1 of 1

Download to read offline

Recommended

Study of indoor air mercury pollution at dental teaching institutions, hospit...

Study of indoor air mercury pollution at dental teaching institutions, hospit...Maryam S. Abbasi

Ěý

The document presents results from a study measuring indoor air mercury pollution at dental sites in Pakistan and other countries. Mercury vapor levels were measured at 18 dental sites in Pakistan and 6 other countries. The results were compared to EPA standards of 300 ng/m3. Mercury levels exceeded EPA limits at most sites measured, indicating dental staff and patients are at serious health risk from mercury exposure. The study recommends banning mercury amalgam, implementing best practices to reduce waste, and developing mercury legislation to protect public health.Business Plan

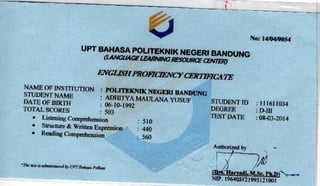

Business PlanAdhitya Maulana Yusuf

Ěý

1) Perusahaan bergerak di bidang jasa perbaikan dan penjualan perangkat keras dan lunak komputer.

2) Analisis SWOT menunjukkan peluang bisnis dari banyaknya pengguna komputer tetapi juga ancaman dari penawaran gratis di internet.

3) Rencana bisnis meliputi target pasar mahasiswa dan masyarakat, biaya modal awal signifikan, dan harga jasa serta produk kompetitif.Cleanrooms 101

Cleanrooms 101Adhitya Maulana Yusuf

Ěý

This document provides an overview of cleanrooms, including their purpose of controlling airborne particle concentrations, classifications based on particle levels, sources of contamination, and design considerations. Cleanrooms aim to maintain cleanliness levels through isolation of contamination sources, filtration of air supplies, and regulating air flow, temperature, and humidity. Particle testing and certification ensure cleanrooms meet standards like ISO 14644-1.SSV PPT

SSV PPTPandu Ssv_Systems

Ěý

Air Care Projects provides clean room solutions as a single window service provider. They have expertise in designing, manufacturing, supplying, installing and commissioning clean rooms for industries such as pharmaceuticals, hospitals, electronics, and food. They create clean rooms of various classes from 100 to 100k. They also provide bio safety labs from BSL-1 to BSL-3 and kitchen ventilation systems. They have completed various clean room projects for customers from industries such as pharmaceuticals, healthcare and research labs.Adhitya

AdhityaAdhitya Maulana Yusuf

Ěý

This document discusses instrumentation topics including accuracy, precision, hysterisis, stability, subdivision, data logging, pressure transmitters, range, sensitivity, error, valves, RTDs, repeatability, resolusi, thermocouples, control, DACs, and ADCs. It was authored by Adhitya Maulana Yusuf with student ID 111611034 studying Refrigeration & Air Conditioning Engineering at Politeknik Negeri Bandung.

Bohomolets Microbiology Lecture#1

Bohomolets Microbiology Lecture#1Dr. Rubz

Ěý

The document provides an overview of microbiology, including the structure and morphology of microorganisms such as bacteria, fungi, protozoa, and viruses. It discusses topics like bacterial cell structure, flagella and pili, endospores, capsules, inclusion bodies, and the contributions of Anton van Leeuwenhoek, who is considered the father of microbiology.Classifications: The 4 Elements of Cleanroom Construction Part 3

Classifications: The 4 Elements of Cleanroom Construction Part 3AM Technical Solutions, Inc

Ěý

One way AMTS is “Constructing an Intelligent Tomorrow” is through the work of our Cleanroom Performance Solutions group. In this 4-part series, our very own Emil Bordelon, a NEBB Certified Professional, outlines the four main elements of a cleanroom that are considered during the design, certification and maintenance phases.

http://amcleanroombuild.com/Classical dosage forms-by Amna Saeed

Classical dosage forms-by Amna SaeedAmna Saeed

Ěý

This document discusses classical dosage forms, which are conventional dosage forms prepared without advanced techniques. It describes lozenges as medicated candies dissolved in the mouth to soothe throat irritation. Pills are small, round solids containing medication. Cachets enclose medication within a wafer shell. Draughts are single-dose liquid preparations packaged in larger volumes. Suppositories and pessaries are solid medications inserted into orifices to exert local or systemic effects as they dissolve.Clean Rooms-Classification-by Amna Saeed

Clean Rooms-Classification-by Amna SaeedAmna Saeed

Ěý

This Presentation gives an Idea about what "Clean Rooms" are, their significance, types and examples from pharmaceutical industry.AMTS Construction Management, Project Management, Facility Solutions Expertise

AMTS Construction Management, Project Management, Facility Solutions ExpertiseAM Technical Solutions, Inc

Ěý

AMTS provides construction management, project management, and facility solutions for various industries including semiconductor manufacturing, solar energy, aerospace, pharmaceuticals, and defense. They have expertise in areas such as base build construction, tool installation, equipment hookup, facility upgrades and expansions, quality programs, and project management. AMTS has experience with projects across North America, South America, Asia, and Europe for clients such as semiconductor foundries and global high tech manufacturers.History of biotechnology-Nhất Camry

History of biotechnology-Nhất CamryTrần Công Nhất

Ěý

This document provides an overview of the history of biotechnology from ancient to modern times. It describes how early civilizations first domesticated plants and animals for food production, and how techniques like fermentation were used to preserve foods. Advances in microscopy allowed for the discovery of microorganisms and laid the foundations for modern genetics research. Figures like Mendel, Watson, Crick and others contributed key findings that enabled recombinant DNA technology and genetic engineering. Modern biotechnology now allows for manipulation of genetic material.Autoclave validation maliba

Autoclave validation malibaMalla Reddy College of Pharmacy

Ěý

This document discusses validation of sterilization equipment. It covers stages of validation including design qualification, installation qualification, operational qualification and performance qualification. Specific validation protocols are described for autoclaves and dry heat sterilizers. Heat distribution and heat penetration studies are important components to determine temperature uniformity within the equipment and establish sterilization conditions. Biological indicators are used to validate the sterilization process achieves sterility assurance levels.Microbiology training module--finger dab& higeine

Microbiology training module--finger dab& higeine Srinath Sasidharan

Ěý

The document provides an overview of quality control procedures related to microbiology and hand hygiene. It discusses the importance of hand hygiene in reducing pathogen transmission, proper hand washing and sanitization techniques, and highlights frequently missed areas. It also describes finger dab testing procedures conducted every six months to monitor bacterial levels on personnel and ensure standards are met. Personnel hygiene policies regarding illness, clothing, and health examinations are outlined to maintain cleanliness. Demonstrations of proper glove removal and disposal techniques conclude the document.08 cleanroom

08 cleanroomshahanapsg

Ěý

This document discusses cleanrooms, including their features, standards, stages of cleanliness, and subsystems. Cleanrooms are controlled environments used in scientific research and lithography to control contamination. They maintain very low levels of environmental pollutants and particles through filtered air, temperature/humidity control, laminar airflow, and other subsystems like water, gas, and construction standards. Cleanrooms are classified based on particle counts using Federal and ISO standards for different stages of static, operational and as-built cleanliness.Environmental monitoring

Environmental monitoringShivangi Somvanshi

Ěý

This document discusses environmental monitoring and various methods used for it. It covers the following key points in 3 sentences:

Environmental monitoring involves systematically sampling air, water, soil, and biota to observe the environment and gain knowledge. It is undertaken for reasons such as identifying pollution levels, sources, and effects on health. Common monitoring methods include ground-based sampling, modeling, and satellite-based monitoring of various environmental aspects such as atmosphere, land, water quality, and natural hazards.Design and operation of clean room PPT MANIK

Design and operation of clean room PPT MANIKImran Nur Manik

Ěý

This document provides information about clean rooms and aseptic areas. It defines clean rooms as rooms with controlled particulate and microbial contamination to minimize introduction of contaminants. Aseptic areas are designed to prevent microbial contamination of products during production. Sources of contamination include external sources like the air system as well as internal sources such as operators, equipment and raw materials. Different types of air flows and classifications of clean rooms are described. Key aspects of clean room design include air filtration and personnel protective clothing requirements.Effective Use of Environmental Monitoring Data Trending

Effective Use of Environmental Monitoring Data TrendingInstitute of Validation Technology

Ěý

In this presentation from the Institute of Validation Technology's Life Sciences Aseptic Processing, Kim Van Antwerpen discusses collecting environmental data, methods for trending, and interpreting and sharing environmental monitoring data.ENVIRONMENTAL MONITORING

ENVIRONMENTAL MONITORINGSrinath Sasidharan

Ěý

The document provides an overview of microbial monitoring in a manufacturing area. It discusses:

1) The purpose of an environmental monitoring program is to provide crucial information on the quality of the aseptic processing environment during manufacturing and to prevent the release of contaminated batches.

2) Microbial monitoring tests for viable and non-viable particles in critical areas like cleanrooms, tank rooms, and packaging areas to demonstrate control of microorganisms.

3) Sources of contamination can come from air, personnel, equipment, cleaning agents and more. Monitoring must meet regulatory standards from agencies like FDA, ISO, and USP.Gowning

GowningChittaranjan Das

Ěý

Gowning refers to wearing special garments to control particulate contamination in cleanrooms. Correct gowning procedures are important because contamination can be invisible. Operators must be well-trained in gowning to avoid introducing contamination. Gowning includes showering and hygiene at home, changing at work while avoiding contact with floors, and wearing multiple layered garments specific to each cleanroom grade that fully cover the body and shed no particles. Proper gowning allows entry to production areas while avoiding contamination.HVAC SYSTEM IN PHARMACEUTICAL INDUSTRY

HVAC SYSTEM IN PHARMACEUTICAL INDUSTRYNamdeo Shinde

Ěý

This document discusses environmental control and air handling systems in pharmaceutical manufacturing. It covers factors like temperature, humidity, air movement and contamination that can impact product quality. Uncontrolled environments can lead to product degradation or contamination. Cross-contamination can be minimized through personnel procedures, adequate facilities, cleaning and protection of products. Proper heating, ventilation and air conditioning (HVAC) systems are important to control airborne particles and microbes and maintain room conditions. Monitoring of HVAC systems includes testing for particulates, filter integrity, air changes and microbiological levels.Ide bisnis eceng gondok

Ide bisnis eceng gondokAdhitya Maulana Yusuf

Ěý

Eceng gondok (Eichhornia crassipes) merupakan gulma air yang berkembangbiak dengan cepat. Salah satu cara menanggulanginya adalah memanfaatkannya sebagai bahan baku kertas seni. Pemanfaatan eceng gondok untuk kertas seni telah dilakukan dan hasilnya cukup memuaskan. Produk kertas seni ini berpotensi dikembangkan dan dipasarkan di daerah wisata sekitar Danau Toba sebagai souvenir.pharmaceutical clean room

pharmaceutical clean room Kiran Thakur

Ěý

This document provides an introduction to pharmaceutical clean rooms. It discusses the purpose of clean rooms which is to promote successful cleanroom operations and ensure safety. Clean rooms are classified according to international standards based on the number of permitted particles per cubic meter of air. Sources of contamination are discussed as well as methods for contamination control including personnel control, environmental control, and atmospheric monitoring. The conclusion states that the main purpose of a clean room is to prevent contamination of products and ensure quality according to good manufacturing practices.More Related Content

Viewers also liked (17)

Bohomolets Microbiology Lecture#1

Bohomolets Microbiology Lecture#1Dr. Rubz

Ěý

The document provides an overview of microbiology, including the structure and morphology of microorganisms such as bacteria, fungi, protozoa, and viruses. It discusses topics like bacterial cell structure, flagella and pili, endospores, capsules, inclusion bodies, and the contributions of Anton van Leeuwenhoek, who is considered the father of microbiology.Classifications: The 4 Elements of Cleanroom Construction Part 3

Classifications: The 4 Elements of Cleanroom Construction Part 3AM Technical Solutions, Inc

Ěý

One way AMTS is “Constructing an Intelligent Tomorrow” is through the work of our Cleanroom Performance Solutions group. In this 4-part series, our very own Emil Bordelon, a NEBB Certified Professional, outlines the four main elements of a cleanroom that are considered during the design, certification and maintenance phases.

http://amcleanroombuild.com/Classical dosage forms-by Amna Saeed

Classical dosage forms-by Amna SaeedAmna Saeed

Ěý

This document discusses classical dosage forms, which are conventional dosage forms prepared without advanced techniques. It describes lozenges as medicated candies dissolved in the mouth to soothe throat irritation. Pills are small, round solids containing medication. Cachets enclose medication within a wafer shell. Draughts are single-dose liquid preparations packaged in larger volumes. Suppositories and pessaries are solid medications inserted into orifices to exert local or systemic effects as they dissolve.Clean Rooms-Classification-by Amna Saeed

Clean Rooms-Classification-by Amna SaeedAmna Saeed

Ěý

This Presentation gives an Idea about what "Clean Rooms" are, their significance, types and examples from pharmaceutical industry.AMTS Construction Management, Project Management, Facility Solutions Expertise

AMTS Construction Management, Project Management, Facility Solutions ExpertiseAM Technical Solutions, Inc

Ěý

AMTS provides construction management, project management, and facility solutions for various industries including semiconductor manufacturing, solar energy, aerospace, pharmaceuticals, and defense. They have expertise in areas such as base build construction, tool installation, equipment hookup, facility upgrades and expansions, quality programs, and project management. AMTS has experience with projects across North America, South America, Asia, and Europe for clients such as semiconductor foundries and global high tech manufacturers.History of biotechnology-Nhất Camry

History of biotechnology-Nhất CamryTrần Công Nhất

Ěý

This document provides an overview of the history of biotechnology from ancient to modern times. It describes how early civilizations first domesticated plants and animals for food production, and how techniques like fermentation were used to preserve foods. Advances in microscopy allowed for the discovery of microorganisms and laid the foundations for modern genetics research. Figures like Mendel, Watson, Crick and others contributed key findings that enabled recombinant DNA technology and genetic engineering. Modern biotechnology now allows for manipulation of genetic material.Autoclave validation maliba

Autoclave validation malibaMalla Reddy College of Pharmacy

Ěý

This document discusses validation of sterilization equipment. It covers stages of validation including design qualification, installation qualification, operational qualification and performance qualification. Specific validation protocols are described for autoclaves and dry heat sterilizers. Heat distribution and heat penetration studies are important components to determine temperature uniformity within the equipment and establish sterilization conditions. Biological indicators are used to validate the sterilization process achieves sterility assurance levels.Microbiology training module--finger dab& higeine

Microbiology training module--finger dab& higeine Srinath Sasidharan

Ěý

The document provides an overview of quality control procedures related to microbiology and hand hygiene. It discusses the importance of hand hygiene in reducing pathogen transmission, proper hand washing and sanitization techniques, and highlights frequently missed areas. It also describes finger dab testing procedures conducted every six months to monitor bacterial levels on personnel and ensure standards are met. Personnel hygiene policies regarding illness, clothing, and health examinations are outlined to maintain cleanliness. Demonstrations of proper glove removal and disposal techniques conclude the document.08 cleanroom

08 cleanroomshahanapsg

Ěý

This document discusses cleanrooms, including their features, standards, stages of cleanliness, and subsystems. Cleanrooms are controlled environments used in scientific research and lithography to control contamination. They maintain very low levels of environmental pollutants and particles through filtered air, temperature/humidity control, laminar airflow, and other subsystems like water, gas, and construction standards. Cleanrooms are classified based on particle counts using Federal and ISO standards for different stages of static, operational and as-built cleanliness.Environmental monitoring

Environmental monitoringShivangi Somvanshi

Ěý

This document discusses environmental monitoring and various methods used for it. It covers the following key points in 3 sentences:

Environmental monitoring involves systematically sampling air, water, soil, and biota to observe the environment and gain knowledge. It is undertaken for reasons such as identifying pollution levels, sources, and effects on health. Common monitoring methods include ground-based sampling, modeling, and satellite-based monitoring of various environmental aspects such as atmosphere, land, water quality, and natural hazards.Design and operation of clean room PPT MANIK

Design and operation of clean room PPT MANIKImran Nur Manik

Ěý

This document provides information about clean rooms and aseptic areas. It defines clean rooms as rooms with controlled particulate and microbial contamination to minimize introduction of contaminants. Aseptic areas are designed to prevent microbial contamination of products during production. Sources of contamination include external sources like the air system as well as internal sources such as operators, equipment and raw materials. Different types of air flows and classifications of clean rooms are described. Key aspects of clean room design include air filtration and personnel protective clothing requirements.Effective Use of Environmental Monitoring Data Trending

Effective Use of Environmental Monitoring Data TrendingInstitute of Validation Technology

Ěý

In this presentation from the Institute of Validation Technology's Life Sciences Aseptic Processing, Kim Van Antwerpen discusses collecting environmental data, methods for trending, and interpreting and sharing environmental monitoring data.ENVIRONMENTAL MONITORING

ENVIRONMENTAL MONITORINGSrinath Sasidharan

Ěý

The document provides an overview of microbial monitoring in a manufacturing area. It discusses:

1) The purpose of an environmental monitoring program is to provide crucial information on the quality of the aseptic processing environment during manufacturing and to prevent the release of contaminated batches.

2) Microbial monitoring tests for viable and non-viable particles in critical areas like cleanrooms, tank rooms, and packaging areas to demonstrate control of microorganisms.

3) Sources of contamination can come from air, personnel, equipment, cleaning agents and more. Monitoring must meet regulatory standards from agencies like FDA, ISO, and USP.Gowning

GowningChittaranjan Das

Ěý

Gowning refers to wearing special garments to control particulate contamination in cleanrooms. Correct gowning procedures are important because contamination can be invisible. Operators must be well-trained in gowning to avoid introducing contamination. Gowning includes showering and hygiene at home, changing at work while avoiding contact with floors, and wearing multiple layered garments specific to each cleanroom grade that fully cover the body and shed no particles. Proper gowning allows entry to production areas while avoiding contamination.HVAC SYSTEM IN PHARMACEUTICAL INDUSTRY

HVAC SYSTEM IN PHARMACEUTICAL INDUSTRYNamdeo Shinde

Ěý

This document discusses environmental control and air handling systems in pharmaceutical manufacturing. It covers factors like temperature, humidity, air movement and contamination that can impact product quality. Uncontrolled environments can lead to product degradation or contamination. Cross-contamination can be minimized through personnel procedures, adequate facilities, cleaning and protection of products. Proper heating, ventilation and air conditioning (HVAC) systems are important to control airborne particles and microbes and maintain room conditions. Monitoring of HVAC systems includes testing for particulates, filter integrity, air changes and microbiological levels.Ide bisnis eceng gondok

Ide bisnis eceng gondokAdhitya Maulana Yusuf

Ěý

Eceng gondok (Eichhornia crassipes) merupakan gulma air yang berkembangbiak dengan cepat. Salah satu cara menanggulanginya adalah memanfaatkannya sebagai bahan baku kertas seni. Pemanfaatan eceng gondok untuk kertas seni telah dilakukan dan hasilnya cukup memuaskan. Produk kertas seni ini berpotensi dikembangkan dan dipasarkan di daerah wisata sekitar Danau Toba sebagai souvenir.pharmaceutical clean room

pharmaceutical clean room Kiran Thakur

Ěý

This document provides an introduction to pharmaceutical clean rooms. It discusses the purpose of clean rooms which is to promote successful cleanroom operations and ensure safety. Clean rooms are classified according to international standards based on the number of permitted particles per cubic meter of air. Sources of contamination are discussed as well as methods for contamination control including personnel control, environmental control, and atmospheric monitoring. The conclusion states that the main purpose of a clean room is to prevent contamination of products and ensure quality according to good manufacturing practices.AMTS Construction Management, Project Management, Facility Solutions Expertise

AMTS Construction Management, Project Management, Facility Solutions ExpertiseAM Technical Solutions, Inc

Ěý