Rnd

- 2. Research & Development / Engineering: Design Failure Mode Effect Analysis (DFMEA): What is DFMEA : DFMEA is a methodical approach used for identifying potential risks introduced in a new or changed design of a product/service. The Design FMEA initially identifies design functions, failure modes and their effects on the customer with corresponding severity ranking / danger of the effect. Then, causes and their mechanisms of the failure mode are identified. High probability causes, indicated by the occurrence ranking, may drive action to prevent or reduce the causeĪ»s impact on the failure mode. The detection ranking highlights the ability of specific tests to confirm the failure mode / causes are eliminated. The DFMEA also tracks improvements through Risk Priority Number (RPN) reductions. By comparing the before and after RPN, a history of improvement and risk mitigation can be chronicled. DFMEA Standards: ? AIAG (Automotive Industry Action Group) ? VDA (Verband Der Automobilindustrie) ? AIAG ©C VDA Harmonization DFMEA Pre-requisites as per AIAG:? Structure Tree & Function Tree ? Boundary Diagram (B ©C Diagram) ? Item Function Requirement List (IFRL) ? Parametric Diagram (P ©C Diagram) ? Robustness Check list ? DFMEA DFMEA Pre-requisites as per VDA: ? Function Specification ? Functional Analysis

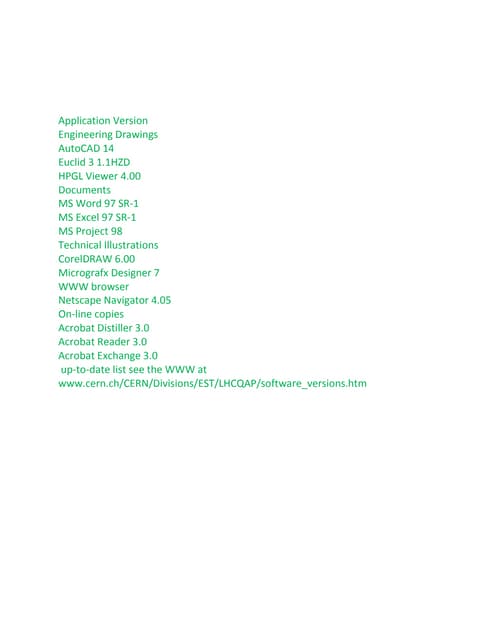

- 3. Research & Development / Engineering: 3D model and 2D drawing review: What is 3D model : 3D modeling (or three-dimensional modeling) is the process of developing a cad model of the component to visualize how the component will be after manufacturing. If it is a part model, we can assemble with the assembly to check the clearance with the surrounding components. What is 2D drawing: 2D drawing (or two-dimensional drawing) is the process of creating the multiple views of the component to visualize for manufacturing with the specified dimensions. Multiview is a type of orthographic projection. There are two conventions for using multiview, first-angle and third-angle. In both cases, the front or main side of the object is the same. First-angle is drawing the object sides based on where they land. Example, looking at the front side, rotate the object 90 degrees to the right. What is seen will be drawn to the right of the front side. Third-angle is drawing the object sides based on where they are. Example, looking at the front side, rotate the object 90 degrees to the right. What is seen is actually the left side of the object and will be drawn to the left of the front side. 3D model / 2D drawing Software:? Catia ? Creo (Pro E) ? Solid works ? Unigraphics NX 3D model types: ? Sketcher ? Part model ? Assembly model 2D model types: ? First Angle Projection ? Third Angle Projection

- 4. Research & Development / Engineering: Bill of Materials (BOM): What is BOM: A bill of materials or product structure (sometimes bill of material, BOM or associated list) is a list of the raw materials, sub-assemblies, intermediate assemblies, sub-components, parts and the quantities of each needed to manufacture an end product. Number of components and quantity in the BOM to be maintained very precisely. Types of BOM: ? Engineering BOM ? Manufacturing BOM Software used: It depends on the organization, BOM software will vary. ? Microsoft Excel ? SAP ? PLM Software (Matrix, Siemens, etc.,)

- 5. Research & Development / Engineering: Benchmarking / Competitive Analysis: What is Benchmarking: Identifying your competitors and evaluating their strategies to determine their strengths and weaknesses relative to those of your own product or service . A competitive analysis is a critical part of your company marketing plan. List of Activities: ? Identify current and future competitors in the market ? Finding market share ? Performing SWOT (Strengths Weakness, Opportunities and Threats) ? Build competition portfolio ? Plan strategies ? Execute strategies ? Follow up

- 6. Type of Control Description Symbols Form Straightness Flatness Circularity Cylindricity Profile Profile of a line Profile of a surface Orientation Perpendicularity Angularity Parallelism Location Symmetry Position Concentricity Runout Circular runout Total runout Research & Development / Engineering: Geometric Dimensioning and Tolerancing (GD&T): What is GD&T: Geometric Dimensioning and Tolerancing (GD&T) is a system for defining and communicating engineering tolerances. It uses a symbolic language on engineering drawings and computer-generated three-dimensional solid models that explicitly describes nominal geometry and its allowable variation. List of GD&T Types & Symbols: ? ? ? ? ? Form Profile Orientation Location Runout

- 7. Research & Development / Engineering: Chain of Dimensions / Stack up: What is Stack up: Geometric Dimensioning and Tolerancing (GD&T) is a system for defining and communicating engineering tolerances. It uses a symbolic language on engineering drawings and computer-generated three-dimensional solid models that explicitly describes nominal geometry and its allowable variation. Types of Stack up: ? 1D Chain of dimension ? 2D Chain of dimension

- 8. Research & Development / Engineering: Design Simulations / Design Calculations: What is Design Simulation: Computer-aided engineering (CAE) is the broad usage of computer software to aid in engineering analysis tasks. It includes finite element analysis (FEA), computational fluid dynamics (CFD), multibody dynamics (MBD), and optimization. CAE tools are very widely used in the automotive industry. In fact, their use has enabled the automakers to reduce product development cost and time while improving the safety, comfort, and durability of the vehicles they produce. The predictive capability of CAE tools has progressed to the point where much of the design verification is now done using computer simulations rather than physical prototype testing. CAE dependability is based upon all proper assumptions as inputs and must identify critical inputs (BJ). Even though there have been many advances in CAE, and it is widely used in the engineering field, physical testing is still a must. It is used for verification and model updating, to accurately define loads and boundary conditions and for final prototype sign-off. List of CAE Simulation software: ? Ansys ? Hypermesh ? Catia ? Nastran List of Other Simulation software: Many Industries have their own software, but most widely used software in the Automotive Industry for complete vehicle simulation ? Matlab ? LMS

- 9. Research & Development / Engineering: Design rule / Design Methodology: What is Design Rule / Design Methodology: Design rule or methodology is a identify or avoid the failures during the testing or validation. This design rule or methodology will help the designers to design the component as per the requirement during the initial component design. It will help the designer to reduce the time and first time perfect design. It will help the standardization of the design from one application to another application. List of Design Rule / Design Methodology: Every Industry have their own design rule or methodology during the development cycle. ? CAD design rule ? Drawing design rule ? Packaging design rule ? Performance design rule

- 10. Research & Development / Engineering: Design review / Drawing review: What is Design review: Design review is the systematic review to identify the risk and define the solution during the development stage of the project. Design review will be performed during the every stage of the project. What is Drawing review: Drawing review is the systematic review to identify the mistakes and define the solution during the drawing release. Drawing review will be performed during the every drawing revision. During the drawing review, all the dimensions and tolerances to be verified with Stack up calculation.

- 11. Research & Development / Engineering: VAVE (Value Analysis & Value Engineering): What is VAVE: Value Analysis/Value Engineering is a systematic and organized procedural decision-making process. It has been used in almost any kind of application. It helps people creatively generate alternatives to secure essential functions at the greatest worth as opposed to costs. Types of VAVE: ? Cost reduction ? Quality Improvement ? Weight reduction

- 12. Research & Development / Engineering: Waste Elimination: Any activity that does not add value to the product or service in the eyes of the customer is a waste. Poor product design such as the inclusion of fancy functions not required by the customer is a waste. A product design causing difficulty in manufacturing is a waste. Standardization reduces the planning and control efforts, the number of parts, and the inventory required. A poor product design without enough standardization leads to waste. The seven manufacturing wastes have been adapted into DE by several authors, a suggestion based on some of the attempts is shown in Figure 14, where the categories have been renamed, and an additional category has been added. 1. Overproduction of Information: ? Producing more information than needed ? Two different groups creating the same deliverable ? Delivering information too early ? Unsynchronized concurrent tasks 2. Over processing of Information: ? Processing information beyond the requirements, i.e. over-engineering ? Converting data back and forth between e.g. IT systems ? Working on redundant tasks ? Process variation 3. Miscommunication of Information: ? Large and long meetings, excessive email distribution lists ? Unnecessary hand-offs instead of continuous responsibility 4. Stockpiling of Information: ? Saving information due to frequent interruptions ? Creating large information repositories due to large batch sizes

- 13. Research & Development / Engineering: Waste Elimination: 5. Generative Defective Information: ? Making errors in component and architecture design ? Creating large information repositories due to large batch sizes 6. Correcting Information: ? Optimization iterations ? Reworking deliverables due to changing targets ? External quality enforcement 7. Waiting: ? Waiting for long lead time activities to finish ? Waiting due to unrealistic schedules ? Waiting for decisions and information 8. Unnecessary Movement of People: ? Obtaining information by walking up and down the hallway ? Travelling to redundant meetings ? Superficial reviews