Phyiscs 4th form - Errors_2023-2024 (1).pptx

Download as PPTX, PDF0 likes7 views

Phyiscs 4th form - Errors_2023-2024 (1).pptx

1 of 14

Download to read offline

Recommended

Science enginering lab report experiment 1 (physical quantities aand measurem...

Science enginering lab report experiment 1 (physical quantities aand measurem...Q Hydar Q Hydar

╠²

This document discusses sources of error in measurement and the importance of accuracy. It explains that random errors can cause inconsistent readings and averaging repeated measurements can reduce these errors. Common sources of error include instrument errors, non-linear relationships in instruments, errors from reading scales incorrectly, environmental factors, and human errors. Taking the average of multiple readings eliminates random variations between readings and provides a more accurate result.Error analytical

Error analyticalLovnish Thakur

╠²

This document discusses experimental errors in scientific measurements. It defines experimental error as the difference between a measured value and the true value. Experimental errors can be classified as systematic errors or random errors. Systematic errors affect accuracy and can result from faulty instruments, while random errors affect precision and arise from unpredictable fluctuations. The document also discusses ways to quantify and describe experimental errors, including percent error, percent difference, mean, and significant figures. Understanding experimental errors is important for analyzing measurement uncertainties and improving experimental design.Principle of measurement

Principle of measurementSushama Nikam

╠²

1) The document discusses various concepts related to measurement principles including accuracy, precision, resolution, sensitivity and error.

2) It describes different types of errors like gross error, systematic error and random error. Systematic error includes instrumental, environmental and observational errors.

3) Accuracy refers to the closeness of a measurement to the true value. Precision refers to the consistency of repeated measurements. Accuracy and precision are related but distinct measures of measurement quality.Assignment on errors

Assignment on errorsIndian Institute of Technology Delhi

╠²

This document discusses various types of errors that can occur when making measurements with instruments. It defines error as the difference between the expected and measured values. There are two main types of errors - static errors, which occur due to limitations in the instrument, and dynamic errors, which occur when the instrument cannot keep up with rapid changes. Static errors include gross errors from human mistakes, systematic errors due to instrument defects, and random errors from small unpredictable factors. The document provides examples of different sources of systematic errors like instrumentation errors, environmental influences, and observational errors. It also discusses methods for estimating random errors and other error types like limiting, parallax, and quantization errors.Accuracy-and-precision.ppt

Accuracy-and-precision.pptwjahx8elooly

╠²

John's measurement is closer to the accepted value of 2.7 g/ml.

John's measurement: 2.649 g/ml

Difference from accepted value: 2.7 - 2.649 = 0.051 g/ml

Percentage accuracy = (Difference/Accepted value) x 100% = (0.051/2.7) x 100% = 1.89%

Sally's measurement: 2.731 g/ml

Difference from accepted value: 2.7 - 2.731 = -0.031 g/ml

Percentage accuracy = (Difference/Accepted value) x 100% = (-0.031/2.7) x 100% = 1.15%

ThereforePhysical measurement and error analysis

Physical measurement and error analysis Parminder Singh Walia

╠²

This document discusses physical measurement and errors in measurement. It defines key terms like measurement, units, observations, and least count. It describes the International System of Units (SI) as the modern metric system. It also discusses different types of errors like absolute error and relative error. Systematic errors can be corrected while random errors are reduced by taking multiple measurements. Accuracy refers to systematic errors while precision describes random errors. The document outlines methods to calculate propagation of errors and statistical treatment of error values.Accuracy

Accuracynabeel neduvalli

╠²

This document discusses key concepts in analytical chemistry including accuracy, precision, mean, and standard deviation. It defines accuracy as closeness to the true value and notes that perfect accuracy is impossible due to errors. Precision refers to the agreement between repeated measurements and does not ensure accuracy if systematic errors are present. The mean is used to estimate the true value and standard deviation measures the dispersion of results. Good precision alone does not guarantee good accuracy as systematic errors can bias results while maintaining precision.The measurement of a physical quantity can never be made with perfect accurac...

The measurement of a physical quantity can never be made with perfect accurac...RuwanKalubowila1

╠²

The measurement of a physical quantity can never be made with perfect accuracy,

there will always be some error or uncertainty present

146056297 cc-modul

146056297 cc-modulhomeworkping3

╠²

homework help,online homework help,online tutors,online tutoring,research paper help,do my homework,

https://www.homeworkping.com/Lecture note 2

Lecture note 2sreenu t

╠²

This document provides an overview of standards of measurement and discusses key concepts:

- Standards are classified as primary or secondary, with primary standards defining fundamental units and secondary standards calibrated against primary standards.

- Standard units discussed include the meter (length), kilogram (mass), second (time), Kelvin (temperature), candela (light intensity), mole (amount of substance), and ampere (electric current).

- Random and systematic errors are defined, with random errors averaging out over repeated measurements but systematic errors requiring correction. Significant figures and calculating relative/absolute errors are also covered.Errors and uncertainties

Errors and uncertaintiesbornalive

╠²

This is a lecture note on Error and its propagation. This slide can be very much useful for As level physics students. It is totally different from the presentation. I would like to name it as slides of lecture notes on Error(uncertainty), difference on precision and accuracy, difference on two types of error (systematic and random errors). Believe me it will help you to enhance your knowledge on Uncertainty and its propagarion.Errors and Error Measurements

Errors and Error MeasurementsMilind Pelagade

╠²

Thorough study of Experimental Errors occurred during experimentation using different experimental techniques.

A clear picture about techniques for error measurement is given in the presentation.EMI-Unit-1 Material.docx

EMI-Unit-1 Material.docxraviteja srinivasula

╠²

This document provides an introduction to instrumentation and measurement. It discusses:

1. The importance of measurement in science, engineering, and daily life. Measurement allows the study of natural phenomena and supports technological advancement.

2. Key concepts in instrumentation including transducers that convert physical quantities to electrical signals, and functional elements like sensing, signal conversion/manipulation, transmission, and display.

3. Performance characteristics of instruments including static characteristics like accuracy, precision, resolution, sensitivity, and errors, and dynamic characteristics related to rapidly changing measurements. Calibration is also discussed.

4. Sources of errors in measurement including gross errors from human mistakes, systematic errors from instruments, environments, and observations, and random errorsErrors in measurement

Errors in measurementRavinder Jarewal

╠²

The document discusses different types of errors that can occur in measurement. It describes gross errors, systematic errors like instrumental errors and environmental errors, and random errors. It also defines key terms used to analyze errors like limit of reading, greatest possible error, and discusses analyzing measurement data using statistical methods like the mean, standard deviation, variance and histograms. Measurement errors can occur due to issues like parallax, calibration, limits of the measuring device, and are analyzed statistically.Introduction to physics

Introduction to physicsCk Sal

╠²

Scalar quantities have magnitude only, such as length, time, temperature. Vector quantities have both magnitude and direction, such as displacement, velocity, force.

There are two main types of errors in measurement - systematic errors and random errors. Systematic errors consistently shift measurements in one direction, such as zero errors or calibration errors. Random errors vary unpredictably between measurements, caused by factors like human error or environmental changes. Precision refers to the consistency of measurements while accuracy refers to how close measurements are to the true value.Nursing Research Measurement errors.pptx

Nursing Research Measurement errors.pptxChinna Chadayan

╠²

This document discusses different types of errors that can occur in measurement. There are five main types of errors:

1) Gross errors are faults made by the person using the instrument, such as incorrect readings or recordings.

2) Systematic errors are due to problems with the instrument itself, environmental factors, or observational errors made by the observer.

3) Random errors remain after gross and systematic errors have been reduced and are due to unknown causes. Taking multiple readings and analyzing them statistically can help minimize random errors.

4) Absolute error is the difference between the expected and measured values.

5) Relative error expresses the error as a percentage of the real measurement.Nursing Research Measurement errors.pptx

Nursing Research Measurement errors.pptxChinna Chadayan

╠²

This document discusses different types of errors that can occur in measurement. There are five main types of errors:

1) Gross errors are faults made by the person using the instrument, such as incorrect readings or recordings.

2) Systematic errors are due to problems with the instrument itself, environmental factors, or observational errors made by the observer.

3) Random errors remain after gross and systematic errors have been reduced and are due to unknown causes. Taking multiple readings and analyzing them statistically can help minimize random errors.

4) Absolute error is the difference between the expected and measured values.

5) Relative error expresses the error as a percentage of the real measurement.errors of measurement and systematic errors

errors of measurement and systematic errorsDr. Hament Sharma

╠²

This document discusses measurement errors and uncertainty. It defines measurement as assigning a number and unit to a property using an instrument. Error is the difference between the measured value and true value. There are two main types of error: random error, which varies unpredictably, and systematic error, which remains constant or varies predictably. Sources of error include the measuring instrument and technique used. Uncertainty is the doubt about a measurement and is quantified with an interval and confidence level, such as 20 cm ┬▒1 cm at 95% confidence. Uncertainty is important for tasks like calibration where it must be reported.1.4 measurement

1.4 measurementKonilia Sual

╠²

1. Errors in measurement can be either systematic or random. Systematic errors consistently shift measurements in one direction, while random errors vary unpredictably between measurements.

2. Systematic errors can be reduced by careful experimentation and using multiple instruments, while random errors are reduced through repeat readings and calculating averages.

3. Precision refers to the consistency of measurements while accuracy refers to how close measurements are to the true value. Both can be improved by eliminating errors and using more sensitive instruments.Numerical approximation and solution of equations

Numerical approximation and solution of equationsRobinson

╠²

1. Numerical approximation involves finding approximate values that are close to the actual values of quantities. There are different types of errors that can occur due to approximation, such as truncation error and rounding error.

2. Accuracy refers to how close an approximate value is to the actual value, while precision describes how close repeated approximations are to each other. Greater accuracy means a lower absolute error, while greater precision means a lower standard deviation between repeated measurements.

3. For a numerical method, convergence means that repeated approximations get closer to the actual value with each iteration. Stability refers to the likelihood that a method will converge rather than diverge for a wide range of problems.Process dynamic control

Process dynamic controlSharvendra DK Omre

╠²

This document discusses types of errors, accuracy, sensitivity, resolution, and linearity in measurements. It defines random error, systematic error including environmental, instrumental and observational errors. Gross errors are discussed. Accuracy is defined as closeness to a true value. Sensitivity is a measure of output change for input change. Resolution is the ability to detect small changes. Linearity refers to how measurement bias is affected by the measurement range. First order response reaches steady state for a step input. Second order response can oscillate to a step input due to overshoot and damping effects.Errors in pharmaceutical analysis

Errors in pharmaceutical analysis Bindu Kshtriya

╠²

Errors in pharmaceutical analysis can be determinate (systematic) or indeterminate (random). Determinate errors are caused by faults in procedures or instruments and cause results to consistently be too high or low. Sources include improperly calibrated equipment, impure reagents, and analyst errors. Indeterminate errors are random and unavoidable, arising from limitations of instruments. Accuracy refers to closeness to the true value, while precision refers to reproducibility. Systematic errors can be minimized by calibrating equipment, analyzing standards, using independent methods, and blank determinations.The uncertainty of measurements

The uncertainty of measurementserwin marlon sario

╠²

This document discusses various sources of uncertainty in physics measurements, including incomplete definitions, unaccounted factors, environmental influences, instrument limitations, calibration errors, physical variations, drifts, response times, and parallax. It emphasizes that all measurements have some degree of uncertainty from multiple sources. Properly reporting uncertainty allows evaluation of experimental quality and comparison to other results. While the true value may not be known exactly, uncertainty analysis helps ascertain a measurement's accuracy and precision.Accuracy precision - resolution

Accuracy precision - resolutionMai An

╠²

1. Accuracy refers to how close a measurement is to the actual value, while precision describes the consistency of repeated measurements.

2. Measurement uncertainty comes from systematic errors in instruments and random errors from noise. Total uncertainty is calculated by combining the uncertainties.

3. Improving precision involves averaging measurements to reduce noise, but this may reduce bandwidth. Resolution is the smallest distinguishable difference in values.Green CHEM. Locating Industrial Plants.ppt

Green CHEM. Locating Industrial Plants.pptjhoyvanwilliams2

╠²

Green CHEM. Locating Industrial Plants.pptMore Related Content

Similar to Phyiscs 4th form - Errors_2023-2024 (1).pptx (20)

146056297 cc-modul

146056297 cc-modulhomeworkping3

╠²

homework help,online homework help,online tutors,online tutoring,research paper help,do my homework,

https://www.homeworkping.com/Lecture note 2

Lecture note 2sreenu t

╠²

This document provides an overview of standards of measurement and discusses key concepts:

- Standards are classified as primary or secondary, with primary standards defining fundamental units and secondary standards calibrated against primary standards.

- Standard units discussed include the meter (length), kilogram (mass), second (time), Kelvin (temperature), candela (light intensity), mole (amount of substance), and ampere (electric current).

- Random and systematic errors are defined, with random errors averaging out over repeated measurements but systematic errors requiring correction. Significant figures and calculating relative/absolute errors are also covered.Errors and uncertainties

Errors and uncertaintiesbornalive

╠²

This is a lecture note on Error and its propagation. This slide can be very much useful for As level physics students. It is totally different from the presentation. I would like to name it as slides of lecture notes on Error(uncertainty), difference on precision and accuracy, difference on two types of error (systematic and random errors). Believe me it will help you to enhance your knowledge on Uncertainty and its propagarion.Errors and Error Measurements

Errors and Error MeasurementsMilind Pelagade

╠²

Thorough study of Experimental Errors occurred during experimentation using different experimental techniques.

A clear picture about techniques for error measurement is given in the presentation.EMI-Unit-1 Material.docx

EMI-Unit-1 Material.docxraviteja srinivasula

╠²

This document provides an introduction to instrumentation and measurement. It discusses:

1. The importance of measurement in science, engineering, and daily life. Measurement allows the study of natural phenomena and supports technological advancement.

2. Key concepts in instrumentation including transducers that convert physical quantities to electrical signals, and functional elements like sensing, signal conversion/manipulation, transmission, and display.

3. Performance characteristics of instruments including static characteristics like accuracy, precision, resolution, sensitivity, and errors, and dynamic characteristics related to rapidly changing measurements. Calibration is also discussed.

4. Sources of errors in measurement including gross errors from human mistakes, systematic errors from instruments, environments, and observations, and random errorsErrors in measurement

Errors in measurementRavinder Jarewal

╠²

The document discusses different types of errors that can occur in measurement. It describes gross errors, systematic errors like instrumental errors and environmental errors, and random errors. It also defines key terms used to analyze errors like limit of reading, greatest possible error, and discusses analyzing measurement data using statistical methods like the mean, standard deviation, variance and histograms. Measurement errors can occur due to issues like parallax, calibration, limits of the measuring device, and are analyzed statistically.Introduction to physics

Introduction to physicsCk Sal

╠²

Scalar quantities have magnitude only, such as length, time, temperature. Vector quantities have both magnitude and direction, such as displacement, velocity, force.

There are two main types of errors in measurement - systematic errors and random errors. Systematic errors consistently shift measurements in one direction, such as zero errors or calibration errors. Random errors vary unpredictably between measurements, caused by factors like human error or environmental changes. Precision refers to the consistency of measurements while accuracy refers to how close measurements are to the true value.Nursing Research Measurement errors.pptx

Nursing Research Measurement errors.pptxChinna Chadayan

╠²

This document discusses different types of errors that can occur in measurement. There are five main types of errors:

1) Gross errors are faults made by the person using the instrument, such as incorrect readings or recordings.

2) Systematic errors are due to problems with the instrument itself, environmental factors, or observational errors made by the observer.

3) Random errors remain after gross and systematic errors have been reduced and are due to unknown causes. Taking multiple readings and analyzing them statistically can help minimize random errors.

4) Absolute error is the difference between the expected and measured values.

5) Relative error expresses the error as a percentage of the real measurement.Nursing Research Measurement errors.pptx

Nursing Research Measurement errors.pptxChinna Chadayan

╠²

This document discusses different types of errors that can occur in measurement. There are five main types of errors:

1) Gross errors are faults made by the person using the instrument, such as incorrect readings or recordings.

2) Systematic errors are due to problems with the instrument itself, environmental factors, or observational errors made by the observer.

3) Random errors remain after gross and systematic errors have been reduced and are due to unknown causes. Taking multiple readings and analyzing them statistically can help minimize random errors.

4) Absolute error is the difference between the expected and measured values.

5) Relative error expresses the error as a percentage of the real measurement.errors of measurement and systematic errors

errors of measurement and systematic errorsDr. Hament Sharma

╠²

This document discusses measurement errors and uncertainty. It defines measurement as assigning a number and unit to a property using an instrument. Error is the difference between the measured value and true value. There are two main types of error: random error, which varies unpredictably, and systematic error, which remains constant or varies predictably. Sources of error include the measuring instrument and technique used. Uncertainty is the doubt about a measurement and is quantified with an interval and confidence level, such as 20 cm ┬▒1 cm at 95% confidence. Uncertainty is important for tasks like calibration where it must be reported.1.4 measurement

1.4 measurementKonilia Sual

╠²

1. Errors in measurement can be either systematic or random. Systematic errors consistently shift measurements in one direction, while random errors vary unpredictably between measurements.

2. Systematic errors can be reduced by careful experimentation and using multiple instruments, while random errors are reduced through repeat readings and calculating averages.

3. Precision refers to the consistency of measurements while accuracy refers to how close measurements are to the true value. Both can be improved by eliminating errors and using more sensitive instruments.Numerical approximation and solution of equations

Numerical approximation and solution of equationsRobinson

╠²

1. Numerical approximation involves finding approximate values that are close to the actual values of quantities. There are different types of errors that can occur due to approximation, such as truncation error and rounding error.

2. Accuracy refers to how close an approximate value is to the actual value, while precision describes how close repeated approximations are to each other. Greater accuracy means a lower absolute error, while greater precision means a lower standard deviation between repeated measurements.

3. For a numerical method, convergence means that repeated approximations get closer to the actual value with each iteration. Stability refers to the likelihood that a method will converge rather than diverge for a wide range of problems.Process dynamic control

Process dynamic controlSharvendra DK Omre

╠²

This document discusses types of errors, accuracy, sensitivity, resolution, and linearity in measurements. It defines random error, systematic error including environmental, instrumental and observational errors. Gross errors are discussed. Accuracy is defined as closeness to a true value. Sensitivity is a measure of output change for input change. Resolution is the ability to detect small changes. Linearity refers to how measurement bias is affected by the measurement range. First order response reaches steady state for a step input. Second order response can oscillate to a step input due to overshoot and damping effects.Errors in pharmaceutical analysis

Errors in pharmaceutical analysis Bindu Kshtriya

╠²

Errors in pharmaceutical analysis can be determinate (systematic) or indeterminate (random). Determinate errors are caused by faults in procedures or instruments and cause results to consistently be too high or low. Sources include improperly calibrated equipment, impure reagents, and analyst errors. Indeterminate errors are random and unavoidable, arising from limitations of instruments. Accuracy refers to closeness to the true value, while precision refers to reproducibility. Systematic errors can be minimized by calibrating equipment, analyzing standards, using independent methods, and blank determinations.The uncertainty of measurements

The uncertainty of measurementserwin marlon sario

╠²

This document discusses various sources of uncertainty in physics measurements, including incomplete definitions, unaccounted factors, environmental influences, instrument limitations, calibration errors, physical variations, drifts, response times, and parallax. It emphasizes that all measurements have some degree of uncertainty from multiple sources. Properly reporting uncertainty allows evaluation of experimental quality and comparison to other results. While the true value may not be known exactly, uncertainty analysis helps ascertain a measurement's accuracy and precision.Accuracy precision - resolution

Accuracy precision - resolutionMai An

╠²

1. Accuracy refers to how close a measurement is to the actual value, while precision describes the consistency of repeated measurements.

2. Measurement uncertainty comes from systematic errors in instruments and random errors from noise. Total uncertainty is calculated by combining the uncertainties.

3. Improving precision involves averaging measurements to reduce noise, but this may reduce bandwidth. Resolution is the smallest distinguishable difference in values.More from jhoyvanwilliams2 (9)

Green CHEM. Locating Industrial Plants.ppt

Green CHEM. Locating Industrial Plants.pptjhoyvanwilliams2

╠²

Green CHEM. Locating Industrial Plants.pptPhysics Csec Electricity 5th _Waves 2024.pptx

Physics Csec Electricity 5th _Waves 2024.pptxjhoyvanwilliams2

╠²

Physics Csec Electricity 5th _Waves 2024.pptxREVIEW OF PHYSICS Electric_Current_CSEC.pdf

REVIEW OF PHYSICS Electric_Current_CSEC.pdfjhoyvanwilliams2

╠²

REVIEW OF PHYSICS Electric_Current_CSEC.pdf17(2.14-3.2) BASICITY .AMINES, AMIDES.ppt

17(2.14-3.2) BASICITY .AMINES, AMIDES.pptjhoyvanwilliams2

╠²

17(2.14-3.2) BASICITY .AMINES, AMIDES.pptDeformation-Hookes Law and Elasticity.pptx

Deformation-Hookes Law and Elasticity.pptxjhoyvanwilliams2

╠²

Deformation-Hookes Law and Elasticity.pptxRecently uploaded (20)

AI, Tariffs and Supply Chains in Knowledge Graphs

AI, Tariffs and Supply Chains in Knowledge GraphsMax De Marzi

╠²

How tarrifs, supply chains and knowledge graphs combine.Gauges are a Pump's Best Friend - Troubleshooting and Operations - v.07

Gauges are a Pump's Best Friend - Troubleshooting and Operations - v.07Brian Gongol

╠²

No reputable doctor would try to conduct a basic physical exam without the help of a stethoscope. That's because the stethoscope is the best tool for gaining a basic "look" inside the key systems of the human body. Gauges perform a similar function for pumping systems, allowing technicians to "see" inside the pump without having to break anything open. Knowing what to do with the information gained takes practice and systemic thinking. This is a primer in how to do that.Best KNow Hydrogen Fuel Production in the World The cost in USD kwh for H2

Best KNow Hydrogen Fuel Production in the World The cost in USD kwh for H2Daniel Donatelli

╠²

The cost in USD/kwh for H2

Daniel Donatelli

Secure Supplies Group

Index

ŌĆó Introduction - Page 3

ŌĆó The Need for Hydrogen Fueling - Page 5

ŌĆó Pure H2 Fueling Technology - Page 7

ŌĆó Blend Gas Fueling: A Transition Strategy - Page 10

ŌĆó Performance Metrics: H2 vs. Fossil Fuels - Page 12

ŌĆó Cost Analysis and Economic Viability - Page 15

ŌĆó Innovations Driving Leadership - Page 18

ŌĆó Laminar Flame Speed Adjustment

ŌĆó Heat Management Systems

ŌĆó The Donatelli Cycle

ŌĆó Non-Carnot Cycle Applications

ŌĆó Case Studies and Real-World Applications - Page 22

ŌĆó Conclusion: Secure SuppliesŌĆÖ Leadership in Hydrogen Fueling - Page 27

Wireless-Charger presentation for seminar .pdf

Wireless-Charger presentation for seminar .pdfAbhinandanMishra30

╠²

Wireless technology used in chargerHow to Build a Maze Solving Robot Using Arduino

How to Build a Maze Solving Robot Using ArduinoCircuitDigest

╠²

Learn how to make an Arduino-powered robot that can navigate mazes on its own using IR sensors and "Hand on the wall" algorithm.

This step-by-step guide will show you how to build your own maze-solving robot using Arduino UNO, three IR sensors, and basic components that you can easily find in your local electronics shop.UNIT 1FUNDAMENTALS OF OPERATING SYSTEMS.pptx

UNIT 1FUNDAMENTALS OF OPERATING SYSTEMS.pptxKesavanT10

╠²

UNIT 1FUNDAMENTALS OF OPERATING SYSTEMS.pptxTurbocor Product and Technology Review.pdf

Turbocor Product and Technology Review.pdfTotok Sulistiyanto

╠²

High Efficiency Chiller System in HVACSachpazis: Foundation Analysis and Design: Single Piles

Sachpazis: Foundation Analysis and Design: Single PilesDr.Costas Sachpazis

╠²

Žü. ╬ÜŽÄŽāŽä╬▒Žé ╬Ż╬▒ŽćŽĆ╬¼╬Č╬ĘŽé: Foundation Analysis and Design: Single Piles

Welcome to this comprehensive presentation on "Foundation Analysis and Design," focusing on Single PilesŌĆöStatic Capacity, Lateral Loads, and Pile/Pole Buckling. This presentation will explore the fundamental concepts, equations, and practical considerations for designing and analyzing pile foundations.

We'll examine different pile types, their characteristics, load transfer mechanisms, and the complex interactions between piles and surrounding soil. Throughout this presentation, we'll highlight key equations and methodologies for calculating pile capacities under various conditions.How Engineering Model Making Brings Designs to Life.pdf

How Engineering Model Making Brings Designs to Life.pdfMaadhu Creatives-Model Making Company

╠²

This PDF highlights how engineering model making helps turn designs into functional prototypes, aiding in visualization, testing, and refinement. It covers different types of models used in industries like architecture, automotive, and aerospace, emphasizing cost and time efficiency.Structural QA/QC Inspection in KRP 401600 | Copper Processing Plant-3 (MOF-3)...

Structural QA/QC Inspection in KRP 401600 | Copper Processing Plant-3 (MOF-3)...slayshadow705

╠²

This presentation provides an in-depth analysis of structural quality control in the KRP 401600 section of the Copper Processing Plant-3 (MOF-3) in Uzbekistan. As a Structural QA/QC Inspector, I have identified critical welding defects, alignment issues, bolting problems, and joint fit-up concerns.

Key topics covered:

Ō£ö Common Structural Defects ŌĆō Welding porosity, misalignment, bolting errors, and more.

Ō£ö Root Cause Analysis ŌĆō Understanding why these defects occur.

Ō£ö Corrective & Preventive Actions ŌĆō Effective solutions to improve quality.

Ō£ö Team Responsibilities ŌĆō Roles of supervisors, welders, fitters, and QC inspectors.

Ō£ö Inspection & Quality Control Enhancements ŌĆō Advanced techniques for defect detection.

¤ōī Applicable Standards: GOST, KMK, SNK ŌĆō Ensuring compliance with international quality benchmarks.

¤ÜĆ This presentation is a must-watch for:

Ō£ģ QA/QC Inspectors, Structural Engineers, Welding Inspectors, and Project Managers in the construction & oil & gas industries.

Ō£ģ Professionals looking to improve quality control processes in large-scale industrial projects.

¤ōó Download & share your thoughts! Let's discuss best practices for enhancing structural integrity in industrial projects.

Categories:

Engineering

Construction

Quality Control

Welding Inspection

Project Management

Tags:

#QAQC #StructuralInspection #WeldingDefects #BoltingIssues #ConstructionQuality #Engineering #GOSTStandards #WeldingInspection #QualityControl #ProjectManagement #MOF3 #CopperProcessing #StructuralEngineering #NDT #OilAndGasTaykon-Kalite belgeleri

Taykon-Kalite belgeleriTAYKON

╠²

Kalite Politikam─▒z

Taykon ├ćelik i├¦in kalite, hayallerinizi bizlerle payla┼¤t─▒─¤─▒n─▒z an ba┼¤lar. Proje ├¦iziminden detaylar─▒n ├¦├Čz├╝m├╝ne, detaylar─▒n ├¦├Čz├╝m├╝nden ├╝retime, ├╝retimden montaja, montajdan teslime hayallerinizin ger├¦ekle┼¤ti─¤ini g├Črd├╝─¤├╝n├╝z ana kadar ge├¦en t├╝m a┼¤amalar─▒, ├¦al─▒┼¤anlar─▒, t├╝m teknik donan─▒m ve ├¦evreyi i├¦ine al─▒r KAL─░TE.15. Smart Cities Big Data, Civic Hackers, and the Quest for a New Utopia.pdf

15. Smart Cities Big Data, Civic Hackers, and the Quest for a New Utopia.pdfNgocThang9

╠²

Smart Cities Big Data, Civic Hackers, and the Quest for a New UtopiaPhyiscs 4th form - Errors_2023-2024 (1).pptx

- 1. Physics Sept 6th, 2023 Topic: Errors and accuracy Whatever you do, do it well

- 2. Errors

- 3. What is an error? A measure of the estimated difference between the observed or calculated value of a quantity and its true value. There are two types of errors that are commonly associated with measuring, (namely), 1. random 2. systematic errors.

- 4. Random errorr? Random Errors are errors that are due to the experimenter and can usually be improved upon. For example: a. Reaction time when using the stopwatch b. Parallax error c. Errors due to environment

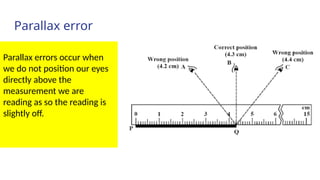

- 5. Parallax error Parallax errors occur when we do not position our eyes directly above the measurement we are reading as so the reading is slightly off.

- 6. Systematic Errors Systematic errors are errors due to the equipment which we are unable to fix or minimise. They will be in every reading we measure with the instrument. For example, If the stopwatch is 2 seconds fast or the triple beam balance does not zero properly. Or when we press the button on the stopwatch, there is a very, very small time delay for the stopwatch to respond.

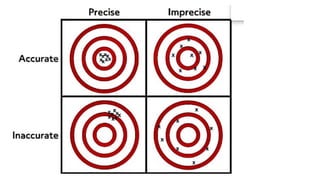

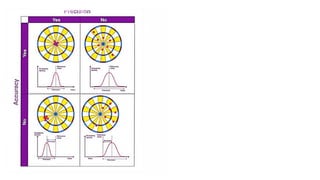

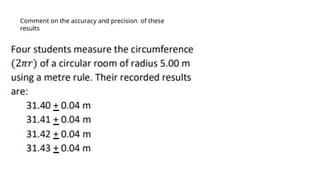

- 8. Accuracy and precision Accuracy is the closeness of agreement between a measured value and a true or accepted value. Measurement error is the amount of inaccuracy. Precision is a measure of how well a result can be determined (without reference to a theoretical or true value). It is the degree of consistency and agreement among independent measurements of the same quantity; also the reliability or reproducibility of the result. Accuracy depends on the experimenter while precision depends on the instrument. You cannot be more precise than your instrument. Nb Accuracy is how close a value is to the true value While Precision is the exactness of the value I.e as the unit gets smaller the value gets more precise.

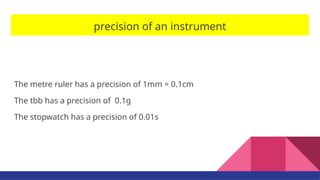

- 9. precision of an instrument The metre ruler has a precision of 1mm = 0.1cm The tbb has a precision of 0.1g The stopwatch has a precision of 0.01s

- 10. precision of an instrument The error associated with any value read from the instrument is 1Ōüä2 of the precision. However the error in a measured value is the precision. Explain.

- 14. Comment on the accuracy and precision of these results