L pac presentation

- 1. PRODUCTION OF L-PHENYLACETYLCARBINOL Integrated Project Presentation Group KB1 NAME MATRIC NO. CHUNG KEN VUI A 98753 LIM KAH HUAY A132816 TEE ZHAO KANG A 132597 SONIA DILIP PATEL A133115 WONG MEI FANG A132213

- 2. CONTENTS ï Literature Review ï Usage of L-PAC ï Economy Analysis: Production & Demand ï Process Description with PFD ï Calculation of material and energy balance in the fermentor ï Pressure Vessel Design ï Heat Utility Design and Heat Integration ï Control Dynamic and Process ï Pollution Control and Cleaner Production

- 3. Literature Review Glucose Benzaldehyde Saccharomyces cerevisiae L-PAC Other products: Ephedrine, pseudoephedrine Pyruvic acid Acetaldehyde Ephedra sinica Standard microbes for the fermentation where ethanol-producers are preferred (Hagel et al. 2012) and gives significant yields (Kumar et al. 2006) Biotransformation route remains the preferred method for the industry (Shukla & Kulkarni 2000) Traditional process to produce ephedrine that is no longer preferred due to tedious and expensive downstream processes (Khan et al. 2012)

- 4. L-PAC: Applications and Usages MethamphetamineD-pseudoephedrineL-ephedrine Used as the precursor for the production of these drugs that are known for the nasal decongestant properties (Oliver et al. 1997, Shukla & Kulkarni 2000)

- 5. Economy Analysis Global demand and supply for L-PAC from 2006 to 2013 (reproduced on MATLABÂŪ) Source: Nanjing Pharmaceutical Company 2006, China Chemical Industry News 2012 2006 2007 2008 2009 2010 2011 2012 2013 800 1000 1200 1400 1600 1800 2000 2200 2400 Global Demand and Supply for L-PAC from 2006 to 2013 Year AmountofL-PAC(in103 kgortonnes) Demand Supply PROPOSED PRODUCTION Mode of operation: Fed-batch fermentation Total demand for L-PAC in Malaysia in 2013 = 21,000 kg (Globinmed 2010) Proposed annual Production: [L-PAC] = 25% of total demand = 5,250 kg Production rate: [L-PAC] = 5,250kg/150 cycles = 35 kg per cycle Bulk price for L-PAC is around RM312.30 per kg (Balantes Pharma 2012)

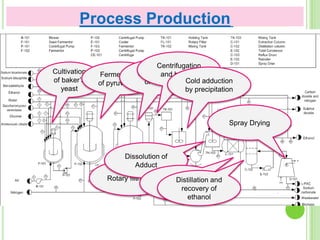

- 6. Process ProductionProcess Production Cultivation of bakerâs yeast Fermentation of pyruvic avid Fermentation of L-PAC Centrifugation and holding Cold adduction by precipitation Rotary filtration Dissolution of Adduct Ethanol extraction Distillation and recovery of ethanol Spray Drying

- 7. Mass Balance Stoichiometric equation: (Shuler & Kargi 2002) Calculations are shown for F-102 and F-103 as examples: Stream In Out Feed Gas Total Product Gas-off Total Glucose 72.00 0 72.00 0.66 0 0.66 C7H6O 3.03 0 3.03 0 0 0 NH3 0.50 0 0.50 0 0 0 Biomass 0.36 0 0.36 3.87 0 3.87 L-PAC 0 0 0 35 0 35 N2 0 1620.87 1620.87 0 1620.87 1620.87 CO2 0 0 0 0 14.53 14.53 H2O 458.71 0 458.71 480.54 0 480.54 Ethanol 5.40 0 5.40 5.40 0 5.40 Total 540.00 1620.87 2160.87 525.47 1635.40 2160.87 Comparison with SuperProÂŪ Designer SuperProÂŪ 533.47 1627.39 2160.86 Error(%) -1.52 0.49 0.00 Mass balance involving F-102 and F-103:

- 8. Energy Balance Unit Metabolism Heat (kJ) Agitation Heat (kJ) Sensible Heat Heat of reaction (kJ) Energy In (kJ) Energy Out (kJ) F-102 75789.55 19639.53 8420.09 8587.11 - 95587.10 F-103 3697.05 18613.42 8606.01 8717.42 -23447.99 E-101 - - 60227.89 10037.98 50189.91 The heat balance inside the fermentor (OâShea 1998): iCON simulation is also used to calculate the energy balance in distillation column, COL-102. Stream 47 48 51 In â Out Energy (W) -11379.47 -3243.51 -5854.92 -2281.04 Utility Condenser Reboiler Change Energy (W) 264819.45 267100.60 -2281.15

- 9. Pressure Vessel Design: Internal Pressure Fermentor, F-102 Specifications and dimensions: Material = SS 316 or ASME SA-240 Radius of vessel = 0.3545 m Diameter of vessel = 0.709 m Height = 1.996 m Cylindrical shell Height = 1.418 m Torispherical heads (Top and Bottom) Knuckle radius = 0.0425 m Crown radius = 0.363 m Height = 0.289 m Calculated that: Design pressure = 69.12 psi = 477 kPa Toverall = 0.14ââ Tmin= 3 mm Design thickness = 5 mm MAWP vessel = 98.94 psi

- 10. Specifications and dimensions: Material = SS 316 or ASME SA-240 Radius of vessel = 0.25 m Diameter of vessel = 0.50 m Height = 3.77 m Cylindrical shell Height = 3.52 m Ellipsoidal heads (Top and Bottom) Height = 0.125 m Calculated that: Design pressure = 20.36psi Toverall = 5.65mm Tmin= 3.65mm Design thickness = 6.35 mm MAWP vessel = 15psi (Atmospheric pressure) Pressure Vessel Design: External Pressure Distillation column, COL-102

- 11. Properties F-102 C0L-102 Design Pressure, PD (psi) 69.12 20.36 Minimum wall thickness, tmin (mm) 3.00 3.65 Design thickness, tD (mm) 5.00 6.35 MAWP vessel (psi) 98.94 15 Circumferential stress, Ï1 (N/mm2) 33.78 3.99 Total longitudinal stress, Ï2 (N/mm2) 16.26 - 1.36 Maximum stress intensity, (ÎÏ)max (N/mm2) 17.52 5.34 Design stress, S (N/mm2) 108.8 132.32 Critical buckling stress,Ïc (N/mm2) 139.08 247.71 Ïcompressive (N/mm2) 0.629 4.0345 Skirt thickness, ts (mm) - 10 Design skirt thickness, tD(mm) - 12 Bolt root diameter, (mm) - 10.41 Impeller diameter, Di (m) Impeller spacing, Hi (m) Impeller blade length, Li (m) Impeller blade height, Wi (m) Location of gas sparger, Hb (m) 0.234 0.468 0.059 0.047 0.117 - - - - - Pressure Vessel Design: Summary

- 12. Heat Utility Design Jacketed Vessel into F-102 Cooler E- 101 Jacketed Vessel into F-103 Condensor E-102 Reboiler E-103 Kettle Reboiler 3.2 mm o.d., 1.9 mm i.d., L = 4.8 m, plain U-tubes Total Condensor 3.2 mm o.d., 1.9 mm i.d., L = 0.508 m, admiralty brass Dimple Jacket SS 316, pattern type 1 (100/100) 11 mm, base length = 63.5 mm U-tube exchanger 6.35 mm o.d., 2.465 mm i.d., L = 6.10 m, cupro-nickel Jacket with spiral baffle Stainless steel 316, channel 15 x 200 mm, 6 spirals Heat Utility Design: Types

- 13. Figure 6.7 Heat Cascade 18.67 0 -23.97 0 -261 18.67 0 -23.97 0 -261 Start with 0 kW Start with 18.67 kW 107.6 97.05 72 25 20 -5 âTmin = 20°C -18.67 -18.67 5.3 5.3 266.3 0 0 42.64 42.64 303.64 QHmin = 18.67 kW 1 2 3 4 5 QCmin = 303.64 kW Heat Utility Design: Heat Integration

- 14. Before After Total energy required 303.64kW 303.64kW Total energy recovery 0% Table 6.10 Total energy requirement Figure 6.8 Grid Representative 20 48 55 30°C 82°C 97.6°C 35°C Cp pinch 1.77 0.51 10.44 âHabove pinch (kW) 0 0 18.67 5°C 87.05°C 107.5°C 107.5°C âHbelow pinch (kW) 261 23.97 0 Heat Utility Design: Heat Integration

- 15. Properties Jacketed Vessel F-102 Cooler E-101 Jacketed Vessel F-103 Condensor E-102 Reboiler E-103 Heat load, Q (kW) 1.106 14.21 0.271 0.0444 2.71 Uestimate (W/m2 720 550 550 650 850 Area required (m2) 9.30 0.0014 0.1909 Area of channel (m2) 3 x 10-3 1.86 x 10-3 hj (W/m2°C) 1661.41 - 967.6 - - hff,v (W/m2°C) 3785 - 3785 - - hff,j (W/m2°C) 4000 - 5000 - - âwall (m) 0.003 - 0.003 - - hv (W/m2°C) 13203.13 - 10562.73 - - hnb (W/m2°C) - - - - 2528.69 hc (W/m2°C) - - - 1000 - ut (m/s) - 0.57 - 2.68 - hi (W/m2°C) - 3557.38 - 16243.92 - us (m/s) - 0.18 - 50.35 2.08 hs (W/m2°C) - 3715.34 - - - Ucalculated (W/m2°C) 726.81 473.47 562.93 649.99 863.56 âPs (kPa) - 36.66 - 52.29 2.09 âPt (kPa) 0.805 30.14 0.178 50.05 - Heat Utility Design: Summary

- 16. Process Dynamic & Control: Modeling Fermentor, F-103 The mathematical models that are used for F-103: 1. (Rate of accumulation) = (Rate in) + (Rate of formation) 2. For component balance â cell: 3. For component balance â product: 4. For component balance â substrate: SK S X dt dX s max XY dt dP XP / dt SSd Y X f SP /

- 17. PD&C: Degree of Freedom Degree of Freedom analysis Number of variables = 10 Number of equation = 4 (as in previous slide) Degree of freedom: Variables to be controlled: Revised degree of freedom: Hence, 3 control loops are to be designed - Level, flow rate into the fermentor, antifoam PXSSFYYVKN fSXXPSV ,,,,,,,,, //max 6410F EVF N NNN SKV ,, max 336FN

- 18. LT LC Sensor â Differential pressure Signal type â Pneumatic Valve â Diaphragm Source: Smith & Corripio 2006 Level sensor detects difference in pressure caused by hydrostatic head Sends pneumatic signal to the transmitter Transmitter directs the signal to the level controller Controller calculates the necessary correction needed Controller sends signal to the diaphragm valve located at the output of F-103 Diaphragm valve moves the diaphragm to open or close the area of flow PD&C: Level Control Loop

- 19. âĒ Based on the Environment Quality (Amendment) Act 2012: 1. Environmental Quality (Clean Air) (Amendment) Regulations 2000 2. Environmental Quality (Industrial Effluent) Regulations 2009 3. Environmental Quality (Scheduled Wastes) (Amendment) Regulations 2007 4. Environmental Quality (Sewage) Regulations 2009 (Source: DOE 2013) Pollution Control and Cleaner Production (1) Unit (2) Standard A (3) Standard B Chemical Oxygen Demand mg/L 80 200 Temperature 0C 40 40 pH value - 6.0-9.0 5.5-9.0 BOD5 at 200C mg/L 20 50 Suspended solid mg/L 50 100 Phenol mg/L 0.001 1.0 Ammoniacal Nitrogen mg/L 10 20 Formaldehyde Colour mg/L ADMI* 1.0 100 2.0 200 Discharge Limit according EQ(IE)R 2009 (Source: Taken and Modified from Department of Environment 2013)

- 20. PC&CP: Wastewater Treatment Plant Overall Diagram for Modified WWTP Stream Q Q + Qr Q - Qw Qu Qr Qw Flow rate (m3/d) 13.15 14.77 9.37 5.40 1.62 3.78 S, BOD(mg/L) 14062.86 18 18 - - - X, SS (mg/L) 0 9410.06 45 9365.06 9365.06 9365.06 Mass Balance for Modified WWTP Equation used (Michael & David 2011): X = 9410.06 mg/L V = 56.46m3 Îļc = 14.83 days O2 = 4471.20 kg/day

- 21. References 1. Bukhari, A. A. 2012. Part I: Treatment of Pharmaceutical Wastewater. Pharmaceutical Waste Treatment and Disposal Practices. KFUPM 2. Cheresources. 2010. Jacketed vessel design forum. http://www.cheresources.com/content/articles/heat-transfer/jacketed-vessel-design [29 April 2013]. 3. China Chemical Industry News. 2012. Synthetic Ephederine from Zhejiang Achievements Conversion Award. http://www.39kf.com/my/tag_1_32032a-24892a-24901/ [16 March 2013]. 4. Department of Environment Malaysia. 2011. Legistration, acts, regulation & order. http://www.doe.gov.my/portal/legislation-actsregulation- order/ [3 April 2013] 5. Geankoplis, C.J. 2003. Transport Processes and Separation Process Principles: Includes Unit Operations. Fourth Edition. New Jersey: Prentice Hall. 6. Globinmed. 2010. Ephedrine and its salt. Price range by year from 2000 to 2007. http://www.globinmed.com/index.php?option=com_content&view=article&id=81286:ephedrine-a-its-salts--price-values-by-year-from-2000- to-200&catid=45&Itemid=137 7. Hagel, J.M., Krizevski, R., Marsolais, F., Lewinsohn, E. & Facchini, P.J. 2012. Biosynthesis of amphetamine analogs in plants. Trends in Plant Science 17(7): 404-412. 8. Khan, M. A., Ul-Haq, I., Javed, M. M., Qadeer, M.A., Akhtar, N. & Bokhari, S.A.I. 2012. Studies on the Production of L-Phenylacetylcarbinol by Candida Utilis in Shake Flask. Pak J. Bot. 44: 361-364. 9. Kostraby, M.M. 1999. The yeast mediated synthesis of the L-ephedrine precursor, L-phenylacetylcarbinol, in an organic solvent. Thesis Doctor of Philosophy, School of Life Sciences and Technology, Victoria University of Technology. 10. Kumar, M.R., Chari, M.A. & Narasu, M.L. 2006. Production of L-phenylacetylcarbinol (L-PAC) by different novel strains of yeasts in molasses and sugar cane juice as production medium. Research Journal of Microbiology 1(5): 433 â 437. 11. McKetta, J.J.. 1991. Heat Transfer Design Methods. New York: Marcel Dekker, Inc. 12. Mohamad Sulong, Astimar A. Aziz & AB Gapor Md. Top 2008 Bio-Fertiliser from palm Oil Biomass and POME Solids by Mobile Composter. MPOB Information Series. ISSN 1511-7871 13. Nanjing Pharmaceutical Company. 2006. Ephederine and Mongolia Shengle Pharmaceutical Research Report. http://wenku./view/dfcea5254b35eefdc8d3331a.html [16 March 2013]. 14. Oliver, A.L., Roddick, F.A., & Anderson, B.N. 1997. Cleaner production of phenylacetylcarbinol by yeast through productivity improvements and waste minimisation. Pure & Applied Chemistry 69(11): 2371-2385. 15. Shukla, V.B. & Kulkarni, P.R. 2000. L-phenylacetylcarbinol (L-PAC) biosynthesis and industrial applications. World Journal of Microbiology and Biotechnology 16(7): 499-506. 16. Smith, C.A. & Corripio, A.B. 2006. Principles andPractice of Automatic Process Control. Third edition. New Jersey: John Wiley & Sons. 17. Towler, G. & Sinnott, R. 2013. Chemical Engineering Design: Principles, Practice and Economics of Plant and Process Design. Second edition. London: Butterworth-Heinemann. 18. Tripathi, C.M., Agarwal, S.C. & Basu, S.K. 1997. Production of L-Phenylacetylcarbinol by fermentation. Journal of Fermentation and Bioengineering 84: 487-492.

- 22. THANK YOU

![Economy Analysis

Global demand and supply for L-PAC from 2006 to 2013 (reproduced on

MATLABÂŪ)

Source: Nanjing Pharmaceutical Company 2006, China Chemical

Industry News 2012

2006 2007 2008 2009 2010 2011 2012 2013

800

1000

1200

1400

1600

1800

2000

2200

2400

Global Demand and Supply for L-PAC from 2006 to 2013

Year

AmountofL-PAC(in103

kgortonnes)

Demand

Supply

PROPOSED PRODUCTION

Mode of operation: Fed-batch

fermentation

Total demand for L-PAC in

Malaysia in 2013 = 21,000 kg

(Globinmed 2010)

Proposed annual Production:

[L-PAC] = 25% of total demand

= 5,250 kg

Production rate:

[L-PAC] = 5,250kg/150 cycles

= 35 kg per cycle

Bulk price for L-PAC is around

RM312.30 per kg (Balantes

Pharma 2012)](https://image.slidesharecdn.com/l-pacpresentation-130522121418-phpapp02/85/L-pac-presentation-5-320.jpg)

![References

1. Bukhari, A. A. 2012. Part I: Treatment of Pharmaceutical Wastewater. Pharmaceutical Waste Treatment and Disposal Practices. KFUPM

2. Cheresources. 2010. Jacketed vessel design forum. http://www.cheresources.com/content/articles/heat-transfer/jacketed-vessel-design [29

April 2013].

3. China Chemical Industry News. 2012. Synthetic Ephederine from Zhejiang Achievements Conversion Award.

http://www.39kf.com/my/tag_1_32032a-24892a-24901/ [16 March 2013].

4. Department of Environment Malaysia. 2011. Legistration, acts, regulation & order. http://www.doe.gov.my/portal/legislation-actsregulation-

order/ [3 April 2013]

5. Geankoplis, C.J. 2003. Transport Processes and Separation Process Principles: Includes Unit Operations. Fourth Edition. New Jersey:

Prentice Hall.

6. Globinmed. 2010. Ephedrine and its salt. Price range by year from 2000 to 2007.

http://www.globinmed.com/index.php?option=com_content&view=article&id=81286:ephedrine-a-its-salts--price-values-by-year-from-2000-

to-200&catid=45&Itemid=137

7. Hagel, J.M., Krizevski, R., Marsolais, F., Lewinsohn, E. & Facchini, P.J. 2012. Biosynthesis of amphetamine analogs in plants. Trends in

Plant Science 17(7): 404-412.

8. Khan, M. A., Ul-Haq, I., Javed, M. M., Qadeer, M.A., Akhtar, N. & Bokhari, S.A.I. 2012. Studies on the Production of L-Phenylacetylcarbinol

by Candida Utilis in Shake Flask. Pak J. Bot. 44: 361-364.

9. Kostraby, M.M. 1999. The yeast mediated synthesis of the L-ephedrine precursor, L-phenylacetylcarbinol, in an organic solvent. Thesis

Doctor of Philosophy, School of Life Sciences and Technology, Victoria University of Technology.

10. Kumar, M.R., Chari, M.A. & Narasu, M.L. 2006. Production of L-phenylacetylcarbinol (L-PAC) by different novel strains of yeasts in

molasses and sugar cane juice as production medium. Research Journal of Microbiology 1(5): 433 â 437.

11. McKetta, J.J.. 1991. Heat Transfer Design Methods. New York: Marcel Dekker, Inc.

12. Mohamad Sulong, Astimar A. Aziz & AB Gapor Md. Top 2008 Bio-Fertiliser from palm Oil Biomass and POME Solids by Mobile Composter.

MPOB Information Series. ISSN 1511-7871

13. Nanjing Pharmaceutical Company. 2006. Ephederine and Mongolia Shengle Pharmaceutical Research Report.

http://wenku./view/dfcea5254b35eefdc8d3331a.html [16 March 2013].

14. Oliver, A.L., Roddick, F.A., & Anderson, B.N. 1997. Cleaner production of phenylacetylcarbinol by yeast through productivity improvements

and waste minimisation. Pure & Applied Chemistry 69(11): 2371-2385.

15. Shukla, V.B. & Kulkarni, P.R. 2000. L-phenylacetylcarbinol (L-PAC) biosynthesis and industrial applications. World Journal of Microbiology

and Biotechnology 16(7): 499-506.

16. Smith, C.A. & Corripio, A.B. 2006. Principles andPractice of Automatic Process Control. Third edition. New Jersey: John Wiley & Sons.

17. Towler, G. & Sinnott, R. 2013. Chemical Engineering Design: Principles, Practice and Economics of Plant and Process Design. Second

edition. London: Butterworth-Heinemann.

18. Tripathi, C.M., Agarwal, S.C. & Basu, S.K. 1997. Production of L-Phenylacetylcarbinol by fermentation. Journal of Fermentation and

Bioengineering 84: 487-492.](https://image.slidesharecdn.com/l-pacpresentation-130522121418-phpapp02/85/L-pac-presentation-21-320.jpg)