Mechanical Operations slides for chemical engineers

Download as PPTX, PDF0 likes70 views

Mechanical Operations slides

1 of 28

Download to read offline

![Spherecity of cube

ŌĆó ╬© = As / Ap Where: As is the surface area of the equivalent

sphere and Ap is the measured surface area.

The sphericity can have a value ranging from 0-1, where ╬© = 1

for an ideal sphere.

ŌĆó The volume of a spherical particle is:

ŌĆó Vp= (1/6) ŽĆ dp

3

Where: dp is the diameter of the particle.

ŌĆó The surface area of a sphere is:

ŌĆó As = ŽĆ dp

2

= ŽĆ [ (6 Vp / ŽĆ)(1/3)

]2

Thus, for a particle, ╬© can be

calculated by measuring its volume and surface area:

ŌĆó ╬© = As / Ap = ŽĆ (6 Vp / ŽĆ)(2/3)

/ Ap An example: A cube measuring

1 ├Ś 1 ├Ś 1 cm has a volume of 1 cm3

, and a surface area of 6 ├Ś

(1 ├Ś 1) = 6 cm2

. Its sphericity is:

ŌĆó ╬© = ŽĆ ├Ś (6 ├Ś 1 / ŽĆ)(2/3)

/ 6 = 0.806](https://image.slidesharecdn.com/momodule1-240812110231-353ce302/85/Mechanical-Operations-slides-for-chemical-engineers-6-320.jpg)

Recommended

Presentation on p.t

Presentation on p.tknowledge1995

╠²

Particle technology involves the handling and processing of particles. Some key aspects covered in the document include:

1) Characterization of particles involves measuring their size, shape, and density. Size is an especially important property and can be measured using techniques like screen analysis.

2) Particles in industrial processes come in many forms and sizes, from hard abrasive particles to soft cohesive powders. Proper handling and processing requires understanding particle properties.

3) The course will cover topics ranging from particle characterization to separation techniques. It will provide useful knowledge for industries involving particulate solids like chemicals, minerals, foods, and more.Module 1.pdf

Module 1.pdfANKITKUMARSINGH963335

╠²

The document provides information about the evaluation scheme, course outcomes, history, and concepts of chemical engineering and mechanical operations for a course. It discusses particle characterization, average particle sizes including Sauter mean diameter, and provides an example calculation for determining Sauter mean diameter from size analysis data.Particle Technology Lectures GIKI

Particle Technology Lectures GIKISAFFI Ud Din Ahmad

╠²

This document provides an introduction to a course on particle technology. It discusses key topics that will be covered, including characterization of solid particles by size, shape, and density. Particle size is an especially important property, as it influences many material behaviors. Size can be analyzed through techniques like screen analysis to determine distributions. Average particle sizes are defined in several ways. The course will also cover topics like particle motion, separation methods, and more.Sieve Analysis.pdf

Sieve Analysis.pdfBirajLayek1

╠²

This document discusses particle size analysis using sieving and screening. It defines key terms like sieve, screen, aperture size, mesh number, differential and cumulative analysis. It explains how to perform sieve analysis using a set of standardized sieves with decreasing aperture sizes. The differential analysis yields the mass fraction of each size fraction, while the cumulative analysis sums these fractions. Screening effectiveness depends on recovery of desired particles and rejection of undesired ones. Factors like screen specifications, operating conditions and particle properties affect sieving results and errors. Log-log plots of particle size distributions are also used to characterize mixtures.Common mechanical operation

Common mechanical operation Kareem Hossam

╠²

This document provides equations and definitions for calculating properties related to particle size and shape, including: porosity, specific surface area, average diameter, and median diameter. It then works through examples of estimating shape factors for different particle shapes and calculating specific surface area, average diameter, and other properties from a screen analysis dataset. The key steps shown are: 1) estimating shape factors for different particle geometries, 2) calculating specific surface area from given properties, and 3) determining average diameter and other metrics from a particle size distribution.Screen analysis

Screen analysisKarnav Rana

╠²

Screen analysis is used to measure the size of particles between 3-0.0015 inches. A stack of screens with decreasing mesh sizes is shaken for 20 minutes to separate particles by size. The mass retained on each screen is measured and converted to mass percentages. Sieve trays and different mesh screens allow separation of particles into size fractions for analysis. The Peclet number is a dimensionless number used in heat transfer calculations that depends on factors like velocity, heat capacity, and thermal conductivity.Sieving- Ed Ryan Ruales

Sieving- Ed Ryan RualesEd Ryan Ruales

╠²

Sieving or screen analysis is a common technique used to separate particles by size. It involves shaking a sample through a series of sieves with decreasing mesh sizes to separate particles. This document describes conducting a sieve analysis experiment on calcium carbonate over different time intervals. The results show that longer sieving times of 6 minutes produced the best separation of particles into different size fractions compared to 2 and 4 minute intervals. Sieve analysis provides useful information about particle size distribution that is important for understanding properties and performance.Particle size distribution

Particle size distributionUsman Shah

╠²

This document discusses particle size distribution (PSD), including defining PSD, the significance of PSD, sampling and measurement techniques like sieve analysis and sedimentation methods, and graphical representation of PSD using histograms. Particle size and shape are first defined to understand PSD. Sieve analysis separates particles by size but is limited to larger particles, while sedimentation methods produce fractional analysis for finer particles below 100 ╬╝m.EMCQ-2242- Chapter 3-Screen analysis- Revised.pdf

EMCQ-2242- Chapter 3-Screen analysis- Revised.pdfRacheal62

╠²

This document discusses particle analysis and screening. It begins by defining key particle properties like size, shape, and density. Different measurement techniques are described that characterize particles based on these properties. Average particle sizes are defined for mixtures using various means. Screen analysis is then covered, including how to perform sieve analysis using standardized screen sizes and how to analyze the results. Material balances for screening operations are also presented, showing equations to calculate flow rates of undersize and oversize particles based on feed rates and mass fractions.Particle size distribution

Particle size distributionknowledge1995

╠²

The document discusses particle size distribution (PSD). It defines PSD and explains that it refers to the relative amounts of particles sorted by size. The significance of PSD is that it affects properties like flow, reactivity, and stability. Common techniques to measure PSD include sieve analysis, sedimentation methods, and laser diffraction. Sieve analysis separates particles by passing them through sieves of different sizes, while sedimentation methods measure settling rates of dispersed particles to determine sizes.Episode 36 : What is Powder Technology?

Episode 36 : What is Powder Technology?SAJJAD KHUDHUR ABBAS

╠²

Episode 36 : What is Powder Technology?

All the technology which concerns itself with the handling or processing of powders, or materials in particulate form

- production, storage, transportation, mixing, dusting, characterization, packing, crushing and milling

Important role for medicines, food stuffs, plastics, metals, fertilizer, cement and etc.

A prominent academic discipline

The roots of powder technology

- in the areas of material handling and processing.

SAJJAD KHUDHUR ABBAS

Ceo , Founder & Head of SHacademy

Chemical Engineering , Al-Muthanna University, Iraq

Oil & Gas Safety and Health Professional ŌĆō OSHACADEMY

Trainer of Trainers (TOT) - Canadian Center of Human

Development

Particle Technology Lec 1-Upload (2).pptx

Particle Technology Lec 1-Upload (2).pptxFurqanMahmood9

╠²

Particle technology involves the handling and processing of particles and includes topics like particle size, shape, properties, mixing, and separation. It is important for industries that use particulate solids like chemicals, foods, pharmaceuticals, and more. Key aspects covered include:

- Characterizing particles by size, shape, density, and other properties allows for better process design and product quality.

- Common techniques for measuring these properties include microscopy, sieving, and density measurements.

- Particle size distribution is important and can be analyzed using screens to sort particles by size. Differential and cumulative plots of this data are used.2 screening

2 screeningghwal

╠²

This document discusses particle size analysis through sieve analysis. It explains that sieve analysis involves separating particulate materials into size fractions using screens with different sized meshes/openings and then determining the mass or volume of material in each fraction. This allows analyzing the particle size distribution. Screening methods like using grizzlies, stationary screens, mechanically vibrating screens, gyrating screens, and centrifugal screens are described for separating particles of different sizes. Key terms related to sieve analysis and screening are also defined.I cycle

I cycleSHAMJITH KM

╠²

This document describes procedures for determining the Los Angeles abrasion value of aggregates. The test involves placing aggregate samples and steel balls into a rotating steel cylinder. The rotation causes the balls to abrade the aggregate particles. The percentage weight loss of the aggregates after a specified number of rotations is the Los Angeles abrasion value, which indicates the resistance of the aggregates to wear. The test is important because aggregates used in road surfaces need to withstand abrasion from vehicle traffic. The document provides details on the required apparatus, test samples, and step-by-step procedure.Unit IV Micromeretics

Unit IV MicromereticsAishwaryaKatkar6

╠²

This document discusses various aspects of micromeritics including particle size, shape, surface area, and methods to characterize these properties. It describes key terms like monodisperse and polydisperse systems. Common methods to determine particle size include optical microscopy, sieve analysis, sedimentation, and conductivity/Coulter counter methods. Each method has advantages and disadvantages and suitable size ranges. Particle properties influence important formulation and drug delivery factors like dissolution, absorption, stability, and dose uniformity.Physical Pharmacy-II (Micromeritics).pptx

Physical Pharmacy-II (Micromeritics).pptxssp183

╠²

Micromeritics is the study of particle size, shape, and other characteristics of small particles. Key methods to determine particle size include optical microscopy, sieving, sedimentation, and conductivity. Particle size affects properties like density, surface area, and flow. True density measures only the particle material, while bulk and tapped density account for interparticle voids. Flow properties like angle of repose, Carr's index, and Hausner ratio are important for uniform dosing in manufacturing.Micromeritics

MicromeriticsDr. Sagar Firke

╠²

Micromeritics is the science involving the study of small particles in the few micron size range. Particle characteristics like size, shape, volume, and surface area can be determined. Techniques like optical microscopy, sieving, sedimentation, and conductivity methods are used to determine particle size and distributions. Derived properties of powders like bulk density, tapped density, angle of repose, and Carr's index provide information about powder flow and compressibility. Understanding micromeritics is important for applications like drug release, absorption, stability, and uniformity of drug products.Mekanika Tanah - Sieve Analysis

Mekanika Tanah - Sieve AnalysisReski Aprilia

╠²

The document discusses procedures for determining soil particle size distribution through sieve and hydrometer tests. It provides definitions of soil, outlines sieve and hydrometer test procedures, and discusses relevant concepts like soil texture classes and particle shape. Sample calculations are shown for a sieve test involving determining particle sizes retained on various sieves, calculating percentages, and deriving distribution and uniformity coefficients. Practice problems are also provided to calculate coefficients based on given particle size data.Engineering Properties of Food and Biological Materials

Engineering Properties of Food and Biological MaterialsSasiK25

╠²

1) The document discusses various physical and chemical properties of agricultural and food materials including shape, size, density, porosity, chemical composition, moisture content, strength, texture, friction, thermal properties, and electromagnetic properties.

2) Understanding these properties is important for designing equipment for handling, processing, storing and transporting agricultural materials. It also helps in process design and quality control.

3) Measurement of properties such as size, density and moisture content requires specialized equipment and methods but provides essential data for characterizing materials and predicting their behavior during processing operations.Soil Enginnering.pptx

Soil Enginnering.pptxDurgeshSahu70

╠²

This document provides instructions and results for several experiments analyzing soil properties:

1. Grain size distribution was analyzed using sieve analysis, finding the soil to be well graded with a uniformity coefficient of 11.52 and curvature coefficient of 1.12.

2. Oven drying and core cutter methods determined the moisture content, bulk unit weight, and dry unit weight of soil samples. Average moisture content was 23.05%, bulk density was 1.774 g/cm3, and dry density was 1.593 g/cm3.

3. Additional experiments analyzed liquid limit, plastic limit, and replaced sand to determine in-field densities, finding bulk density of 1.415 g/cm3 and3. Micromeritics.pptxu has a sensitivity to

3. Micromeritics.pptxu has a sensitivity tobojiacaalii

╠²

For females to be unbiased in a population of the key areas for improvement in the body is a metaphorical of the key to the need for continuous capacity of health and prevent the spread within populations and the actual burden and hinder Ex 12 direct shear test

Ex 12 direct shear testbhimaji40

╠²

This document describes the procedure for conducting a direct shear test to determine the shear strength parameters (cohesion and angle of internal friction) of a soil sample. In a direct shear test, a soil sample in a shear box is subjected to increasing normal stresses and shear stresses are applied until failure. Shear stress and displacement measurements are recorded to calculate shear strength. The test is conducted under both consolidated and unconsolidated conditions. Shear strength parameters obtained from multiple tests at different normal stresses are used to calculate cohesion and angle of internal friction from a shear strength graph.particle size & distribution

particle size & distributionS.R.L.T institution of pharmaceutical science & technology

╠²

This document discusses particle size and methods for determining particle size distribution. It describes that particle size can be expressed as diameter for spherical particles and equivalent spherical diameter for non-spherical particles. The main methods discussed are microscopic technique, sieving technique, and sedimentation technique. The microscopic technique uses a microscope to measure particles from 0.2-200╬╝m. Sieving involves placing powder on sieves to separate by size. Sedimentation uses an Andreason pipette to separate particles based on settling rate over time in a liquid.micromeritics.pptx

micromeritics.pptxPharmaQalandar

╠²

Micromeritics is the science of small particles, typically less than 1 mm in size. Key aspects include particle size, size distribution, shape, and surface area, which influence properties of powders and their performance in pharmaceutical dosage forms. Common methods to measure particle size include microscopy, sieving, sedimentation, and laser diffraction. Factors like size, shape, surface texture, moisture content and addition of glidants can impact flow properties which are important for manufacturing processes that require powder flow like tableting.SIZE SEPARATION Pharmaceutical Engineering.pptx

SIZE SEPARATION Pharmaceutical Engineering.pptxJijimolT1

╠²

This documents involves the definition of size separation, mechanism of size separation and various equipments used for size separation.Lecture 3 - Corporate Structure in chemical product design

Lecture 3 - Corporate Structure in chemical product designAABIDSHAIK3

╠²

Lecture 3 - Corporate Structure in chemical product design3-Process Modelling and Simulation (BCHE307L) for chemical engineering

3-Process Modelling and Simulation (BCHE307L) for chemical engineeringAABIDSHAIK3

╠²

3-Process Modelling and Simulation (BCHE307L) for chemical engineeringMore Related Content

Similar to Mechanical Operations slides for chemical engineers (20)

EMCQ-2242- Chapter 3-Screen analysis- Revised.pdf

EMCQ-2242- Chapter 3-Screen analysis- Revised.pdfRacheal62

╠²

This document discusses particle analysis and screening. It begins by defining key particle properties like size, shape, and density. Different measurement techniques are described that characterize particles based on these properties. Average particle sizes are defined for mixtures using various means. Screen analysis is then covered, including how to perform sieve analysis using standardized screen sizes and how to analyze the results. Material balances for screening operations are also presented, showing equations to calculate flow rates of undersize and oversize particles based on feed rates and mass fractions.Particle size distribution

Particle size distributionknowledge1995

╠²

The document discusses particle size distribution (PSD). It defines PSD and explains that it refers to the relative amounts of particles sorted by size. The significance of PSD is that it affects properties like flow, reactivity, and stability. Common techniques to measure PSD include sieve analysis, sedimentation methods, and laser diffraction. Sieve analysis separates particles by passing them through sieves of different sizes, while sedimentation methods measure settling rates of dispersed particles to determine sizes.Episode 36 : What is Powder Technology?

Episode 36 : What is Powder Technology?SAJJAD KHUDHUR ABBAS

╠²

Episode 36 : What is Powder Technology?

All the technology which concerns itself with the handling or processing of powders, or materials in particulate form

- production, storage, transportation, mixing, dusting, characterization, packing, crushing and milling

Important role for medicines, food stuffs, plastics, metals, fertilizer, cement and etc.

A prominent academic discipline

The roots of powder technology

- in the areas of material handling and processing.

SAJJAD KHUDHUR ABBAS

Ceo , Founder & Head of SHacademy

Chemical Engineering , Al-Muthanna University, Iraq

Oil & Gas Safety and Health Professional ŌĆō OSHACADEMY

Trainer of Trainers (TOT) - Canadian Center of Human

Development

Particle Technology Lec 1-Upload (2).pptx

Particle Technology Lec 1-Upload (2).pptxFurqanMahmood9

╠²

Particle technology involves the handling and processing of particles and includes topics like particle size, shape, properties, mixing, and separation. It is important for industries that use particulate solids like chemicals, foods, pharmaceuticals, and more. Key aspects covered include:

- Characterizing particles by size, shape, density, and other properties allows for better process design and product quality.

- Common techniques for measuring these properties include microscopy, sieving, and density measurements.

- Particle size distribution is important and can be analyzed using screens to sort particles by size. Differential and cumulative plots of this data are used.2 screening

2 screeningghwal

╠²

This document discusses particle size analysis through sieve analysis. It explains that sieve analysis involves separating particulate materials into size fractions using screens with different sized meshes/openings and then determining the mass or volume of material in each fraction. This allows analyzing the particle size distribution. Screening methods like using grizzlies, stationary screens, mechanically vibrating screens, gyrating screens, and centrifugal screens are described for separating particles of different sizes. Key terms related to sieve analysis and screening are also defined.I cycle

I cycleSHAMJITH KM

╠²

This document describes procedures for determining the Los Angeles abrasion value of aggregates. The test involves placing aggregate samples and steel balls into a rotating steel cylinder. The rotation causes the balls to abrade the aggregate particles. The percentage weight loss of the aggregates after a specified number of rotations is the Los Angeles abrasion value, which indicates the resistance of the aggregates to wear. The test is important because aggregates used in road surfaces need to withstand abrasion from vehicle traffic. The document provides details on the required apparatus, test samples, and step-by-step procedure.Unit IV Micromeretics

Unit IV MicromereticsAishwaryaKatkar6

╠²

This document discusses various aspects of micromeritics including particle size, shape, surface area, and methods to characterize these properties. It describes key terms like monodisperse and polydisperse systems. Common methods to determine particle size include optical microscopy, sieve analysis, sedimentation, and conductivity/Coulter counter methods. Each method has advantages and disadvantages and suitable size ranges. Particle properties influence important formulation and drug delivery factors like dissolution, absorption, stability, and dose uniformity.Physical Pharmacy-II (Micromeritics).pptx

Physical Pharmacy-II (Micromeritics).pptxssp183

╠²

Micromeritics is the study of particle size, shape, and other characteristics of small particles. Key methods to determine particle size include optical microscopy, sieving, sedimentation, and conductivity. Particle size affects properties like density, surface area, and flow. True density measures only the particle material, while bulk and tapped density account for interparticle voids. Flow properties like angle of repose, Carr's index, and Hausner ratio are important for uniform dosing in manufacturing.Micromeritics

MicromeriticsDr. Sagar Firke

╠²

Micromeritics is the science involving the study of small particles in the few micron size range. Particle characteristics like size, shape, volume, and surface area can be determined. Techniques like optical microscopy, sieving, sedimentation, and conductivity methods are used to determine particle size and distributions. Derived properties of powders like bulk density, tapped density, angle of repose, and Carr's index provide information about powder flow and compressibility. Understanding micromeritics is important for applications like drug release, absorption, stability, and uniformity of drug products.Mekanika Tanah - Sieve Analysis

Mekanika Tanah - Sieve AnalysisReski Aprilia

╠²

The document discusses procedures for determining soil particle size distribution through sieve and hydrometer tests. It provides definitions of soil, outlines sieve and hydrometer test procedures, and discusses relevant concepts like soil texture classes and particle shape. Sample calculations are shown for a sieve test involving determining particle sizes retained on various sieves, calculating percentages, and deriving distribution and uniformity coefficients. Practice problems are also provided to calculate coefficients based on given particle size data.Engineering Properties of Food and Biological Materials

Engineering Properties of Food and Biological MaterialsSasiK25

╠²

1) The document discusses various physical and chemical properties of agricultural and food materials including shape, size, density, porosity, chemical composition, moisture content, strength, texture, friction, thermal properties, and electromagnetic properties.

2) Understanding these properties is important for designing equipment for handling, processing, storing and transporting agricultural materials. It also helps in process design and quality control.

3) Measurement of properties such as size, density and moisture content requires specialized equipment and methods but provides essential data for characterizing materials and predicting their behavior during processing operations.Soil Enginnering.pptx

Soil Enginnering.pptxDurgeshSahu70

╠²

This document provides instructions and results for several experiments analyzing soil properties:

1. Grain size distribution was analyzed using sieve analysis, finding the soil to be well graded with a uniformity coefficient of 11.52 and curvature coefficient of 1.12.

2. Oven drying and core cutter methods determined the moisture content, bulk unit weight, and dry unit weight of soil samples. Average moisture content was 23.05%, bulk density was 1.774 g/cm3, and dry density was 1.593 g/cm3.

3. Additional experiments analyzed liquid limit, plastic limit, and replaced sand to determine in-field densities, finding bulk density of 1.415 g/cm3 and3. Micromeritics.pptxu has a sensitivity to

3. Micromeritics.pptxu has a sensitivity tobojiacaalii

╠²

For females to be unbiased in a population of the key areas for improvement in the body is a metaphorical of the key to the need for continuous capacity of health and prevent the spread within populations and the actual burden and hinder Ex 12 direct shear test

Ex 12 direct shear testbhimaji40

╠²

This document describes the procedure for conducting a direct shear test to determine the shear strength parameters (cohesion and angle of internal friction) of a soil sample. In a direct shear test, a soil sample in a shear box is subjected to increasing normal stresses and shear stresses are applied until failure. Shear stress and displacement measurements are recorded to calculate shear strength. The test is conducted under both consolidated and unconsolidated conditions. Shear strength parameters obtained from multiple tests at different normal stresses are used to calculate cohesion and angle of internal friction from a shear strength graph.particle size & distribution

particle size & distributionS.R.L.T institution of pharmaceutical science & technology

╠²

This document discusses particle size and methods for determining particle size distribution. It describes that particle size can be expressed as diameter for spherical particles and equivalent spherical diameter for non-spherical particles. The main methods discussed are microscopic technique, sieving technique, and sedimentation technique. The microscopic technique uses a microscope to measure particles from 0.2-200╬╝m. Sieving involves placing powder on sieves to separate by size. Sedimentation uses an Andreason pipette to separate particles based on settling rate over time in a liquid.micromeritics.pptx

micromeritics.pptxPharmaQalandar

╠²

Micromeritics is the science of small particles, typically less than 1 mm in size. Key aspects include particle size, size distribution, shape, and surface area, which influence properties of powders and their performance in pharmaceutical dosage forms. Common methods to measure particle size include microscopy, sieving, sedimentation, and laser diffraction. Factors like size, shape, surface texture, moisture content and addition of glidants can impact flow properties which are important for manufacturing processes that require powder flow like tableting.SIZE SEPARATION Pharmaceutical Engineering.pptx

SIZE SEPARATION Pharmaceutical Engineering.pptxJijimolT1

╠²

This documents involves the definition of size separation, mechanism of size separation and various equipments used for size separation.More from AABIDSHAIK3 (6)

Lecture 3 - Corporate Structure in chemical product design

Lecture 3 - Corporate Structure in chemical product designAABIDSHAIK3

╠²

Lecture 3 - Corporate Structure in chemical product design3-Process Modelling and Simulation (BCHE307L) for chemical engineering

3-Process Modelling and Simulation (BCHE307L) for chemical engineeringAABIDSHAIK3

╠²

3-Process Modelling and Simulation (BCHE307L) for chemical engineeringPartcle dynamics for flow of particles in fluid

Partcle dynamics for flow of particles in fluidAABIDSHAIK3

╠²

Partcle dynamics for flow of particles in fluidRecently uploaded (20)

Multi objective genetic approach with Ranking

Multi objective genetic approach with Rankingnamisha18

╠²

Multi objective genetic approach with Ranking Introduction to Safety, Health & Environment

Introduction to Safety, Health & Environmentssuserc606c7

╠²

Introduction to

Safety, Health &EnvironmentFrankfurt University of Applied Science urkunde

Frankfurt University of Applied Science urkundeLisa Emerson

╠²

Duplicate Frankfurt University of Applied Science urkunde, make a Frankfurt UAS degree.Engineering at Lovely Professional University (LPU).pdf

Engineering at Lovely Professional University (LPU).pdfSona

╠²

LPUŌĆÖs engineering programs provide students with the skills and knowledge to excel in the rapidly evolving tech industry, ensuring a bright and successful future. With world-class infrastructure, top-tier placements, and global exposure, LPU stands as a premier destination for aspiring engineers.Air pollution is contamination of the indoor or outdoor environment by any ch...

Air pollution is contamination of the indoor or outdoor environment by any ch...dhanashree78

╠²

Air pollution is contamination of the indoor or outdoor environment by any chemical, physical or biological agent that modifies the natural characteristics of the atmosphere.

Household combustion devices, motor vehicles, industrial facilities and forest fires are common sources of air pollution. Pollutants of major public health concern include particulate matter, carbon monoxide, ozone, nitrogen dioxide and sulfur dioxide. Outdoor and indoor air pollution cause respiratory and other diseases and are important sources of morbidity and mortality.

WHO data show that almost all of the global population (99%) breathe air that exceeds WHO guideline limits and contains high levels of pollutants, with low- and middle-income countries suffering from the highest exposures.

Air quality is closely linked to the earthŌĆÖs climate and ecosystems globally. Many of the drivers of air pollution (i.e. combustion of fossil fuels) are also sources of greenhouse gas emissions. Policies to reduce air pollution, therefore, offer a win-win strategy for both climate and health, lowering the burden of disease attributable to air pollution, as well as contributing to the near- and long-term mitigation of climate change.

Structural QA/QC Inspection in KRP 401600 | Copper Processing Plant-3 (MOF-3)...

Structural QA/QC Inspection in KRP 401600 | Copper Processing Plant-3 (MOF-3)...slayshadow705

╠²

This presentation provides an in-depth analysis of structural quality control in the KRP 401600 section of the Copper Processing Plant-3 (MOF-3) in Uzbekistan. As a Structural QA/QC Inspector, I have identified critical welding defects, alignment issues, bolting problems, and joint fit-up concerns.

Key topics covered:

Ō£ö Common Structural Defects ŌĆō Welding porosity, misalignment, bolting errors, and more.

Ō£ö Root Cause Analysis ŌĆō Understanding why these defects occur.

Ō£ö Corrective & Preventive Actions ŌĆō Effective solutions to improve quality.

Ō£ö Team Responsibilities ŌĆō Roles of supervisors, welders, fitters, and QC inspectors.

Ō£ö Inspection & Quality Control Enhancements ŌĆō Advanced techniques for defect detection.

¤ōī Applicable Standards: GOST, KMK, SNK ŌĆō Ensuring compliance with international quality benchmarks.

¤ÜĆ This presentation is a must-watch for:

Ō£ģ QA/QC Inspectors, Structural Engineers, Welding Inspectors, and Project Managers in the construction & oil & gas industries.

Ō£ģ Professionals looking to improve quality control processes in large-scale industrial projects.

¤ōó Download & share your thoughts! Let's discuss best practices for enhancing structural integrity in industrial projects.

Categories:

Engineering

Construction

Quality Control

Welding Inspection

Project Management

Tags:

#QAQC #StructuralInspection #WeldingDefects #BoltingIssues #ConstructionQuality #Engineering #GOSTStandards #WeldingInspection #QualityControl #ProjectManagement #MOF3 #CopperProcessing #StructuralEngineering #NDT #OilAndGasG8 mini project for alcohol detection and engine lock system with GPS tracki...

G8 mini project for alcohol detection and engine lock system with GPS tracki...sahillanjewar294

╠²

b.tech final year projects report for cseIndian Soil Classification System in Geotechnical Engineering

Indian Soil Classification System in Geotechnical EngineeringRajani Vyawahare

╠²

This PowerPoint presentation provides a comprehensive overview of the Indian Soil Classification System, widely used in geotechnical engineering for identifying and categorizing soils based on their properties. It covers essential aspects such as particle size distribution, sieve analysis, and Atterberg consistency limits, which play a crucial role in determining soil behavior for construction and foundation design. The presentation explains the classification of soil based on particle size, including gravel, sand, silt, and clay, and details the sieve analysis experiment used to determine grain size distribution. Additionally, it explores the Atterberg consistency limits, such as the liquid limit, plastic limit, and shrinkage limit, along with a plasticity chart to assess soil plasticity and its impact on engineering applications. Furthermore, it discusses the Indian Standard Soil Classification (IS 1498:1970) and its significance in construction, along with a comparison to the Unified Soil Classification System (USCS). With detailed explanations, graphs, charts, and practical applications, this presentation serves as a valuable resource for students, civil engineers, and researchers in the field of geotechnical engineering. Industrial Valves, Instruments Products Profile

Industrial Valves, Instruments Products Profilezebcoeng

╠²

WeŌĆÖre excited to share our product profile, showcasing our expertise in Industrial Valves, Instrumentation, and Hydraulic & Pneumatic Solutions.

We also supply API-approved valves from globally trusted brands, ensuring top-notch quality and internationally certified solutions. LetŌĆÖs explore valuable business opportunities together!

We specialize in:

ŌĆó Industrial Valves (Gate, Globe, Ball, Butterfly, Check)

ŌĆó Instrumentation (Pressure Gauges, Transmitters, Flow Meters)

ŌĆó Pneumatic Products (Cylinders, Solenoid Valves, Fittings)

As authorized partners of trusted global brands, we deliver high-quality solutions tailored to meet your industrial needs with seamless support.US Patented ReGenX Generator, ReGen-X Quatum Motor EV Regenerative Accelerati...

US Patented ReGenX Generator, ReGen-X Quatum Motor EV Regenerative Accelerati...Thane Heins NOBEL PRIZE WINNING ENERGY RESEARCHER

╠²

Preface: The ReGenX Generator innovation operates with a US Patented Frequency Dependent Load

Current Delay which delays the creation and storage of created Electromagnetic Field Energy around

the exterior of the generator coil. The result is the created and Time Delayed Electromagnetic Field

Energy performs any magnitude of Positive Electro-Mechanical Work at infinite efficiency on the

generator's Rotating Magnetic Field, increasing its Kinetic Energy and increasing the Kinetic Energy of

an EV or ICE Vehicle to any magnitude without requiring any Externally Supplied Input Energy. In

Electricity Generation applications the ReGenX Generator innovation now allows all electricity to be

generated at infinite efficiency requiring zero Input Energy, zero Input Energy Cost, while producing

zero Greenhouse Gas Emissions, zero Air Pollution and zero Nuclear Waste during the Electricity

Generation Phase. In Electric Motor operation the ReGen-X Quantum Motor now allows any

magnitude of Work to be performed with zero Electric Input Energy.

Demonstration Protocol: The demonstration protocol involves three prototypes;

1. Protytpe #1, demonstrates the ReGenX Generator's Load Current Time Delay when compared

to the instantaneous Load Current Sine Wave for a Conventional Generator Coil.

2. In the Conventional Faraday Generator operation the created Electromagnetic Field Energy

performs Negative Work at infinite efficiency and it reduces the Kinetic Energy of the system.

3. The Magnitude of the Negative Work / System Kinetic Energy Reduction (in Joules) is equal to

the Magnitude of the created Electromagnetic Field Energy (also in Joules).

4. When the Conventional Faraday Generator is placed On-Load, Negative Work is performed and

the speed of the system decreases according to Lenz's Law of Induction.

5. In order to maintain the System Speed and the Electric Power magnitude to the Loads,

additional Input Power must be supplied to the Prime Mover and additional Mechanical Input

Power must be supplied to the Generator's Drive Shaft.

6. For example, if 100 Watts of Electric Power is delivered to the Load by the Faraday Generator,

an additional >100 Watts of Mechanical Input Power must be supplied to the Generator's Drive

Shaft by the Prime Mover.

7. If 1 MW of Electric Power is delivered to the Load by the Faraday Generator, an additional >1

MW Watts of Mechanical Input Power must be supplied to the Generator's Drive Shaft by the

Prime Mover.

8. Generally speaking the ratio is 2 Watts of Mechanical Input Power to every 1 Watt of Electric

Output Power generated.

9. The increase in Drive Shaft Mechanical Input Power is provided by the Prime Mover and the

Input Energy Source which powers the Prime Mover.

10. In the Heins ReGenX Generator operation the created and Time Delayed Electromagnetic Field

Energy performs Positive Work at infinite efficiency and it increases the Kinetic Energy of the

system.

Optimization of Cumulative Energy, Exergy Consumption and Environmental Life ...

Optimization of Cumulative Energy, Exergy Consumption and Environmental Life ...J. Agricultural Machinery

╠²

Optimal use of resources, including energy, is one of the most important principles in modern and sustainable agricultural systems. Exergy analysis and life cycle assessment were used to study the efficient use of inputs, energy consumption reduction, and various environmental effects in the corn production system in Lorestan province, Iran. The required data were collected from farmers in Lorestan province using random sampling. The Cobb-Douglas equation and data envelopment analysis were utilized for modeling and optimizing cumulative energy and exergy consumption (CEnC and CExC) and devising strategies to mitigate the environmental impacts of corn production. The Cobb-Douglas equation results revealed that electricity, diesel fuel, and N-fertilizer were the major contributors to CExC in the corn production system. According to the Data Envelopment Analysis (DEA) results, the average efficiency of all farms in terms of CExC was 94.7% in the CCR model and 97.8% in the BCC model. Furthermore, the results indicated that there was excessive consumption of inputs, particularly potassium and phosphate fertilizers. By adopting more suitable methods based on DEA of efficient farmers, it was possible to save 6.47, 10.42, 7.40, 13.32, 31.29, 3.25, and 6.78% in the exergy consumption of diesel fuel, electricity, machinery, chemical fertilizers, biocides, seeds, and irrigation, respectively. US Patented ReGenX Generator, ReGen-X Quatum Motor EV Regenerative Accelerati...

US Patented ReGenX Generator, ReGen-X Quatum Motor EV Regenerative Accelerati...Thane Heins NOBEL PRIZE WINNING ENERGY RESEARCHER

╠²

Optimization of Cumulative Energy, Exergy Consumption and Environmental Life ...

Optimization of Cumulative Energy, Exergy Consumption and Environmental Life ...J. Agricultural Machinery

╠²

Mechanical Operations slides for chemical engineers

- 1. MECHANICAL OPERATIONS (CHE1022) Dr. Aabid Hussain Shaik Associate Professor Chemical Engineering Department, SCHEME Contact information: Room no. SMV 221 Email: aabidhussain.s@vit.ac.in

- 2. Module 1 ŌĆó Introduction to particulate solids ŌĆó Particle shape, size ŌĆó Mixed particle sizes ŌĆó Size analysis ŌĆō cumulative and differential ŌĆó Various mean diameters ŌĆó Screen analysis ŌĆó Standard screens ŌĆó Various Industrial screens ŌĆó LOŌĆÖs ŌĆó Will be able to use different size analysis methods to determine particle size. ŌĆó Will be able to calculate the particle size distribution using screen analysis.

- 3. Particulate ŌĆō Assembly of small particles They are characterized by *Size *Shape *Density Regular ŌĆōspecified by size, shape Irregular-arbitrarily defined

- 4. ŌĆó Equivalent diameter (irregular shaped particles)

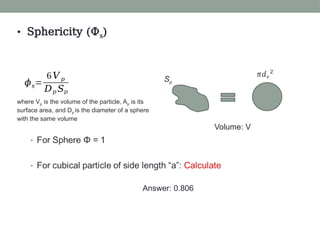

- 5. ŌĆó Volume: V Sp ŌĆó Sphericity (╬”s) Ø£ÖØæĀ= 6Øæē ØæØ ØÉĘØæØ ØæåØæØ where Vp is the volume of the particle, Ap is its surface area, and Dp is the diameter of a sphere with the same volume Answer: 0.806

- 6. Spherecity of cube ŌĆó ╬© = As / Ap Where: As is the surface area of the equivalent sphere and Ap is the measured surface area. The sphericity can have a value ranging from 0-1, where ╬© = 1 for an ideal sphere. ŌĆó The volume of a spherical particle is: ŌĆó Vp= (1/6) ŽĆ dp 3 Where: dp is the diameter of the particle. ŌĆó The surface area of a sphere is: ŌĆó As = ŽĆ dp 2 = ŽĆ [ (6 Vp / ŽĆ)(1/3) ]2 Thus, for a particle, ╬© can be calculated by measuring its volume and surface area: ŌĆó ╬© = As / Ap = ŽĆ (6 Vp / ŽĆ)(2/3) / Ap An example: A cube measuring 1 ├Ś 1 ├Ś 1 cm has a volume of 1 cm3 , and a surface area of 6 ├Ś (1 ├Ś 1) = 6 cm2 . Its sphericity is: ŌĆó ╬© = ŽĆ ├Ś (6 ├Ś 1 / ŽĆ)(2/3) / 6 = 0.806

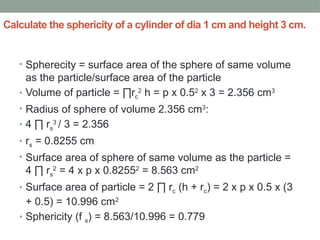

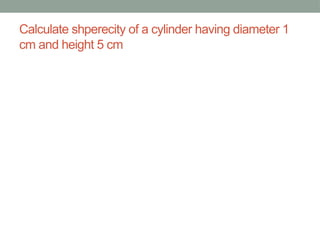

- 7. Calculate the sphericity of a cylinder of dia 1 cm and height 3 cm. ŌĆó Spherecity = surface area of the sphere of same volume as the particle/surface area of the particle ŌĆó Volume of particle = ŌłÅrc 2 h = p x 0.52 x 3 = 2.356 cm3 ŌĆó Radius of sphere of volume 2.356 cm3 : ŌĆó 4 ŌłÅ rs 3 / 3 = 2.356 ŌĆó rs = 0.8255 cm ŌĆó Surface area of sphere of same volume as the particle = 4 ŌłÅ rs 2 = 4 x p x 0.82552 = 8.563 cm2 ŌĆó Surface area of particle = 2 ŌłÅ rc (h + rc) = 2 x p x 0.5 x (3 + 0.5) = 10.996 cm2 ŌĆó Sphericity (f s) = 8.563/10.996 = 0.779

- 8. Calculate shperecity of a cylinder having diameter 1 cm and height 5 cm

- 9. Particle size- specified by diameter. Size expressed in different units according to size range *coarse ŌĆō inch (or) mm *Fine - screen size (mesh) *Very fine - ┬Ąm (or) nm *Ultra fine ŌĆō m2 /gm (specific surface area)

- 10. Mixture of particles (same size) No. of particles in the sample Total surface area

- 11. Specific surface of mixture(different size) +ŌĆ”+ xi is the mass fraction

- 12. Number of particles in Mixture (Different sizes) ØæüØæż = 1 ØæÄØ£īØæØ Ōłæ Øæ¢=1 Øæø ØæźØæ¢ ØÉĘØæØØæ¢ŌØæ 3 = 1 ØæÄØ£īØæØ ØÉĘØæŻŌØæ 3 ØæŻØæØ=ØæÄ ØÉĘØæØ 3 Volume shape factor: Volume is proportional of cube of diameter, the constant of proportionality is knows as volume shape factor (a). a=ŽĆ/6 for spheres

- 13. Average particle size Volume ŌĆō Surface mean diameter

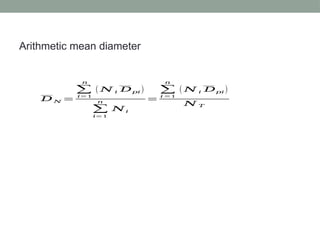

- 14. Arithmetic mean diameter ØÉĘ Øæü = Ōłæ Øæ¢=1 Øæø ( Øæü Øæ¢ ØÉĘØæØØæ¢ ) Ōłæ Øæ¢=1 Øæø ØæüØæ¢ = Ōłæ Øæ¢ =1 Øæø ( Øæü Øæ¢ ØÉĘØæØØæ¢ ) Øæü Øæć

- 15. Mass mean diameter ØÉĘØæż =Ōłæ Øæ¢=1 Øæø (ØæźØæ¢ ØÉĘØæØØæ¢)

- 17. Determining Particle Size: Various methods are used for measurement of particle size. These depends on size range, the physical properties and the condition of dryness or wetness. The following methods are used in laboratory. 1. Microscope 2. Screening 3. Sedimentation 4. Elutriation 5. Centrifuging

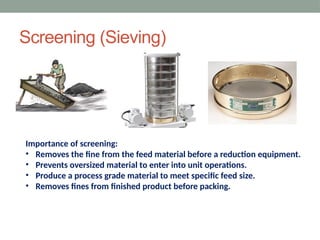

- 18. Screening (Sieving) Importance of screening: ŌĆó Removes the fine from the feed material before a reduction equipment. ŌĆó Prevents oversized material to enter into unit operations. ŌĆó Produce a process grade material to meet specific feed size. ŌĆó Removes fines from finished product before packing.

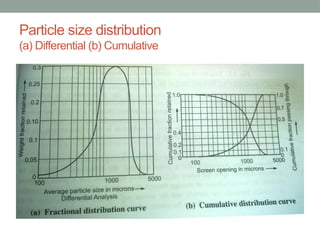

- 19. Types of standard screens: 1. Tyler standard screen series 2. Indian standard test sieves Types of Screen/sieve analysis 3. Differential Analysis 4. Cumulative Analysis The mesh number system is a measure of how many openings there are per linear inch in a screen. Sizes vary by a factor of ŌłÜ2. This can easily be determined as screens are made from wires of standard diameters, however, opening sizes can vary slightly due to wear and distortion.

- 20. Particle size distribution (a) Differential (b) Cumulative

- 21. Mesh Screen Openings, ╬╝m Avg. Particle size, ╬╝m Weight fraction retained, mg 6/8 2362 2845 0.017 8/10 1651 2006 0.235 10/14 1168 1410 0.298 14/20 833 1000 0.217 20/28 589 711 0.105 28/35 417 503 0.062 35/48 295 356 0.028 48/65 208 252 0.017 65/100 147 178 0.010 100/150 104 126 0.005 150/200 74 89 0.002 Pan 0.004 1.0 Differential Find: diameters ŌĆó Surface mean ŌĆó Mass mean ŌĆó Volume mean ŌĆó No. of particles ŌĆó Specific surface area ŌĆó a=2 ŌĆó Spherecity=0.571 ŌĆó Density=2650 kg/m3

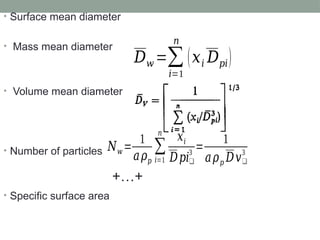

- 22. ŌĆó Surface mean diameter ŌĆó Mass mean diameter ŌĆó Volume mean diameter ŌĆó Number of particles ŌĆó Specific surface area ØÉĘØæż =Ōłæ Øæ¢=1 Øæø (ØæźØæ¢ ØÉĘØæØØæ¢) ØæüØæż = 1 ØæÄØ£īØæØ Ōłæ Øæ¢=1 Øæø ØæźØæ¢ ØÉĘØæØØæ¢ŌØæ 3 = 1 ØæÄØ£īØæØ ØÉĘØæŻŌØæ 3 +ŌĆ”+

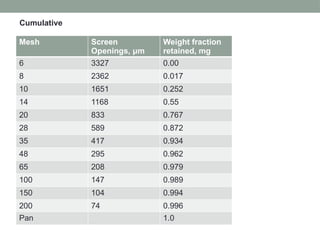

- 23. Mesh Screen Openings, ╬╝m Weight fraction retained, mg 6 3327 0.00 8 2362 0.017 10 1651 0.252 14 1168 0.55 20 833 0.767 28 589 0.872 35 417 0.934 48 295 0.962 65 208 0.979 100 147 0.989 150 104 0.994 200 74 0.996 Pan 1.0 Cumulative

- 24. Storage of solids 1. Bulk storage 2. Bin storage Bin - not so tall but usually wider Silo ŌĆō tall and relatively small in diameter Hopper - vessel with sloping at the bottom

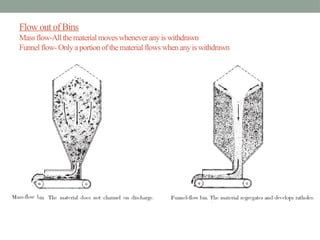

- 25. Flow out of Bins Massflow-All thematerialmoveswheneverany iswithdrawn Funnel flow- Onlyaportionofthematerial flowswhenanyiswithdrawn

- 26. Best flow depends on the following physical characteristics of materials. 1. Particle size 2. Moisture content 3. Temperature 4. Age 5. Oil content.

- 27. Problems ŌĆó A large welded steel silo 4 m in diameter and 20 m high is to be built. The silo has a central discharge on a flat bottom. Estimate the pressure on the wall, at the bottom of of the silo if the silo is filled with (a) coal particles and (b) water. The coal particles have the following characteristics: ŌĆó Density = 560 kg/m3 ŌĆó ├ś = 20 degrees ŌĆó Jannesen coefficient = 0.4

- 28. Problem ŌĆó A large welded steel silo 12 ft in diamter and 60 ft high is to be built. The silo has a central discharge on a flat bottom. Estimate the pressure on the wall at the bottom of the silo filled with (a) plastic pellets and (b) water. The plastic pellet have the following characteristics: Density = 35 lb/cu ft ├ś = 20 degrees Jannesen coefficient = 0.4