MerchantÔÇÖs circle

Download as PPTX, PDF1 like886 views

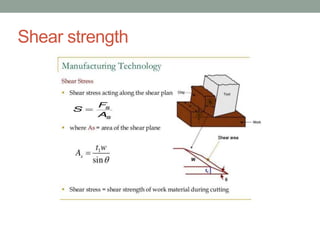

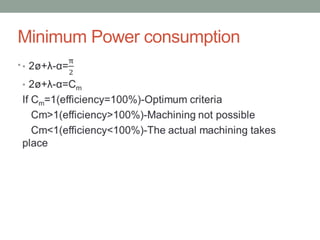

This document discusses Merchant's circle analysis for orthogonal metal cutting. It introduces key terms like shear velocity, chip velocity, shear strain, and shear strength. It lists assumptions of the model including a perfectly sharp tool, planar shear surface, straight cutting edge generating a flat surface, and uniform velocities. Merchant's circle analysis relates the cutting forces - feed force F, thrust force Ft, and shear force Fs - to the shear plane angle ├© and tool rake angle ╬▒ through trigonometric relationships. The goal of Merchant's circle is to analyze minimum power consumption during metal cutting.

1 of 9

Downloaded 13 times

More Related Content

What's hot (20)

Similar to MerchantÔÇÖs circle (15)

Ad

Recently uploaded (20)

Ad

MerchantÔÇÖs circle

- 1. MERCHANTÔÇÖS CIRCLE By- Bishal Das Nit Mizoram

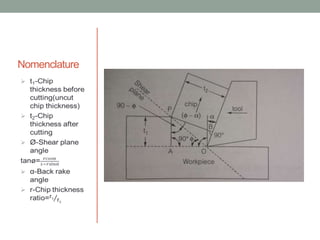

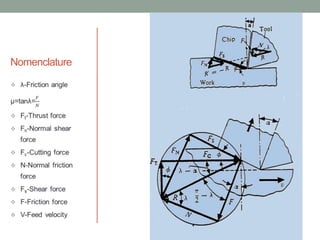

- 2. Nomenclature

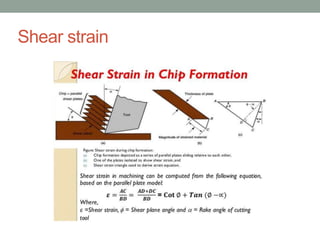

- 4. Shear strain

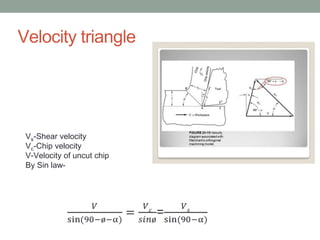

- 5. Velocity triangle Vs-Shear velocity Vc-Chip velocity V-Velocity of uncut chip By Sin law-

- 6. Assumptions: ´éóThe tool is perfectly sharp and has no contact along the clearance face ´éóThe surface, where shear is occurring is a plane ´éóThe cutting edge is a straight line extending perpendicular to the direction of motion and generates a plane surface as the work moves past it ´éóThe chip does not flow to either side or no side spread. ´éóUncut chip thickness is constant ´éóWidth moves with a uniform velocity ´éóA continuous chip is produced without any BUE ´éóWork moves with a uniform velocity ´éóThe stress on the spear plane are uniformly distributed.

- 7. Nomenclature

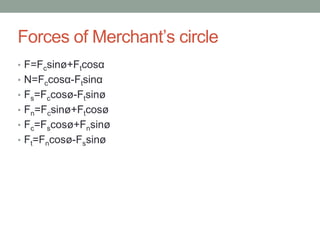

- 8. Forces of MerchantÔÇÖs circle ÔÇó F=Fcsin├©+Ftcos╬▒ ÔÇó N=Fccos╬▒-Ftsin╬▒ ÔÇó Fs=Fccos├©-Ftsin├© ÔÇó Fn=Fcsin├©+Ftcos├© ÔÇó Fc=Fscos├©+Fnsin├© ÔÇó Ft=Fncos├©-Fssin├©