Sewing workflow

- 1. T C B L E U P R O J E C T M A R I A A D E L E C I P O L L A E - Z A V O D Task 4.3: Laboratories

- 2. What is a ÔÇ£laboratoryÔÇØ? ´éù A laboratory is distinguished from a factory mainly by size and staff. ´éù Sometimes a laboratory is part of a bigger production chain. ´éù Some laboratories only adjust ÔÇ£ready to wearÔÇØ garments. ´éù Other laboratories lack expertise in cutting, so they use e.g. Burda Patterns (http://www.burdastyle.com/). ´éù There are also highly specialized laboratories such as those for men's tailoring o wedding gowns. ´éù In laboratories, each garment is made entirely by one operator or is island assembled (i.e. one worker makes collars, one makes cuffs, another hems, and so on). ´éù Some laboratories work on demand one off, some sew garments cut elsewhere according to sizes. ´éù In some laboratories, workers move freely between various workstations, talking to each other. ´éù Compared to factories, there is greater accuracy in assembly and finishing in laboratories. ´éù Laboratories produce a limited number of items for each model. ´éù Laboratories have great flexibility, because models can be changed with little effort. ´éù In laboratories, workers take responsibility for their work and have the satisfaction of being able to complete part or all of the production cycle.

- 3. The heart of the laboratory: sewing ´éù Today in Europe, brand brochures, vocational school textbooks, business reports, trade-association research papers and so on, place much emphasis on the garment cutting phase, where one is now able to cut thousands of clothes at once. However, little attention is paid to the description of what happens in the sewing department. ´éù Sometimes the advice is simply to ÔÇ£find a factoryÔÇØ, in the sense of finding a subcontractor abroad. ´éù There are many important activities in laboratories that we will need to explore further ÔÇô including cutting ÔÇô but it can be argued that the key issue for TCBL is to re-examine the potential of the role of sewing. An illustration from ÔÇ£Garment Construction GuideÔÇØ, Union Special Corporation, Technical Training centre, Huntly, Illinois (published during 1970ÔÇÖ, now difficult to find)

- 4. Innovation: everywhere except sewing ´éù Innovation in the clothing industry has mainly addressed pattern design, cutting, placement, ironing, embroidery, and quilting. ´éù Sewing has undergone little innovation since the invention of the sewing machine. ´éù Sewing is in fact highly knowledge intensive: the process is driven by the sewerÔÇÖs touch and ability to make many micro-decisions on the spot. ´éù Sewing therefore represents a significant innovation opportunity for TCBL.

- 5. From laboratories to assembly line ´éù The labor-intensive role of sewing creates a cost threshold, with attempts to lower it with assembly line production (and, more recently, attempts at robotisation). ´éù But the specificity of garment production makes it difficult to reduce it to standard assembly. ´éù In the laboratories of the past, knowledge was exchanged by talking while sewing: how can we recover that knowledge heritage? ´éù Each step in the sewing process is rich with knowledge: the speed and noise of industrial sewing machines is ultimately destroying this value.

- 6. ´éù We need to identify flexible forms of production, somewhere between the assembly line and artisan ateliers. ´éù Sewing is like cooking: recipes for the same cake may differ, and people enjoy exchanging them. ´éù Still, there is a tendency to ask for step by step instructions, even though ultimately everyone adds their personal touch (if nothing else to avoid boredom). ´éù Sewing is ripe for promotion as a ÔÇ£desirableÔÇØ activity (think of the impact of MasterChef on cooking). We may not all become tailors, but we would pay greater respect for fine garments. The social dimension of sewing

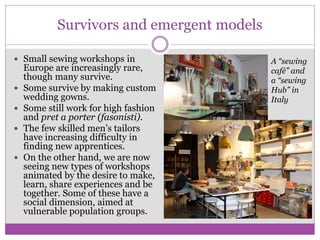

- 7. Survivors and emergent models ´éù Small sewing workshops in Europe are increasingly rare, though many survive. ´éù Some survive by making custom wedding gowns. ´éù Some still work for high fashion and pret a porter (fasonisti). ´éù The few skilled menÔÇÖs tailors have increasing difficulty in finding new apprentices. ´éù On the other hand, we are now seeing new types of workshops animated by the desire to make, learn, share experiences and be together. Some of these have a social dimension, aimed at vulnerable population groups. A ÔÇ£sewing caf├®ÔÇØ and a ÔÇ£sewing HubÔÇØ in Italy

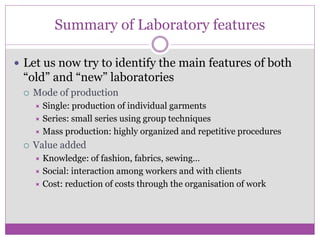

- 8. Summary of Laboratory features ´éù Let us now try to identify the main features of both ÔÇ£oldÔÇØ and ÔÇ£newÔÇØ laboratories ´éí Mode of production ´âÀ Single: production of individual garments ´âÀ Series: small series using group techniques ´âÀ Mass production: highly organized and repetitive procedures ´éí Value added ´âÀ Knowledge: of fashion, fabrics, sewingÔǪ ´âÀ Social: interaction among workers and with clients ´âÀ Cost: reduction of costs through the organisation of work

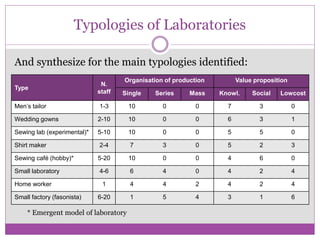

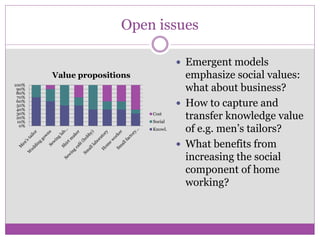

- 9. Typologies of Laboratories Type N. staff Organisation of production Value proposition Single Series Mass Knowl. Social Lowcost MenÔÇÖs tailor 1-3 10 0 0 7 3 0 Wedding gowns 2-10 10 0 0 6 3 1 Sewing lab (experimental)* 5-10 10 0 0 5 5 0 Shirt maker 2-4 7 3 0 5 2 3 Sewing caf├® (hobby)* 5-20 10 0 0 4 6 0 Small laboratory 4-6 6 4 0 4 2 4 Home worker 1 4 4 2 4 2 4 Small factory (fasonista) 6-20 1 5 4 3 1 6 And synthesize for the main typologies identified: * Emergent model of laboratory

- 10. Open issues ´éù Emergent models emphasize social values: what about business? ´éù How to capture and transfer knowledge value of e.g. menÔÇÖs tailors? ´éù What benefits from increasing the social component of home working? 0% 10% 20% 30% 40% 50% 60% 70% 80% 90% 100% Value propositions Cost Social Knowl.