Make a Castanets - Movil

- 1. Notebook How to make Castanets July 1984 1

- 2. Legend Castanets are an ancient musical instrument, often used for street musicians in bands and orchestras. In Spain as a general rule are used in folk dances: Jotas, Malagueñas, Sevillanas... The Castanets in some Spaniard regions are known as sticks. To make them, can be used light wood as ilex (quercus ilex), almond (prunus dulcis), oak (quercus robur), beech (fagus sylvatica), or dark woods as ebony (diospyros crassiflora), african blackwood (dalbergia melanoxylon) and cocobolo (dalbergia retusa). The tools required are: a coping saw, two rasps, a file, two chisels, four gouges, two drill bits, two clamps, a drill and sandpaper. Once made and sanded, the next step is the polished, often matt, this is achieved with beeswax and turpentine in double boiler. With this preparation Castanets are waxed, next day burnish to rub the piece it will highlight the natural color of wood. Then the two halves are joined with a cord. According taste, ends can be completed, with tassels and ribbons of color. 2

- 3. Process steps: 1st step Draw a template of the model and size we want to do. Picture 1 represents the model and the natural size of the castanets for adults. It’s usually made with thin cardboard. 2nd step Getting the proper lumber. 3

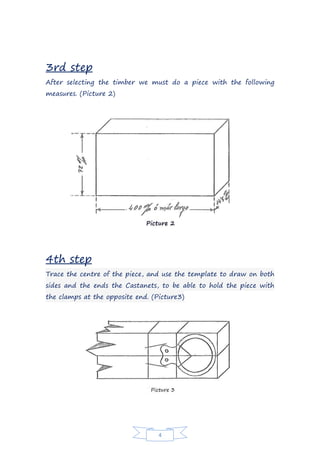

- 4. 3rd step After selecting the timber we must do a piece with the following measures. (Picture 2) 4th step Trace the centre of the piece, and use the template to draw on both sides and the ends the Castanets, to be able to hold the piece with the clamps at the opposite end. (Picture3) 4

- 5. 5th step Using half-round gouges, proceed to empty the Castanets, then you must sand them, taking advantage that the piece is clamped. (Picture 4) 6th step After put some card boards to avoid damage the piece, hold it in the workbench vise. Use the coping saw to cut all the Castanets, then smooth it with a rasp, ending the task with a fine file. (Picture 5) 5

- 6. 7th step Make the centre of the holes with a punch, then use the drill and a 2,5 mm drill bit, to make two holes that serve as a guide. Finally make the definitive holes with 4.5 mm drill bit. 8th step Mark sidelines, they serve as reference for the depth of sawing. Sidelines and real measures in Picture 6. 6

- 7. 9th step Hold the piece in the workbench, leaving free the part to cut, until reaching the depth of 6 mm. With a 32 half-round gouge and a mallet, devastate from smaller at greater depth, from the apex of the mulch to the bottom of saw cut or line of 6mm, this recess is smoothed with a extra fine rasp and the with a fine file. (Picture 7) 7

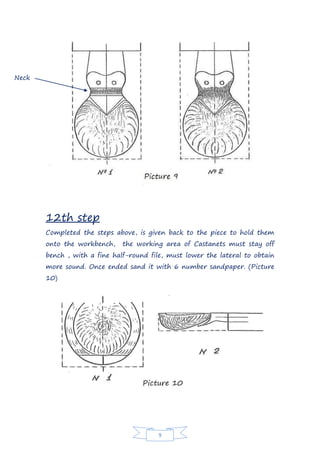

- 8. 10th step Use a ruler to redial the lines we have done away with by making the recess, this is the central line and the parallel to the saw cut. After, that use the template to draw the Castanets, trying to look perfect the vertex of the triangle of mulch. Then, to avoid deforming the sides of the triangle of mulch, mark them with the 30 mm chisel. It will make a slit with the V4 gouge, on the outside of the mulch, a millimeter of the strokes, to be able go lowering on the mulch trying to avoid damaging the triangle, this operation (of mark with the chisel the triangle) will serve as may be necessary, try to do it with delicacy to not breaking the Castanets, already second is more comfortable to use 20 mm chisel. The operations to make the triangle are usually 3 or 4, we will use the 20 mm chisel. The back of the mulch is rounded with a 32 half-round gouge. We end this task with the help of a rasp and a fine file. (Picture 8) 11th step With a rasp round of 8 mm trench 1 ½ mm deep along the line parallel to the saw cut, then with the 22 curved gouge be devastate from the apex of the triangle of Mulch toward the mulch’s neck of the Castanets , end this operation with a medium-fine file. (Picture 9) 8

- 9. Neck 12th step Completed the steps above, is given back to the piece to hold them onto the workbench, the working area of Castanets must stay off bench , with a fine half-round file, must lower the lateral to obtain more sound. Once ended sand it with 6 number sandpaper. (Picture 10) 9

- 10. 13th step Then mark a line on the two holes of the Castanets, brush top of them and it is parallel to another path that will be one millimeter beyond the end of the Castanets, on this last stroke use the coping saw to cut 4 mm deep, then with the help of a 10 mm chisel proceed to downgrade to top from the stroke out there on the two holes to the bottom of the cut of 4 mm of depth, then smooth the recess with the file, it fine to slightly rounded angle that was us participate together with the two holes-after drawing the Castanets again on labour completed, before releasing the piece, with the mountain range of DIY separates the Castanets of the rest of the wood, must continue the last court that we have made to separate completely the Castanets. (Picture 11) 14th step Mount the piece or Castanets we have separated from the rest of the wood in the Bank screw, having released in advance said screw a few caps or squadrons made of about 2 mm thick cardboard to avoid 10

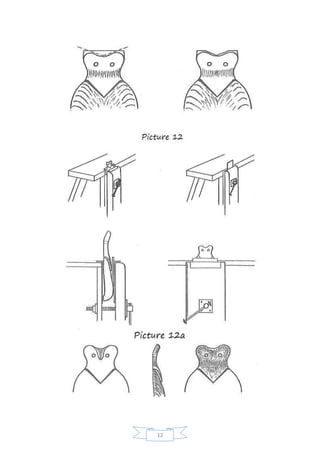

- 11. damaging the piece, also we will put between the mulch and spine of the Castanets and the squadron of cardboard a piece of 3 mm thick Board by 70 mm wide and 30 mm height, so that do the subject to do so equally and the piece is not check with which would be damaged. The position of subject of the piece is put the mulch and spine of the Castanets to the operator that is going to work. Once subject, with the mountain range of DIY is cut approximately more strokes and triangle-shaped the central curve cut once we end up with the fine rasp average cane and finally with the fine file of average cane around the contour of the Castanets left visible traces. Then it is removed from the screw of the Castanets Bank to put in place a wood of 23 cm long by 5 cm. wide by 1 inch thick, which stands out the Bank about 10 cm screw that help us support to provide with the operation of the finish of the Castanets, take the piece with his left hand support on the wood in the position to keep up and in front of the operator the mulch and spine of the Castanets, to subsequently with a 8 mm round rasp of make a slit or channel of minor to major from the centre of the piece, starting from her Sheepdog holes until you reach the edge of the opposite side then continuing with the thin half-round file rounding the edges of the ears or head of the Castanets of the same face, and once completed this operation we turn sand completely the Castanets with number 6 sandpaper. (Picture 12) 11

- 12. 12

- 13. 15th step Once finished the previous phase, we will give color and brightness to the Castanets. If we want them in dark or black color, we'll apply them walnut stain, this is achieved by mixing walnut stain with water until the desired tone, then apply beeswax, we will obtain gloss finish rubbing them with a piece of towel or with a grass scrubber, seeing as it highlights the natural color of wood. Method for the preparation of the stain, if you want to colorize:  In a glass bowl put water, gradually adding walnut stain to achieve the desired tone. Formula for wax:  3 parts of beeswax  5 parts of pure turpentine.  Dissolve the beeswax in turpentine, heating in double boiler. 13

- 14. 16th step As a final stage, come together every two halves with the cord, the ends can be completed according to taste, with tassels or color full ribbons. For the complicated picture of the knot, I refrain from doing now and give more details. The cord is especially for Castanets and they exist in some colors, the most common is black, the approximate diameter of the size for an adult is 4 mm. See Annex 2. To find out the names of the parts making up the Castanets, see Annex 1. I will end these notes, hoping to be useful in a timely manner. The author and writer José Torregrosa Moltó July 1984 14

- 15. Annex 1 How I call the parts accord my way of the parts that make up the Castanets. (Picture 13) Head, ears, neck, mulch, spine, edge, recess, holes or eyes, hollow, mouth, anvil. 15

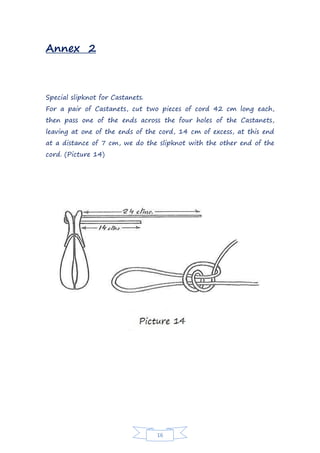

- 16. Annex 2 Special slipknot for Castanets. For a pair of Castanets, cut two pieces of cord 42 cm long each, then pass one of the ends across the four holes of the Castanets, leaving at one of the ends of the cord, 14 cm of excess, at this end at a distance of 7 cm, we do the slipknot with the other end of the cord. (Picture 14) 16

- 17. Note 1 7/8/1985 Important note Today I saw a TV report about "The Castanets of Lucero Tena", she took a Briefcase full of Castanets, indispensable instrument for her profession of dancer. She said that they were made of Ebony, African Black-wood and Cocobolo, she also had some IVORY Castanets. 17

- 18. Note 2 9/20/1987 Important note Today, I spoke with a gentleman at the Sanctuary of Our Lady of Hope (Calasparra, Murcia), referring to make Castanets type Region of Murcia, which I saw and I had in my hands, and he told me that the best are made of wood from plum and cherry, he also tended to pine wood, but these tended to crack, he said that the best are sold in Murcia for 3,500 pesetas. 18