Imran CV

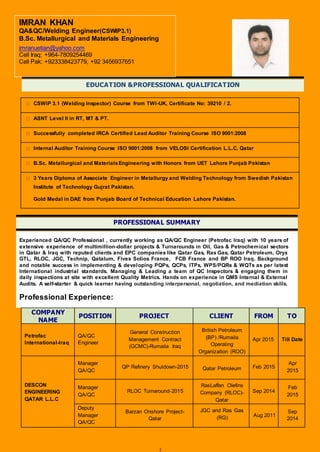

- 1. 1 EDUCATION &PROFESSIONAL QUALIFICATION ïŠ CSWIP 3.1 (Welding Inspector) Course from TWI-UK, Certificate No: 39210 / 2. ïŠ ASNT Level II in RT, MT & PT. ïŠ Successfully completed IRCA Certified Lead Auditor Training Course ISO 9001:2008 ïŠ Internal Auditor Training Course ISO 9001:2008 from VELOSI Certification L.L.C. Qatar ïŠ B.Sc. Metallurgical and MaterialsEngineering with Honors from UET Lahore Punjab Pakistan ïŠ 3 Years Diploma of Associate Engineer in Metallurgy and Welding Technology from Swedish Pakistan Institute of Technology Gujrat Pakistan. Gold Medal in DAE from Punjab Board of Technical Education Lahore Pakistan. PROFESSIONAL SUMMARY Experienced QA/QC Professional , currently working as QA/QC Engineer (Petrofac Iraq) with 10 years of extensive experience of multimillion-dollar projects & Turnarounds in Oil, Gas & Petrochemical sectors in Qatar & Iraq with reputed clients and EPC companies like Qatar Gas, Ras Gas, Qatar Petroleum, Oryx GTL, RLOC, JGC, Technip, Qatalum, Fives Solios France, FCB France and BP ROO Iraq. Background and notable success in implementing & developing PQPs, QCPs, ITPs, WPS/PQRs & WQTs as per latest International industrial standards. Managing & Leading a team of QC Inspectors & engaging them in daily inspections at site with excellent Quality Metrics. Hands on experience in QMS Internal & External Audits. A self-starter & quick learner having outstanding interpersonal, negotiation, and mediation skills. Professional Experience: COMPANY NAME POSITION PROJECT CLIENT FROM TO Petrofac International-Iraq QA/QC Engineer General Construction Management Contract (GCMC)-Rumaila Iraq British Petroleum (BP) /Rumaila Operating Organization (ROO) Apr 2015 Till Date DESCON ENGINEERING QATAR L.L.C Manager QA/QC QP Refinery Shutdown-2015 Qatar Petroleum Feb 2015 Apr 2015 Manager QA/QC RLOC Turnaround-2015 RasLaffan Olefins Company (RLOC)- Qatar Sep 2014 Feb 2015 Deputy Manager QA/QC Barzan Onshore Project- Qatar JGC and Ras Gas (RG) Aug 2011 Sep 2014 IMRAN KHAN QA&QC/Welding Engineer(CSWIP3.1) B.Sc. Metallurgical and Materials Engineering imranuetian@yahoo.com Cell Iraq: +964-7809254469 Cell Pak: +923338423779, +92 3456937651

- 2. 2 DUTIES & RESPONSIBILITIES IN PETROFAC INTERNATIONAL IRAQ ïž Responsible for monitoring and reporting compliance with project specifications, drawings, codes, standards and procedures of all fabrication, installation, erection and testing ïž processes during construction leading to mechanical completion. ïž Recommend methods to improve overall quality and assists in analyzing quality concerns. ïž Supervise and coordinate Other Contractorsâ inspection personnel. ïž Monitor, supervise and assist Other Contractorsâ to achieve the planned quality objectives. ïž Witness inspection/test within their disciplines based on approved ITPs. ïž Ensure installation and test procedure(s) are followed. ïž Coordinate all site inspections with the site subcontractors. ïž Assist discipline leader in forecasting Inspection/Test requirements of each tagged items ïž Ensure that all inspection reports are accurate and that all attached documents are current status. ïž Ensure all work is correctly prepared prior to any inspection being undertaken. ïž Review all inspection reports for compliance. ïž Liaise with the site construction engineers and provide assistance when requested. ïž Prepare non-conformance reports to the SQM and assist in developing corrective actions. ïž Coordinate with the site subcontractors to ensure that communications exist and are maintained. ïž Assist the site subcontractors in the resolution of drawing interpretation. ïž Review work procedures and method statements for compliance with good work practices and the customers contract specializations. ïž The issuance of non-conformance reports in conjunction with the SQM. ïž The completion of QC site instructions and coordinate their closure. The review of inspection test packages during the course of construction activities. ïž Compliance with the site's health and safety regulations. ïž Ensure installation in compliance with project specifications, drawings and applicable code requirements. ïž Monitor performance of sub-contractors, ensure personnel are qualified and competent to perform allocated tasks, have valid certification, where required, for the techniques in use. ïž Monitor calibration status and condition of Inspection/Test and Measuring instruments. DESCON ENGINEERING QATAR L.L.C Lead QA&QC /Welding Engineer First Shut Down of Plateau Maintenance Project (PMP) in RLIC, Qatar (Qatar Gas) TCJV and QATAR GAS Jan 2011 Aug 2011 QA&QC /Welding Engineer EPIC of Up-gradation of Maleic Acid Dosing System Project at Oryx GTL, Qatar Oryx GTL Jun 2010 Jan 2011 QA&QC /Welding Engineer Fahahil Main, North, South Degassing Station Dukhan Fields (Qatar Petroleum) Qatar Petroleum Mar 2010 Jun 2010 Welding/Piping Inspector QATALUM Project, Meseieed Qatar Fives Solios, France Jan 2009 Mar 2010 Welding/Piping Inspector QNCC Cement Plant- Umm Bab, Qatar FCB Cement, France Jan 2008 Jan 2009 DESCON ENINEERING LTD LAHORE Pak. Welding/Piping Inspector DEW Workshop Lahore BHP, OGDCL, SNGPL, Packages Ltd, MOL, ENI Jan 2007 Jan 2008

- 3. 3 ïž Coordinate with construction supervisors for timely issue of RFIâs as work progress. ïž Reports inspection results and quality performance to related Discipline Leader on a daily basis. ïž Ensure closure of all RFIâs and related inspection/test records (ITRs) immediately after successful completion of each inspection. ïž Report daily RFI and ITR closure status to discipline leader at the end of the each working day. ïž Monitor completion of system/sub system in his area based on previously forecasted ITRâs. ïž Report back to discipline leader, if any refining required in ITR forecast based on actual site condition. ïž Immediately report any cost effecting inspection results to discipline leader and also highlight to engineering. ïž Perform Daily Surveillance at site and report findings to SQM. Participate in Quality Walkthroughs. ïž Perform pre-acceptance survey of works and documentation prior to testing. ïž Carry out any other duties as and when required by the discipline supervisor. DUTIES & RESPONSIBILITIES IN DESCON ENGINEERING QATARL.L.C ïž Liaising with client in project kick off meeting. ïž Preparing QA/QC manpower mobilization plan. ïž Estimating welding consumable quantities and reviewing purchase orders for consumables. ïž Review of MARs pertaining to consumables & materials as per project specification. ïž Prepare & review project specifications and developing Procedures, ITPâs, Method Statements, Level-4 formats and project related quality documents as per requirements. ïž Incoming materials inspections as per MTCâs and controlling the store IMTE as per procedures. ïž Calculating appraisal and failure costs as per SOP. ïž True implementation of QMS at project site. ïž Conducting in house audits to ensure effective implementation of procedures and system as per ISO 9001:2008. ïž Conducting trainings and refresher sessions for improving QA/QC personnel technically as well professionally. ïž Stream lining all ongoing activities as per inspection frequencies and ITPs both at site & fab shops. ïž Managing a team of QC Inspectors & engaging them at site & fab shops for inspections as per approved ITPs. ïž Review of work scope to determine WPS requirements with respect to ranges of materials, sizes and proposed welding processes in line with specification and code requirements. ïž Plan & Prepare WPS/PQRs as per ASME IX/ASME B31.3/ASME B31.8/AWS D1.1 standards. ïž Conducting Procedure Qualification Records (PQRs) and Welder Qualification Tests as per specification & code requirements. ïž Advising Construction of welderâs qualification range for the works. ïž Welding experience on a number of different materials like Carbon Steels, Low Carbon Steels, Stainless Steel, Super Stainless Steel (SMO254), Duplex SS (S31803), Super Duplex SS (S32750), Copper Nickel, Inconel (N06625), Incolloy (N08825), CS with SS Clad, Titanium, Alloy Steel (P11 & P22) and welding of dissimilar materials. ïž To conduct quality tool box talks at site regarding prevailing issues. ïž Monitoring and reporting welder performance throughout project duration per specification and code requirements. ïž Detecting unacceptable trends in welding and performance and initiating corrective action.

- 4. 4 ïž Selection and approval of welding consumables. ïž Specify WPSâs on isometric control sheet. ïž To carry out Assessments of Welding, Piping & NDE Control at site on bi-weekly basis. ïž Coordinating & monitoring NDT, PWHT, PMI and Test pack activities. ïž Compiling and handing over final dossier to client as per contract requirement. ïž Material receiving inspection (Pipes, Fittings, Flanges) as per Specifications & Standards. ïž Fabrication inspection for different grades of material ranging in different thicknesses. ïž Welding stage inspection as Pre welding, during welding and post welding phases. ïž Reviewing the weekly and cumulatively date base regarding weld rejection rate as per applicable procedure. ïž Hands on experience in the inspection of equipment (rotary & static) & steel structure. ïž Conducting the weekly quality meeting with client to address & discuss quality matters at project. ïž Reviewing the test packs as per approved procedure. ïž Witnessing the hydro-test as per piping ITP. ïž Ensuring compliance to Quality, Environment, Safety system requirements and documentation like Record control, Record submission etc. ïž Coordination with Field Engineering Dept. Construction Dept. and Client for smooth running of the Project. ïž Monitoring and reporting welder performance throughout project duration per specification and code requirements. ïž Issuance of NCRs as a result of any non-compliance at site. ïž Follow up of NCRs for corrective actions as per approved dispositions till its closure. CERTIFICATION / TRAININGS ïŠ Safe Use of Nuclear Gauges from Pakistan Nuclear Regulatory Authority (PNRA). Two Days ïŠ Cathodic protection from SUI Northern Gas Pipelines LTD One week ïŠ Pipelines integrity Assessment from SUI Northern Gas Pipelines LTD One week ïŠ Two months comprehensive training on âCONSTRUCTION TECHNOLOGY,MANAGEMENT AND PLANNINGâ from DESCON ENGINEERING LAHORE Two months ïŠ Training on Welding Engineering from DMBA (Descon Manufacturing Business Area) Two weeks ïŠ Training on Quality Control at DESCON Headquarters Lahore 20 Days ïŠ H2S Safety Training for QP Fahahil Shut Down 1 Day ïŠ Internship on Cathodic Protection with SNGPL during final year of my Graduation Two months ïŠ In House Internal Auditor Training of ISO 9001 at Descon-Qatar Two Days ïŠ Training on Safety work at Height conducted by Marine & Offshore Group Pvt. Ltd 1 Day ïŠ Full safety induction package at Barzan Onshore Project-Qatar 1 Day

- 5. 5 ïŠ Attended safety induction by Rumaila Operating Organization (ROO)-Iraq 1 Day SKILLS ï§ Welding Engineering (WPS/PQR & WQT) ï§ Materials ï§ QMS Auditing ï§ Preparation of ITPs & QCPs ï§ Site Inspections Coordination ï§ NDT Techniques & Management at sites ï§ PWHT ï§ Project Management ï§ Communication (Written & Verbal) ï§ Quality Documentation & Handover ï§ Team Work ï§ Time Management ï§ Piping (Fabrication & Erection) ï§ Equipment Installations (Quality Perspective) ï§ Steel Structure Erection (Quality Perspective) COMPUTER SKILLS ï Having institutional knowledge & working experience of MS Windows &Internet. ï MS Excel, MS Work, MS Power Point PERSONAL QUALITIES & INTERESTS ï Strong Safety work ethic ï Team player ï Positive attitude ï Ability to deliver solutions ï Ability to embrace and deliver change when required ï Excellent verbal and written communication. ï Technical Studies ï Book Reading ï Cricket & Badminton ï Social Work & Welfare ï Swimming LANGUAGES ï English ï Urdu ï Hindi ï Arabic ï Punjabi Fatherâs Name GhulamRasool Marital Status Married Permanent Address Village Gajoo, P/O Haji Muhammad, Teh. Kharian Distt. Gujrat-Pakistan Date of Birth 05Nov 1979 Nationality Pakistani PERSONAL DATA

- 6. 6 Blood Group AB+ CNIC Number 34202-0712805-7 Passport No. UW4108052 Qatari Driving License 27958602228