Triz competition 2014 part2

- 1. ? Machine constantly breakdown every few weeks. ? Used 2 days to solve the problem (temporarily) ? Cause loss of time and money

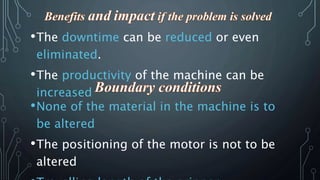

- 2. ?The downtime can be reduced or even eliminated. ?The productivity of the machine can be increased ?None of the material in the machine is to be altered ?The positioning of the motor is not to be altered ?Travelling length of the gripper

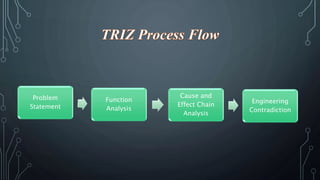

- 3. Problem Statement Function Analysis Cause and Effect Chain Analysis Engineering Contradiction

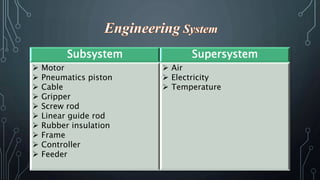

- 4. Subsystem Supersystem ? Motor ? Pneumatics piston ? Cable ? Gripper ? Screw rod ? Linear guide rod ? Rubber insulation ? Frame ? Controller ? Feeder ? Air ? Electricity ? Temperature

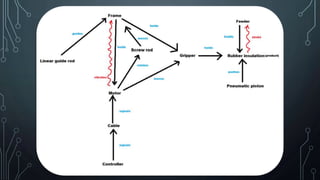

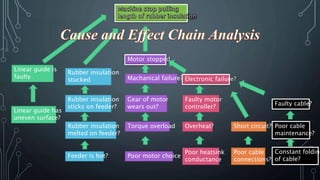

- 6. Linear guide is faulty Linear guide has uneven surface? Rubber insulation stucked Rubber insulation sticks on feeder? Rubber insulation melted on feeder? Feeder is hot? Motor stopped Machanical failure? Gear of motor wears out? Torque overload Poor motor choice Electronic failure? Faulty motor controller? Overheat? Poor heatsink conductance Short circuit? Poor cable connections? Faulty cable? Poor cable maintenance? Constant folding of cable?

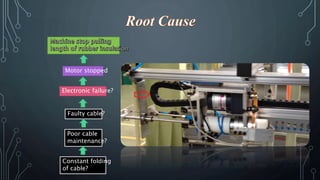

- 7. Motor stopped Electronic failure? Faulty cable? Poor cable maintenance? Constant folding of cable?

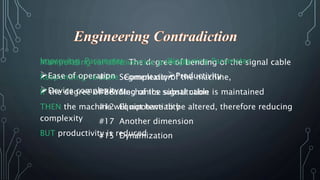

- 8. Improving Parameter : ?Ease of operation ?Device complexity Worsening Parameter : ?Productivity Manipulating variable: Inventive The degree principle of bending of the signal cable Responding variable: Complexity of the machine, IF the degree of bending of the signal cable is maintained THEN the machine will not have to be altered, therefore reducing complexity BUT productivity is reduced #1 Segmentation #28 Mechanics substitution #12 Equipotentiality #17 Another dimension #15 Dynamization

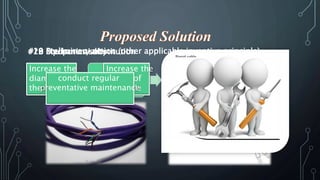

- 9. #28 10 Mechanics Preliminary substitution action (other applicable inventive principle) normal fixed length cable flexible coiled cable 12 Equipotentiality Increase the diameter of the imaginary Increase the length of the cable conduct OR regular preventative maintenance

- 10. After TRIZ applied : ? Problem of the machine has been identified ? Best Solution : Replace signal cables with the flexible coiled cable