IoT Hackathon

- 1. IoT Hackathon / Teplotni senzor @RDPanek

- 2. bit.ly/rdpanekiot Tuto prezentaci najdete na ∫›∫›fl£Share

- 3. Ruzni vyrobci / ruzne technologie Drahe / nekomunikuji spolu / ruzne UX ovladani

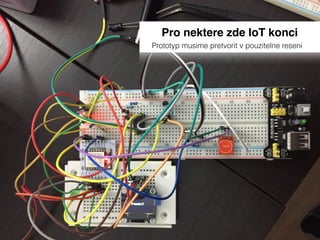

- 4. Pro nektere zde IoT konci Prototyp musime pretvorit v pouzitelne reseni

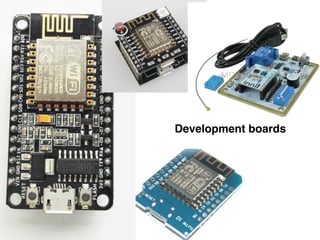

- 5. Lze postavit i to, co nelze koupit platformy / moduly / open-hardware

- 6. Shieldy rozsiruji schopnosti Nekonecne moznosti vlastni vyroby

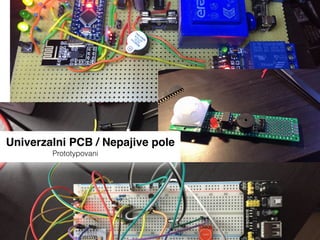

- 7. Univerzalni PCB / Nepajive pole Prototypovani

- 8. Univerzalni PCB Rychle zhotoveni a prototypovani

- 9. PCB

- 10. Dratovani hmmmm

- 11. Raspberry Pi

- 12. ESP8266 / ATMEGA 328P / ATtiny / ... Software

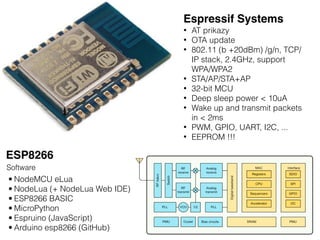

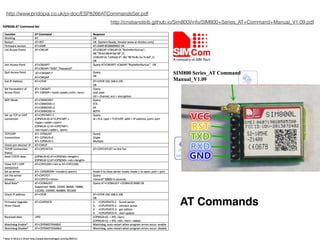

- 13. ESP8266 Software • NodeMCU eLua • NodeLua (+ NodeLua Web IDE) • ESP8266 BASIC • MicroPython • Espruino (JavaScript) • Arduino esp8266 (GitHub) Espressif Systems • AT prikazy • OTA update • 802.11 (b +20dBm) /g/n, TCP/ IP stack, 2.4GHz, support WPA/WPA2 • STA/AP/STA+AP • 32-bit MCU • Deep sleep power < 10uA • Wake up and transmit packets in < 2ms • PWM, GPIO, UART, I2C, ... • EEPROM !!!

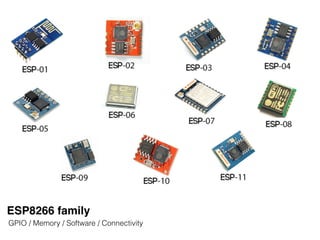

- 14. ESP8266 family GPIO / Memory / Software / Connectivity

- 15. ESP8266 blizsi pohled PCB kompaktibilita

- 17. ESP8266 redukce Lze zasadit do nepajiveho pole, ci PCB a lze zvolit typ ESP

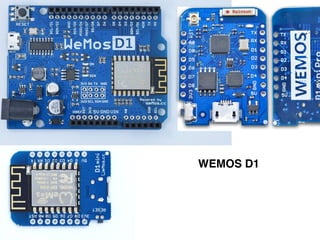

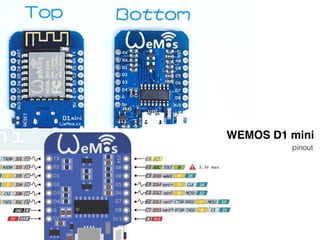

- 18. WEMOS D1

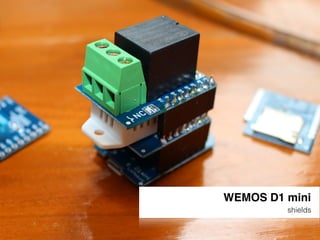

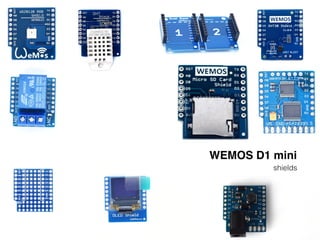

- 22. WEMOS D1 mini shields Vyhody / nevyhody koupeneho / vlastniho shieldu

- 24. Teplotni senzor Wemos D1 mini, OLED, DualBase, Protoboard, LDR, LED, DS18B20, rezistors

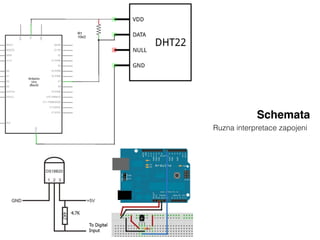

- 25. Use case ESP8266 PCB + 3D print, DHT22 shield, OLED shield - LDR - DS18B20 - dualbase, smokeTester, PIR senzor - buzzer, rellay

- 26. Use case - Turris Omnia Open-source, 1.6Ghz 2core, 2GB RAM, 8GB flash, 5 x Gbit LAN, 1 x Gbit WAN, 2 x USB 3.0, Mini PCI Express, mSATA, Wi-Fi 802.11 a/c/b/g/n, GPIO, OpenVrt, AutoUpdater, HoneyPot, programmable RGB, Cryptochip

- 27. LXC container - Elasticsearch Turris Omnia hosti LXC konteiner s Elasticsearch a jako persistentni uloziste se pouziva dodatecne pridany 120GB mSata disk

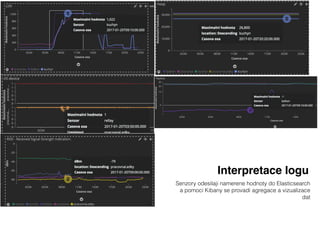

- 28. Interpretace logu Senzory odesilaji namerene hodnoty do Elasticsearch a pomoci Kibany se provadi agregace a vizualizace dat

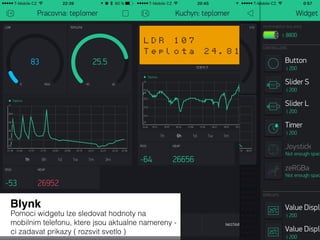

- 29. Blynk Pomoci widgetu lze sledovat hodnoty na mobilnim telefonu, ktere jsou aktualne namereny - ci zadavat prikazy ( rozsvit svetlo )

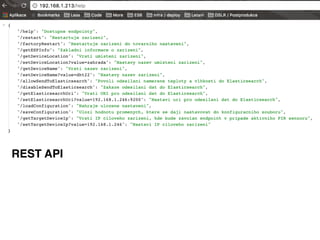

- 30. REST API

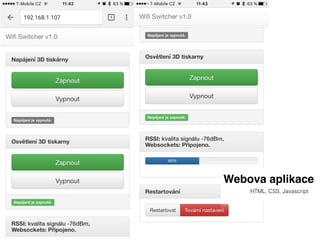

- 31. Webova aplikace HTML, CSS, Javascript

- 32. Proces vyvoje Od prototypovani po finalni produkt

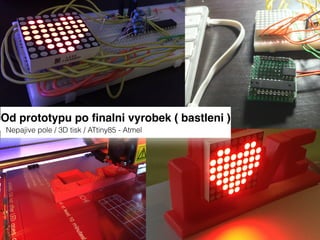

- 33. Od prototypu po finalni vyrobek ( bastleni ) Nepajive pole / 3D tisk / ATtiny85 - Atmel

- 34. O krok dale ( bastleni ) Bezdratove ovladani zasuvky 433MHz

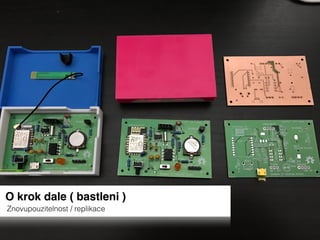

- 35. O krok dale ( bastleni ) Znovupouzitelnost / replikace

- 36. Pomucky ( bastleni )

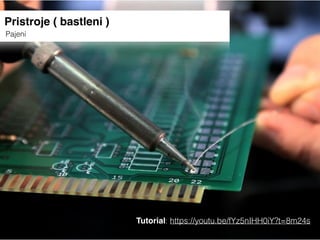

- 37. Pristroje ( bastleni ) Pajeni Tutorial: https://youtu.be/fYz5nIHH0iY?t=8m24s

- 38. Pristroje ( bastleni ) Horkovzdusne pajeni

- 39. Pristroje ( bastleni ) Laboratorni zdroj

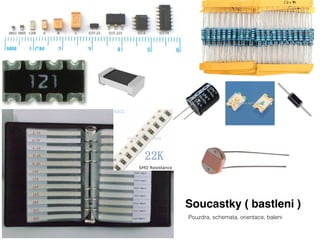

- 40. Soucastky ( bastleni ) Pouzdra, schemata, orientace, baleni

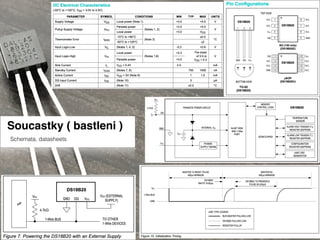

- 41. Soucastky ( bastleni ) Schemata, datasheets

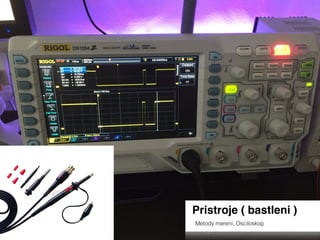

- 42. Pristroje ( bastleni ) Metody mereni, Multimetr

- 43. Pristroje ( bastleni ) Metody mereni, Osciloskop

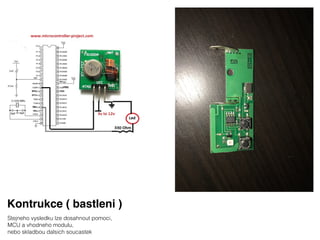

- 44. Kontrukce ( bastleni ) Stejneho vysledku lze dosahnout pomoci, MCU a vhodneho modulu, nebo skladbou dalsich soucastek

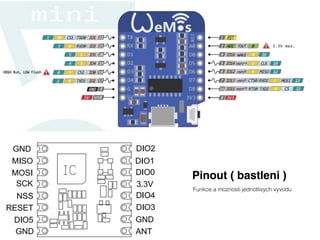

- 45. Pinout ( bastleni ) Funkce a moznosti jednotlivych vyvodu

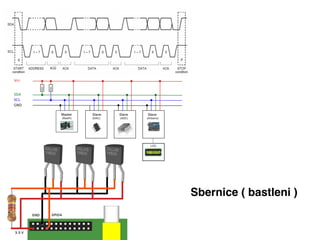

- 46. Sbernice ( bastleni )

- 47. Programovani ( bastleni ) https://www.arduino.cc/en/Reference/HomePage

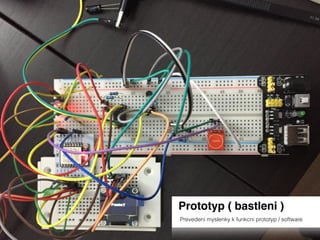

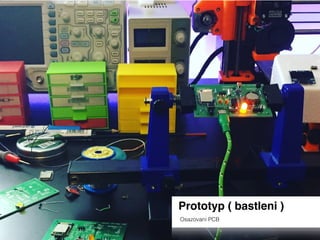

- 49. Prototyp ( bastleni ) Prevedeni myslenky k funkcni prototyp / software

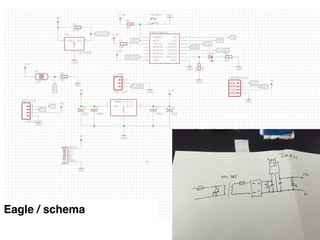

- 50. Eagle / schema

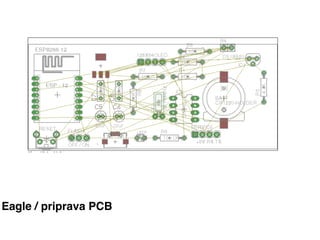

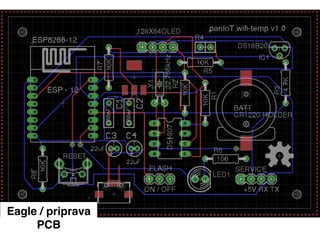

- 51. Eagle / priprava PCB

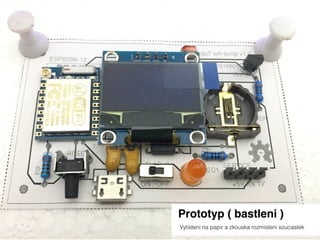

- 53. Prototyp ( bastleni ) Vytisteni na papir a zkouska rozmisteni soucastek

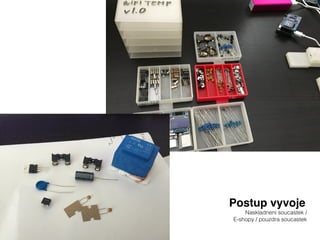

- 54. Postup vyvoje Naskladneni soucastek / E-shopy / pouzdra soucastek

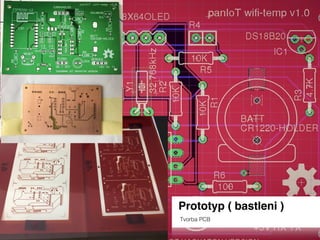

- 55. Prototyp ( bastleni ) Tvorba PCB

- 56. Prototyp ( bastleni ) Osazovani PCB

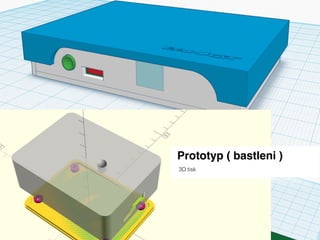

- 57. Prototyp ( bastleni ) Prusa MK2 / 3D tisk

- 58. Prototyp ( bastleni ) 3D tisk

- 59. Prototyp ( bastleni ) Finalizace

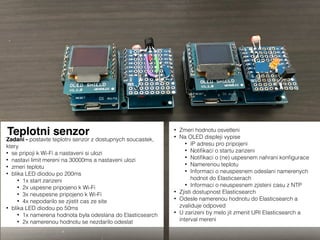

- 60. Teplotni senzor Zadani - postavte teplotni senzor z dostupnych soucastek, ktery • se pripoji k Wi-Fi a nastaveni si ulozi • nastavi limit mereni na 30000ms a nastaveni ulozi • zmeri teplotu • blika LED diodou po 200ms • 1x start zarizeni • 2x uspesne pripojeno k Wi-Fi • 3x neuspesne pripojeno k Wi-Fi • 4x nepodarilo se zjistit cas ze site • blika LED diodou po 50ms • 1x namerena hodnota byla odeslana do Elasticsearch • 2x namerenou hodnotu se nezdarilo odeslat • Zmeri hodnotu osvetleni • Na OLED displeji vypise • IP adresu pro pripojeni • Notifikaci o startu zarizeni • Notifikaci o (ne) uspesnem nahrani konfigurace • Namerenou teplotu • Informaci o neuspesnem odeslani namerenych hodnot do Elasticserach • Informaci o neuspesnem zjisteni casu z NTP • Zjisti dostupnost Elasticsearch • Odesle namerenou hodnotu do Elasticsearch a zvaliduje odpoved • U zarizeni by melo jit zmenit URI Elasticsearch a interval mereni

- 62. V baleni WemosD1 mini, Oled display, prototype board, dualbase, rezistory, LDR, LED, Dallas DS18B20

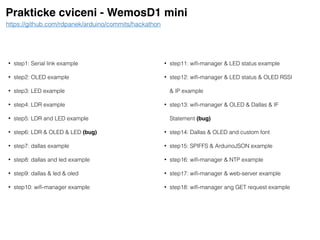

- 63. Prakticke cviceni - WemosD1 mini • step1: Serial link example • step2: OLED example • step3: LED example • step4: LDR example • step5: LDR and LED example • step6: LDR & OLED & LED (bug) • step7: dallas example • step8: dallas and led example • step9: dallas & led & oled • step10: wifi-manager example https://github.com/rdpanek/arduino/commits/hackathon • step11: wifi-manager & LED status example • step12: wifi-manager & LED status & OLED RSSI & IP example • step13: wifi-manager & OLED & Dallas & IF Statement (bug) • step14: Dallas & OLED and custom font • step15: SPIFFS & ArduinoJSON example • step16: wifi-manager & NTP example • step17: wifi-manager & web-server example • step18: wifi-manager ang GET request example

- 64. Priprava a pajeni Vyzkousime si sestaveni celeho zarizeni a napajime hrebeny na dualbase shield

- 65. Pajeni Vyzkousime si sestaveni celeho zarizeni a napajime hrebeny na dualbase shield

- 66. Pajeni Pripajime prvni a posledni pin pro ukotveni, pote zbyle piny

- 67. Pajeni Pripraveny dualbase shield s pripajenymi hrebeny

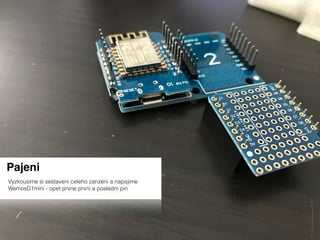

- 68. Pajeni Vyzkousime si sestaveni celeho zarizeni a napajime WemosD1mini a protoboard shield

- 69. Pajeni Vyzkousime si sestaveni celeho zarizeni a napajime WemosD1mini - opet prvne prvni a posledni pin

- 70. Pajeni Vyzkousime si sestaveni celeho zarizeni a napajime protoboard shield - opet prvne prvni a posledni pin

- 71. Pajeni Vyzkousime si sestaveni celeho zarizeni a napajime OLED display Zarizeni je pripraveno na oziveni. Muzeme nahrat prvni kod z Arduino IDE

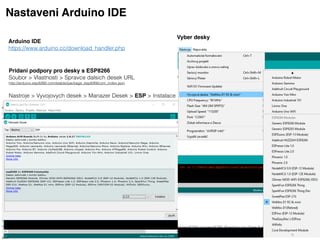

- 72. Arduino IDE‚Ä® https://www.arduino.cc/download_handler.php Nastaveni Arduino IDE Vyber desky Pridani podpory pro desky s ESP8266 Soubor > Vlastnosti > Spravce dalsich desek URL http://arduino.esp8266.com/stable/package_esp8266com_index.json ‚Ä® Nastroje > Vyvojovych desek > Manazer Desek > ESP > Instalace

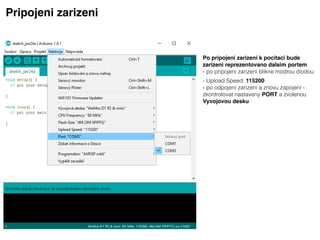

- 73. Pripojeni zarizeni Po pripojeni zarizeni k pocitaci bude zarizeni reprezentovano dalsim portem - po pripojeni zarizeni blikne modrou diodou - Upload Speed: 115200 - po odpojeni zarizeni a znovu zapojeni - zkontrolovat nastaveny PORT a zvolenou Vyvojovou desku

- 75. Prakticke cviceni - step1: Serial link example Nastroje > Seriovy monitor > 115200 - pri uploadu sketche do zarizeni blika modra‚Ä® led dioda

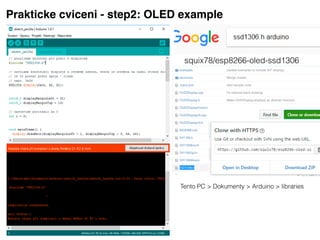

- 76. Prakticke cviceni - step2: OLED example Pocitadlo

- 77. Prakticke cviceni - step2: OLED example Prohledneme si pozorne spodni stranu shieldu

- 78. Prakticke cviceni - step2: OLED example squix78/esp8266-oled-ssd1306 Tento PC > Dokumenty > Arduino > libraries

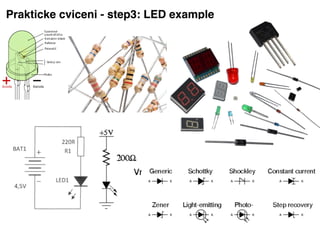

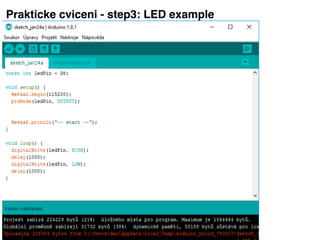

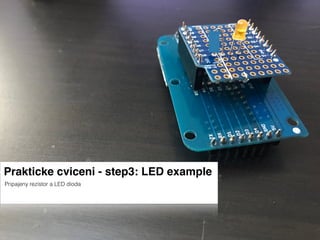

- 79. Prakticke cviceni - step3: LED example

- 80. Prakticke cviceni - step3: LED example

- 81. Prakticke cviceni - step3: LED example Podle barevneho oznaceni rezisotru vybereme ten spravny a podle pinu v kodu jej napajime na dany pin do protoboardu

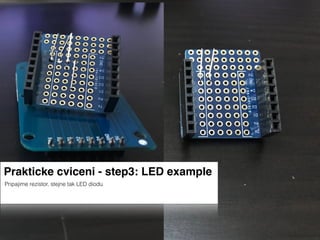

- 82. Prakticke cviceni - step3: LED example Pripajime rezistor, stejne tak LED diodu

- 83. Prakticke cviceni - step3: LED example Pripajeny rezistor a LED dioda

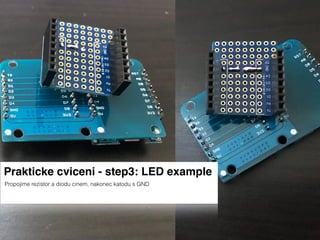

- 84. Prakticke cviceni - step3: LED example Propojime rezistor a diodu cinem, nakonec katodu s GND

- 85. Prakticke cviceni - step3: LED example Po uploadu software bude LED dioda blikat

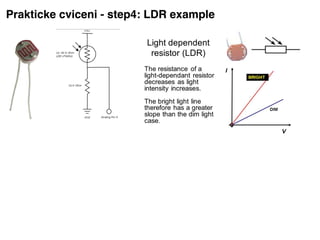

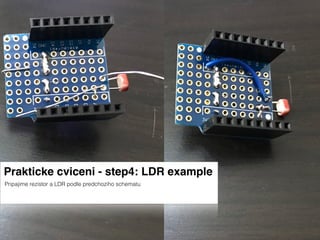

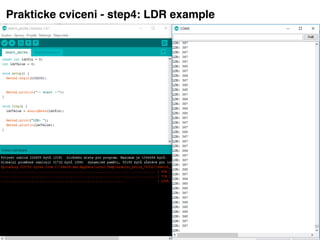

- 86. Prakticke cviceni - step4: LDR example

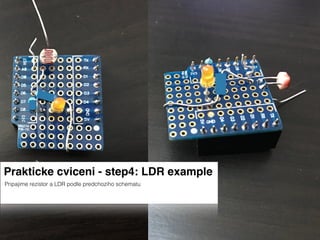

- 87. Prakticke cviceni - step4: LDR example Pripajime rezistor a LDR podle predchoziho schematu

- 88. Prakticke cviceni - step4: LDR example Pripajime rezistor a LDR podle predchoziho schematu

- 89. Prakticke cviceni - step4: LDR example Pripajime rezistor a LDR podle predchoziho schematu

- 90. Prakticke cviceni - step4: LDR example

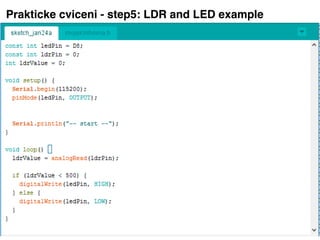

- 91. Prakticke cviceni - step5: LDR and LED example

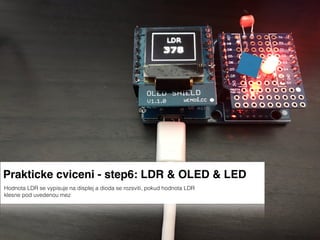

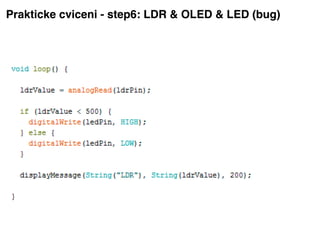

- 92. Prakticke cviceni - step6: LDR & OLED & LED Hodnota LDR se vypisuje na displej a dioda se rozsviti, pokud hodnota LDR klesne pod uvedenou mez

- 93. Prakticke cviceni - step6: LDR & OLED & LED (bug)

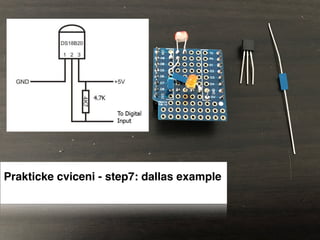

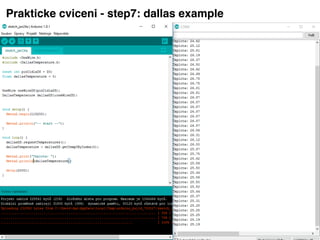

- 94. Prakticke cviceni - step7: dallas example

- 95. Prakticke cviceni - step7: dallas example

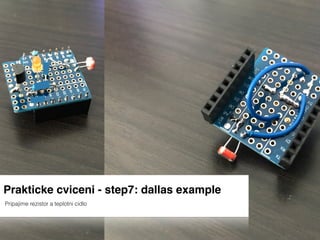

- 96. Prakticke cviceni - step7: dallas example Pripajime rezistor a teplotni cidlo

- 97. Kompletne osazeny prototype shield Konec pajeni - kazdy osazeny prototype shield muze vypadat jinak

- 98. Kompletne osazeny prototype shield Konec pajeni - kazdy osazeny prototype shield muze vypadat jinak

- 99. Kompletne osazeny prototype shield Konec pajeni - kazdy osazeny prototype shield muze vypadat jinak Kompletne osazeny prototype shield Konec pajeni - kazdy osazeny prototype shield muze vypadat jinak

- 100. Konec pajeni - kazdy osazeny prototype shield muze vypadat jinak Kompletne osazeny prototype shield Konec pajeni - kazdy osazeny prototype shield muze vypadat jinak

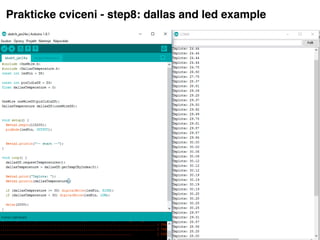

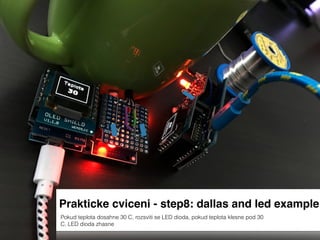

- 101. Prakticke cviceni - step8: dallas and led example

- 102. Prakticke cviceni - step8: dallas and led example Pokud teplota dosahne 30 C, rozsviti se LED dioda, pokud teplota klesne pod 30 C, LED dioda zhasne

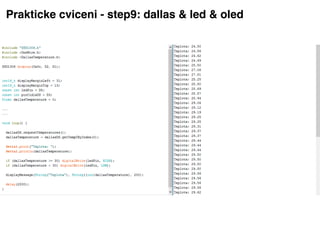

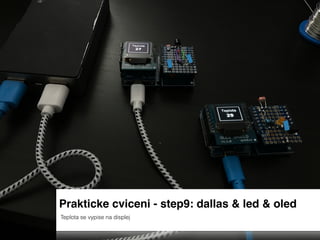

- 103. Prakticke cviceni - step9: dallas & led & oled

- 104. Prakticke cviceni - step9: dallas & led & oled Teplota se vypise na displej

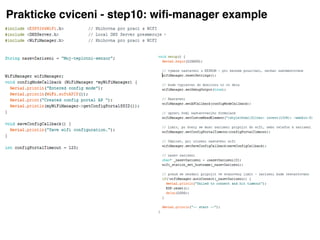

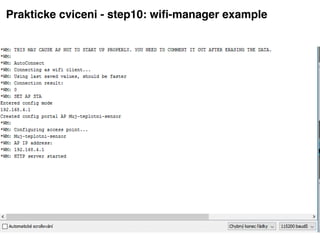

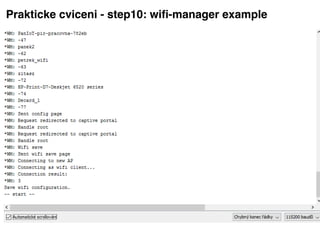

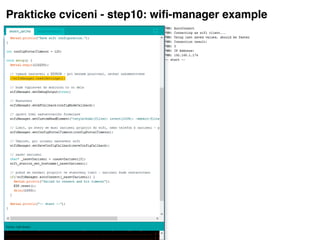

- 105. Prakticke cviceni - step10: wifi-manager example

- 106. Prakticke cviceni - step10: wifi-manager example

- 107. Prakticke cviceni - step10: wifi-manager example

- 108. Prakticke cviceni - step10: wifi-manager example

- 109. Prakticke cviceni - step10: wifi-manager example

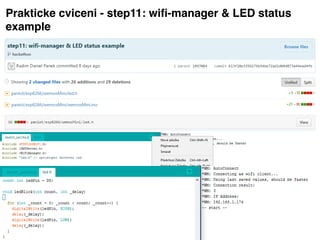

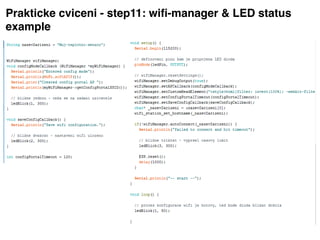

- 110. Prakticke cviceni - step11: wifi-manager & LED status example

- 111. Prakticke cviceni - step11: wifi-manager & LED status example

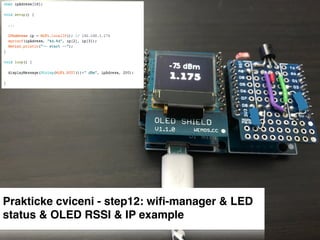

- 112. Prakticke cviceni - step12: wifi-manager & LED status & OLED RSSI & IP example

- 113. Prakticke cviceni - step12: wifi-manager & LED status & OLED RSSI & IP example

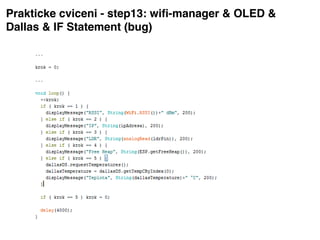

- 114. Prakticke cviceni - step13: wifi-manager & OLED & Dallas & IF Statement (bug)

- 115. Prakticke cviceni - step13: wifi-manager & OLED & Dallas & IF Statement (bug) Teplota se vypise na displej

- 116. Prakticke cviceni - step13: wifi-manager & OLED & Dallas & IF Statement (bug) IP adresa se vypise na displej

- 117. Prakticke cviceni - step13: wifi-manager & OLED & Dallas & IF Statement (bug) IP adresa se vypise na displej

- 118. Prakticke cviceni - step13: wifi-manager & OLED & Dallas & IF Statement (bug) Volna pamet se vypise na displej

- 119. Prakticke cviceni - step13: wifi-manager & OLED & Dallas & IF Statement (bug) RSSI se vypise na displej

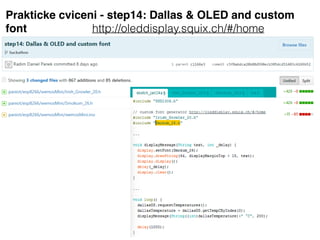

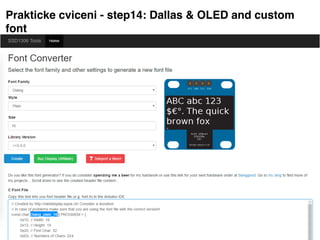

- 120. Prakticke cviceni - step14: Dallas & OLED and custom font http://oleddisplay.squix.ch/#/home

- 121. Prakticke cviceni - step14: Dallas & OLED and custom font

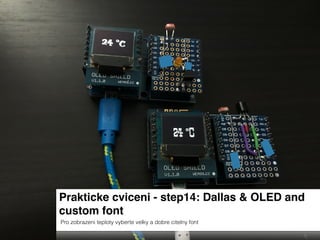

- 122. Prakticke cviceni - step14: Dallas & OLED and custom font Pro zobrazeni teploty vyberte velky a dobre citelny font

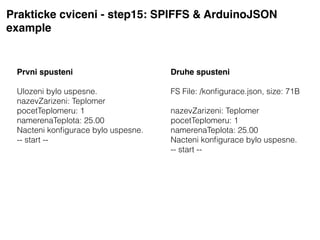

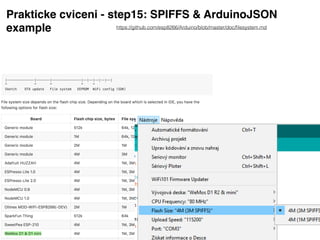

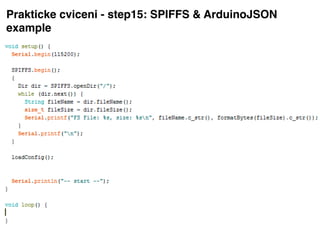

- 123. Prakticke cviceni - step15: SPIFFS & ArduinoJSON example https://github.com/esp8266/Arduino/blob/master/doc/filesystem.md

- 124. Prakticke cviceni - step15: SPIFFS & ArduinoJSON example { "nazevZarizeni": "Teplomer", "pocetTeplomeru": 1, "namerenaTeplota": 24 } Promenne JSON Promenne String nazevZarizeni = "Teplomer"; int pocetTeplomeru = 1; float namerenaTeplota = 25.00; nazevZarizeni = json["nazevZarizeni"].as<String>(); pocetTeplomeru = json["pocetTeplomeru"]; namerenaTeplota = json["namerenaTeplota"]; Restart zarizeni Ulozeni konfigurace Nacteni konfigurace String konfiguracniSoubor = "/konfigurace.json"; String konfiguracniSoubor = "/konfigurace.json";

- 125. Prakticke cviceni - step15: SPIFFS & ArduinoJSON example

- 126. Prakticke cviceni - step15: SPIFFS & ArduinoJSON example Bug: nazevZarizeni = json["nazevZarizeni"] reseni v /examples

- 127. Prakticke cviceni - step15: SPIFFS & ArduinoJSON example Prvni spusteni Ulozeni bylo uspesne. nazevZarizeni: Teplomer pocetTeplomeru: 1 namerenaTeplota: 25.00 Nacteni konfigurace bylo uspesne. -- start -- Druhe spusteni FS File: /konfigurace.json, size: 71B nazevZarizeni: Teplomer pocetTeplomeru: 1 namerenaTeplota: 25.00 Nacteni konfigurace bylo uspesne. -- start --

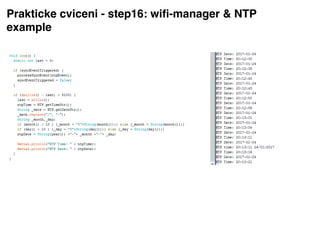

- 128. Prakticke cviceni - step16: wifi-manager & NTP example

- 129. Prakticke cviceni - step16: wifi-manager & NTP example

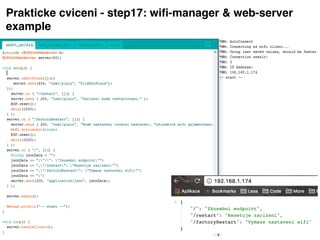

- 130. Prakticke cviceni - step17: wifi-manager & web-server example

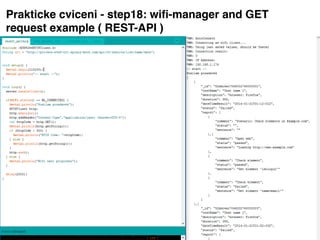

- 131. Prakticke cviceni - step18: wifi-manager and GET request example ( REST-API )

- 132. Arduino libraries

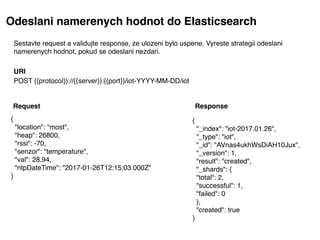

- 133. Odeslani namerenych hodnot do Elasticsearch { Ã˝ "location": "most", Ã˝ "heap": 26800, Ã˝ "rssi": -70, Ã˝ "senzor": "temperature", Ã˝ "val": 28.94, Ã˝ "ntpDateTime": "2017-01-26T12:15:03.000Z" } { Ã˝ "_index": "iot-2017.01.26", Ã˝ "_type": "iot", Ã˝ "_id": "AVnas4ukhWsDiAH10Jux", Ã˝ "_version": 1, Ã˝ "result": "created", Ã˝ "_shards": { Ã˝ "total": 2, Ã˝ "successful": 1, Ã˝ "failed": 0 Ã˝ }, Ã˝ "created": true } POST {{protocol}}://{{server}}:{{port}}/iot-YYYY-MM-DD/iot URI Request Response Sestavte request a validujte response, ze ulozeni bylo uspene. Vyreste strategii odeslani namerenych hodnot, pokud se odeslani nezdari.

![Prakticke cviceni - step15: SPIFFS & ArduinoJSON

example

{

"nazevZarizeni": "Teplomer",

"pocetTeplomeru": 1,

"namerenaTeplota": 24

}

Promenne

JSON

Promenne

String nazevZarizeni = "Teplomer";

int pocetTeplomeru = 1;

float namerenaTeplota = 25.00;

nazevZarizeni = json["nazevZarizeni"].as<String>();

pocetTeplomeru = json["pocetTeplomeru"];

namerenaTeplota = json["namerenaTeplota"];

Restart zarizeni

Ulozeni konfigurace

Nacteni konfigurace

String konfiguracniSoubor = "/konfigurace.json";

String konfiguracniSoubor = "/konfigurace.json";](https://image.slidesharecdn.com/iothackathon-170126163314/85/IoT-Hackathon-124-320.jpg)

![Prakticke cviceni - step15: SPIFFS & ArduinoJSON

example Bug: nazevZarizeni = json["nazevZarizeni"]

reseni v /examples](https://image.slidesharecdn.com/iothackathon-170126163314/85/IoT-Hackathon-126-320.jpg)