Tamdeed for design and construction .pptx

Download as PPTX, PDF0 likes7 views

Tamdeed for design and construction

1 of 31

Download to read offline

Ad

Recommended

Understanding the Key Components of a Cathodic Protection System

Understanding the Key Components of a Cathodic Protection SystemTec

?

This document provides a comprehensive overview of cathodic protection systems, which prevent corrosion to ensure the longevity of infrastructure. It details key components such as anodes, rectifiers, reference electrodes, and control panels, emphasizing their roles in monitoring and maintaining system performance. Additionally, it discusses the importance of compliance with regulations and explores emerging trends in technology that enhance corrosion protection.Company Profile Jan 2015 International

Company Profile Jan 2015 InternationalCraig Donald

?

This document provides information about ISIS Technical Services, a company that offers subsea inspection, corrosion prevention, and cathodic protection systems. It has offices located in Malaysia, the UK, Europe, and Singapore. The company aims to exceed client expectations by providing professional and efficient services such as subsea cathodic protection surveys, design and optimization of cathodic protection systems, and project support personnel. ISIS prides itself on its experienced team and track record of exceptional performance on hundreds of underwater structure inspection projects worldwide.Cathodic Protection Installation Preserving Structures for Generations

Cathodic Protection Installation Preserving Structures for GenerationsTec

?

Cathodic protection is an electrochemical process that protects metallic structures from corrosion by creating a protective current. It has widespread applications in preserving pipelines, storage tanks, bridges, and offshore platforms by combating corrosion through galvanic or impressed current systems. The cathodic protection installation process involves assessing the structure, designing a customized system, installing anodes and cables, setting up monitoring, and testing to ensure effective long-term corrosion protection.Cathodic protection fundamentals

Cathodic protection fundamentalsAbinash Padhy

?

The document provides information about Cathodic Protection services offered by NDTCCS, including:

- NDTCCS has been operating in Saudi Arabia since 1975 providing Cathodic Protection and non-destructive testing services to prevent corrosion in pipelines, refineries, storage tanks, and other industrial structures.

- Cathodic Protection services include feasibility studies, design, installation, monitoring and maintenance using both sacrificial anode and impressed current Cathodic Protection systems.

- Cathodic Protection works by making the structure a cathode through an external anode to reduce corrosion. Proper monitoring and potential measurements are needed to ensure adequate protection levels are achieved.Cathodic protection fundamentals

Cathodic protection fundamentalsAbinash Padhy

?

The document provides information about Cathodic Protection services offered by NDTCCS, including:

- NDTCCS has been operating in Saudi Arabia since 1975 providing Cathodic Protection and non-destructive testing services to prevent corrosion in pipelines, refineries, storage tanks, and other industrial structures.

- Cathodic Protection services include feasibility studies, design, installation, monitoring and maintenance using both sacrificial anode and impressed current cathode protection systems.

- Cathodic Protection works by making the structure a cathode through an external anode to reduce corrosion. Proper monitoring and potential measurements are important to ensure adequate protection.training-presentation-on-cathodic-pritection_compress.pdf

training-presentation-on-cathodic-pritection_compress.pdfMonikaSrivastava68

?

The document details a training session on cathodic protection, focusing on its significance in preventing corrosion, outlining various types, and methods used to control it. Key topics covered include the principles of corrosion, the functionality of cathodic protection systems, and practical applications for pipelines and storage tanks. The training, led by corrosion expert Ahmed Asad, emphasizes the importance of effective monitoring and implementation of corrosion prevention techniques across various structures.M.Ricciardi_Benchmark_Cathodic_Protection.pptx

M.Ricciardi_Benchmark_Cathodic_Protection.pptxAnonymouse9EIwbUY9

?

1) The document discusses the results of a benchmark study conducted with 20 pipeline companies on topics related to cathodic protection effectiveness, remote monitoring, and cathodic protection services.

2) The study involved companies responding to 11 questions in each topic area and the responses being analyzed and compared based on international standards.

3) Key findings included that 9 out of 16 companies reported their remote monitoring systems allow for remote control of CP rectifiers, and that companies showed no homogeneous organization for outsourcing cathodic protection activities.Concrete Cathodic Protection De Nora

Concrete Cathodic Protection De Nora winstonmosby

?

The document discusses how concrete structures like bridges corrode over time due to factors like moisture, oxygen, chlorides from salt, and acids, and how cathodic protection systems using titanium or zinc-based anode materials can be applied to the reinforcing steel to prevent corrosion, extending the life of the structure for over 40 years. It provides examples of different types of structures that benefit from cathodic protection including bridges, docks, parking garages, and buildings.Edo ppp-coe-cor-int-xxx-014-208-236-rev-a-tml lisco cathodic protection system

Edo ppp-coe-cor-int-xxx-014-208-236-rev-a-tml lisco cathodic protection systemErol DAG

?

This document provides details on the cathodic protection system being designed and installed for the steel piles at the Libyan Iron and Steel Company's Bulk Berth No. 2 and Loading Berth development project. The system will use impressed current cathodic protection delivered via 22 transformer/rectifier units to protect the piles across 11 modules. Key aspects of the design include electrical isolation of modules, redundancy provisions, and connection of the steel piles to ensure uniform protection.Protasis Gp 2011 6

Protasis Gp 2011 6Evi Katogoudis

?

PROTASIS is an engineering company that provides consulting and systems integration services for electrical power systems. It offers solutions for power generation plants, transmission and distribution utilities, and industrial clients. Using simulation tools and testing equipment, PROTASIS provides services such as substation design, power systems studies, protection and control systems, commissioning, and automatic metering solutions. It has international experience in the oil and gas sector, having completed projects for numerous refineries and gas treatment plants.Ac&dc power p ppresentation

Ac&dc power p ppresentationAdam Phillips

?

AC & DC Power Technologies is a company that has provided power distribution and quality solutions since 1997. They offer nationwide engineered, furnished, and installed critical power services including emergency repair, preventative maintenance, system design, and training. The company supports UPS, battery, generator, and other power equipment from major brands. Their expertise includes designing, installing, and servicing solutions for data centers, facilities, and other commercial/industrial customers.Rectifier Operations & Maintenance - Don Olson - 2.4.2020

Rectifier Operations & Maintenance - Don Olson - 2.4.2020nacetwincities

?

This document provides an overview of a basic cathodic protection rectifier training course. The course covers principles of cathodic protection, safety practices, rectifier circuitry, types of rectifiers and their applications, basic rectifier theory, installation and maintenance procedures, and hands-on troubleshooting of standard rectifier units. The instructor has over 30 years of experience in cathodic protection and rectifier technologies.Edo ppp-coe-cor-int-xxx-014-208-236-rev-a-tml lisco cathodic protection system

Edo ppp-coe-cor-int-xxx-014-208-236-rev-a-tml lisco cathodic protection systemErol DAG

?

This document provides details on the cathodic protection system design for steel piles at the Libyan Iron and Steel Company port. The system will use impressed current cathodic protection with mixed metal oxide coated titanium anodes. Key aspects of the design include:

- The port is divided into 11 modules, each with its own independent cathodic protection system and transformer/rectifier units for redundancy.

- Within each module, the steel piles are connected in a mesh to ensure protection even if parts of the connection fail. Permanent reference cells monitor pile potentials.

- Anodes will be suspended between piles using a special hanging mechanism to provide uniform current distribution. Distribution and connection boxes connect anodes and cathodes to the transformerCorrosion

CorrosionMohammad Qiasvand

?

Cathodic protection systems are designed to protect metal structures from corrosion by creating a sacrificial anode. However, if the system fails or is not properly maintained, the protective current can find alternative paths that cause unintended corrosion of nearby structures. Three case studies are presented where failed cathodic protection systems resulted in corrosion of underground utilities, electrical shock hazards, and costly pipeline repairs. The document emphasizes the importance of proper installation, maintenance, testing and record-keeping of cathodic protection systems according to industry standards to prevent such issues.Resume-Sudhin

Resume-Sudhinsudhin radhakrishnan

?

This document contains the resume of Sudhin R, an Electrical Engineer with over 5 years of experience in oil, gas, and petrochemical fields. It outlines his qualifications including a Master's in Electronics and Communication and Bachelor's in the same, as well as NACE 2 level certification. His responsibilities involved designing and testing transformer rectifiers, solar systems, and communication systems. He is skilled in areas such as cathodic protection design, transformer testing, and providing remote monitoring and SCADA solutions. His career history includes roles with RACTECH and BSS Technologies focusing on transformer rectifier commissioning and design.Do You Know CMA/Flodyne/Hydradyne?

Do You Know CMA/Flodyne/Hydradyne?CMA/Flodyne/Hydradyne

?

CMA/Flodyne/Hydradyne is a fluid power company that has been in business for over 30 years. In addition to fluid power, they also offer motion and logic controls, machine safety, field service, engineered systems, and warehouse distribution. The document provides details on their capabilities, partnerships, fabrication, field service, distribution, customer service, training programs, and examples of custom hydraulic systems they have created for customers.cathodic protection on grade storage tank.pdf

cathodic protection on grade storage tank.pdfAzharGulzar2

?

The document covers the importance of cathodic protection for on-grade storage tanks and buried piping, discussing corrosion causes, government regulations, and maintenance requirements. It highlights that approximately 25% of states require cathodic protection for new or refurbished tanks to prevent corrosion and ensure compliance with SPCC regulations. Key elements involve anode and cathode functions, galvanic protection systems, and maintenance practices to minimize environmental impact and liability.2005-01-1428

2005-01-1428Song You (??)

?

This document provides an overview of remote diagnosis and maintenance (RD&M) for automotive systems. It discusses problems with current vehicle diagnosis and maintenance approaches and the significance of RD&M. An example RD&M architecture is presented that includes intelligent vehicle systems to provide trouble codes and sensor data to a remote diagnosis and maintenance center via wireless communication. The center includes advanced diagnostic programs and a human advisor to interact with the driver, diagnose problems, and arrange maintenance. RD&M offers benefits like unobtrusive vehicle health monitoring and early problem detection to help reduce costs and increase safety.Safeguarding Infrastructure with Cathodic Protection Services

Safeguarding Infrastructure with Cathodic Protection ServicesTec

?

Cathodic protection services are essential for safeguarding critical infrastructure against corrosion, which is a significant issue that leads to extensive maintenance costs. This technology works through electrochemical methods, including sacrificial anodes and impressed current systems, to extend the service life of assets in various industries like oil and gas, water treatment, and transportation. The advantages of implementing cathodic protection include increased longevity, cost-effectiveness, enhanced safety, and environmental benefits.cathodic protection and maintenance requred 3.pptx

cathodic protection and maintenance requred 3.pptxMAHMOUDMOHAMED431205

?

1) Cathodic protection controls corrosion by making the entire metal surface a cathode through the use of an external current source. This stops the metal from corroding by acting as the anode in an electrochemical cell.

2) There are two main types of cathodic protection systems - sacrificial anode systems which use more electrically active metals as anodes that corrode instead of the structure, and impressed current systems which use an external current source such as transformers.

3) Proper installation and material selection is important for cathodic protection systems to function effectively. Factors like soil conditions, coating quality, and reference electrodes must be considered to ensure adequate protection and prevent overprotection of the metal surface.Catalogue 08 ing_v0208

Catalogue 08 ing_v0208Ryme

?

This document provides an overview and specifications for various vehicle inspection equipment produced by Ryme, a Spanish company specializing in equipment for the automotive industry and vehicle inspection. It describes mobile inspection units, play detectors for testing vehicle axles and components, side slip testers, brake testers, suspension benches, combined systems, speedometers and taximeters, dynamometric test benches, emissions testing equipment, network management systems, garage tools, and riveting machines. Ryme emphasizes its experience, wide product range, quality certifications, pioneering software applications, leadership in network systems, qualified personnel, and aftersales support both in Spain and abroad.CorrosionRADAR applications

CorrosionRADAR applicationsPrafull Sharma

?

The CorrosionRADAR system can be implemented in a variety of industrial situations by using flexible and modular sensor arrangements and node placements that can be adjusted to individual facility requirements. The sensors can be deployed longitudinally along piping or in mesh formations on vessels to monitor for corrosion under insulation. The system provides remote monitoring capabilities to detect corrosion early and reduce costs for industries such as oil and gas, power and utilities, manufacturing, and renewable and civil infrastructure projects.Prem CV Oct 2015

Prem CV Oct 2015Prem Kumar

?

K Prem Kumar has over 25 years of experience in corrosion and cathodic protection, including 13 years specifically working in cathodic protection. He holds several professional certifications and has worked on a wide variety of cathodic protection projects across industries. Some of the major projects he has worked on include pipelines, tanks, offshore structures, and ships for companies like Saudi Aramco, ADCO, and the Indian Navy.M.Ibrahim_Adv

M.Ibrahim_AdvMohamed Ibrahim

?

Mohamed Ibrahim is a senior electrical engineer with over 13 years of experience in testing and commissioning protection relays, switchgear, and transformers. He has worked for companies such as Siemens, Lucy Electric, and NDEDC in various roles involving commissioning electrical systems, overseeing substations, and training customers. Ibrahim holds a Bachelor's degree in Electrical Power and Machine Engineering and is licensed to work in the UAE.How Machine Connectivity is Transforming Automation and Equipment Efficiency.pdf

How Machine Connectivity is Transforming Automation and Equipment Efficiency.pdfHYDAC in AU

?

IO-link technology is essential to the safe and efficient operation of modern machinery offering good machine connectivity, including those used in automobiles, farms, elevators, and material handling equipment, among other places. The majority of machinery in the mining and construction industries nowadays depend heavily on hydraulics and motion control systems, which is why these services and systems are necessary.cathodic protection

cathodic protectionAbhishek Mishra

?

The document discusses cathodic protection methods for corrosion control. It describes two main types of cathodic protection - sacrificial anode and impressed current. Sacrificial anode uses more reactive metals like zinc or aluminum as anodes, while impressed current uses an external DC power source and insoluble anodes like graphite. Common applications include protecting pipelines, ships, and marine structures. Issues that can arise include hydrogen embrittlement, cathodic disbonding, and safety concerns with rectifiers.Advancements cathodic protection for on grade storage tanks

Advancements cathodic protection for on grade storage tanksAudubon Engineering Company

?

This document discusses advancements in cathodic protection design for on-grade storage tanks. It covers regulatory requirements for cathodic protection, foundation design considerations, different cathodic protection methods including galvanic anode and impressed current systems, criteria for cathodic protection system design, and recommendations to improve cathodic protection system specifications and validate protection criteria.Cathodic protection

Cathodic protectionBiplabjit Barmon

?

Corrosion is the gradual destruction of materials by chemical reaction with the environment, usually affecting metals. Cathodic protection is a method of corrosion control that protects buried or submerged metallic structures by supplying an external cathodic current to move the structure's electrochemical potential into the immune range. There are two main types of cathodic protection systems - sacrificial anode systems which use more reactive "sacrificial" metals to corrode instead of the protected structure, and impressed current systems which use an external DC source and insoluble anodes to supply current to the structure. Cathodic protection is widely used to protect structures like pipelines, storage tanks, ship hulls, and reinforced concrete.More Related Content

Similar to Tamdeed for design and construction .pptx (20)

Edo ppp-coe-cor-int-xxx-014-208-236-rev-a-tml lisco cathodic protection system

Edo ppp-coe-cor-int-xxx-014-208-236-rev-a-tml lisco cathodic protection systemErol DAG

?

This document provides details on the cathodic protection system being designed and installed for the steel piles at the Libyan Iron and Steel Company's Bulk Berth No. 2 and Loading Berth development project. The system will use impressed current cathodic protection delivered via 22 transformer/rectifier units to protect the piles across 11 modules. Key aspects of the design include electrical isolation of modules, redundancy provisions, and connection of the steel piles to ensure uniform protection.Protasis Gp 2011 6

Protasis Gp 2011 6Evi Katogoudis

?

PROTASIS is an engineering company that provides consulting and systems integration services for electrical power systems. It offers solutions for power generation plants, transmission and distribution utilities, and industrial clients. Using simulation tools and testing equipment, PROTASIS provides services such as substation design, power systems studies, protection and control systems, commissioning, and automatic metering solutions. It has international experience in the oil and gas sector, having completed projects for numerous refineries and gas treatment plants.Ac&dc power p ppresentation

Ac&dc power p ppresentationAdam Phillips

?

AC & DC Power Technologies is a company that has provided power distribution and quality solutions since 1997. They offer nationwide engineered, furnished, and installed critical power services including emergency repair, preventative maintenance, system design, and training. The company supports UPS, battery, generator, and other power equipment from major brands. Their expertise includes designing, installing, and servicing solutions for data centers, facilities, and other commercial/industrial customers.Rectifier Operations & Maintenance - Don Olson - 2.4.2020

Rectifier Operations & Maintenance - Don Olson - 2.4.2020nacetwincities

?

This document provides an overview of a basic cathodic protection rectifier training course. The course covers principles of cathodic protection, safety practices, rectifier circuitry, types of rectifiers and their applications, basic rectifier theory, installation and maintenance procedures, and hands-on troubleshooting of standard rectifier units. The instructor has over 30 years of experience in cathodic protection and rectifier technologies.Edo ppp-coe-cor-int-xxx-014-208-236-rev-a-tml lisco cathodic protection system

Edo ppp-coe-cor-int-xxx-014-208-236-rev-a-tml lisco cathodic protection systemErol DAG

?

This document provides details on the cathodic protection system design for steel piles at the Libyan Iron and Steel Company port. The system will use impressed current cathodic protection with mixed metal oxide coated titanium anodes. Key aspects of the design include:

- The port is divided into 11 modules, each with its own independent cathodic protection system and transformer/rectifier units for redundancy.

- Within each module, the steel piles are connected in a mesh to ensure protection even if parts of the connection fail. Permanent reference cells monitor pile potentials.

- Anodes will be suspended between piles using a special hanging mechanism to provide uniform current distribution. Distribution and connection boxes connect anodes and cathodes to the transformerCorrosion

CorrosionMohammad Qiasvand

?

Cathodic protection systems are designed to protect metal structures from corrosion by creating a sacrificial anode. However, if the system fails or is not properly maintained, the protective current can find alternative paths that cause unintended corrosion of nearby structures. Three case studies are presented where failed cathodic protection systems resulted in corrosion of underground utilities, electrical shock hazards, and costly pipeline repairs. The document emphasizes the importance of proper installation, maintenance, testing and record-keeping of cathodic protection systems according to industry standards to prevent such issues.Resume-Sudhin

Resume-Sudhinsudhin radhakrishnan

?

This document contains the resume of Sudhin R, an Electrical Engineer with over 5 years of experience in oil, gas, and petrochemical fields. It outlines his qualifications including a Master's in Electronics and Communication and Bachelor's in the same, as well as NACE 2 level certification. His responsibilities involved designing and testing transformer rectifiers, solar systems, and communication systems. He is skilled in areas such as cathodic protection design, transformer testing, and providing remote monitoring and SCADA solutions. His career history includes roles with RACTECH and BSS Technologies focusing on transformer rectifier commissioning and design.Do You Know CMA/Flodyne/Hydradyne?

Do You Know CMA/Flodyne/Hydradyne?CMA/Flodyne/Hydradyne

?

CMA/Flodyne/Hydradyne is a fluid power company that has been in business for over 30 years. In addition to fluid power, they also offer motion and logic controls, machine safety, field service, engineered systems, and warehouse distribution. The document provides details on their capabilities, partnerships, fabrication, field service, distribution, customer service, training programs, and examples of custom hydraulic systems they have created for customers.cathodic protection on grade storage tank.pdf

cathodic protection on grade storage tank.pdfAzharGulzar2

?

The document covers the importance of cathodic protection for on-grade storage tanks and buried piping, discussing corrosion causes, government regulations, and maintenance requirements. It highlights that approximately 25% of states require cathodic protection for new or refurbished tanks to prevent corrosion and ensure compliance with SPCC regulations. Key elements involve anode and cathode functions, galvanic protection systems, and maintenance practices to minimize environmental impact and liability.2005-01-1428

2005-01-1428Song You (??)

?

This document provides an overview of remote diagnosis and maintenance (RD&M) for automotive systems. It discusses problems with current vehicle diagnosis and maintenance approaches and the significance of RD&M. An example RD&M architecture is presented that includes intelligent vehicle systems to provide trouble codes and sensor data to a remote diagnosis and maintenance center via wireless communication. The center includes advanced diagnostic programs and a human advisor to interact with the driver, diagnose problems, and arrange maintenance. RD&M offers benefits like unobtrusive vehicle health monitoring and early problem detection to help reduce costs and increase safety.Safeguarding Infrastructure with Cathodic Protection Services

Safeguarding Infrastructure with Cathodic Protection ServicesTec

?

Cathodic protection services are essential for safeguarding critical infrastructure against corrosion, which is a significant issue that leads to extensive maintenance costs. This technology works through electrochemical methods, including sacrificial anodes and impressed current systems, to extend the service life of assets in various industries like oil and gas, water treatment, and transportation. The advantages of implementing cathodic protection include increased longevity, cost-effectiveness, enhanced safety, and environmental benefits.cathodic protection and maintenance requred 3.pptx

cathodic protection and maintenance requred 3.pptxMAHMOUDMOHAMED431205

?

1) Cathodic protection controls corrosion by making the entire metal surface a cathode through the use of an external current source. This stops the metal from corroding by acting as the anode in an electrochemical cell.

2) There are two main types of cathodic protection systems - sacrificial anode systems which use more electrically active metals as anodes that corrode instead of the structure, and impressed current systems which use an external current source such as transformers.

3) Proper installation and material selection is important for cathodic protection systems to function effectively. Factors like soil conditions, coating quality, and reference electrodes must be considered to ensure adequate protection and prevent overprotection of the metal surface.Catalogue 08 ing_v0208

Catalogue 08 ing_v0208Ryme

?

This document provides an overview and specifications for various vehicle inspection equipment produced by Ryme, a Spanish company specializing in equipment for the automotive industry and vehicle inspection. It describes mobile inspection units, play detectors for testing vehicle axles and components, side slip testers, brake testers, suspension benches, combined systems, speedometers and taximeters, dynamometric test benches, emissions testing equipment, network management systems, garage tools, and riveting machines. Ryme emphasizes its experience, wide product range, quality certifications, pioneering software applications, leadership in network systems, qualified personnel, and aftersales support both in Spain and abroad.CorrosionRADAR applications

CorrosionRADAR applicationsPrafull Sharma

?

The CorrosionRADAR system can be implemented in a variety of industrial situations by using flexible and modular sensor arrangements and node placements that can be adjusted to individual facility requirements. The sensors can be deployed longitudinally along piping or in mesh formations on vessels to monitor for corrosion under insulation. The system provides remote monitoring capabilities to detect corrosion early and reduce costs for industries such as oil and gas, power and utilities, manufacturing, and renewable and civil infrastructure projects.Prem CV Oct 2015

Prem CV Oct 2015Prem Kumar

?

K Prem Kumar has over 25 years of experience in corrosion and cathodic protection, including 13 years specifically working in cathodic protection. He holds several professional certifications and has worked on a wide variety of cathodic protection projects across industries. Some of the major projects he has worked on include pipelines, tanks, offshore structures, and ships for companies like Saudi Aramco, ADCO, and the Indian Navy.M.Ibrahim_Adv

M.Ibrahim_AdvMohamed Ibrahim

?

Mohamed Ibrahim is a senior electrical engineer with over 13 years of experience in testing and commissioning protection relays, switchgear, and transformers. He has worked for companies such as Siemens, Lucy Electric, and NDEDC in various roles involving commissioning electrical systems, overseeing substations, and training customers. Ibrahim holds a Bachelor's degree in Electrical Power and Machine Engineering and is licensed to work in the UAE.How Machine Connectivity is Transforming Automation and Equipment Efficiency.pdf

How Machine Connectivity is Transforming Automation and Equipment Efficiency.pdfHYDAC in AU

?

IO-link technology is essential to the safe and efficient operation of modern machinery offering good machine connectivity, including those used in automobiles, farms, elevators, and material handling equipment, among other places. The majority of machinery in the mining and construction industries nowadays depend heavily on hydraulics and motion control systems, which is why these services and systems are necessary.cathodic protection

cathodic protectionAbhishek Mishra

?

The document discusses cathodic protection methods for corrosion control. It describes two main types of cathodic protection - sacrificial anode and impressed current. Sacrificial anode uses more reactive metals like zinc or aluminum as anodes, while impressed current uses an external DC power source and insoluble anodes like graphite. Common applications include protecting pipelines, ships, and marine structures. Issues that can arise include hydrogen embrittlement, cathodic disbonding, and safety concerns with rectifiers.Advancements cathodic protection for on grade storage tanks

Advancements cathodic protection for on grade storage tanksAudubon Engineering Company

?

This document discusses advancements in cathodic protection design for on-grade storage tanks. It covers regulatory requirements for cathodic protection, foundation design considerations, different cathodic protection methods including galvanic anode and impressed current systems, criteria for cathodic protection system design, and recommendations to improve cathodic protection system specifications and validate protection criteria.Cathodic protection

Cathodic protectionBiplabjit Barmon

?

Corrosion is the gradual destruction of materials by chemical reaction with the environment, usually affecting metals. Cathodic protection is a method of corrosion control that protects buried or submerged metallic structures by supplying an external cathodic current to move the structure's electrochemical potential into the immune range. There are two main types of cathodic protection systems - sacrificial anode systems which use more reactive "sacrificial" metals to corrode instead of the protected structure, and impressed current systems which use an external DC source and insoluble anodes to supply current to the structure. Cathodic protection is widely used to protect structures like pipelines, storage tanks, ship hulls, and reinforced concrete.Recently uploaded (20)

×îĐ°ćÎ÷°ŕŃŔŔĂÉÂł¶ű´óѧ±Ďҵ֤Ł¨±«¸éł˘±Ďҵ֤Ę飩԰涨ÖĆ

×îĐ°ćÎ÷°ŕŃŔŔĂÉÂł¶ű´óѧ±Ďҵ֤Ł¨±«¸éł˘±Ďҵ֤Ę飩԰涨ÖĆTaqyea

?

ÎŢ·¨±ĎҵŁżĽřÓÚ´ËąşÂňÎÄĆľˇľqޱ1954292140ˇżĐ޸ÄŔĂÉÂł¶ű´óѧłÉĽ¨µĄµç×Ó°ćgpaČĂѧŔú¸üłöÉ«,URLÎÄĆľÖĆ×÷Á÷łĚČ·±ŁŃ§ŔúŐćʵĐÔŁ¬ÎÄĆľąşÂňŁ¬±Ďҵ֤°ěŔíŁ¬ÎÄĆľ°ěŔíÖ»ĘÇ»ů´ˇŇµÎńˇŁˇľqޱ1954292140ˇżŇ»±ČŇ»»ąÔąúÍâ´óѧ±Ďҵ֤Ł¬¶¨ÖĆąúÍâ´óѧѧŔúŁ¬ÖĆ×÷ąúÍâ´óѧÎÄĆľŁ¬¸´żĚąúÍâ´óѧ±Ďҵ֤Ę顣ĎëŇŞŐćʵ¸ĐĘÜŔĂÉÂł¶ű´óѧ×îĐ°ć±Ďҵ֤ͼƬµÄĆ·Öʵă»÷˛éż´Ďę˝âŁ¬Ń§Î»Ö¤1:1ÍęĂŔ»ąÔşŁÍâ¸÷´óѧ±Ďҵ˛ÄÁĎÉϵŤŇŐŁşË®ÓˇŁ¬ŇőÓ°µ×ÎĆŁ¬¸ÖÓˇLOGOĚĚ˝đĚĚŇřŁ¬LOGOĚĚ˝đĚĚŇř¸´şĎÖصţˇŁÎÄ×ÖÍĽ°¸¸ˇµńˇ˘Ľ¤ąâŔŘÉ䡢×ĎÍâÓ«ąâˇ˘Î¸С˘¸´Óˇ·ŔαµČ·Ŕαą¤ŇŐˇŁ

Ö÷ÓŞĎîÄżŁş

1ˇ˘Őćʵ˝ĚÓý˛żąúÍâѧŔúѧλČĎÖ¤ˇ¶Î÷°ŕŃŔ±ĎҵÎÄĆľÖ¤ĘéżěËŮ°ěŔíŔĂÉÂł¶ű´óѧłÉĽ¨µĄ¶¨Öơ·ˇľq΢1954292140ˇżˇ¶ÂŰÎÄĂ»ąýŔĂÉÂł¶ű´óѧŐýĘ˝łÉĽ¨µĄˇ·Ł¬˝ĚÓý˛ż´ćµµŁ¬˝ĚÓý˛żÁô·ţÍřŐľ100%żÉ˛é.

2ˇ˘°ěŔíURL±Ďҵ֤Ł¬¸ÄłÉĽ¨µĄˇ¶URL±Ďҵ֤Ă÷°ěŔíŔĂÉÂł¶ű´óѧÁôĐĹÍřČĎÖ¤ˇ·ˇľQ/WeChatŁş1954292140ˇżBuy Universitat Ramon Llull Certificatesˇ¶ŐýĘ˝łÉĽ¨µĄÂŰÎÄĂ»ąýˇ·Ł¬ŔĂÉÂł¶ű´óѧOfferˇ˘ÔÚ¶ÁÖ¤Ă÷ˇ˘Ń§Éúż¨ˇ˘Đŷ⡢֤Ă÷ĐŵČČ«ĚײÄÁĎŁ¬´Ó·Ŕαµ˝ÓˇË˘Ł¬´Óˮӡµ˝¸ÖÓˇĚ̽𣬸߾«·Â¶Č¸úѧУ԰ć100%Ďŕͬ.

3ˇ˘ŐćʵʹąÝČĎÖ¤Ł¨Ľ´ÁôѧČËÔ±»ŘąúÖ¤Ă÷Ł©Ł¬ĘąąÝ´ćµµżÉͨąý´óĘąąÝ˛éŃŻČ·ČĎ.

4ˇ˘ÁôĐĹÍřČĎÖ¤Ł¬ąúĽŇרҵČ˲ĹČĎÖ¤ÖĐĐÄ°ä·˘ČëżâÖ¤Ę飬ÁôĐĹÍř´ćµµżÉ˛é.

°ěŔíURLѧŔúÓëѧλ֤ĘéͶ×ĘδŔ´µÄ×îĽŃÍľľ¶ˇľq΢1954292140ˇż°ěŔíÎ÷°ŕŃŔURL±ľżĆѧŔú,°ěŔíŔĂÉÂł¶ű´óѧłÉĽ¨µĄ¸ßÖĘÁż±ŁĂܵĸöĐÔ»Ż·ţÎń¸ß·ÂŐ滹ÔÎ÷°ŕŃŔÎÄĆľÖ¤ĘéşÍÍâżÇŁ¬¶¨ÖĆÎ÷°ŕŃŔŔĂÉÂł¶ű´óѧłÉĽ¨µĄşÍĐŷ⡣±Ďҵ֤¶ŞĘ§˛ą°ěURL±Ďҵ֤ˇľq΢1954292140ˇżĽŮÎÄĆľ»ŘąúŐŇą¤×÷ŔĂÉÂł¶ű´óѧoffer/ѧλ֤ѧλČĎÖ¤ÖŞşőˇ˘ÁôĐŹٷ˝Ń§ŔúČĎÖ¤Ł¨ÓŔľĂ´ćµµŐćʵżÉ˛éŁ©˛ÉÓĂѧУ԰ćÖ˝Őš˘ĚŘĘ⹤ŇŐÍęČ«°´ŐŐÔ°ćŇ»±ČŇ»ÖĆ×÷ˇŁ°ďÄă˝âľöŔĂÉÂł¶ű´óѧѧŔúѧλČĎÖ¤ÄŃĚ⡣

ˇľČçşÎżěËŮ°ěŔíˇ¶ŔĂÉÂł¶ű´óѧ±Ďҵ֤URLłÉĽ¨µĄˇ·Buy Universitat Ramon Llull Transcriptsˇż

ąşÂňČŐş«łÉĽ¨µĄˇ˘Ó˘ąú´óѧłÉĽ¨µĄˇ˘ĂŔąú´óѧłÉĽ¨µĄˇ˘°ÄÖŢ´óѧłÉĽ¨µĄˇ˘ĽÓÄĂ´ó´óѧłÉĽ¨µĄŁ¨q΢1954292140Ł©ĐÂĽÓĆ´óѧłÉĽ¨µĄˇ˘ĐÂÎ÷ŔĽ´óѧłÉĽ¨µĄˇ˘°®¶űŔĽłÉĽ¨µĄˇ˘Î÷°ŕŃŔłÉĽ¨µĄˇ˘µÂąúłÉĽ¨µĄˇŁłÉĽ¨µĄµÄŇâŇĺÖ÷ŇŞĚĺĎÖÔÚÖ¤Ă÷ѧϰÄÜÁ¦ˇ˘ĆŔąŔѧĘő±łľ°ˇ˘ŐąĘľ×ŰşĎËŘÖʡ˘Ěá¸ß¼ȡÂĘŁ¬ŇÔĽ°ĘÇ×÷ÎŞÁôĐĹČĎÖ¤ÉęÇë˛ÄÁϵÄŇ»˛ż·ÖˇŁ

ŔĂÉÂł¶ű´óѧłÉĽ¨µĄÄÜą»ĚĺĎÖÄúµÄµÄѧϰÄÜÁ¦Ł¬°üŔ¨ŔĂÉÂł¶ű´óѧżÎłĚłÉĽ¨ˇ˘×¨ŇµÄÜÁ¦ˇ˘ŃĐľżÄÜÁ¦ˇŁŁ¨q΢1954292140Ł©ľßĚĺŔ´ËµŁ¬łÉĽ¨±¨¸ćµĄÍ¨łŁ°üş¬Ń§ÉúµÄѧϰĽĽÄÜÓëĎ°ąßˇ˘¸÷żĆłÉĽ¨ŇÔĽ°ŔĎʦĆŔÓďµČ˛ż·ÖŁ¬Ňň´ËŁ¬łÉĽ¨µĄ˛»˝öĘÇѧÉúѧĘőÄÜÁ¦µÄÖ¤Ă÷Ł¬Ň˛ĘÇĆŔąŔѧÉúĘÇ·ńĘĘşĎÄł¸ö˝ĚÓýĎîÄżµÄÖŘŇŞŇŔľÝŁˇ

Buy Universitat Ramon Llull Diplomaˇ¶ŐýĘ˝łÉĽ¨µĄÂŰÎÄĂ»ąýˇ·ÓĐÎÄƾȴµĂ˛»µ˝ČĎÖ¤ˇŁÓÖ¸ĂÔőĂ´°ěŁżĽřÓÚ´ËŁ¬ąşÂňÎ÷°ŕŃŔ±Ďҵ֤ˇľq΢1954292140ˇżÎ÷°ŕŃŔÎÄĆľąşÂňŁ¬Î÷°ŕŃŔÎÄĆľąşÂňŁ¬Î÷°ŕŃŔÎÄĆľ¶¨ÖĆŁ¬Î÷°ŕŃŔÎÄĆľ˛ą°ěˇŁ×¨ŇµÔÚĎ߶¨ÖĆÎ÷°ŕŃŔ´óѧÎÄĆľŁ¬¶¨×öÎ÷°ŕŃŔ±ľżĆÎÄĆľŁ¬ˇľq΢1954292140ˇż¸´ÖĆÎ÷°ŕŃŔUniversitat Ramon Llull completion letterˇŁÔÚĎßżěËٲą°ěÎ÷°ŕŃŔ±ľżĆ±Ďҵ֤ˇ˘Ë¶ĘżÎÄĆľÖ¤Ę飬ąşÂňÎ÷°ŕŃŔѧλ֤ˇ˘ŔĂÉÂł¶ű´óѧOfferŁ¬URLŔĂÉÂł¶ű´óѧ±Ďҵ֤Ęé¶ŕÉŮÇ®ˇŁAI-Driven-Personalization-in-UX-Designing-for-One-in-a-Million.pdf

AI-Driven-Personalization-in-UX-Designing-for-One-in-a-Million.pdfSultan Shalakhti

?

Why you should attend this event

Talk Title: AI-Driven Personalization in UX: Designing for One in a Million

In this session, Sultan Shalakhti explores how artificial intelligence is reshaping user experience through smart, adaptive personalization. From e-commerce to banking, personalized design has become a key differentiatorˇŞwhen done right. Learn how to apply AI tools to enhance user journeys, balance personalization with privacy, and build experiences that feel uniquely human. This talk blends strategy, ethics, and real-world use cases for UX professionals ready to embrace the future.

?

????? ??????: ??????? ??????? ??????? ????????? ?? ????? ????????: ????? ???? ??? ??? ??? ???

??? ??????:

?????? ????? ????? ?? ??? ?????? ?? ???? ??? ??? ???? ?????? ????????? ????? ????? ???????? ?? ???? ??????? ????? ??????????. ?? ??????? ??????????? ??? ?????? ??????? ???? ??????? ?????? ?????? ?? ???? ???????ˇŞ???? ??? ??? ?????? ?????? ??????. ?????? ??? ????? ????? ????? ?????? ????????? ?????? ??????? ???????? ?????? ??????? ??? ??????? ?????????? ????? ????? ????? ???? ????? ????????. ???? ???? ???? ??? ????????????? ???????????? ??????? ?????? ???????? ????????? ?? ???? UX.

What you will learn in this session

Understand the Core Concepts of AI-Driven Personalization

Explore UX Design Strategies for Hyper-Personalization

Identify Key Tools and Technologies Behind Personalization

Evaluate the Ethical and Privacy Considerations

Apply Personalization Tactics to Real UX ChallengesInternet Download Manager (IDM) Crack Free Download 2025

Internet Download Manager (IDM) Crack Free Download 2025Designer

?

Copy Link & Paste in Google:??? http://alipc.pro/dl

Internet Download Manager increases download speed with built-in download logic accelerator, resume and schedule downloads.Quectel M10 AT commands Arduino Microcontroller

Quectel M10 AT commands Arduino MicrocontrollerAdamSunusiHaruna1

?

Quectel M10 AT commands Arduino Microcontroller FLOURISHING THROUGH SENSES: FROM Abˇ®SENSEˇŻ to Preˇ®SENSEˇŻ to Esˇ®SENSEˇŻ to Re-...

FLOURISHING THROUGH SENSES: FROM Abˇ®SENSEˇŻ to Preˇ®SENSEˇŻ to Esˇ®SENSEˇŻ to Re-...Samuel Thuo

?

A presentation By Samuel Thuo, The Senses Architect to FxD Community for a PechaKucha Format titled: Flourishing Through Senses: From Abˇ®senseˇŻ to Preˇ®senseˇŻ to Esˇ®senseˇŻ to Re-sensing the World

In a world where skyscrapers rise and senses fall, this presentation explores how architecture can either numb or nourish our humanity.

? Act I ¨C Abˇ®senseˇŻ: The Crisis of Sensory Deprivation

We begin in the concrete jungle, a habitat built for function, but not for feeling. Glass, steel, white walls. Children indoors, glued to screens. Cities that silence rain and sterilize smell. We've lost touch with the sensory essence of living. We're living in a pandemic of nonsense environments.

? Act II ¨C Preˇ®senseˇŻ: The Power of Sensory Grounding

We rediscover presence in barefoot steps on soil, bark under fingertips, beams of sunlight through timber, whispers of wind and scent of wet earth. Flourishing starts when all senses are awake, not just sight. ItˇŻs a return to how we once knew the world, intimately, bodily.

? Act III ¨C Esˇ®senseˇŻ: Remembering Our Sensory Nature

Flourishing is rooted in our essence, as sensing, emotional beings. We learn from natureˇŻs flow, from indigenous African architecture, from animals in tune with their environment, and even from cooking. These are acts of multisensory design, where wisdom is embodied, not abstract. Beauty is not in the eyes of the beholder, but all the senses of the beholder.

? Act IV ¨C Re-sensing: A Vision for the Future

ItˇŻs time to re-sense the world. Pallasmaa said that architecture is the art of reconciliation between ourselves and the world, and this mediation happens through the senses. We must go back to creating senseful environments that allow this dialogue between us and the world. Homes like Falling water that merge with land. Playful spaces for children. Healing cities filled with texture, sound, and smell. Bodies that root into nature. We must shift from building cold structures to designing sensescapes that foster wellbeing.Grade-9-COT.pptxGrade-9-COT.pptxGrade-9-COT.pptxGrade-9-COT.pptx

Grade-9-COT.pptxGrade-9-COT.pptxGrade-9-COT.pptxGrade-9-COT.pptxMaKristinaBuenaventu1

?

Grade-9-COT.pptxIndian_Constitution_Presentation.pptx , images

Indian_Constitution_Presentation.pptx , imagesjaglandushyant

?

Indian constitution with pictures like ambedkar, institution and other relevant pics of constitution Austin TX Connecting Neighborhoods Presentation

Austin TX Connecting Neighborhoods PresentationAmerican Institute of Architects

?

Final presentation of Design Assistance Team to Austin TX concerning future of Hancock Cherrywood, Wilshire Wood, Delwood and I35 corridorAd

Tamdeed for design and construction .pptx

- 3. TAMDEED is a specialized company located in Cairo, Egypt in Corrosion prevention methods mainly Cathodic Protection with highly qualified and NACE (National Association of Corrosion Engineers) certified staff(CP4). About Us

- 4. TO PROTECT and EXTEND the assets lifespan using the cathodic protection. (Design ¨C Material supply ¨C Installation and Testing & Commissioning ). VISION

- 5. To support our clients in protecting their assets against corrosion by providing engineering solutions and latest technological applications with high quality and economical performance. MISSION

- 6. Tamdeed has been established on February 2021, started registration in Egyptian Petroleum sector vendor list and increasing its presence step by step. ESTABLISHMENT

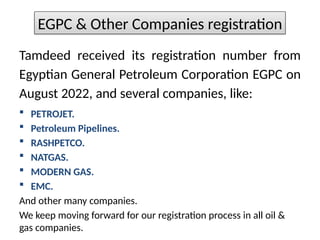

- 7. Tamdeed received its registration number from Egyptian General Petroleum Corporation EGPC on August 2022, and several companies, like: ? PETROJET. ? Petroleum Pipelines. ? RASHPETCO. ? NATGAS. ? MODERN GAS. ? EMC. And other many companies. We keep moving forward for our registration process in all oil & gas companies. EGPC & Other Companies registration

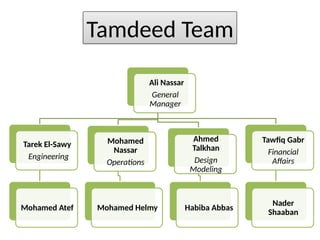

- 8. Ali Nassar General Manager Tarek El-Sawy Engineering Mohamed Atef Mohamed Nassar Operations Mohamed Helmy Ahmed Talkhan Design Modeling Habiba Abbas Tawfiq Gabr Financial Affairs Nader Shaaban Tamdeed Team

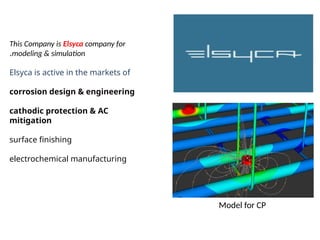

- 9. ? By May 2021, Tamdeed became an Authorized distributer in Egypt and Africa for a number of respectful companies to supply Cathodic Protection materials such as: o Integrated Rectifiers Technology, Canada. o Borin Manufacturing, USA. o Materials & Corrosion Protection Limited Company, UK. o Cortec Middle East. o Elsyca. PARTENERS

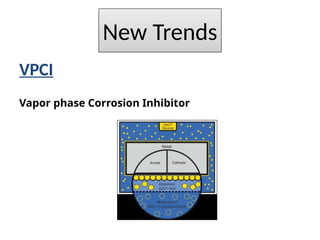

- 11. ? In partnership with Cortec Co. and cooperated together in multiple projects to solve some serious problems using their product of VPCI related to tank farms weather newly constructed or in service. ? As well as strong relationship with manufacturing companies located in UK, Italy and KSA.

- 12. ? By October 2021, Tamdeed obtained it is first contract from Petrojet for supplying Zinc anodes for tank internals at ASORC Extension Project. PROJECTS

- 13. ?By February 2022, our second contract for Design, Supply of Materials, System Installation and Testing & Commissioning for Jet Fuel Hydrant at Borj Al- Arab International Airport northern Egypt in partnership with Petrojet (main contractor) and Misr Petroleum (Client).

- 16. ?On March 2022, we got a contract for Supplying ICCP system for fire tanks water tanks in Egyptian Refining Company ERC and in partnership with Petrojet.

- 18. ? On May 2022, we got an order for supplying Transformer Rectifiers units for Modern Company for Natural Gas (Modern Gas).

- 19. On November 2022, we got a contract for Supplying 78 Test post for NATGAS company .

- 20. On November 2022, we got a contract for Supplying Power feed for El Raswa project extension for PETROJET .

- 21. ?Currently, we are involved in ongoing projects regarding two tank farms, one is located in western Egypt for in-service tanks and the other for a tank farm in southern Egypt for newly constructed tanks.

- 22. VPCI Vapor phase Corrosion Inhibitor New Trends

- 23. RMCU Remote Monitoring & Control Units For test post For Rectifiers New Trends

- 24. For Test post : have been in service for the Corrosion Industry since 1992 the most far-reaching experience in the corrosion industry than any other system on the market . Remote Monitoring Unit models can be accessed through the BORIN? Data Center .

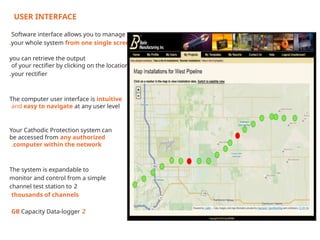

- 25. USER INTERFACE Software interface allows you to manage your whole system from one single screen . you can retrieve the output of your rectifier by clicking on the location of your rectifier . The computer user interface is intuitive and easy to navigate at any user level Your Cathodic Protection system can be accessed from any authorized computer within the network . The system is expandable to monitor and control from a simple 2 channel test station to thousands of channels 2 GB Capacity Data-logger

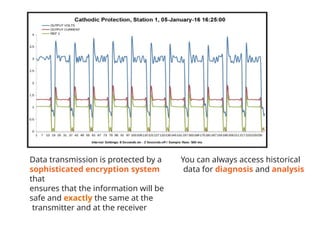

- 26. Data transmission is protected by a sophisticated encryption system that ensures that the information will be safe and exactly the same at the transmitter and at the receiver You can always access historical data for diagnosis and analysis

- 27. Information is transmitted from the field to a data center and vice versa through ANY communication system available: GSM cellular network, satellite, fiber optic, radio, microwave, SCADA, MODBUS, et cetera Smart phone optimized web access to get your readings while in the field . Complete alarm system with text message and e-mail capabilities .

- 28. For Rectifiers : Standard model will monitor 3 rectifiers and is expandable to 72 other devices . Reads every variable in your CP system and/ or any other signal from external systems . Slick technology gives you access to your entire system of Rectifiers, Reference Electrodes, Anode beds, etc. Conveniently through your desktop computer, smart phone and/or tablet makes consistent and continuous accurate readings. This is not possible with the sporadic nature of in-person monitoring . You protect your assets, we protect your data .

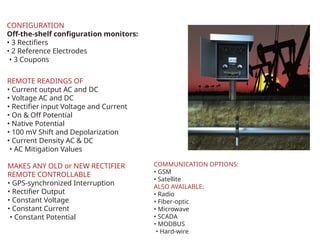

- 29. CONFIGURATION Off-the-shelf configuration monitors: ? 3 Rectifiers ? 2 Reference Electrodes ? 3 Coupons REMOTE READINGS OF ? Current output AC and DC ? Voltage AC and DC ? Rectifier input Voltage and Current ? On & Off Potential ? Native Potential ? 100 mV Shift and Depolarization ? Current Density AC & DC ? AC Mitigation Values MAKES ANY OLD or NEW RECTIFIER REMOTE CONTROLLABLE ? GPS-synchronized Interruption ? Rectifier Output ? Constant Voltage ? Constant Current ? Constant Potential COMMUNICATION OPTIONS: ? GSM ? Satellite ALSO AVAILABLE: ? Radio ? Fiber-optic ? Microwave ? SCADA ? MODBUS ? Hard-wire

- 30. At present, modeling is one of the most useful techniques that have become active in many fields . Modeling of Cathodic protection systems is not common in Egypt . We work on it to be available here with an experienced company . Modeling & Simulation

- 31. This Company is Elsyca company for modeling & simulation . Elsyca is active in the markets of corrosion design & engineering cathodic protection & AC mitigation surface finishing electrochemical manufacturing Model for CP