Ecpn operations presentation 1

- 1. from Exploration to Operation

- 2. Before Digging • The natural landscape is cleared at the El Capitan mine site.

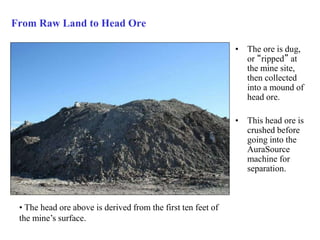

- 3. From Raw Land to Head Ore • The ore is dug, or “ripped” at the mine site, then collected into a mound of head ore. • This head ore is crushed before going into the AuraSource machine for separation. • The head ore above is derived from the first ten feet of the mine’s surface.

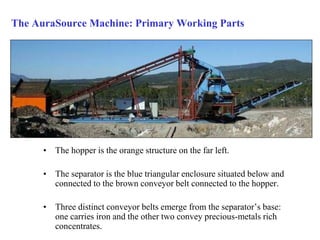

- 4. The AuraSource Machine: Primary Working Parts • The hopper is the orange structure on the far left. • The separator is the blue triangular enclosure situated below and connected to the brown conveyor belt connected to the hopper. • Three distinct conveyor belts emerge from the separator’s base: one carries iron and the other two convey precious-metals rich concentrates.

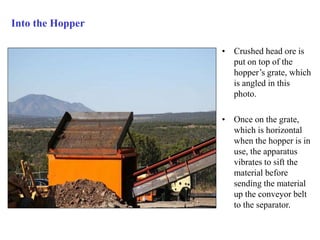

- 5. Into the Hopper • Crushed head ore is put on top of the hopper’s grate, which is angled in this photo. • Once on the grate, which is horizontal when the hopper is in use, the apparatus vibrates to sift the material before sending the material up the conveyor belt to the separator.

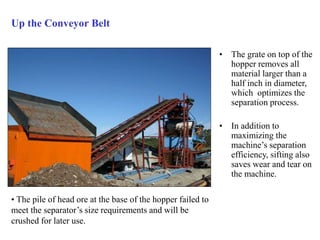

- 6. Up the Conveyor Belt • The grate on top of the hopper removes all material larger than a half inch in diameter, which optimizes the separation process. • In addition to maximizing the machine’s separation efficiency, sifting also saves wear and tear on the machine. • The pile of head ore at the base of the hopper failed to meet the separator’s size requirements and will be crushed for later use.

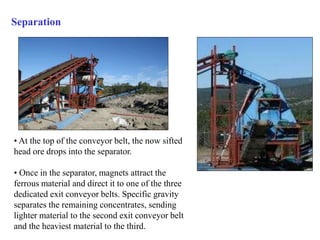

- 7. Separation • At the top of the conveyor belt, the now sifted head ore drops into the separator. • Once in the separator, magnets attract the ferrous material and direct it to one of the three dedicated exit conveyor belts. Specific gravity separates the remaining concentrates, sending lighter material to the second exit conveyor belt and the heaviest material to the third.

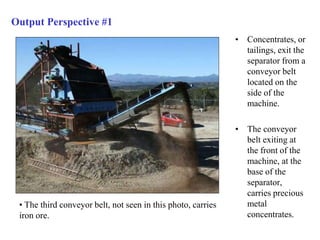

- 8. Output Perspective #1 • Concentrates, or tailings, exit the separator from a conveyor belt located on the side of the machine. • The conveyor belt exiting at the front of the machine, at the base of the separator, carries precious metal concentrates. • The third conveyor belt, not seen in this photo, carries iron ore.

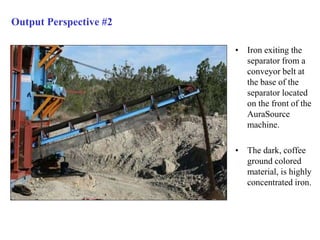

- 9. Output Perspective #2 • Iron exiting the separator from a conveyor belt at the base of the separator located on the front of the AuraSource machine. • The dark, coffee ground colored material, is highly concentrated iron.

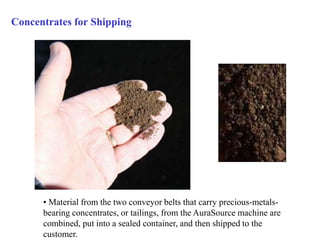

- 10. Concentrates for Shipping • Material from the two conveyor belts that carry precious-metals-bearing concentrates, or tailings, from the AuraSource machine are combined, put into a sealed container, and then shipped to the customer.

- 11. Green Technology Monetizes the Land • ECPN operates the only AuraSource Precious Metals separation machine in the USA. • The process does not use any water or toxic chemicals. It is, arguably, the greenest industrial extraction of precious metals ever developed. • At full capacity, the machine can process 400 tons of head ore per hour. Note: the above image was sourced via Google Images.

- 12. Summary Note: the above image was sourced via Google Images. • ECPN has transitioned from an exploratory emphasis to an operational strategy of repeatable precious metals recovery. • Operational status commences revenue generation to fund further mining, creates cash flow, and validates commercial viability. • This strategy of multiple production processes, both iron and precious metals, facilitates the execution of the long-standing objective of selling the company.