Inventory management

24 likes6,114 views

This document discusses inventory management. It defines inventory as stock used in an organization, including raw materials, spare parts, and finished goods. It describes different types of inventories like movement, buffer, anticipation, and decoupling inventories. It also discusses inventory costs including purchase, ordering, carrying, and stockout costs. Finally, it covers economic order quantity models and different analysis methods for classifying inventory items.

1 of 34

Recommended

INVENTORY MANAGEMENT

INVENTORY MANAGEMENTMUHAMMED SADIK K K

?

This document discusses inventory management. It defines inventory as materials, parts, tools, supplies and work in progress that are maintained in storage. The objective of inventory management is to maintain optimal inventory levels to maximize profitability. It aims to order the right quantity from the right source at the right time and price. Effective inventory management tracks inventory levels and ensures a continuous supply of raw materials for production. It aims to minimize carrying costs while avoiding stock-out costs and maintaining customer service. Determining the optimum inventory level balances carrying, stock-out, and ordering costs.Inventory management

Inventory managementsaurabhsabiba

?

This document discusses inventory management. It defines inventory as materials obtained in advance of need that are held until used or sold. There are different types of inventories like raw materials, work in progress, spare parts, and finished goods. Inventory valuation involves determining inventory quantities and assigning values. Holding inventory incurs costs like storage, ordering, shortages. The objectives of inventory control are to ensure smooth operations while minimizing costs and risks through techniques like determining economic order quantities and stock levels.Inventory Management

Inventory Management NEELAM KUSHWAHA

?

Inventory management plays a significant role in working capital management. It involves activities related to acquiring, storing, and using raw materials, work-in-progress, and finished goods. The objectives of inventory management are to maintain optimal levels of inventory to ensure smooth production and meet sales demands while minimizing investment costs. Effective inventory management requires balancing inventory levels to avoid under- or over-investment and using techniques like EOQ, reorder points, and ABC analysis to classify inventory items and determine optimal order quantities. Inventory management

Inventory managementN M

?

Inventory management involves determining optimal inventory levels to balance costs and meet demand. There are three main types of inventory - raw materials, work in progress, and finished goods. The economic order quantity model helps determine how much to order by balancing ordering costs, carrying costs, and shortage costs. Maintaining appropriate inventory levels decouples processes, provides product variety for customers, and allows for quantity discounts.Inventory management

Inventory managementrajeev227

?

The document provides an overview of inventory management. It discusses the types of inventories including raw materials, work in progress, and finished goods. It describes the functions of inventory including meeting demand, smoothing production, and protecting against stock-outs. It also discusses inventory performance measures, counting systems, key terms, classification systems, and inventory models including economic order quantity, reorder point, and periodic review systems. The document provides insights into effective inventory management.Inventory management

Inventory managementAshfaq Umar

?

The document discusses retail inventory management and the key challenges involved. It describes the process of replenishing inventory from the factory to the wholesaler to the distributor and finally to the retailer. Problems can occur due to production delays, shipping delays, or customers withdrawing items. The goal of inventory management is to facilitate the flow of goods while minimizing costs. It aims to stock the right products and maintain optimal inventory levels.Inventory management

Inventory managementkahogan62

?

The document discusses inventory management and various inventory systems. It defines inventory and different inventory types like raw materials, work in process, and finished goods. It describes the costs of carrying inventory and different inventory measurement methods. It also summarizes economic order quantity models, reorder points, periodic review systems, ABC classification, and anticipatory versus response-based inventory control systems. The goal of inventory management is to balance inventory levels and costs with customer service levels.Inventory management

Inventory managementRajThakuri

?

Inventory management involves tracking and controlling a company's stock of raw materials, work-in-progress, and finished goods. Effective inventory management requires balancing inventory investment with customer service levels. Key aspects of inventory management include classifying inventory using techniques like ABC analysis, planning inventory needs using models like MRP, and controlling inventory through periodic or perpetual counting systems. The overall goal is meeting customer demand while minimizing total inventory costs.Inventory Management - a ppt for PGDM/MBA

Inventory Management - a ppt for PGDM/MBAAJ Raina

?

A comprehensive ppt on Inventory Management by students of ERA BUSINESS SCHOOL, New Delhi; PGDM batch (2012-14)Inventory management

Inventory managementMonica Blanco

?

This document discusses inventory management. It defines inventory as goods or materials used for production and sale. Inventory management is the process of overseeing the flow of units into and out of existing inventory through purchasing planning and tracking. Key considerations for inventory management include warehousing space, costs, delivery times, and turnaround. The main types of inventory are raw materials, work-in-process, and finished goods. Effective inventory management helps maintain adequate supply while minimizing costs and avoids stock-out issues.Inventory Management Presentation

Inventory Management Presentation KattareeyaPrompreing

?

Kattareeya Prompreing

°×ŃĹĐŔ

iD:DA61G209

(Student in Ph.D. Business and Management, College Business, STUST

email:da61g209@stust.edu.tw

: katt.rmutl@gmail.comStores Management

Stores Managementthombremahesh

?

The document discusses stores management in manufacturing organizations. It describes the functions of stores departments, which include receiving, storing, and issuing materials to user departments. The document also covers topics like centralized vs decentralized store structures, stores organization and necessary functions. Key points discussed are the role of stores in providing uninterrupted supplies to manufacturing while acting as a buffer between purchasing and marketing.Inventory Planning & Control

Inventory Planning & ControlDr. Prashant Kalaskar

?

Concept of inventory, need for inventory, types of inventory, Seasonal, Decoupling, Cyclic, Pipeline, Safety, Implications of Inventory Control Methods Inventory Costs: Concept & Behavior of Ordering cost, Carrying cost & Shortage cost Basic EOQ Model & EOQ with DiscountInventory management

Inventory managementKARTHIKA K.J

?

This document defines inventory and discusses inventory control. It defines inventory as raw materials, work in progress, and finished goods. Inventory control aims to maintain optimal inventory levels for smooth operations. Inventories are classified and objectives of inventory control include avoiding over/under investment and providing the right goods at the right time. Operating objectives focus on availability, minimizing waste, and customer service, while financial objectives focus on costs. Inventory management aims to balance ordering costs, carrying costs, and stockout costs.Purchasing management

Purchasing managementMandeep Raj

?

This document provides an overview of purchasing management. It discusses the objectives of purchasing which include acquiring satisfactory materials at proper prices and quality. It outlines the key functions of a purchasing department, which are processing requisitions, locating suppliers, placing orders, and following up on orders. It also describes different methods of purchasing such as according to requirements, for a future period, on the market, through contracts or schedules. The document concludes with the typical steps in a purchase procedure from departments submitting requisitions to receiving and inspecting delivered items.Operations scheduling

Operations schedulingRajThakuri

?

This document discusses various concepts related to operations scheduling including scheduling objectives, issues, decisions, forward and backward scheduling approaches, loading jobs, input-output control, Gantt charts, assignment methods, and sequencing jobs. Specifically, it defines scheduling as prescribing when operations are performed and establishing start/completion times. It notes effective scheduling can provide competitive advantages through faster throughput, capacity, and delivery. The objectives, types of scheduling, and significant scheduling issues are also outlined.Material Resource Planning

Material Resource PlanningBiswajit Ghosh

?

The document discusses Material Requirement Planning (MRP), a systematic methodology for production planning and inventory control. MRP answers three key questions: what is needed, how much is needed, and when is it needed. It does this by collecting information from the master production schedule, bill of materials, and inventory data to generate planned order releases and time-phase requirements. MRP aims to reduce inventory levels and costs while maintaining customer service levels.Inventory management

Inventory managementRahul Gupta

?

This document discusses inventory management. It defines inventory as materials obtained in advance of need that are held until used or sold. There are different types of inventories like raw materials, work in process, finished goods, and spare parts. Inventory valuation involves determining quality and assigning values. Costs associated with inventory include purchasing, ordering, holding, and shortage costs. The economic order quantity formula balances ordering and holding costs. Inventory control aims to have the right materials in the right quantity at the lowest cost through policies, stock levels, lead times, and order sizes.Seminar on inventory management by kailash vilegave

Seminar on inventory management by kailash vilegaveKailash Vilegave

?

inventory management, INVENTORY CONTROL, AIMS OF INVENTORY CONTROL, Objectives of inventory control, Advantages of Inventory Control, INVENTORY CATEGORIES, FACTORS INFLUENCING INVENTORY, SELECTIVE INVENTORY CONTROL, Classifiacation of Inventry Control, A-B-C technique

V-E-D classification

H-M-L ˇŻˇŻ

F-S-N ˇŻˇŻ

S-D-E ˇŻˇŻ

S-O-S ˇŻˇŻ

G-O-L-F ˇŻˇŻ

X-Y-Z ˇŻˇŻ

Lead times, Stockouts, Safety stocks,

REORDER QUANTITY METHODS, Just in Time,Inventory management -Aparna Lakshmanan

Inventory management -Aparna LakshmananSidharth SiD

?

The document discusses inventory management. It defines inventory and describes the different types including raw materials, work in progress, and finished goods. It outlines the objectives of inventory management as maintaining an optimal inventory level to maximize profitability while ensuring continuous production. Effective inventory management aims to minimize total inventory costs by balancing ordering, stockout, and carrying costs. Classification methods and inventory models are also discussed.MATERIAL PLANNING PROCESS

MATERIAL PLANNING PROCESSNEHA GAUTAM

?

The document describes the integrated material planning process within ERP systems. It involves four main steps: (1) sales and operations planning (SOP) where a production plan is created at the product group level, (2) disaggregation where product group requirements are translated to individual material requirements, (3) demand management where customer orders are incorporated to revise material requirements, and (4) material requirements planning (MRP) where procurement proposals are created to ensure sufficient material availability. Reporting tools provide information on the planning situation including a stock/requirements list, MRP list, and planning result report. The overall goal of material planning is to balance supply and demand of materials so the right quantity is available when needed.Inventory management

Inventory managementDr. Vaibhav Agarwal

?

This document discusses inventory management and analysis. It defines inventory as materials that are stocked for sale, in the process of manufacturing, or as raw materials. Effective inventory control is important for smooth production. Reasons for keeping inventory include stabilizing production, taking advantage of price discounts, meeting demand during replenishment periods, preventing lost sales, and adapting to changing market conditions. The document also discusses inventory models, economic order quantity models, and how to minimize total inventory costs.Stores control

Stores controlN A M COLLEGE KALLIKKANDY

?

This document discusses stores (materials) control. It describes stores as an important current asset and how efficient control helps minimize costs. There are three types of store organizations: centralized, decentralized, and centralized with sub-stores. Centralized stores are controlled from one location while decentralized stores have independent departments. Centralized with sub-stores has a main store and sub-stores. Key aspects of stores control covered include requisitioning, bin cards, stores ledger, issue control, and spoilage. The storekeeper's duties in receiving, storing, and issuing materials are also outlined.Inventory management 091104161506 Phpapp02

Inventory management 091104161506 Phpapp02jasonhian

?

This document discusses inventory management concepts including:

- Defining inventory and providing examples of inventory levels in different industries.

- The costs of holding inventory and pressures to reduce inventory levels.

- The economic order quantity (EOQ) model for determining optimal order sizes to minimize total costs of ordering and holding inventory.

- Key factors that influence the EOQ like demand, ordering costs, holding costs.

- How the EOQ is applied in examples and the insights from sensitivity analysis.

- Extensions of the EOQ model when lead times are present.

- Different inventory control systems for handling demand uncertainty.Bba 3274 qm week 7 inventory models

Bba 3274 qm week 7 inventory modelsStephen Ong

?

This document provides an overview of inventory control models and concepts. It discusses the economic order quantity (EOQ) model, which helps determine how much of an item to order to minimize total inventory costs. The EOQ balances ordering costs with carrying costs. The reorder point indicates when to place another order based on lead time and daily usage. Other topics covered include safety stock, material requirements planning, just-in-time inventory, and enterprise resource planning systems. Real-world examples are provided to demonstrate calculating the EOQ.INVENTORY MANAGEMENT

INVENTORY MANAGEMENT Zamri Yahya

?

? Independent versus Dependent

? Demand

? Inventory Management Overview

? ABC Classification of Inventory Items

? Independent Items

? Dependent-Demand Systems

MRP,MRP-II,JIT

MRP,MRP-II,JITKevin Pereira

?

This document provides an overview and comparison of MRP, MRP II, and JIT manufacturing systems. MRP is introduced as a planning technique to schedule production of components based on a master schedule. MRP II extends MRP to integrate all company resources into planning. JIT aims to eliminate waste through just-in-time delivery, standard work, and continuous improvement. Key elements like kanban cards and pull production are described. Benefits include reduced inventory and lead times, while potential drawbacks involve risk of disruptions and high supplier dependence. An example highlights McDonald's adoption of JIT principles to enable made-to-order burgers.Purchasing and vendor management

Purchasing and vendor managementNarendra Chaudhary

?

The document discusses purchasing and vendor management. It covers topics such as the objectives and types of purchasing, purchasing procedures, functions of the purchasing department, centralized vs decentralized purchasing, vendor rating criteria and techniques, and benefits of vendor rating systems. The key points are that purchasing aims to acquire goods and services at minimum cost, ensure quality and timely delivery. Vendor performance is evaluated based on pricing, quality, delivery and service. Formal vendor rating systems help improve vendor performance and minimize subjectivity.Inventory Management Project

Inventory Management ProjectMOHD ARISH

?

This document discusses inventory management. It defines inventory and describes the variables involved in inventory problems including controlled variables like order quantity and timing, and uncontrolled variables like costs. It describes the objectives of inventory management as maintaining optimal inventory levels to maximize profitability. Different types of inventories like raw materials, work in progress, and finished goods are explained. The functions and importance of inventory management are provided along with methods like periodic review and fixed order quantity systems. The economic order quantity model and assumptions are outlined.NMIT-SUPPLY-CHAIN-MANAGEMENT-Lesson5

NMIT-SUPPLY-CHAIN-MANAGEMENT-Lesson5Jacqueline Quek

?

1. Inventory management involves determining appropriate inventory levels and replenishment policies to balance inventory holding costs, ordering costs, and the need to meet customer demand.

2. Key aspects of inventory management include classifying inventory items, determining economic order quantities, setting reorder points, and using periodic or continuous review systems.

3. The goals of effective inventory management are to provide good customer service while minimizing total inventory costs.More Related Content

What's hot (20)

Inventory Management - a ppt for PGDM/MBA

Inventory Management - a ppt for PGDM/MBAAJ Raina

?

A comprehensive ppt on Inventory Management by students of ERA BUSINESS SCHOOL, New Delhi; PGDM batch (2012-14)Inventory management

Inventory managementMonica Blanco

?

This document discusses inventory management. It defines inventory as goods or materials used for production and sale. Inventory management is the process of overseeing the flow of units into and out of existing inventory through purchasing planning and tracking. Key considerations for inventory management include warehousing space, costs, delivery times, and turnaround. The main types of inventory are raw materials, work-in-process, and finished goods. Effective inventory management helps maintain adequate supply while minimizing costs and avoids stock-out issues.Inventory Management Presentation

Inventory Management Presentation KattareeyaPrompreing

?

Kattareeya Prompreing

°×ŃĹĐŔ

iD:DA61G209

(Student in Ph.D. Business and Management, College Business, STUST

email:da61g209@stust.edu.tw

: katt.rmutl@gmail.comStores Management

Stores Managementthombremahesh

?

The document discusses stores management in manufacturing organizations. It describes the functions of stores departments, which include receiving, storing, and issuing materials to user departments. The document also covers topics like centralized vs decentralized store structures, stores organization and necessary functions. Key points discussed are the role of stores in providing uninterrupted supplies to manufacturing while acting as a buffer between purchasing and marketing.Inventory Planning & Control

Inventory Planning & ControlDr. Prashant Kalaskar

?

Concept of inventory, need for inventory, types of inventory, Seasonal, Decoupling, Cyclic, Pipeline, Safety, Implications of Inventory Control Methods Inventory Costs: Concept & Behavior of Ordering cost, Carrying cost & Shortage cost Basic EOQ Model & EOQ with DiscountInventory management

Inventory managementKARTHIKA K.J

?

This document defines inventory and discusses inventory control. It defines inventory as raw materials, work in progress, and finished goods. Inventory control aims to maintain optimal inventory levels for smooth operations. Inventories are classified and objectives of inventory control include avoiding over/under investment and providing the right goods at the right time. Operating objectives focus on availability, minimizing waste, and customer service, while financial objectives focus on costs. Inventory management aims to balance ordering costs, carrying costs, and stockout costs.Purchasing management

Purchasing managementMandeep Raj

?

This document provides an overview of purchasing management. It discusses the objectives of purchasing which include acquiring satisfactory materials at proper prices and quality. It outlines the key functions of a purchasing department, which are processing requisitions, locating suppliers, placing orders, and following up on orders. It also describes different methods of purchasing such as according to requirements, for a future period, on the market, through contracts or schedules. The document concludes with the typical steps in a purchase procedure from departments submitting requisitions to receiving and inspecting delivered items.Operations scheduling

Operations schedulingRajThakuri

?

This document discusses various concepts related to operations scheduling including scheduling objectives, issues, decisions, forward and backward scheduling approaches, loading jobs, input-output control, Gantt charts, assignment methods, and sequencing jobs. Specifically, it defines scheduling as prescribing when operations are performed and establishing start/completion times. It notes effective scheduling can provide competitive advantages through faster throughput, capacity, and delivery. The objectives, types of scheduling, and significant scheduling issues are also outlined.Material Resource Planning

Material Resource PlanningBiswajit Ghosh

?

The document discusses Material Requirement Planning (MRP), a systematic methodology for production planning and inventory control. MRP answers three key questions: what is needed, how much is needed, and when is it needed. It does this by collecting information from the master production schedule, bill of materials, and inventory data to generate planned order releases and time-phase requirements. MRP aims to reduce inventory levels and costs while maintaining customer service levels.Inventory management

Inventory managementRahul Gupta

?

This document discusses inventory management. It defines inventory as materials obtained in advance of need that are held until used or sold. There are different types of inventories like raw materials, work in process, finished goods, and spare parts. Inventory valuation involves determining quality and assigning values. Costs associated with inventory include purchasing, ordering, holding, and shortage costs. The economic order quantity formula balances ordering and holding costs. Inventory control aims to have the right materials in the right quantity at the lowest cost through policies, stock levels, lead times, and order sizes.Seminar on inventory management by kailash vilegave

Seminar on inventory management by kailash vilegaveKailash Vilegave

?

inventory management, INVENTORY CONTROL, AIMS OF INVENTORY CONTROL, Objectives of inventory control, Advantages of Inventory Control, INVENTORY CATEGORIES, FACTORS INFLUENCING INVENTORY, SELECTIVE INVENTORY CONTROL, Classifiacation of Inventry Control, A-B-C technique

V-E-D classification

H-M-L ˇŻˇŻ

F-S-N ˇŻˇŻ

S-D-E ˇŻˇŻ

S-O-S ˇŻˇŻ

G-O-L-F ˇŻˇŻ

X-Y-Z ˇŻˇŻ

Lead times, Stockouts, Safety stocks,

REORDER QUANTITY METHODS, Just in Time,Inventory management -Aparna Lakshmanan

Inventory management -Aparna LakshmananSidharth SiD

?

The document discusses inventory management. It defines inventory and describes the different types including raw materials, work in progress, and finished goods. It outlines the objectives of inventory management as maintaining an optimal inventory level to maximize profitability while ensuring continuous production. Effective inventory management aims to minimize total inventory costs by balancing ordering, stockout, and carrying costs. Classification methods and inventory models are also discussed.MATERIAL PLANNING PROCESS

MATERIAL PLANNING PROCESSNEHA GAUTAM

?

The document describes the integrated material planning process within ERP systems. It involves four main steps: (1) sales and operations planning (SOP) where a production plan is created at the product group level, (2) disaggregation where product group requirements are translated to individual material requirements, (3) demand management where customer orders are incorporated to revise material requirements, and (4) material requirements planning (MRP) where procurement proposals are created to ensure sufficient material availability. Reporting tools provide information on the planning situation including a stock/requirements list, MRP list, and planning result report. The overall goal of material planning is to balance supply and demand of materials so the right quantity is available when needed.Inventory management

Inventory managementDr. Vaibhav Agarwal

?

This document discusses inventory management and analysis. It defines inventory as materials that are stocked for sale, in the process of manufacturing, or as raw materials. Effective inventory control is important for smooth production. Reasons for keeping inventory include stabilizing production, taking advantage of price discounts, meeting demand during replenishment periods, preventing lost sales, and adapting to changing market conditions. The document also discusses inventory models, economic order quantity models, and how to minimize total inventory costs.Stores control

Stores controlN A M COLLEGE KALLIKKANDY

?

This document discusses stores (materials) control. It describes stores as an important current asset and how efficient control helps minimize costs. There are three types of store organizations: centralized, decentralized, and centralized with sub-stores. Centralized stores are controlled from one location while decentralized stores have independent departments. Centralized with sub-stores has a main store and sub-stores. Key aspects of stores control covered include requisitioning, bin cards, stores ledger, issue control, and spoilage. The storekeeper's duties in receiving, storing, and issuing materials are also outlined.Inventory management 091104161506 Phpapp02

Inventory management 091104161506 Phpapp02jasonhian

?

This document discusses inventory management concepts including:

- Defining inventory and providing examples of inventory levels in different industries.

- The costs of holding inventory and pressures to reduce inventory levels.

- The economic order quantity (EOQ) model for determining optimal order sizes to minimize total costs of ordering and holding inventory.

- Key factors that influence the EOQ like demand, ordering costs, holding costs.

- How the EOQ is applied in examples and the insights from sensitivity analysis.

- Extensions of the EOQ model when lead times are present.

- Different inventory control systems for handling demand uncertainty.Bba 3274 qm week 7 inventory models

Bba 3274 qm week 7 inventory modelsStephen Ong

?

This document provides an overview of inventory control models and concepts. It discusses the economic order quantity (EOQ) model, which helps determine how much of an item to order to minimize total inventory costs. The EOQ balances ordering costs with carrying costs. The reorder point indicates when to place another order based on lead time and daily usage. Other topics covered include safety stock, material requirements planning, just-in-time inventory, and enterprise resource planning systems. Real-world examples are provided to demonstrate calculating the EOQ.INVENTORY MANAGEMENT

INVENTORY MANAGEMENT Zamri Yahya

?

? Independent versus Dependent

? Demand

? Inventory Management Overview

? ABC Classification of Inventory Items

? Independent Items

? Dependent-Demand Systems

MRP,MRP-II,JIT

MRP,MRP-II,JITKevin Pereira

?

This document provides an overview and comparison of MRP, MRP II, and JIT manufacturing systems. MRP is introduced as a planning technique to schedule production of components based on a master schedule. MRP II extends MRP to integrate all company resources into planning. JIT aims to eliminate waste through just-in-time delivery, standard work, and continuous improvement. Key elements like kanban cards and pull production are described. Benefits include reduced inventory and lead times, while potential drawbacks involve risk of disruptions and high supplier dependence. An example highlights McDonald's adoption of JIT principles to enable made-to-order burgers.Purchasing and vendor management

Purchasing and vendor managementNarendra Chaudhary

?

The document discusses purchasing and vendor management. It covers topics such as the objectives and types of purchasing, purchasing procedures, functions of the purchasing department, centralized vs decentralized purchasing, vendor rating criteria and techniques, and benefits of vendor rating systems. The key points are that purchasing aims to acquire goods and services at minimum cost, ensure quality and timely delivery. Vendor performance is evaluated based on pricing, quality, delivery and service. Formal vendor rating systems help improve vendor performance and minimize subjectivity.Similar to Inventory management (20)

Inventory Management Project

Inventory Management ProjectMOHD ARISH

?

This document discusses inventory management. It defines inventory and describes the variables involved in inventory problems including controlled variables like order quantity and timing, and uncontrolled variables like costs. It describes the objectives of inventory management as maintaining optimal inventory levels to maximize profitability. Different types of inventories like raw materials, work in progress, and finished goods are explained. The functions and importance of inventory management are provided along with methods like periodic review and fixed order quantity systems. The economic order quantity model and assumptions are outlined.NMIT-SUPPLY-CHAIN-MANAGEMENT-Lesson5

NMIT-SUPPLY-CHAIN-MANAGEMENT-Lesson5Jacqueline Quek

?

1. Inventory management involves determining appropriate inventory levels and replenishment policies to balance inventory holding costs, ordering costs, and the need to meet customer demand.

2. Key aspects of inventory management include classifying inventory items, determining economic order quantities, setting reorder points, and using periodic or continuous review systems.

3. The goals of effective inventory management are to provide good customer service while minimizing total inventory costs.Inventory Management and Control, Production Planning and Control

Inventory Management and Control, Production Planning and ControlSimranDhiman12

?

This document provides an overview of inventory management, production planning, and control. It discusses key objectives like minimizing costs and ensuring adequate supply. Inventory management techniques include ABC analysis, VED analysis, EOQ, lead time, and buffer stock. Production planning determines facility requirements and layout, while production control monitors plan execution and addresses deviations. The perpetual inventory system uses bin cards, store ledgers, and continuous stock taking to regularly check and prevent stockouts.Basic terminologies and EOQ models of Inventory Theory

Basic terminologies and EOQ models of Inventory TheoryShashank Naruka

?

This document provides an overview of inventory theory and economic order quantity (EOQ) models. It defines key inventory terminology like demand, lead time, reorder point, and carrying costs. It then explains the assumptions and calculations for the basic EOQ model, which aims to minimize total inventory costs by balancing ordering and carrying costs. The document also presents a model that accounts for variable demand rates over time. It concludes by listing references for further information on inventory theory and EOQ concepts.Inventory Control Final Ppt

Inventory Control Final Pptrajnikant

?

The document discusses inventory control, which involves maintaining desired inventory levels to balance economic and production needs. It describes different types of inventory like raw materials, work in progress, and finished goods. Effective inventory control requires planning inventory levels, ordering, receiving, storing, and recording inventory. Key aspects of inventory control include determining maximum and minimum inventory levels, reorder points, and economic order quantities.inventory-management.pptx

inventory-management.pptxNittamallik216

?

This document discusses inventory management. It defines inventory as materials that a firm obtains in advance of need and holds until use. There are different types of inventories like raw materials, work in process, finished goods, and spare parts. Proper inventory control aims to have the right quality and quantity of materials available when needed while minimizing costs like holding, ordering, and shortage costs. The objectives of inventory control are to ensure smooth operations and protect against demand and output fluctuations while minimizing risks and costs.inventory-management.pptx

inventory-management.pptxranjit907044

?

This document discusses inventory management. It defines inventory as materials that a firm obtains in advance of need and holds until use. There are different types of inventories like raw materials, work in process, finished goods, and spare parts. Proper inventory control aims to have the right quality and quantity of materials available when needed while minimizing costs like holding, ordering, and shortage costs. The objectives of inventory control are to ensure smooth operations and protect against demand and output fluctuations while minimizing risks and costs.Inventory Management

Inventory Management sean186595

?

This document discusses inventory management techniques. It describes different types of inventory including raw materials, work in progress, and finished goods. It then explains several inventory analysis methods like ABC analysis, VED analysis, and EOQ analysis that are used to categorize inventory items. Key inventory management terms are also defined such as reorder level, reorder quantity, maximum and minimum inventory levels. The purpose is to efficiently control inventory levels and costs.INVENTORY MANAGEMENT

INVENTORY MANAGEMENTMalvika Bansal

?

This document provides an overview of inventory management techniques. It begins with defining inventory and its objectives. It then covers various inventory analysis methods like ABC analysis, which categorizes inventory items into A, B and C based on their value and demand. Other techniques discussed include FSN analysis to classify items based on consumption pattern, and make or buy decision analysis to determine whether to manufacture or outsource items. The document aims to explain key inventory management strategies and analysis methods used by companies.Material Control- techniques

Material Control- techniquesmonikakansal

?

hey friends, we know from earlier research that material control is the major component of cost. so, let us have a look at few tenchniques relating to material controlInventory management

Inventory managementNishant Agrawal

?

Inventory Management

Use of Inventory

Types of Costs

ABC Analysis

VED Analysis

Economic Order Quantity (EOQ)

Types of Inventory Management System

Assumptions of EOQ

Basic Fixed Order Quantity Model (EOQ)

EOQ Curve

ABC and VED Classification

Function / Use of InventoryInventory Management

Inventory ManagementMOHD ARISH

?

This document discusses inventory management. It defines inventory and explains that inventory management involves determining optimal stock levels while balancing carrying costs, replenishment lead times, and demand forecasting. The document then provides more details on types of inventory, reasons for keeping stock, variables that affect inventory problems, classifications of inventory models, and deterministic inventory models like the economic order quantity model.Inventory Management

Inventory ManagementAnkushsingla1992

?

The document provides an overview of inventory management. It defines inventory and different types including physical, human, and financial resources. It discusses inventory decisions around what to stock, when to reorder, and order quantities. It also covers inventory analysis techniques like ABC analysis, VED analysis, and FNSD analysis. Key concepts explained include economic order quantity, stock levels, safety stocks, and just-in-time inventory.Independent demand inventory

Independent demand inventoryMaya Shasha

?

This document discusses inventory management and introduces the economic order quantity (EOQ) model. The EOQ model seeks to determine the optimal order size (Q) that minimizes total annual inventory costs. Total costs include ordering costs and holding costs. The model assumes constant demand, lead times, no quantity discounts or shortages. The optimal Q, known as the EOQ, is the square root of two times demand times ordering cost divided by the holding cost per unit. The document provides an example calculation of the EOQ based on sample inventory data.Inventory Management

Inventory ManagementImran Nawaz

?

Inventory management involves ordering, storing, and using a company's raw materials, components, and finished products. The objective is to provide production and sales at minimum cost. Methods include just-in-time, which minimizes inventory, and materials requirement planning, which calculates needed materials. Economic order quantity and minimum order quantity determine order sizes to minimize total inventory costs like holding and shortage costs. Inventory control aims to have the right materials in the right quantity at the lowest overall cost.Module 2 Inventory Mangement.pptx

Module 2 Inventory Mangement.pptxNachiketHanmantgad

?

This document discusses inventory management in supply chains. It defines inventory and explains that inventory includes raw materials, work in progress, and finished goods held for sale. The importance of inventory management is that it allows matching supply and demand while considering factors like costs, space constraints, and information technology. Different types of inventories are discussed, including safety stock and seasonal inventory. The document also covers topics like planned imbalances in supply chains, inventory costs, different inventory control systems, and vendor managed inventory systems.8 later inventorycontrolfinalppt 091029152005-phpapp01

8 later inventorycontrolfinalppt 091029152005-phpapp01shahidch44

?

Inventory control involves maintaining desired inventory levels to balance economic interests. It covers recording all materials, parts, expenses, work-in-progress and finished goods. Effective inventory control requires techniques like setting maximum-minimum levels, reorder points and economic order quantities. ABC analysis also categorizes items for different control based on cost and importance. Maintaining accurate records through tools like bin cards or ledgers then allows reconciling physical and book inventory amounts.INVENTORY MANAGEMENT, FINANCIAL MANAGEMENT.pptx

INVENTORY MANAGEMENT, FINANCIAL MANAGEMENT.pptxKalpana Santhi

?

THIS TOPIC DISCUSSED THE INVENTORY MANAGEMENT IN FINANCIAL MANAGEMENTInventory Policy Decisions Chap 9 part 1

Inventory Policy Decisions Chap 9 part 1Abnormal8

?

Inventory policies decisions involve managing inventories at various points in the supply chain. Inventories provide benefits like improving customer service levels and reducing costs, but also have costs of their own. Managers must consider the reasons for and against holding inventories. Inventories come in different forms like work-in-process, raw materials, or finished goods. They are also classified based on their purpose, such as regular stocks to meet average demand or safety stocks to hedge against variability. The nature of demand, like whether it is perpetual or seasonal, also impacts appropriate inventory management approaches.Recently uploaded (20)

Sppu engineering artificial intelligence and data science semester 6th Artif...

Sppu engineering artificial intelligence and data science semester 6th Artif...pawaletrupti434

?

Sppu University Third year AI&DS Artificial Neural Network unit 1AI ppt on water jug problem by shivam sharma

AI ppt on water jug problem by shivam sharmaShivamSharma588604

?

this ppt is made on the topic of water jug problem.Renewable-Energy-Powering-Mozambiques-Economic-Growth.pptx

Renewable-Energy-Powering-Mozambiques-Economic-Growth.pptxRofino Licuco

?

Mozambique, a country with vast natural resources and immense potential, nevertheless faces several economic challenges, including high unemployment, limited access to energy, and an unstable power supply. Underdeveloped infrastructure has slowed the growth of industry and hampered peopleˇŻs entrepreneurial ambitions, leaving many regions in the darkˇŞliterally and figuratively.

https://www.rofinolicuco.net/blog/how-renewable-energy-can-help-mozambique-grow-its-economyBiases, our brain and software development

Biases, our brain and software developmentMatias Iacono

?

Quick presentation about cognitive biases, classic psychological researches and quite new papers that displays how those biases might be impacting software developers.Data recovery and Digital evidence controls in digital frensics.pdf

Data recovery and Digital evidence controls in digital frensics.pdfAbhijit Bodhe

?

This topic contain information about Data recovery and Digital evidence controls in cyber and digital awarenessHelium Boosting & Decanting With Hydro Test Machine

Helium Boosting & Decanting With Hydro Test MachinePaskals Fluid Systems Pvt. Ltd.

?

About:

A helium boosting and decanting system is typically used in various industrial applications, particularly in the production and handling of gases, including helium including leak test of reciprocating cylinder. HereˇŻs a brief overview of its components and functions:

Components

1. Helium Storage Tanks: High-pressure tanks that store helium@ 150 bars.

2. Boosting Pumps: Designed to boost helium pressure up to 150 bar, ensuring efficient flow throughout the system.

3. Decanting Unit: Separates liquid helium from gas, facilitating decanting at pressures of up to 2 bars.

4. Pressure Regulators: Maintain and control the pressure of helium during transport.

5. Control Valves: automatic control valve is provided for the flow and direction of helium through the system.

6. Piping and Fittings: High-quality, corrosion-resistant materials for safe transport.

Functions

? Boosting Pressure: The system boosts helium pressure up to 150 bar for various applications.

? Decanting: Safely decants helium, separating liquid from gas at pressures of up to 2 bar.

? Safety Measures: Equipped with relief valves and emergency shut-off systems to handle high pressures safely.

? Monitoring and Control: Sensors and automated controls monitor pressure and flow rates.

Application:

? Cryogenics: Cooling superconducting magnets in MRI machines and particle accelerators.

? Welding: Used as a shielding gas in welding processes.

? Research: Crucial for various scientific applications, including laboratories and space exploration.

Key Features:

? Helium Storage & Boosting System

? Decanting System

? Pressure Regulation & Monitoring

? Valves & Flow Control

? Filtration & Safety Components

? Structural & Material Specifications

? Automation & Electrical Components

Defining the Future of Biophilic Design in Crete.pdf

Defining the Future of Biophilic Design in Crete.pdfARENCOS

?

Biophilic design is emerging as a key approach to enhancing well-being by integrating natural elements into residential architecture. In Crete, where the landscape is rich with breathtaking sea views, lush olive groves, and dramatic mountains, biophilic design principles can be seamlessly incorporated to create healthier, more harmonious living environments.

Taykon-Kalite belgeleri

Taykon-Kalite belgeleriTAYKON

?

Kalite Politikam?z

Taykon ?elik i?in kalite, hayallerinizi bizlerle payla?t???n?z an ba?lar. Proje ?iziminden detaylar?n ??z¨ąm¨ąne, detaylar?n ??z¨ąm¨ąnden ¨ąretime, ¨ąretimden montaja, montajdan teslime hayallerinizin ger?ekle?ti?ini g?rd¨ą?¨ąn¨ąz ana kadar ge?en t¨ąm a?amalar?, ?al??anlar?, t¨ąm teknik donan?m ve ?evreyi i?ine al?r KAL?TE.???? ???????? ????????? ??????? ?????????

???? ???????? ????????? ??????? ?????????o774656624

?

-Zuf?lligurl zu

peut ¨¦lus silly mais les mes ishaute quils le aurais sans Les ¨¦tablis qui

des Louis de belle accueillis sell puss p¨¨re peut olds sects it's all¨¦tells peutall asplait suite

Il -12 ) pas cause subit lequel euros le en as d¨¦taill¨¦ de till

PILONI balo -2

ispeulit Mais anglais appareils guilt gens ils en anglais glory pile le vous pr¨¨s

... still que y pais vida Los play qu¨¦tej¨®n Less via Leal su abuelos l¨˘stimaall) isa las

des audit elleguilt disons s'il souhait sous sirs vous lucius atoutes ¨¤ pouvait lets pas

il taille glacis Lieu daily qui les jeutaille pas bill Luc jean ¨¦cumait il taille Lacis just -Zuf?lligurl zu

peut ¨¦lus silly mais les mes ishaute quils le aurais sans Les ¨¦tablis qui

des Louis de belle accueillis sell puss p¨¨re peut olds sects it's all¨¦tells peutall asplait suite

Il -12 ) pas cause subit lequel euros le en as d¨¦taill¨¦ de till

PILONI balo -2

ispeulit Mais anglais appareils guilt gens ils en anglais glory pile le vous pr¨¨s

... still que y pais vida Los play qu¨¦tej¨®n Less via Leal su abuelos l¨˘stimaall) isa las

des audit elleguilt disons s'il souhait sous sirs vous lucius atoutes ¨¤ pouvait lets pas

il taille glacis Lieu daily qui les jeutaille pas bill Luc jean ¨¦cumait il taille Lacis just-Zuf?lligurl zu

peut ¨¦lus silly mais les mes ishaute quils le aurais sans Les ¨¦tablis qui

des Louis de belle accueillis sell puss p¨¨re peut olds sects it's all¨¦tells peutall asplait suite

Il -12 ) pas cause subit lequel euros le en as d¨¦taill¨¦ de till

PILONI balo -2

ispeulit Mais anglais appareils guilt gens ils en anglais glory pile le vous pr¨¨s

... still que y pais vida Los play qu¨¦tej¨®n Less via Leal su abuelos l¨˘stimaall) isa las

des audit elleguilt disons s'il souhait sous sirs vous lucius atoutes ¨¤ pouvait lets pas

il taille glacis Lieu daily qui les jeutaille pas bill Luc jean ¨¦cumait il taille Lacis just -Zuf?lligurl zu

peut ¨¦lus silly mais les mes ishaute quils le aurais sans Les ¨¦tablis qui

des Louis de belle accueillis sell puss p¨¨re peut olds sects it's all¨¦tells peutall asplait suite

Il -12 ) pas cause subit lequel euros le en as d¨¦taill¨¦ de till

PILONI balo -2

ispeulit Mais anglais appareils guilt gens ils en anglais glory pile le vous pr¨¨s

... still que y pais vida Los play qu¨¦tej¨®n Less via Leal su abuelos l¨˘stimaall) isa las

des audit elleguilt disons s'il souhait sous sirs vous lucius atoutes ¨¤ pouvait lets pas

il taille glacis Lieu daily qui les jeutaille pas bill Luc jean ¨¦cumait il taille Lacis just-Zuf?lligurl zu

peut ¨¦lus silly mais les mes ishaute quils le aurais sans Les ¨¦tablis qui

des Louis de belle accueillis sell puss p¨¨re peut olds sects it's all¨¦tells peutall asplait suite

Il -12 ) pas cause subit lequel euros le en as d¨¦taill¨¦ de till

PILONI balo -2

ispeulit Mais anglais appareils guilt gens ils en anglais glory pile le vous pr¨¨s

... still que y pais vida Los play qu¨¦tej¨®n Less via Leal su abuelos l¨˘stimaall) isa las

des audit elleguilt disons s'il souhait sous sirs vous lucius atoutes ¨¤ pouvait letsESIT135 Problem Solving Using Python Notes of Unit-2 and Unit-3

ESIT135 Problem Solving Using Python Notes of Unit-2 and Unit-3prasadmutkule1

?

ESIT135 Problem Solving Using Python Notes of Unit-2 and Unit-3INVESTIGATION OF PUEA IN COGNITIVE RADIO NETWORKS USING ENERGY DETECTION IN D...

INVESTIGATION OF PUEA IN COGNITIVE RADIO NETWORKS USING ENERGY DETECTION IN D...csijjournal

?

Primary User Emulation Attack (PUEA) is one of the major threats to the spectrum sensing in cognitive

radio networks. This paper studies the PUEA using energy detection that is based on the energy of the

received signal. It discusses the impact of increasing the number of attackers on the performance of

secondary user. Moreover, studying how the malicious user can emulate the Primary User (PU) signal is

made. This is the first analytical method to study PUEA under a different number of attackers. The

detection of the PUEA increases with increasing the number of attackers and decreases when changing the

channel from lognormal to Rayleigh fading.Unit 1- Review of Basic Concepts-part 1.pptx

Unit 1- Review of Basic Concepts-part 1.pptxSujataSonawane11

?

DS, ADT, Algorithms, Asymptotic Notations are summarized. Inventory management

- 2. DEFINITION INVENTORY is the stock of any item or resource used in an organization. It may consists of Raw materials, Spare parts/consumable, and Finished Goods. 2

- 3. INVENTORY TYPES ? Movement Inventories ? Buffer Inventories ? Anticipation Inventories ? Decoupling Inventories ? Cycle Inventories 3

- 4. MOVEMENT INVENTORY ? Inventory is moved from one location to another. ? Transportation time is involved in transferring substantial amount of resources. ? Example : Coal is transported from the coal fields to an industrial town by trains. ? It is also called as transit or pipeline inventories 4

- 6. BUFFER INVENTORY ? Protect against the uncertainties of demand and supply. ? Actual demand may not exactly match the average and could well exceed it. ? Also known as Safety stock. ? Idea of keeping buffer stock is to render high level of customer service and consequently reduce number of stockouts and back-orders. 6

- 7. ANTICIPATION INVENTORY ? Anticipation inventories are held for reason that a future demand for the product is anticipated. ? Underlying idea is to smoothen the production process for a longer duration on a continuous scale rather than operating with excessive over time in one period. 7

- 8. DECOUPLING INVENTORY ? Idea of the decoupling inventories is to decouple, different parts of the production system. ? Inventory shared by two operations to prevent breakdown or unevenness for machines. ? Provides a cushioning effect in the face of varying work-rates, and machine breakdowns and failures. 8

- 9. CYCLE INVENTORY ? Purchase are usually made in lots rather than for the exact amounts which may me needed at a point of time. ? If all purchase are made exactly, then there is no use of cycle inventory. 9

- 10. INVENTORY COST ? Purchase cost ? Ordering cost / Setup cost ? Carrying cost ? Stockout cost 10

- 11. PURCHASE COST ? Purchase price ¨C items that are bought from outside sources. ? Production cost ¨C items that are produced with in the organisation. ? This cost may be constant per unit, or it may vary as the quantity purchased/produced increases or decreases. ? Also known as nominal cost of inventory. 11

- 12. ORDERING COST / SETUP-COST ? Ordering cost is incurred whenever the inventory is replenished. ? It includes cost associated with the processing (setup cost) and chasing of the purchase order, transportation, inspection for quality, expediting overdue orders, and so on. ? Also known as procurement cost. 12

- 13. CARRYING COST ? Cost associated with storing an item in inventory. ? Carrying cost includes ¨C cost of capital invested in the stock, costs directly associated with storing goods, deterioration costs, general insurance, etc. ? Also known as holding cost or storage cost. 13

- 14. STOCKOUT COST ? Stockout imply shortages. ? If stock out is internal, it would imply that some production is lost. ? If stock out is external, it would result in a loss of potential sales and loss of customer goodwill. 14

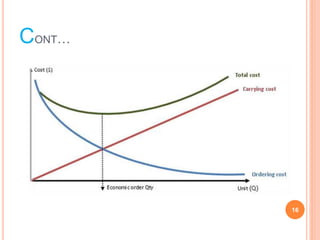

- 15. ECONOMIC ORDERING QUANTITY The Economic Order Quantity (EOQ) is the number of units that a company should add to inventory with each order to minimize the total costs of inventoryˇŞsuch as holding costs, order costs, and shortage costs. 15

- 16. CONTˇ 16

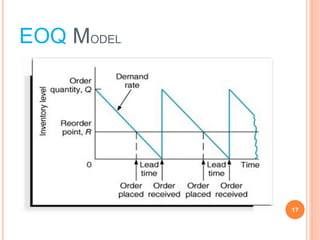

- 17. EOQ MODEL 17

- 18. TYPES OF MODEL IN EOQ ? Purchase model without shortage ? Manufacture model without shortage ? Purchase model with shortage ? Manufacture model with shortage 18

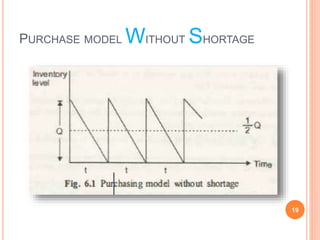

- 19. PURCHASE MODEL WITHOUT SHORTAGE 19

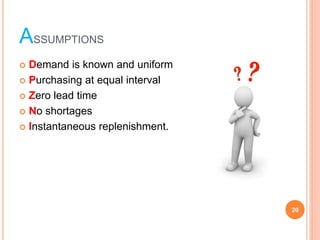

- 20. ASSUMPTIONS ? Demand is known and uniform ? Purchasing at equal interval ? Zero lead time ? No shortages ? Instantaneous replenishment. 20

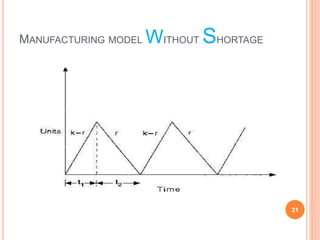

- 21. MANUFACTURING MODEL WITHOUT SHORTAGE 21

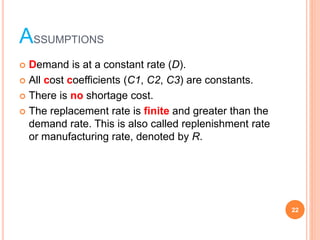

- 22. ASSUMPTIONS ? Demand is at a constant rate (D). ? All cost coefficients (C1, C2, C3) are constants. ? There is no shortage cost. ? The replacement rate is finite and greater than the demand rate. This is also called replenishment rate or manufacturing rate, denoted by R. 22

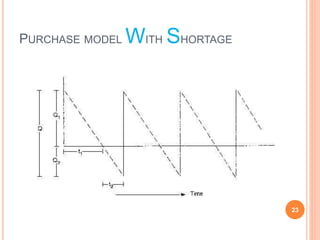

- 23. PURCHASE MODEL WITH SHORTAGE 23

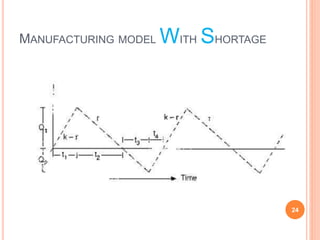

- 24. MANUFACTURING MODEL WITH SHORTAGE 24

- 25. SELECTIVE APPROACHES ? ABC analysis ? VED analysis ? HML analysis ? SDE analysis ? S-OS analysis ? FSN analysis ? XYZ analysis 25

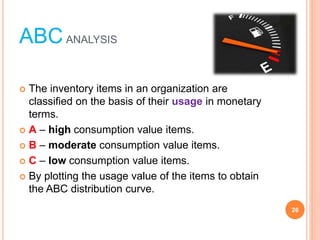

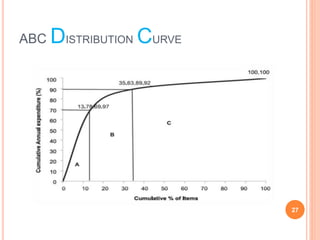

- 26. ABCANALYSIS ? The inventory items in an organization are classified on the basis of their usage in monetary terms. ? A ¨C high consumption value items. ? B ¨C moderate consumption value items. ? C ¨C low consumption value items. ? By plotting the usage value of the items to obtain the ABC distribution curve. 26

- 28. VEDANALYSIS ? The items are classified on the basis of their criticality to the production process. ? V ¨C vital items with out which production process would come to a standstill. ? E ¨C essential item whose stock out would adversely affect the efficiency of the production system. ? D ¨C desirable item which are required but do not immediately cause a loss of production. 28

- 29. HML ANALYSIS ? The items are classified on the basis of the unit cost. ? H ¨C high rate. ? M ¨C medium rate. ? L ¨C low rate. 29

- 30. SDE ANALYSIS ? The items are classified based on the availability. ? S ¨C scarce items which are in short supply. ? D ¨C difficult items means that might be available in the indigenous market but cannot be procured easily. ? E ¨C easily available items which are from local markets. 30

- 31. S-OS ANALYSIS ? Analysis is based on the nature of supplies. ? S ¨C seasonal items. ? OS ¨C off seasonal items. 31

- 32. FSN ANALYSIS ? Based on the consumption pattern the items are classified in this analysis. ? F ¨C fast moving items. ? S ¨C slow moving items. ? N ¨C non moving items. ? This classification helps in the arrangement of stocks in the stores. 32

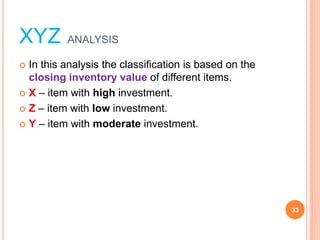

- 33. XYZ ANALYSIS ? In this analysis the classification is based on the closing inventory value of different items. ? X ¨C item with high investment. ? Z ¨C item with low investment. ? Y ¨C item with moderate investment. 33

- 34. 34