock Mass Classification

Rock Mass ClassificationAndi Anriansyah

╠²

The document provides an overview of rock mass classification systems used in engineering geology, emphasizing concepts related to the properties and behavior of rocks under different conditions. It discusses major classification systems, factors influencing rock stability, and methods like the Rock Mass Rating (RMR) and Geological Strength Index (GSI) to evaluate rock mass quality. Additionally, it covers geological processes, the impact of earthquakes, and the usefulness of geology in environmental protection and construction planning.Petroleum Operations Geology - An Outline

Petroleum Operations Geology - An OutlineAndi Anriansyah

╠²

The document provides an overview of the roles and responsibilities of an Operations Geologist. It describes how an Operations Geologist must conduct geological planning for wells, including risk analysis and data acquisition programs. During well execution, the geologist monitors coring, wireline logging, and pore pressure evaluation. Post-well duties include end of well reporting, data distribution, and archiving. The modern role of the Operations Geologist involves well planning, monitoring well execution, and reporting on end-of-well activities.30 Best drone 2019 on geekbuying overview

30 Best drone 2019 on geekbuying overviewAndi Anriansyah

╠²

This document provides an overview of 30 different drones available on geekbuying.com in 2019. It lists each drone along with 1-3 sentences describing its key features. The drones range from inexpensive mini drones to high-performance racing drones. Features highlighted include camera resolution, transmission range, battery life, obstacle avoidance, and automated flight modes. Links are provided for each drone to view more details on geekbuying.com.Seismic interpretation - Fluvial Deltaic System

Seismic interpretation - Fluvial Deltaic SystemAndi Anriansyah

╠²

This document provides an overview of seismic interpretation methods for studying fluvial deltaic systems. It discusses key geological concepts, seismic data acquisition and processing methods, and techniques for structural and stratigraphic interpretation. These include identifying reflection configurations, fault geometries, channel elements, and depositional facies associated with fluvial and deltaic depositional environments through seismic horizon slicing and interpretation of prograding deltas and syndepositional features. The goal is to interpret seismic data to reconstruct the geological evolution of fluvial and deltaic systems.SUBSURFACE EVALUATION FULL SCALE EOR WATER FLOODING A - M FAULT ANTICLINE SHA...

SUBSURFACE EVALUATION FULL SCALE EOR WATER FLOODING A - M FAULT ANTICLINE SHA...Andi Anriansyah

╠²

The document evaluates full-scale Enhanced Oil Recovery (EOR) through water flooding in the A-M fault anticline of the O field in South Sumatera Basin, detailing 13 distinct flooding patterns. It projects a recoverable reserve of 1,918.8 million barrels of oil (mbo) over a 15-year period, with an anticipated peak production gain of 725 barrels of oil per day (bopd) by the eighth year. Recommendations for well work programs and water injection infrastructure are also provided to support production optimization.PRODUCTION OPTIMIZATION USING SURFACTANT STIMULATION HUFF & PUFF AND CONTINUE...

PRODUCTION OPTIMIZATION USING SURFACTANT STIMULATION HUFF & PUFF AND CONTINUE...Andi Anriansyah

╠²

The document outlines a strategy for optimizing oil production in the O Field of the South Sumatera Basin using surfactant stimulation techniques, specifically huff & puff and continuous injection methods. It presents an evaluation of candidate wells, forecasting a minimum gain of 6 bopd from each well, with the potential for peak production reaching 138 bopd by the 15th month following the implementation of the strategy. The evaluation includes recommendations for laboratory tests, engineering consultations, and continuous monitoring to enhance reservoir performance.Petroleum Appraisal & Development Overview

Petroleum Appraisal & Development OverviewAndi Anriansyah

╠²

This document provides an overview of petroleum appraisal and development. It describes hydrocarbon production rates and the equipment used in field appraisal and development. It discusses the evolution of exploration wells into production wells and the appraisal phase of field development. It covers procedures for appraising and developing onshore and offshore fields, including delineation wells, step-out drilling, well spacing, and infill wells. It also describes improving hydrocarbon production through workover operations, re-stimulation, and repairing casing leaks and faulty well equipment. Suggestions are requested for the next book on overview of the petroleum and mining industries.Petroleum Artificial Lift Overview

Petroleum Artificial Lift OverviewAndi Anriansyah

╠²

This document provides an overview of petroleum artificial lift. It begins by describing the reservoir production cycle and how natural lift is used initially, but artificial lift is later needed when natural pressures decline. It then outlines the main types of artificial lift systems, including sucker rod pumping, gas lift, and ESP. The document discusses reservoir underbalanced conditions that allow natural lift to occur and the obstacles that later require artificial lift. It provides diagrams and explanations of how several common artificial lift systems work. Finally, it covers factors for selecting the appropriate artificial lift method based on reservoir, wellbore, surface, and field characteristics.Petroleum Drilling Overview

Petroleum Drilling OverviewAndi Anriansyah

╠²

This document provides an overview of petroleum drilling. It describes the types of rigs used in both onshore and offshore drilling. The main systems of rigs are explained, including the rotating system, hoisting system, circulating system, and pressure control system. Drilling crew roles and routine procedures like drilling ahead, making connections, and logging operations are outlined. Common drilling problems such as stuck pipe, hole caving, and lost circulation are also discussed. Suggestions are requested to improve the next edition covering the petroleum industry overview.Petroleum Exploration Overview

Petroleum Exploration OverviewAndi Anriansyah

╠²

This document provides an overview of petroleum exploration. It describes the life cycle of an oil and gas field, including the exploration, appraisal and development, production, and abandonment phases. The exploration process involves studying surface features like oil seeps and outcrops to identify potential hydrocarbon reservoirs. Subsurface data from techniques like seismic surveys is also used. Basin analysis examines sedimentary basins where source rocks may have generated hydrocarbons that migrated and were trapped in reservoir rocks. The goal is to identify "petroleum plays" with the highest probability of containing producible oil and gas to justify drilling exploratory wells. Subsurface data acquisition methods help map underground geology before drilling begins.Petroleum Formation Evaluation Overview

Petroleum Formation Evaluation OverviewAndi Anriansyah

╠²

This document provides an overview and table of contents for a book about petroleum formation evaluation. The foreword introduces topics that will be covered, including formation evaluation procedures, drilling data, well logging, log interpretation, integration with seismic data, well deviation and steering, and production testing. Suggestions are welcomed for improving the next edition which will provide further overview of the petroleum industry. The book aims to describe the measurement, sampling, testing and analysis methods used to characterize rock and fluid properties during the various stages of drilling, logging and production testing a well.Petroleum reservoir performance overview

Petroleum reservoir performance overviewAndi Anriansyah

╠²

This document provides an overview of petroleum reservoir performance terms and concepts. It begins with definitions of key reservoir fluid terms like fluid, density, solution gas, critical saturation, bubble point pressure, gas cap, associated and non-associated gas, viscosity, condensate, and formation volume factor. It then describes hydrocarbon classifications and recovery methods. The document outlines natural driving forces in reservoirs including solution gas, water drive, and gravity drainage. It also discusses enhanced oil recovery methods such as water flooding, thermal recovery, and microbial flooding. Suggestions are made to improve future editions covering the petroleum industry overview.Petroleum well completion overview

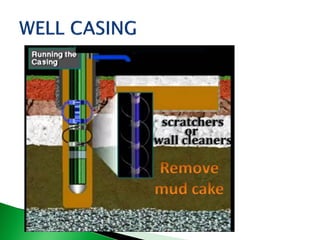

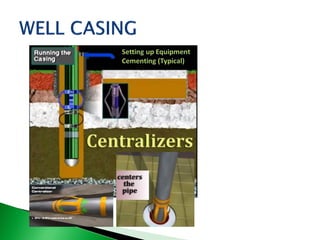

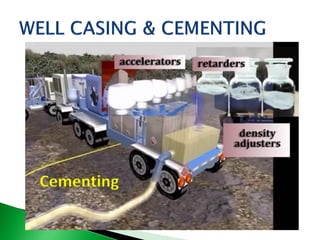

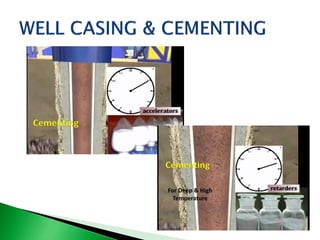

Petroleum well completion overviewAndi Anriansyah

╠²

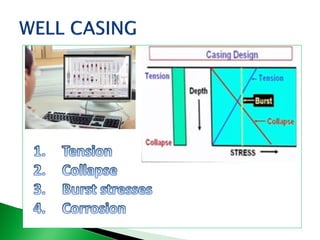

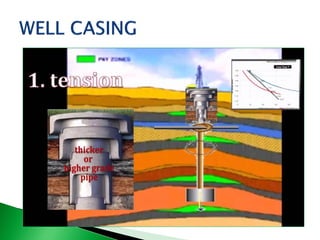

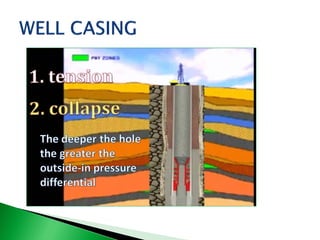

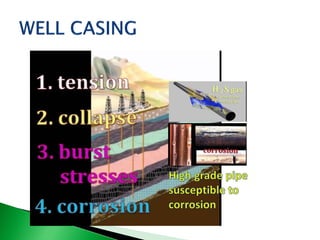

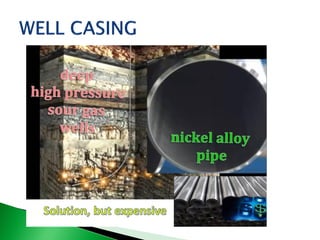

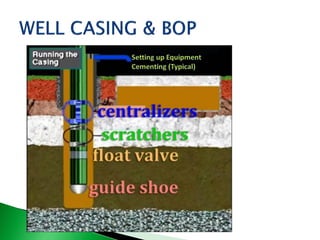

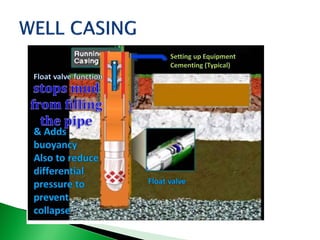

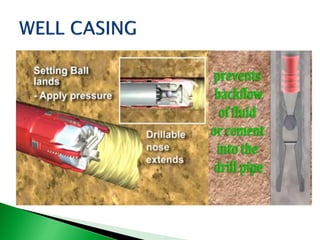

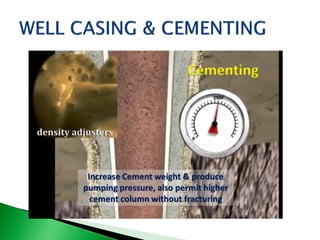

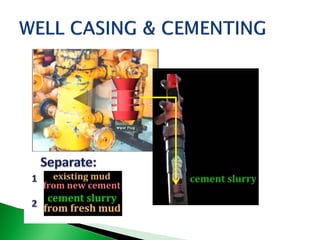

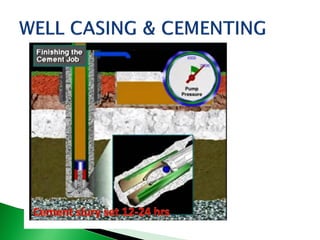

This document provides an overview of well completion processes and equipment. It describes common casing types like surface casing, intermediate casing, and production casing. It explains the functions of casing to protect the wellbore, isolate fluid zones, and provide a conduit for tools. The document outlines the typical steps in a well completion, including running and cementing casing, perforating, stimulating, gravel packing if needed, and installing tubing and a Christmas tree. It provides details on related equipment like centralizers, float shoes, and packers. The document is intended as an introduction to well completion concepts and components for educational purposes.Introduction - Artificial lift

Introduction - Artificial liftAndi Anriansyah

╠²

This document discusses artificial lift methods used in oil production. It covers three commonly used artificial lift equipment: sucker-rod pumps, gas lift, and electric submersible pumps (ESPs). As the reservoir pressure declines after initial production, artificial lift methods are needed to supplement and replace the natural reservoir pressure in lifting oil to the surface. Sucker-rod pumps are driven from the surface to pump oil up the wellbore via the sucker rods. Gas lift uses injected gas to reduce the density of downhole fluid, making it easier to lift. ESPs are submersible pumps placed downhole that use an electric motor to pump fluid up.Petroleum economics

Petroleum economicsAndi Anriansyah

╠²

Investment decisions are among the most important decisions an organization can make as they are capital intensive, irreversible, and high risk. This document discusses the main elements of economic investment analysis including calculating a project's cash flow over its lifetime while accounting for inflation, time value of money, and uncertainty. It describes key decision criteria like net present value and internal rate of return to evaluate whether a project should be accepted or rejected based on whether its NPV is positive or its IRR exceeds the discount rate. The quality of the economic analysis depends on accurate cash flow projections and using the proper discount rate.An introduction to oil and gas production

An introduction to oil and gas productionAndi Anriansyah

╠²

This document provides an overview of the oil and gas production and shipping industry, including exploration, upstream production facilities, midstream facilities, and transportation. It describes the key stages and facilities involved, from exploration and drilling to separation, processing, storage, pipelines and export. The upstream section involves wellheads, manifolds, separation and processing facilities. Midstream includes gas plants for processing, pipelines for transportation, and LNG facilities for liquefaction and regasification. Various offshore and onshore production structures are also outlined.WELL COMPLETION, WELL INTERVENTION/ STIMULATION, AND WORKOVER

WELL COMPLETION, WELL INTERVENTION/ STIMULATION, AND WORKOVERAndi Anriansyah

╠²

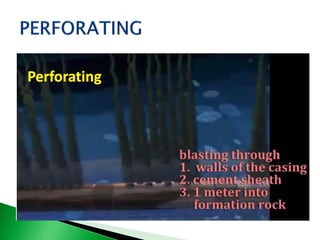

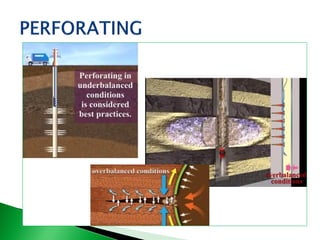

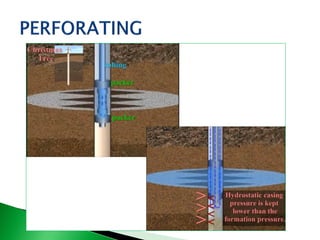

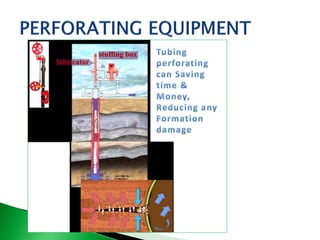

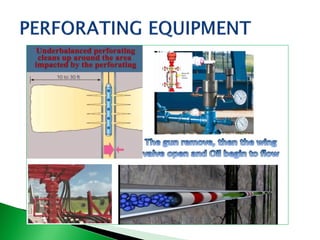

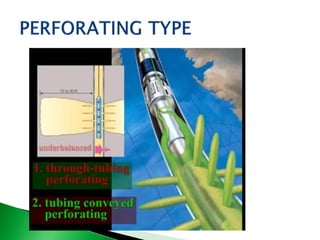

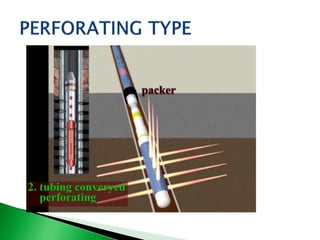

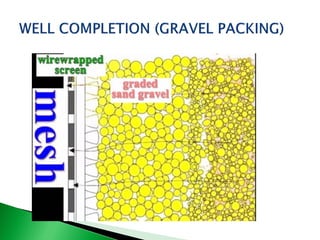

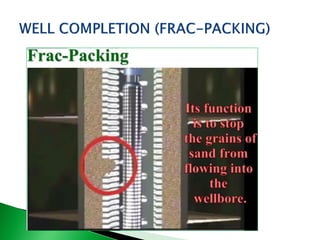

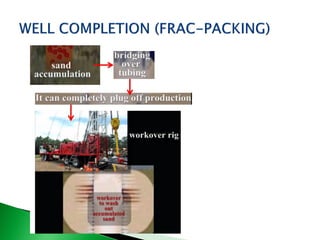

This document discusses various well completion, intervention, and workover topics including:

- Well completion involves preparing the well for production by installing equipment like casing and tubing.

- Open hole and cased hole completions are described, along with advantages and disadvantages of each.

- Well intervention operations like scale removal, acidizing, and sand cleaning are performed during production.

- Formation damage from fluids introduced into the well is also discussed.

- Stimulation techniques like acidizing and hydraulic fracturing aim to increase well productivity. The document outlines the processes, equipment, and evaluation of these operations.

- Other topics covered include intelligent well completions, perforating, sand control, squeeze cementDrilling operations

Drilling operationsAndi Anriansyah

╠²

The document discusses drilling operations including directional drilling, casing design, and bottom hole assembly components. Directional drilling involves deviating wellbores from vertical to intersect targets. Key directional drilling types include "J", "S", and slant wells. Casing is designed and set at depths to isolate formations and support wellheads. Bottom hole assemblies use drill pipe, heavy drill pipe, drill collars, and bits to transfer rotation and weight to drill the well.Ad

Recently uploaded (20)

Deep Learning for Image Processing on 16 June 2025 MITS.pptx

Deep Learning for Image Processing on 16 June 2025 MITS.pptxresming1

╠²

This covers how image processing or the field of computer vision has advanced with the advent of neural network architectures ranging from LeNet to Vision transformers. It covers how deep neural network architectures have developed step-by-step from the popular CNNs to ViTs. CNNs and its variants along with their features are described. Vision transformers are introduced and compared with CNNs. It also shows how an image is processed to be given as input to the vision transformer. It give the applications of computer vision.Fatality due to Falls at Working at Height

Fatality due to Falls at Working at Heightssuserb8994f

╠²

It is related to fatality due to falls at working at heightComplete guidance book of Asp.Net Web API

Complete guidance book of Asp.Net Web APIShabista Imam

╠²

Unlock the full potential of modern web development with the Complete Guidance Book of ASP.NET Web APIŌĆöyour all-in-one resource for mastering RESTful services using MicrosoftŌĆÖs powerful ASP.NET Core framework. This book takes you on a step-by-step journey from beginner to expert, covering everything from routing and controllers to security, performance optimization, and real-world architecture.Rapid Prototyping for XR: Lecture 4 - High Level Prototyping.

Rapid Prototyping for XR: Lecture 4 - High Level Prototyping.Mark Billinghurst

╠²

This is lecture 4 in the course on Rapid Prototyping for XR, taught by Mark Billinghurst on June 11th, 2025. This lecture is about High Level Prototyping.May 2025: Top 10 Read Articles in Data Mining & Knowledge Management Process

May 2025: Top 10 Read Articles in Data Mining & Knowledge Management ProcessIJDKP

╠²

Data mining and knowledge discovery in databases have been attracting a significant amount of research, industry, and media attention of late. There is an urgent need for a new generation of computational theories and tools to assist researchers in extracting useful information from the rapidly growing volumes of digital data.

This Journal provides a forum for researchers who address this issue and to present their work in a peer-reviewed open access forum. Authors are solicited to contribute to the Journal by submitting articles that illustrate research results, projects, surveying works and industrial experiences that describe significant advances in the following areas, but are not limited to these topics only.(Continuous Integration and Continuous Deployment/Delivery) is a fundamental ...

(Continuous Integration and Continuous Deployment/Delivery) is a fundamental ...ketan09101

╠²

(Continuous Integration and Continuous Deployment/Delivery) is a fundamental practice in DevOps that streamlines software development and deployment.Tesla-Stock-Analysis-and-Forecast.pptx (1).pptx

Tesla-Stock-Analysis-and-Forecast.pptx (1).pptxmoonsony54

╠²

this is data science ppt for tesla stock (linear regression)How to Un-Obsolete Your Legacy Keypad Design

How to Un-Obsolete Your Legacy Keypad DesignEpec Engineered Technologies

╠²

For any number of circumstances, obsolescence risk is ever present in the electronics industry. This is especially true for human-to-machine interface hardware, such as keypads, touchscreens, front panels, bezels, etc. This industry is known for its high mix and low-volume builds, critical design requirements, and high costs to requalify hardware. Because of these reasons, many programs will face end-of-life challenges both at the component level as well as at the supplier level.

Redesigns and qualifications can take months or even years, so proactively managing this risk is the best way to deter this. If an LED is obsolete or a switch vendor has gone out of business, there are options to proceed.

In this webinar, we cover options to redesign and reverse engineer legacy keypad and touchscreen designs.

For more information on our HMI solutions, visit https://www.epectec.com/user-interfaces.

Call For Papers - 17th International Conference on Wireless & Mobile Networks...

Call For Papers - 17th International Conference on Wireless & Mobile Networks...hosseinihamid192023

╠²

17th International Conference on Wireless & Mobile Networks (WiMoNe 2025) will provide

an excellent international forum for sharing knowledge and results in theory, methodology and

applications of Wireless & Mobile computing Environment. Current information age is witnessing

a dramatic use of digital and electronic devices in the workplace and beyond. Wireless, Mobile

Networks & its applications had received a significant and sustained research interest in terms of

designing and deploying large scale and high performance computational applications in real life.

The aim of the conference is to provide a platform to the researchers and practitioners from both

academia as well as industry to meet and share cutting-edge development in the field.Rapid Prototyping for XR: Lecture 2 - Low Fidelity Prototyping.

Rapid Prototyping for XR: Lecture 2 - Low Fidelity Prototyping.Mark Billinghurst

╠²

This is lecture 2 on the Rapid Prototyping for XR course taught by Mark Billingurst on June 10th 2025. This lecture is about Low Fidelity Prototyping.Introduction to Natural Language Processing - Stages in NLP Pipeline, Challen...

Introduction to Natural Language Processing - Stages in NLP Pipeline, Challen...resming1

╠²

Lecture delivered in 2021. This gives an introduction to Natural Language Processing. It describes the use cases of NLP in daily life. It discusses the stages in NLP Pipeline. It highlights the challenges involved covering the different levels of ambiguity that could arise. It also gives a brief note on the present scenario with the latest language models, tools and frameworks/libraries for NLP.Microwatt: Open Tiny Core, Big Possibilities

Microwatt: Open Tiny Core, Big PossibilitiesIBM

╠²

Microwatt is a lightweight, open-source core based on the OpenPOWER ISA.

ItŌĆÖs designed for FPGAs and easy experimentation in chip design.

Ideal for education, prototyping, and custom silicon development.

Fully open, it empowers developers to learn, modify, and innovate.Call For Papers - 17th International Conference on Wireless & Mobile Networks...

Call For Papers - 17th International Conference on Wireless & Mobile Networks...hosseinihamid192023

╠²

Ad

Introduction - Well completion

- 1. ANDI A. Practical use and reference LBS (Learning by Sharing)

- 19. OFFSHORE

- 71. STIMULATION

- 86. ’üĮ From many Sources