Study on manual pattern making of a given T-shirt.

0 likes976 views

1. The document describes the process of manually making patterns for a T-shirt from measurements. Key steps included selecting a standard size, measuring dimensions, plotting points on graph paper, connecting points to form shapes, and duplicating patterns for the front/back and sleeves. 2. Patterns were made for the front, back, and sleeves of a size L t-shirt by measuring dimensions from a technical specification sheet and plotting corresponding points and lines on graph paper. 3. Manual pattern making provides an understanding of garment design and dimensions that can be used to estimate fabric costs and assess garment design.

1 of 9

Download to read offline

Recommended

Study on body measurement of a basic shirt | Body measurement of a basic shirt

Study on body measurement of a basic shirt | Body measurement of a basic shirt Md Rakibul Hassan

╠²

Study On Body Measurement Of A Basic ShirtStudy on Marker Making of a Basic Shirt | Marker Making Of a Basic Shirt

Study on Marker Making of a Basic Shirt | Marker Making Of a Basic ShirtMd Rakibul Hassan

╠²

Study on Marker Making of a Basic Shirt Study on Flatlock & Overlock Sewing Machine | Overlock Machine | Flatlock Mac...

Study on Flatlock & Overlock Sewing Machine | Overlock Machine | Flatlock Mac...Md Rakibul Hassan

╠²

Study on Flatlock & Overlock Sewing MachineTerry fabric

Terry fabricµ»ģ ķÖł

╠²

Terry fabric is a knitted fabric with ring yarn or terry covering at one or both sides. It belongs to one of the fancy knitted fabrics. Terry fabric is characterized by soft touch, thick texture, excellent water absorption and heat retention. Terry fabric can be divided into single-sided and double-sided terry loop fabrics. The terry can form pattern effect on the knitting surface distributed according to some certain rules. Terry fabric after shearing or other process can be turned into fleece fabric or velvet fabric.

Study on desizing on cotton fabric with acid

Study on desizing on cotton fabric with acidAbdur Rahman Nasim

╠²

This lab report summarizes a study on desizing cotton fabric with acid. The report was submitted by Abdur Rahman Nasim, student ID 163014002, to Md. Mahbubur Rahman, S. Lecturer and Program Coordinator in the Department of Textile Engineering at Green University of Bangladesh. The work was conducted on May 18th, 2018 and the report was submitted on May 25th, 2018 for the Textile Coloration I Lab course.Study on different components of a basic woven shirt | Different Component of...

Study on different components of a basic woven shirt | Different Component of...Md Rakibul Hassan

╠²

Study On Different Components Of A Basic Woven ShirtPlain Single Jersey Fabric.pptx

Plain Single Jersey Fabric.pptxRashedulIslam608777

╠²

1. Plain or single jersey is the simplest type of weft knitted fabric produced using a single set of needles.

2. It has a V-shape pattern on the technical face and interlocking semi-circles on the technical back.

3. Single jersey fabric is produced using a plain circular latch needle machine, which uses a single set of latch needles to form loops.Double lift and single cylinder

Double lift and single cylinderashutosh2229

╠²

This document summarizes the double lift and single cylinder (DLSC) jacquard shedding system. It explains that in a DLSC jacquard, each yarn end is controlled by two hooks attached to a single needle, allowing the end to be lifted or lowered independently over two picks. It describes how two sets of knives move in opposite phases to control the two hooks and raise or lower each end. The DLSC jacquard produces a semi-open shed and allows the cylinder to turn only every other pick, unlike a single lift single cylinder jacquard.Special Yarns

Special YarnsMinhazul Hassan

╠²

The document introduces various types of special or fancy yarns. It begins by explaining that fancy yarns are produced through spinning, twisting, wrapping and other processes to create unique textures and optical effects. Some types of fancy yarns mentioned include marl yarn, spiral yarn, knop yarn, slub yarn, fasciated yarn, tape yarn, chainette yarn, and ribbon yarns. Each type is then defined and its uses or production process described. The document aims to provide an overview of different specialty yarns beyond basic spun yarns.175035 apparel lab 03

175035 apparel lab 03Mahbubay Rabbani Mim

╠²

This lab report summarizes the student's study of straight knife and round knife cutting machines. The straight knife machine uses a straight blade to cut large pieces and curves, while the round knife machine uses a round blade and is better for small-scale cutting and gentle curves. Key differences are that the straight knife can cut fabrics from any angle, has higher productivity, but requires more skill, while the round knife is easier to use but can only cut at 90 degree angles. Both machines require regular blade sharpening and cleaning to maintain optimal performance.Fully Fashion Knitwear

Fully Fashion KnitwearKhaled MD. Ridwan

╠²

This document discusses different types of knitted structures used in fully fashioned knitwear production. It defines weaving and the three basic weave types. It then defines knitting as the interlocking of yarn loops to form a structure. Different knitted structures are discussed, including single jersey, rib, and double jersey stitches. The key properties, identification features, and end uses of each structure are provided. Fully fashioning is defined as a method of shaping knitted structures by increasing or decreasing wales or needles. The advantages and disadvantages of fully fashioning are also summarized.Study on Hand Sock Circular Knitting Machine

Study on Hand Sock Circular Knitting MachineNazmulHasanAnan

╠²

This document describes an experiment conducted on a hand sock circular knitting machine. It includes a diagram of the yarn path, specifications of the machine, descriptions of the main parts, and the working principle. The objectives are to understand the machine's operating system, functions, and loop formation. The procedure explains how to thread the yarn and rotate the handle to form loops around the cylinder to knit a sock. Care must be taken during operation to avoid missing loops. The conclusion discusses that this simple, manual machine can be used to start a small business producing socks.Feeder stripe, Auto stripe, Engineering stripe

Feeder stripe, Auto stripe, Engineering stripeMd Nazmul Huda Shuvo

╠²

This document summarizes the differences between feeder stripes, engineering stripes, and auto stripes in knitted fabrics. It explains that:

Feeder stripes are small repeating patterns less than 1.9 inches that can be produced on most circular knitting machines at low cost. Engineering stripes are large non-repeating patterns across the whole garment produced using special finger devices that increase costs. Auto stripes are repeating patterns greater than 1.9 inches that require computers and special finger machines, resulting in higher costs than feeder stripes. The document also discusses when auto stripes are needed over feeder stripes and the invention of multi-feeder machines to reduce auto stripe machine use.Study on Flat Bed Knitting Machine

Study on Flat Bed Knitting MachineNazmulHasanAnan

╠²

This document is an 11-page lab report on studying a flat bed knitting machine. It includes diagrams of the machine's yarn path, needle beds arranged in a V formation, and cam carriage system. The report describes the machine parts like the needle beds, yarn carriers, and different cams. It explains the knitting action where the needle butts are lifted and lowered by the cam system to transfer stitches and form new loops. The conclusion states that this experiment provided an introduction to flat bed knitting machine operations and settings that could help with industrial applications.Jute spinning assingnment_MD. SALIM RANA_DUET

Jute spinning assingnment_MD. SALIM RANA_DUETSaLim Rana

╠²

This document provides information about the jute spinning process. It discusses the objectives of spinning which are to reduce the weight of sliver, impart twist to form yarn, and wind the yarn onto bobbins. There are two main types of spinning - sliver spinning which produces yarn directly from sliver, and roving spinning which produces finer yarn from roving. The main tasks of the spinning frame are drafting, twisting, and winding. Drafting systems include slip draft, apron draft, and V-grooved roller draft. Twisting is imparted by the flyers and winding occurs on bobbins. The document also discusses machine parts, operations, and quality checks.basics-of-knitting-purl-and-interlock-fabric

basics-of-knitting-purl-and-interlock-fabricShahbazAhmad736457

╠²

This document discusses purl and interlock knit fabrics. It begins by defining purl fabric as having alternating knit and purl courses that create loops in opposite directions. Purl fabric is produced on special purl machines using double-headed needles that transfer between beds. Interlock fabric is made from two interlocked 1x1 rib structures that create a reversible fabric with technical faces on both sides. Interlock is produced on circular or flatbed machines using long and short needles and two feeders to knit separate half courses. Examples of applications for each fabric type are given.An assignment on Dobby and Jacquard loom

An assignment on Dobby and Jacquard loom ABDUL HAMID

╠²

The document discusses Dobby and Jacquard looms. It describes a Dobby loom as using a dobby device to control the warp threads and can be operated manually or by computer. It lists the main parts of a Dobby loom. It then explains that a Jacquard loom controls a large number of warp threads individually using a pattern card to produce complex designs without heald shafts. It notes the advantages of a Jacquard shedding system for producing intricate patterns by controlling each warp thread.Finihing machine

Finihing machineMd. Mazadul Hasan Shishir

╠²

This document provides information about various finishing machines used after fabric production. It describes the slitting machine, which opens tubular fabric into open width. It also describes the squeezing machine, which extracts water from dyed fabric. Finally, it outlines the stenter machine, dryer machine, and hot air circulation systems, which apply heat to dry fabrics and set chemicals. The main purpose of these machines is to finish fabrics by opening, squeezing, drying, and setting them for further processing or end use. Fabric cutting Machine

Fabric cutting MachineMd. Mazadul Hasan Shishir

╠²

This document provides an overview of various fabric cutting methods used in the garment industry. It begins with an introduction to the purpose of fabric cutting and requirements for cutting. It then describes several cutting methods including manual (hand scissors, power knives), computerized (computer-controlled knife cutting, laser beam cutting, water jet cutting, plasma torch cutting), and their advantages and disadvantages. Popular garment cutting machine manufacturers are listed at the end.Needle Loop & Sinker Loop

Needle Loop & Sinker LoopAmirul Eahsan

╠²

Needle loop refers to the upper part of the knitted loop formed by the needle drawing yarn. There are three main types of needles used. Sinker loop refers to the lower part that connects two adjacent needle loops in the same course.

Sinker is a thin metal plate that assists with loop formation, holding loops down, and pushing fabric forward between needle movements. It plays an important role in restricting loop movement and supporting the fabric.

Needle loop and sinker loop are the two vital components that make up each stitch in knitting and understanding the difference between them is important for knitting technology.Study on Dyeing of Cotton Fabric with Vat Dyes.docx

Study on Dyeing of Cotton Fabric with Vat Dyes.docxMostafizur Rahman

╠²

Vat dyes are insoluble in water but can be converted to a water-soluble leuco compound using a reducing agent in an alkaline solution, allowing them to dye cotton fabric. This study examined dyeing cotton with vat dyes to provide the desired color and obscure the fabric surface while meeting market designs and improving durability. The dyeing process involved creating a leuco compound at 70C for 15 minutes using 5% dye, sodium hydroxide, sodium carbonate, and other chemicals to bond the dye to the cotton fibers.Knitting technology

Knitting technologyAboni Knit Wear Ltd ( Babylon Group)

╠²

Dear Viewers ,

Good News to you.

Here I Attach a Assignment To you. Its helped to u make a Assignment in Knit Technology.

Tnx to all. fabric manufacturing technology-1

fabric manufacturing technology-1Md. Mazadul Hasan Shishir

╠²

1) A textile is a woven fabric made by interlacing warp and weft threads. Textiles now also refer to fibers, yarns and products made from them.

2) Weaving produces fabric by intersecting the warp (lengthwise) and weft (crosswise) threads. Yarn preparation involves winding yarn onto packages to facilitate weaving and removing faults.

3) Different types of fabrics include woven, knitted, non-woven and special fabrics. Proper yarn preparation and tension are important to produce good quality fabric during weaving.Important parts on ring frame

Important parts on ring frameMdibrahimkhalil31

╠²

This presentation summarizes the important parts of a ring frame machine. It discusses the main operations of the ring frame as creeling, drafting, twisting, winding and doffing. It then describes the main parts of the ring frame such as the roving bobbin, roving, creel, guide rail, drafting arrangement, yarn, yarn guide, spindle, traveler and ring. Diagrams are included to illustrate the condenser, apron, ring and traveler, spindle and lappet. The presentation provides an overview of the key components and processes involved in ring frame spinning.Flatlock stitches and its Mechanisms

Flatlock stitches and its MechanismsUniversal institute of fashion technology

╠²

Flat lock machines are specialized, high-speed machines that use two or more needle threads to form stitches by passing through fabric and interlocking on the top and bottom sides. They have multiple needles, loopers, and spreaders and can sew at speeds up to 6000 SPM. Flat lock machines are mainly used for sewing knitted garments but can also be used for woven fabrics. They require numerous thread types and adjustments to operate properly.Faults in the Knitted Fabrics

Faults in the Knitted FabricsÓ”£Ó¦üÓ”¼Ó”ŠÓ¦¤Ó¦ćÓ”░ Ó”åÓ”╣Ó”«Ó¦ćÓ”” Ó”żÓ¦ŹÓ”¼Ó”╣Ó”Š

╠²

This document discusses various types of defects that can occur in knitted fabrics, including yarn-related defects, knitting element defects, machine setting defects, dyeing defects, and finishing defects. Specific defects are defined such as drop stitches, barriness, imperfections, and spirality. The causes and remedies are provided for each defect. In conclusion, detecting faults during knitted fabric production is important for quality and productivity, and identifying the source and solutions for defects can help knitters overcome faults.Needle & cam arrangement of knit fabric

Needle & cam arrangement of knit fabricMd. Mazadul Hasan Shishir

╠²

This document provides contact information for Mazadul Hasan sheshir, a student in the 13th batch of the Wet Processing Technology program at Southeast University in Bangladesh. It lists his student ID, email address, and the department and address for Southeast University's Department of Textile Engineering.Terry-a pile fabric

Terry-a pile fabricshivraj jaiswal

╠²

Pile fabrics: Manufacturing methods include woven pile fabric formation & others methods such as knit pile fabric, tufted pile fabrics etc. A "Terry" or a "Terry Towel" as is generally known is a woven pile fabric formed by slack tension weave process. of weaving.Study on pattern making of a given T-shirt using CAD.

Study on pattern making of a given T-shirt using CAD.NazmulHasanAnan

╠²

1. The document describes an experiment on pattern making of a T-shirt using CAD software.

2. The steps taken include opening CAD software, drawing rectangles and curves to design the neck, shoulders, armholes and sleeves, adjusting patterns, unfolding sleeves, and renaming the final pattern.

3. While no final pattern is shown due to pandemic restrictions, the document outlines the process of computer-aided pattern making and highlights its benefits over manual methods.Study on grading the develop pattern in CAD.

Study on grading the develop pattern in CAD.NazmulHasanAnan

╠²

1. The document describes an experiment on grading patterns in CAD software. It involves taking a master pattern for a T-shirt and grading it to produce patterns of different sizes.

2. Key steps in the grading process include inputting measurement changes between sizes into a grading table, copying grading from the front pattern to the back, and adjusting sleeve lengths and widths.

3. The result is a set of graded patterns for a T-shirt in various sizes that are produced accurately and quickly using CAD software compared to manual grading methods.More Related Content

What's hot (20)

Special Yarns

Special YarnsMinhazul Hassan

╠²

The document introduces various types of special or fancy yarns. It begins by explaining that fancy yarns are produced through spinning, twisting, wrapping and other processes to create unique textures and optical effects. Some types of fancy yarns mentioned include marl yarn, spiral yarn, knop yarn, slub yarn, fasciated yarn, tape yarn, chainette yarn, and ribbon yarns. Each type is then defined and its uses or production process described. The document aims to provide an overview of different specialty yarns beyond basic spun yarns.175035 apparel lab 03

175035 apparel lab 03Mahbubay Rabbani Mim

╠²

This lab report summarizes the student's study of straight knife and round knife cutting machines. The straight knife machine uses a straight blade to cut large pieces and curves, while the round knife machine uses a round blade and is better for small-scale cutting and gentle curves. Key differences are that the straight knife can cut fabrics from any angle, has higher productivity, but requires more skill, while the round knife is easier to use but can only cut at 90 degree angles. Both machines require regular blade sharpening and cleaning to maintain optimal performance.Fully Fashion Knitwear

Fully Fashion KnitwearKhaled MD. Ridwan

╠²

This document discusses different types of knitted structures used in fully fashioned knitwear production. It defines weaving and the three basic weave types. It then defines knitting as the interlocking of yarn loops to form a structure. Different knitted structures are discussed, including single jersey, rib, and double jersey stitches. The key properties, identification features, and end uses of each structure are provided. Fully fashioning is defined as a method of shaping knitted structures by increasing or decreasing wales or needles. The advantages and disadvantages of fully fashioning are also summarized.Study on Hand Sock Circular Knitting Machine

Study on Hand Sock Circular Knitting MachineNazmulHasanAnan

╠²

This document describes an experiment conducted on a hand sock circular knitting machine. It includes a diagram of the yarn path, specifications of the machine, descriptions of the main parts, and the working principle. The objectives are to understand the machine's operating system, functions, and loop formation. The procedure explains how to thread the yarn and rotate the handle to form loops around the cylinder to knit a sock. Care must be taken during operation to avoid missing loops. The conclusion discusses that this simple, manual machine can be used to start a small business producing socks.Feeder stripe, Auto stripe, Engineering stripe

Feeder stripe, Auto stripe, Engineering stripeMd Nazmul Huda Shuvo

╠²

This document summarizes the differences between feeder stripes, engineering stripes, and auto stripes in knitted fabrics. It explains that:

Feeder stripes are small repeating patterns less than 1.9 inches that can be produced on most circular knitting machines at low cost. Engineering stripes are large non-repeating patterns across the whole garment produced using special finger devices that increase costs. Auto stripes are repeating patterns greater than 1.9 inches that require computers and special finger machines, resulting in higher costs than feeder stripes. The document also discusses when auto stripes are needed over feeder stripes and the invention of multi-feeder machines to reduce auto stripe machine use.Study on Flat Bed Knitting Machine

Study on Flat Bed Knitting MachineNazmulHasanAnan

╠²

This document is an 11-page lab report on studying a flat bed knitting machine. It includes diagrams of the machine's yarn path, needle beds arranged in a V formation, and cam carriage system. The report describes the machine parts like the needle beds, yarn carriers, and different cams. It explains the knitting action where the needle butts are lifted and lowered by the cam system to transfer stitches and form new loops. The conclusion states that this experiment provided an introduction to flat bed knitting machine operations and settings that could help with industrial applications.Jute spinning assingnment_MD. SALIM RANA_DUET

Jute spinning assingnment_MD. SALIM RANA_DUETSaLim Rana

╠²

This document provides information about the jute spinning process. It discusses the objectives of spinning which are to reduce the weight of sliver, impart twist to form yarn, and wind the yarn onto bobbins. There are two main types of spinning - sliver spinning which produces yarn directly from sliver, and roving spinning which produces finer yarn from roving. The main tasks of the spinning frame are drafting, twisting, and winding. Drafting systems include slip draft, apron draft, and V-grooved roller draft. Twisting is imparted by the flyers and winding occurs on bobbins. The document also discusses machine parts, operations, and quality checks.basics-of-knitting-purl-and-interlock-fabric

basics-of-knitting-purl-and-interlock-fabricShahbazAhmad736457

╠²

This document discusses purl and interlock knit fabrics. It begins by defining purl fabric as having alternating knit and purl courses that create loops in opposite directions. Purl fabric is produced on special purl machines using double-headed needles that transfer between beds. Interlock fabric is made from two interlocked 1x1 rib structures that create a reversible fabric with technical faces on both sides. Interlock is produced on circular or flatbed machines using long and short needles and two feeders to knit separate half courses. Examples of applications for each fabric type are given.An assignment on Dobby and Jacquard loom

An assignment on Dobby and Jacquard loom ABDUL HAMID

╠²

The document discusses Dobby and Jacquard looms. It describes a Dobby loom as using a dobby device to control the warp threads and can be operated manually or by computer. It lists the main parts of a Dobby loom. It then explains that a Jacquard loom controls a large number of warp threads individually using a pattern card to produce complex designs without heald shafts. It notes the advantages of a Jacquard shedding system for producing intricate patterns by controlling each warp thread.Finihing machine

Finihing machineMd. Mazadul Hasan Shishir

╠²

This document provides information about various finishing machines used after fabric production. It describes the slitting machine, which opens tubular fabric into open width. It also describes the squeezing machine, which extracts water from dyed fabric. Finally, it outlines the stenter machine, dryer machine, and hot air circulation systems, which apply heat to dry fabrics and set chemicals. The main purpose of these machines is to finish fabrics by opening, squeezing, drying, and setting them for further processing or end use. Fabric cutting Machine

Fabric cutting MachineMd. Mazadul Hasan Shishir

╠²

This document provides an overview of various fabric cutting methods used in the garment industry. It begins with an introduction to the purpose of fabric cutting and requirements for cutting. It then describes several cutting methods including manual (hand scissors, power knives), computerized (computer-controlled knife cutting, laser beam cutting, water jet cutting, plasma torch cutting), and their advantages and disadvantages. Popular garment cutting machine manufacturers are listed at the end.Needle Loop & Sinker Loop

Needle Loop & Sinker LoopAmirul Eahsan

╠²

Needle loop refers to the upper part of the knitted loop formed by the needle drawing yarn. There are three main types of needles used. Sinker loop refers to the lower part that connects two adjacent needle loops in the same course.

Sinker is a thin metal plate that assists with loop formation, holding loops down, and pushing fabric forward between needle movements. It plays an important role in restricting loop movement and supporting the fabric.

Needle loop and sinker loop are the two vital components that make up each stitch in knitting and understanding the difference between them is important for knitting technology.Study on Dyeing of Cotton Fabric with Vat Dyes.docx

Study on Dyeing of Cotton Fabric with Vat Dyes.docxMostafizur Rahman

╠²

Vat dyes are insoluble in water but can be converted to a water-soluble leuco compound using a reducing agent in an alkaline solution, allowing them to dye cotton fabric. This study examined dyeing cotton with vat dyes to provide the desired color and obscure the fabric surface while meeting market designs and improving durability. The dyeing process involved creating a leuco compound at 70C for 15 minutes using 5% dye, sodium hydroxide, sodium carbonate, and other chemicals to bond the dye to the cotton fibers.Knitting technology

Knitting technologyAboni Knit Wear Ltd ( Babylon Group)

╠²

Dear Viewers ,

Good News to you.

Here I Attach a Assignment To you. Its helped to u make a Assignment in Knit Technology.

Tnx to all. fabric manufacturing technology-1

fabric manufacturing technology-1Md. Mazadul Hasan Shishir

╠²

1) A textile is a woven fabric made by interlacing warp and weft threads. Textiles now also refer to fibers, yarns and products made from them.

2) Weaving produces fabric by intersecting the warp (lengthwise) and weft (crosswise) threads. Yarn preparation involves winding yarn onto packages to facilitate weaving and removing faults.

3) Different types of fabrics include woven, knitted, non-woven and special fabrics. Proper yarn preparation and tension are important to produce good quality fabric during weaving.Important parts on ring frame

Important parts on ring frameMdibrahimkhalil31

╠²

This presentation summarizes the important parts of a ring frame machine. It discusses the main operations of the ring frame as creeling, drafting, twisting, winding and doffing. It then describes the main parts of the ring frame such as the roving bobbin, roving, creel, guide rail, drafting arrangement, yarn, yarn guide, spindle, traveler and ring. Diagrams are included to illustrate the condenser, apron, ring and traveler, spindle and lappet. The presentation provides an overview of the key components and processes involved in ring frame spinning.Flatlock stitches and its Mechanisms

Flatlock stitches and its MechanismsUniversal institute of fashion technology

╠²

Flat lock machines are specialized, high-speed machines that use two or more needle threads to form stitches by passing through fabric and interlocking on the top and bottom sides. They have multiple needles, loopers, and spreaders and can sew at speeds up to 6000 SPM. Flat lock machines are mainly used for sewing knitted garments but can also be used for woven fabrics. They require numerous thread types and adjustments to operate properly.Faults in the Knitted Fabrics

Faults in the Knitted FabricsÓ”£Ó¦üÓ”¼Ó”ŠÓ¦¤Ó¦ćÓ”░ Ó”åÓ”╣Ó”«Ó¦ćÓ”” Ó”żÓ¦ŹÓ”¼Ó”╣Ó”Š

╠²

This document discusses various types of defects that can occur in knitted fabrics, including yarn-related defects, knitting element defects, machine setting defects, dyeing defects, and finishing defects. Specific defects are defined such as drop stitches, barriness, imperfections, and spirality. The causes and remedies are provided for each defect. In conclusion, detecting faults during knitted fabric production is important for quality and productivity, and identifying the source and solutions for defects can help knitters overcome faults.Needle & cam arrangement of knit fabric

Needle & cam arrangement of knit fabricMd. Mazadul Hasan Shishir

╠²

This document provides contact information for Mazadul Hasan sheshir, a student in the 13th batch of the Wet Processing Technology program at Southeast University in Bangladesh. It lists his student ID, email address, and the department and address for Southeast University's Department of Textile Engineering.Terry-a pile fabric

Terry-a pile fabricshivraj jaiswal

╠²

Pile fabrics: Manufacturing methods include woven pile fabric formation & others methods such as knit pile fabric, tufted pile fabrics etc. A "Terry" or a "Terry Towel" as is generally known is a woven pile fabric formed by slack tension weave process. of weaving.Similar to Study on manual pattern making of a given T-shirt. (20)

Study on pattern making of a given T-shirt using CAD.

Study on pattern making of a given T-shirt using CAD.NazmulHasanAnan

╠²

1. The document describes an experiment on pattern making of a T-shirt using CAD software.

2. The steps taken include opening CAD software, drawing rectangles and curves to design the neck, shoulders, armholes and sleeves, adjusting patterns, unfolding sleeves, and renaming the final pattern.

3. While no final pattern is shown due to pandemic restrictions, the document outlines the process of computer-aided pattern making and highlights its benefits over manual methods.Study on grading the develop pattern in CAD.

Study on grading the develop pattern in CAD.NazmulHasanAnan

╠²

1. The document describes an experiment on grading patterns in CAD software. It involves taking a master pattern for a T-shirt and grading it to produce patterns of different sizes.

2. Key steps in the grading process include inputting measurement changes between sizes into a grading table, copying grading from the front pattern to the back, and adjusting sleeve lengths and widths.

3. The result is a set of graded patterns for a T-shirt in various sizes that are produced accurately and quickly using CAD software compared to manual grading methods.Pattern making men c1& c2

Pattern making men c1& c2Ashenafi Solomon

╠²

The document provides information about pattern making for men's clothing. It discusses what pattern making is, the purpose of pattern making, and common pattern making tools. It also describes different pattern making methods like direct drafting, flat pattern, and draping. Measurement is a key part of pattern making to accurately create patterns for garments. The document outlines important body measurement landmarks and techniques for properly measuring the body or a form. It also discusses other important pattern making documents like cost sheets, pattern charts, design specification sheets, and technical packs which provide production details for patterns and garments. Accurate measurement and documentation are essential for successful pattern making.775 basic pattern development-ms

775 basic pattern development-msneerajkapoor41

╠²

This document provides instructions and questions for a pattern development exam. It contains 3 printed pages and 31 total questions divided into two sections - Section A and Section B. Section A contains multiple choice and short answer questions worth 1, 2, or 3 marks. Section B contains longer answer questions worth 5 marks each. Students are instructed to write the question number before answering and are given 15 minutes to read the paper before the exam begins.Study on Pattern Making in Apparel Industry

Study on Pattern Making in Apparel IndustryMd Rakibul Hassan

╠²

This document provides information about pattern making in the apparel industry. It begins with an introduction that defines pattern and describes pattern making as an art that involves shaping flat fabric pieces to fit the human body. It then discusses the different types of paper patterns, including standardized, individual, final, block, readymade, graded, and commercial patterns. The document also describes the main methods of pattern making, which are pattern drafting, pattern draping, and making flat paper patterns. It provides details on pattern drafting, including measurements, ease allowances, and construction guidelines. Measurement guidelines and tools used for pattern drafting are also outlined.Bdft ii, d&pm, unit-i, draping

Bdft ii, d&pm, unit-i, drapingRai University

╠²

The document provides instructions for draping fabric on a dress form to design garments. It discusses preparing the dress form by constructing it using strips of paper molded to the body. It then explains the basic steps of draping, including aligning and anchoring the fabric, clipping excess fabric, and pinning darts. Key areas like the waist, princess seam, and shoulders are marked to transfer the design to the fabric. The overall goal is to manipulate the fabric to obtain perfect fit and harmony for the garment design.175035 apparel lab 02 asad sir

175035 apparel lab 02 asad sirMahbubay Rabbani Mim

╠²

This lab report summarizes an experiment on pattern drafting for a skirt. The objectives were to learn about pattern drafting, measurements for different skirt parts, and how to create a skirt pattern according to standard body measurements. Tools used included a curve scale, pattern paper, pencil, and T-scale. The report describes taking measurements, drawing lines for the skirt length, hip depth, back and front hip arcs, and waist arcs. It discusses adjusting the pattern to fit an A4 sheet of paper and drawing curves by hand. The conclusion is that the experiment taught how to measure for and make a skirt pattern.Apparel CAD and Grading Learning Diary

Apparel CAD and Grading Learning DiaryAkansha Choudhary

╠²

Learning diary / theoretical material of 2D Apparel CAD and Grading. Contains important terminologies for the subject, primarily terms revolving around pattern making, pattern grading, measurements, CAD, marker making, spreading and cutting of apparel. A go-to theory book to quickly understand grade concepts, extremely helpful for concerned students. Dressmaking Grade 10

Dressmaking Grade 10joalcalde17

╠²

its all about dressmaking !!!!!

meaning and example of the topic!

lahat ng gusto mo malaman tignan lang ito salamat!?

:) ;) sleeves and collars.pptx

sleeves and collars.pptxkhushboo705073

╠²

The document provides details about fashion design courses, workshops, and drafting instructions. It includes information on workshops covering construction details of plackets and fasteners, pockets and necklines, and pre-teen tops with collars and sleeves. It also provides instructions for drafting a basic bodice block, pre-teen bodice, basic sleeve, and variations of sleeves including set in, kimono, raglan and bell sleeves. Further, it describes different types of collars like peter pan, sailor, straight, shawl and Chinese collars.Three dimensional dress form

Three dimensional dress formAdithy_Kottangal

╠²

The document provides information on using three-dimensional dress forms for designing and fitting clothing. It discusses how dress forms come in different sizes to represent different body types and how they allow designers to see how garments will fit and drape on the body. Adjustable forms can be tailored to fit specific individuals. The document then gives step-by-step instructions for making a custom dress form to match an individual's exact measurements and outlines the materials and methods needed.Garment manufacturing spreading to pressing

Garment manufacturing spreading to pressingKarthikeyan M R

╠²

The document provides information on measuring body dimensions for garment manufacturing. It includes measurements for bust, waist, neck, shoulders, sleeve length, skirt length, and more. It also discusses drafting paper patterns, types of patterns, spreading fabric, and marker planning which is the process of allocating pattern pieces on fabric while meeting requirements for quality, production needs, and fabric grain.Bdft ii, d&pm, unit-iii, pattern making term

Bdft ii, d&pm, unit-iii, pattern making termRai University

╠²

This document discusses key terms and methods related to pattern making. It describes pattern making as the process of manipulating fabric to conform to the human body via a paper template. There are three main methods: drafting uses measurements, draping involves shaping fabric on a form, and flat patternmaking develops basic fitted patterns. Key terms defined include grain lines, darts, balance lines, and pattern pieces like bodice fronts and backs. The document also discusses production patterns, marker makers who lay out patterns efficiently, and fashion-specific terms.Module-2-TLE-Dressmaking-10-Self-Learning-Material_edited (1).pdf

Module-2-TLE-Dressmaking-10-Self-Learning-Material_edited (1).pdfBeatrizOrbitaPacanza

╠²

This document provides instructions for taking body measurements needed for drafting a ladies' skirt pattern. It discusses the importance of accurate measurements for well-fitting garments. Key body measurements covered include bust distance, waistline circumference, hip depth, hip circumference, and skirt length. Instructions are given for using a tape measure correctly, identifying measurement markings, and filling out a personal measurement chart. The overall goal is for learners to understand and demonstrate how to take clients' body measurements for sewing ladies' skirts.fashion_design_portfolio_updating.pptx

fashion_design_portfolio_updating.pptxHafizobaidullah

╠²

The third document outlines the 40 size pattern drafting procedure in 25 steps. It details howPattern making is an art

Pattern making is an artNur Alam Bappy

╠²

Pattern making is a highly skilled technique that connects garment design to production. It involves manipulating flat fabric pieces to conform to the three-dimensional shapes of the human body. There are three main methods of pattern making - drafting, which uses measurements to draw construction lines on paper; draping, where fabric is draped on a form to create patterns; and flat pattern making, which develops basic sloper patterns that can then be manipulated for different designs. Pattern making requires both technical precision in translating designs as well as an artistic understanding of how fabrics will drape on the body. It is a fundamental step in dress design and production.Childrens body measurement

Childrens body measurementEzekiel Vic Eboy

╠²

This document provides information about measuring children's bodies and selecting appropriate sizes for garments. It includes sizing charts with body measurements for babies, children, women and men. It also includes charts about garment length and fit that recommend adding 1-6 inches of ease for different garment styles. The document describes how to measure various body parts, including the chest, waist, hips and limbs. It provides guidelines for drafting basic bodice patterns for men and women based on body measurements.Bdft ii, d& pm, unit-i, patter making process

Bdft ii, d& pm, unit-i, patter making processRai University

╠²

This document provides information on different methods of pattern making, including drafting and draping. It discusses the advantages and disadvantages of each method. Drafting involves drawing patterns on paper based on body measurements and allows for accurate fitting. Draping involves placing fabric directly on a model or body. While draping allows for more styles to be tested, it requires more skill, fabric, and a model. The document also covers drafting personal patterns using measurements versus commercial patterns, and provides instructions for key principles of pattern drafting such as ease allowances and marking details on the pattern.He module 6

He module 6none

╠²

This module teaches students how to sew a basic collarless sleeveless shirt. It begins with an introduction that explains the purpose and objectives of the module. The document then provides a sample project plan template to guide students in planning their shirt project, including selecting materials, listing steps, and evaluating progress. Subsequent lessons explain how to accurately copy a commercial shirt pattern, select a suitable unisex fabric, and prepare the fabric for cutting out and assembling the shirt.175035 apparel lab 05 asad sir

175035 apparel lab 05 asad sirMahbubay Rabbani Mim

╠²

This lab report summarizes a student's experiment on basic pattern drafting of sleeves. The student learned how to make a basic sleeve pattern using standard body measurements. Key steps included marking the sleeve length and grain line, identifying points for the bicep and elbow, measuring and marking these dimensions, and drafting the sleeve head curve. The objectives were to understand basic sleeve patterns, drafting techniques, and how to make a pattern that can be used to manufacture sleeves.Recently uploaded (20)

Taykon-Kalite belgeleri

Taykon-Kalite belgeleriTAYKON

╠²

Kalite Politikam─▒z

Taykon ├ćelik i├¦in kalite, hayallerinizi bizlerle payla┼¤t─▒─¤─▒n─▒z an ba┼¤lar. Proje ├¦iziminden detaylar─▒n ├¦├Čz├╝m├╝ne, detaylar─▒n ├¦├Čz├╝m├╝nden ├╝retime, ├╝retimden montaja, montajdan teslime hayallerinizin ger├¦ekle┼¤ti─¤ini g├Črd├╝─¤├╝n├╝z ana kadar ge├¦en t├╝m a┼¤amalar─▒, ├¦al─▒┼¤anlar─▒, t├╝m teknik donan─▒m ve ├¦evreyi i├¦ine al─▒r KAL─░TE.decarbonization steel industry rev1.pptx

decarbonization steel industry rev1.pptxgonzalezolabarriaped

╠²

Webinar Decarbonization steel industryTurbocor Product and Technology Review.pdf

Turbocor Product and Technology Review.pdfTotok Sulistiyanto

╠²

High Efficiency Chiller System in HVACVon karman Equation full derivation .pdf

Von karman Equation full derivation .pdfEr. Gurmeet Singh

╠²

Von karman Equation full derivation

By Er. GURMEET SINGH

G.C.E.T JAMMU

Contact: gurmeet.b.tech@gmail.com

M.tech Transportation Engineering Indian Soil Classification System in Geotechnical Engineering

Indian Soil Classification System in Geotechnical EngineeringRajani Vyawahare

╠²

This PowerPoint presentation provides a comprehensive overview of the Indian Soil Classification System, widely used in geotechnical engineering for identifying and categorizing soils based on their properties. It covers essential aspects such as particle size distribution, sieve analysis, and Atterberg consistency limits, which play a crucial role in determining soil behavior for construction and foundation design. The presentation explains the classification of soil based on particle size, including gravel, sand, silt, and clay, and details the sieve analysis experiment used to determine grain size distribution. Additionally, it explores the Atterberg consistency limits, such as the liquid limit, plastic limit, and shrinkage limit, along with a plasticity chart to assess soil plasticity and its impact on engineering applications. Furthermore, it discusses the Indian Standard Soil Classification (IS 1498:1970) and its significance in construction, along with a comparison to the Unified Soil Classification System (USCS). With detailed explanations, graphs, charts, and practical applications, this presentation serves as a valuable resource for students, civil engineers, and researchers in the field of geotechnical engineering. TASK-DECOMPOSITION BASED ANOMALY DETECTION OF MASSIVE AND HIGH-VOLATILITY SES...

TASK-DECOMPOSITION BASED ANOMALY DETECTION OF MASSIVE AND HIGH-VOLATILITY SES...samueljackson3773

╠²

The Science Information Network (SINET) is a Japanese academic backbone network for more than 800

universities and research institutions. The characteristic of SINET traffic is that it is enormous and highly

variableSorting Algorithms: Bubble Sort, Selection Sort,

Sorting Algorithms: Bubble Sort, Selection Sort,Dr. Madhuri Jawale

╠²

Sorting Algorithms :

Internal and external sorting,

Bubble Sort,

Selection Sort,G8 mini project for alcohol detection and engine lock system with GPS tracki...

G8 mini project for alcohol detection and engine lock system with GPS tracki...sahillanjewar294

╠²

b.tech final year projects report for cseBiases, our brain and software development

Biases, our brain and software developmentMatias Iacono

╠²

Quick presentation about cognitive biases, classic psychological researches and quite new papers that displays how those biases might be impacting software developers.Mathematics behind machine learning INT255 INT255__Unit 3__PPT-1.pptx

Mathematics behind machine learning INT255 INT255__Unit 3__PPT-1.pptxppkmurthy2006

╠²

Mathematics behind machine learning INT255 Sppu engineering artificial intelligence and data science semester 6th Artif...

Sppu engineering artificial intelligence and data science semester 6th Artif...pawaletrupti434

╠²

Sppu University Third year AI&DS Artificial Neural Network unit 1AI ppt on water jug problem by shivam sharma

AI ppt on water jug problem by shivam sharmaShivamSharma588604

╠²

this ppt is made on the topic of water jug problem.Data recovery and Digital evidence controls in digital frensics.pdf

Data recovery and Digital evidence controls in digital frensics.pdfAbhijit Bodhe

╠²

This topic contain information about Data recovery and Digital evidence controls in cyber and digital awarenessUNIT_2_ DIAGNOSTICS- UNIT II BIOMECHANICAL THERAPEUTIC EQUIPMENT

UNIT_2_ DIAGNOSTICS- UNIT II BIOMECHANICAL THERAPEUTIC EQUIPMENTDJERALDINAUXILLIAECE

╠²

BIOMECHANICAL

THERAPEUTIC EQUIPMENTDesigning Flex and Rigid-Flex PCBs to Prevent Failure

Designing Flex and Rigid-Flex PCBs to Prevent FailureEpec Engineered Technologies

╠²

Flex and rigid-flex printed circuit boards (PCBs) can be considered at the basic level some of the most complex PCBs in the industry. With that in mind, itŌĆÖs incredibly easy to make a mistake, to leave something out, or to create a design that was doomed from the start.

Such design failures can end up leading to an eventual failure by delamination, short circuits, damage to the flex portions, and many other things. The easiest way to circumvent these is to start at the beginning, to design with preventing failure in mind rather than trying to fix existing designs to accommodate for problems.

In this webinar, we cover how to design flex and rigid-flex PCBs with failure prevention in mind to save time, money, and headaches, and what failure can look like.

For more information on our flex and rigid-flex PCB solutions, visit https://www.epectec.com/flex.Study on manual pattern making of a given T-shirt.

- 1. KHULNA UNIVERSITY OF ENGINEERING & TECHNOLOGY KUET SESSIONAL REPORT Course No- TE3230 Experiment No. 01 Name of the Experiment Study on manual pattern making of a given T-shirt. Remarks Date of Performance- 12-04-21 Date of Submission- 13-06-21 Name- Nazmul Hasan Anan Roll- 1721015 Session- 2019-20 Year- 3rd Semester- 2nd Group- A

- 2. Experiment No: 01 Name of the Experiment: Study on manual pattern making of a given T-shirt. 1. Introduction: All garments are drawn scientifically, usually on paper, and used to cut fabric by spreading it on fabric layers known as markers. The replica, shape, or template of a part of a garment is called the pattern. There are two ways of marker making 1. Manual marker making 2. Computer-aided marker making Manual marker making is a method where physical and mental labor is a must. We can do manual markers with full sizes patterns as well as with small sizes patterns. Usually, the patterns will plot on a pattern paper, which is one type of thick paper, and then the whole design is placed in this pattern paper. For establishing a better outlook of garments, proper patterning is a must. In Starting, we get the technical pack which contains the list of sizes. According to this site, we will make our pattern from the garments. If there are more sizes available for single clothes, we should select the middle size. We know that we also make a raff estimation of the product in the time of pattern making. If we design with the smallest one, there is little chance of this fabric order for this size. The scouring of this fabric becomes lower also. The same things also happened if we used the most significant size; here,

- 3. we get the excessive material, increasing garment making. So, we select the marginal size, ensuring the perfect combination of scouring and standard final garments production cost. But it also changed according to the order quantity of garments. The selection of the pattern between the largest one and the size of the middle is perfect. Lower risk is also maintained. Supposed if we get S M L XL size, it's safe to design with M but with L is the safest without any doubt. 2. Objectives: ’ü« Able to produce a design on design paper. ’ü« Able to know the general steps required for pattern making. ’ü« Able to know which size pattern should create if there are lots of methods. ’ü« Able to make a design that we can transfer to computer design employing digitizing. ’ü« Able to get e idea of manual marker making and then make a grading from the base pattern. 3. Apparatus: 1. Pencil 2. Eraser 3. Pattern Board 4. T-Scale 5. Long Scale 6. Curve Scale 7. Scissor 8. Calculator

- 4. 4. Working Procedure: At first, take the measurement sheets from the technical pack and select a standard and efficient size for pattern making. In our size sheets, we get S, M, L, XL sizes. Among them, we chose the L size for our pattern making. Now we observed all the measurements of the garment L. We see the measure of 1/2 chest, 1/2 bottom, HPS, front width 1/2 armhole, shoulder to shoulder, shoulder slant, neck width straight, neck drop CB, neck drop CF, sleeve length, 1/2 armhole, 1/2 biceps, 1/2 bottom sleeve, back width 1/2 armhole. T-shirts are symmetric in design and mirror image. So we can quickly draw one side and unfold it to another for getting the complete design. We minimized the widthwise measurements to half for this folding and evolving, and then lengthwise measures remain unchanged. We should keep in mind that we consider the highest benchmarks for every portion of the garment. In this T-Shirt for L size, we see that the highest value lengthwise is HPS which is 43. So we consider these measurements for drawing and patterning in the pattern board. For our limitation, we used graph paper (Due to coronavirus pandemic, the physical lab is not possible, and that's why pattern board is unavailable). We get three measurements, 1/2 bottom, 1/2 chest, front width 1/2 armhole for the front. Among them, 1/2 bottom measurements are the biggest one, and we consider it for pattern making. Due to folding the paper, we use half of the measurements so, we used (33/2=16.5) 16.5 in the graph paper. The position of the neck and sleeve varies according to the fold line. Suppose we consider the left side, the channel set on the left

- 5. side, and the sleeve to the right side. If we alter the direction, the design will change the direction. For considering the neck measurements, we both think of the length and widthwise direction. .For widthwise consideration, we use the neck width straight. At the very beginning, we fold the paper, so here we should use the half-length of neck width straight, which is 15.5/2=7.75. The lengthwise direction we quickly get from neck drop CB and neck drop CF. From the top position of the graph on the Y axis, we plot the measurement of neck drop CB=2 and neck drop CF=7.5. For drawing the curve, we must use the curve scale. We can do it manually, but we should keep in mind that we should not change the neck's outlook. Supposed if it is round in shape, we should keep it around after design. If it is V-shaped, we should retain its original form as well as position. The measurements of shoulder to shoulder is 27 and, we get the neck width is 15.5. After subtraction we get value (27-15.5=11.5). For one shoulder, the line we were drawing from the top of the fold line, we cover the distance on the X-axis and determine the point. Now we draw a curve for the armhole. Before drafting an arc of the armhole, we should determine a point through which the curve passes. To find the end lengthwise, we add the (1/2 arm hole/2 +Shoulder Slant) (14/2+1.7=8.7) measurement from the top of the fold line in the Y-axis and draw a parallel line on the x-axis. We set up a point 11.5 on the X-axis in this similar line, which we get from front width 1/2 armhole /2 (23/2=11.5). Here we get 3 points. After joining them, we fully draw the armhole. Now entering the lower portion, we finalized the design of the patternŌĆöa curve for the back 1/2 armhole also illustrated in the pattern paper.

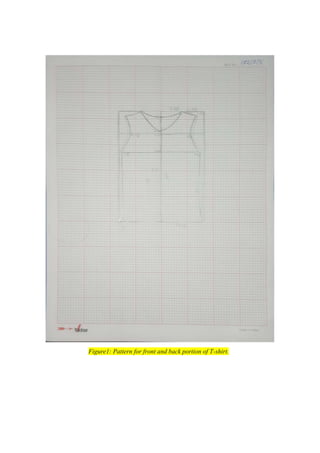

- 6. Previously we made a pattern for the front and back part of a T-shirt; now, we will try to make a pattern for the sleeve. We take the length of the sleeve from the measurements sheet, which is 42. Now it is a time of confusion; there are too many widths; what should we choose? We know that we should take the largest measurement for any portion. Among 1/2 armhole, 1/2 biceps, 1/2 bottom sleeve, we see that the armhole is not the sleeve's parts. It is a portion where the sleeve joins by sewing. So we take the 1/2 bottom opening for pattern making. We plot the value of sleeve length measurement on the X-axis, which is 42, and 1/2 biceps on the Y-axis. Here we also use the folding method by which the alternate sleeve pattern can get quickly. After joining the line of the point, it is time to place the 1/2 bottom sleeve in the Y-axis on the right side of the line and the sleeve head on the top from left to right. We plot point 9.5 on the X-axis and 7.5 from bottom to top on Y-axis. After joining the line and unfolding the line, we get the entire pattern for the sleeve. 5. Result: According to the instruction, I plot those patterns in a graph paper, which is attached below- In graph paper, we consider one square box as one unit.

- 7. Figure1: Pattern for front and back portion of T-shirt.

- 8. Figure2: Pattern for sleeve of T-shirt 6. Precaution: ’ü« All the measurement should take accurately and plot those on the graph paper ’ü« For joining the arc, we should be careful ’ü« The grain line should indicate on the form. ’ü« During unfolding and duplicating the design, we draw it appropriately. ’ü« During working, we should secure the piece from tearing or any hampered. 7. Conclusion: Pattern making is the basic knowledge for apparel production. We can quickly get an idea about the design and outlook of a garment by pattern making. In this experiment, we get an idea about manual pattern making and know-how and which method will

- 9. follow in pattern making. We can easily assume fabric and raw cost of production in the time of pattern making. Here we get an idea for pattern making, which will help us in the future for making a pattern of any apparel and also ensure our essential skill in the job section