RAJU CV

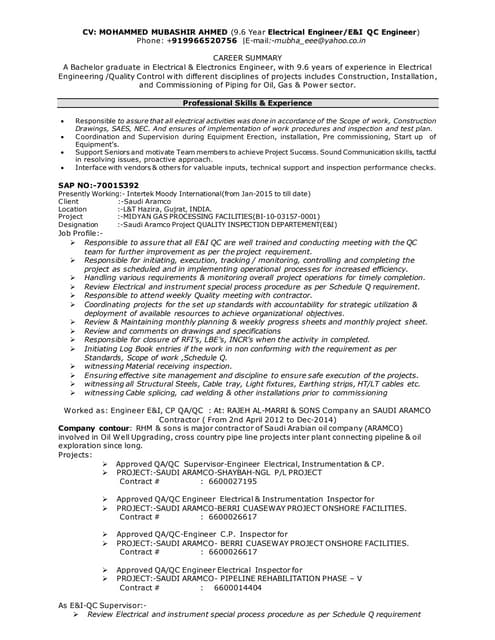

- 1. ALLADI PALLAPA RAJU QA/QC INSPECTOR CURRICULAM VITAE ALLADI PALLAPA RAJU E-mail: saisriram2009@gmail.com Mob: +65-90603119 Objectives and Goals:- Serve to the best of my knowledge and abilities and establish myself as an asset to the Organization. Experience Summary:- With more than 16 Years of working experience in QA/QC and involved in expediting & inspection of fabrication work of Bridge structures, Offshore drilling jack up rig and onshore structures, Oil & Gas fields, Pressure pipelines, Pressure vessels, Heat exchanger, Tank, Structural components, Petroleum & Refineries Industries. Have thorough knowledge & hands-on experience in performing, interpretation & evaluation of various NDT methods such as UT, MPT, LPT, VT & RT (Interpretation) as well as PAUT & Gate to Gate. Well conversant with various welding processes and various international code such ASME Section â V, VIII & Sec. IX, API â 1104, AWS D1.1, ASME- B 31.3, AWS D1.5, BS EN 473 etc. Educational Qualification:- ïž Diploma in Mechanical Engineering, from Singapore Technical Qualification:- ïž CSWIP 3.1 (Certified Welding Inspector by TWI, Cambridge, UK, and Certificate No: 69788, December 2012. ïž QMS Lead Auditor Conducted by (GIC) Guardian Independent Certification, ïž ASNT level-II in RT, UT, MT, PT and RTFI. ïž SAFETY COURSE NTUC Learning Hub Singapore (Shipyard Safety Supervisor Course May 2015) Experience Profile:- Organisation : Southern Inspection services Pte Ltd, Singapore Designation : QA/QC INSPECTOR Period : Present

- 2. ALLADI PALLAPA RAJU QA/QC INSPECTOR Organisation : Royscan Engineering Pte Limited, Singapore Designation : NDT / QA/QC INSPECTOR Period : Aug 2001 to Mar 2014 Client and Projects Executed at: Company : M/s. ABS Consulting. Project Period : Mar 2013 to Feb 2014 Project Name : Proposed Development at Tanjong Pagar (Client: Samsung) QA/QC Inspector Company : M/s. BUREAU VERITAS. Project Period : Oct 2012 to Feb 2013 Project Name : Zawtika (Client: PTTIEPI) QA/QC Inspector Company : M/s. Keppel Shipyard Ltd. Project Period : Apr 2011 to Sep 2012 Project Name : PLV-Castorone (Client: Saipem) QA/QC Inspector Company : M/s. Milan International Pte Ltd. Project Period : Jan 2010 to Mar 2011. Project Name : Marina Coastal Expressway C482 (Client: L.T.A) QA/QC Inspector Company : M/s. Rotary Engineering Pte Ltd. Project Period : Feb 2009 to Dec 2009 Project Name : SEPC-MEG PROJECT (Client: Foster Wheeler) QA/QC Inspector Company : M/s. Jurong Shipyard Ltd. Project Period : Dec 2007 to Sep 2008. Project Name : Petro Rig 1, Petro Rig 2 and Noble Danny Adkins QA/QC Inspector Company : M/s. Keppel Tuas. Project Period : Mar 2006 to Jun 2007. Project Name : Petrobras P-53 QA/QC/NDT Inspector Company : M/S Keppel Fels. Project Period : Mar 2004 to Feb 2006 NDT Inspector Project Company : M/S Malaysia Shipyard & Eng Sdn Bhd. Project Period : May 2003 to Feb 2004 (Malaysia) NDT Inspector)

- 3. ALLADI PALLAPA RAJU QA/QC INSPECTOR Project Company : M/S Keppel Shipyard Ltd. Project Period : Oct 2002 to Apr 2003 (Singapore) Project Name : FPSO MARLIMSUL NDT Inspector Project Company : M/S Jurong Shipyard Ltd Project Period : Aug 2001 to Sep 2002 (Singapore). Project Name : Petrobras P-47 NDT Inspector Duties & Responsibilities: ïž Liaise with production supervisor, NDT and certification supervisor, Discipline Engineer, Project Engineer, Operations Engineer, Field Engineer, certifying authority, customer. ïž Determine product conformity as per customer specification and relevant code/standard through independent inspection and tests in accordance with the Project Quality Plan. ïž Identify non conformity for rectification and assure final resolution. ïž Ensure all inspection results are documented and if non conformity exists documentation shall be raised to establish corrective and preventive action. ïž Provide interpretation of applicable code/specifications and customer requirements. Any deviation, clarification and waivers are deemed necessary, shall be notified to the supervisor for generating change management process such as site query, technical query, technical deviation, etc. ïž Co-ordinate interface with operations, certifying authority, Client assuring conformity to project specifications. ïž Exercise proactive approach in prevention of a problem by interaction with production, Engineers, Management personnel. ïž Preparation of internal punch list and clearance inspection during fabrication. ïž Witness of Hydro tests and Pneumatic tests of Piping. Co-ordination with civil/ construction departments for testing/ backfilling activities. ïž To carry out reinstatement of piping and report preparation. ïž To check and prepare orifice flange inspection and pipe flange alignment report. ïž To study the P&ID and other circuit diagrams in the test pack. Co-ordination with painting department for performing wrapping/ coating, holiday test, and maintaining QC reports. ïž To study the isometric drawing received from the clients and to identify the pipe lines and carry out the inspection work. ïž Monitoring the calibration of test instruments and equipments. ïž Assistance for the document control. ïž Preparation of RT selection list for the Daily Radiography works. Inspection and testing activities as per the inspection procedure. ïž To check the fit up stage prior and confirm that root gap, off set, bevel angle are with in acceptable limits. ïž To witness preheating process as per Saudi Aramco procedures. ïž Ensure Piping is as per the standard and specification. ïž Co- ordinates the different type of welding works.

- 4. ALLADI PALLAPA RAJU QA/QC INSPECTOR ïž To select the joint for the NDT as per the welder coverage and line class percentage. Maintaining of all inspection report and related documents in QA/ QC department. ïž Co-coordinating with client on a daily basis. ïž Control calibrated measuring and test equipment used on the project. ïž Preparation of punch list and clearance to next stage like Erection and painting. ïž Preparation of test packs and submit to the higher authorities. Co- ordinate with NDT for activities like radiographic testing, magnet particle testing, Ultrasonic testing, Phased array ultrasonic testing and penetrant testing. ïž Conduct all worker activities in the safe and environmental policies and procedure. ïž Fit-up and visual welding inspection of Structural welding and structural erections of wellhead and auxiliary oil and gas offshore platforms and Bridges according to AWS D1.1 ïž Check Inspection of raw material as per procurement order and reviewing of related procurement documents for traceability and conformance to mechanical /chemical properties in accordance with applicable Codes & standard like ASTM, ASME, AWS, BS, AND API, etc. ïž Inspection of filler rods, fluxes and shielding gases. Preparing IMIR (incoming material inspection report), ïž Witness Welder Qualification tests in association with the client. Conducting Weld Audit periodically to ensure the quality of the welding activity, Maintaining records of all welders and ensures their qualification continuity. ïž Continuously monitoring the performance of the welders. ïž Performing Welding Procedure Qualification Record (PQR) in case of variation in the essentials variable with existing PQR, as per international standards and additional requirement of client. Monitoring Welding activities, NDT, Mechanical Testing, Material Inspection, RT film interpretation and related documentation. ïž Inspection of the fit-ups in the in-process stage with respect to visual, dimensional and orientation compliance as per the approved drawings and specifications. Documentation control certificates & technical data as required by the customer such as NDT Reports, Final Inspection Reports, Calibration Records, and Welder Performance Certificates etc. (Visual/Dimensional Inspection Reports, Weld Map, WPS/PQR/WQRT, NDT Reports) ïž Review of Final Dossiers prior to acceptance of the Product. ïž Worked on various units inside the refinery that includes vapor distillation unit (VDU), motor spirit quality unit (MSQ), vist breaker unit (VBU), feed preparation unit (FPU), fluid catalytic cracker unit (FCCU), crude distillation unit (CDU), Hydrogen bullet unit etc .Able to carry out procedure qualification & performance qualification test for welding works, ïž Executing welding plans and carrying out quality control in every stage of production (according to WPS & PQR),, ïž Pre-Welding inspection such as bending, weld edge preparation, level angle, root face, root gap alignment. In process weld inspection such as travel speed, voltage, polarity, welding techniques, inter pass temperature, Pre heat and post weld heat treatment, ïž Post-Welding inspection such as visual check for arc strikes, welding defect, welding contour, weld width and final dimension check,

- 5. ALLADI PALLAPA RAJU QA/QC INSPECTOR ïž Visual Inspection Of Carbon Steel, Stainless steel and Alloy steel, Material verification, traceability, fit-up and visual welding inspection, Non-Destructive testing (NDT) inspection, Hydrostatic test and leak test, Conversant with various welding process, Structural welding and structural erections according to AWS D1.1, RTR pipe inspections and installation process according to quality procedure. ïž Conversant with ASME code section â II, V, IX, ASME B31.3, B31.5 and API 1104 Organisation : Techno Weld Industries, Visakhapatnam Designation : QA/QC INSPECTOR Period : Jan 1997 to June 2001 Clients & Projects Executed at: Bharat Heavy Plates & Vessels Limited, Visakhapatnam Hindustan Petroleum Corporation Limited, Visakhapatnam Hindustan Shipyard Limited, Visakhapatnam Nalco, Damanjodi-Orissa Coromondal Fertilizers, Visakhapatnam Nagarjuna Fertilizers, Kakinada Oil & Natural gas Commission, Kakinada Cairn Energy, Rava Offshore, Kakinada Duties & Responsibilities:- ïž Evaluation of materials documents based on project specifications requirements. ïž WPS, PQR preparations and welders qualification. ïž Making awareness about the welding by conducting tool box meetings. ïž Arranging NDT, witness and reporting to client for getting clearance. ïž Responsible for the inspection of materials delivered at site including fabricated materials. ïž Preparation of Company System Manual, Procedures. ïž Preparation of Projects Specific Quality manuals, quality assurance such as ïž Inspection test plans, Quality control procedures, method statements. ïž Fulfilling the requirements of Audit â ISO 9001 and maintaining the records as per the quality management systems. ïž Taking care of quality related activities like NDT of piping and pipeline as per ASME standards. ïž Planning, monitoring of all inspection activities. ïž Weld repair control by controlling the welding process and weld consumable control. ïž Ensuring implementation of Quality Control Plan, Procedure and Inspection & Test Plan. ïž Prepare inspection request prior to accept the construction piping / welding work, pressure testing and releasing of fabricated pipelines in order to prepare certification for the completed items.

- 6. ALLADI PALLAPA RAJU QA/QC INSPECTOR ïž Coordinate with construction, testing group, and QC department in the preparation test requirement of each pack and facilitate close out of any outstanding punch items before and after the pressure tests. ïž Evaluation of materials documents based on project specifications requirements. ïž Responsible on inspection of the proper orientation for all fabricated pipe with regards to isometric drawings, including visual inspection of all welding profiles and conducted an inspection for all welding materials that conform to WPS. ïž Responsible for the inspection of materials delivered at site including fabricated materials. ïž Ensuring implementation of Quality Control Plan, Procedure and Inspection & Test Plan. ïž Prepare inspection request prior to accept the construction piping / welding work, pressure testing and releasing of fabricated pipelines in order to prepare certification for the completed items. ïž Coordinate with construction, testing group, and QC department in the preparation test requirement of each pack and facilitate close out of any outstanding punch items before and after the pressure tests. ïž Check, monitoring of spools fabrications. ïž Documentation and recording of all testing activities, daily welding reports, weld repair rate, welders performance etc. ïž Co-ordinate with construction, testing group, and QC group in the preparation test requirement of each test pack. ïž Prepare and submit inspection reports of fit-ups, dimensional, visual, material summary for proper document and approval. Personal Profile: Name : ALLADI PALLAPA RAJU Fathers Name : Alladi Ramakrishna Date of birth : 05-08-1975 Marital Status : Married Present Address : ALLADI PALLAPA RAJU Block.No:243 #09-32, Bukit Batok East Avenue 5 Singapore 650243 Nationality : Indian Passport Details : Passport No: H0479449 Issue Date: 23/06/2009 Expiry Date: 22/06/2019 Languages known : English, Telugu &Tamil

- 7. ALLADI PALLAPA RAJU QA/QC INSPECTOR Palce: Singapore Date: (ALLADI PALLAPA RAJU)