Fish in the Loop: Exploring RAS - Julie Hansen Bergstedt

0 likes142 views

Fish in the Loop: Exploring RAS Julie Hansen Bergstedt, DTU Aqua, Denmark

1 of 18

Recommended

Prof Graham Mills - The Fate of Pharmaceutical Residues in the Aquatic Enviro...

Prof Graham Mills - The Fate of Pharmaceutical Residues in the Aquatic Enviro...onthewight

╠²

Professor Graham Mills presented his talk "The Fate of Pharmaceutical Residues in the Aquatic Environment"

A full background of what contaminates water, from Pharmacology and Agriculture. People passing medicines they have taken or disposing of them by throwing them down the toilet are causing major changes to fish and other water dwelling creatures.

- October 2014 - Cafe Scientifique Isle of WightMonitoring of Water quality in aquaculture production system

Monitoring of Water quality in aquaculture production systemhg panmei

╠²

#Water quality parameters and Management.

#Recent advances in monitoring of water quality in Aquaculture Production system.

Ichthyology_II_2012_Physiology_Lectures_Part_1.pptx

Ichthyology_II_2012_Physiology_Lectures_Part_1.pptxSafaa Sharaf

╠²

1) The document discusses respiration in fish, including how oxygen levels differ between water and air, how fish extract oxygen from water using gills, and how their metabolism compares to other aquatic animals like turtles.

2) It describes the challenges of living in water, which is more dense and viscous than air, and how fish have developed efficient respiratory and circulatory systems to overcome this.

3) Intermittent respirometry is discussed as a method to measure oxygen consumption and metabolic rates in fish, with examples given of how it has been used to study the effects of stress and oxygen levels on metabolism.The effect of climate change on natural food levels

The effect of climate change on natural food levelsAbd El-Rahman Khattaby

╠²

Climate change is affecting natural food levels in oceans and seas in several ways:

1) Rising water temperatures and ocean acidification are damaging coral reefs and reducing habitats for fish and other marine life.

2) Changes in rainfall patterns and melting ice are altering freshwater flows into oceans, affecting food sources and habitats.

3) Increased frequency of extreme weather events like hurricanes are causing disruption to marine ecosystems.End of pipe treatment: Unlocking the potential of RAS waste - Carlos Octavio ...

End of pipe treatment: Unlocking the potential of RAS waste - Carlos Octavio ...Faculty of Applied Chemistry and Materials Science

╠²

End of pipe treatment: Unlocking the potential of RAS waste

Carlos Octavio Letelier-Gordo, DTU Aqua, DenmarkBjarne hald-olsen-developments-in-recirculating-aquaculture-systems-for-salmo...

Bjarne hald-olsen-developments-in-recirculating-aquaculture-systems-for-salmo...George Stefanov

╠²

The document discusses developments in recirculating aquaculture systems (RAS) for salmon grow-out in Europe and Asia. It provides an introduction to Billund Aquaculture, a Danish company experienced in RAS design and operation. Examples are given of several large-scale RAS facilities for salmon in Europe and Asia, including details on their design and performance. Challenges with disease experienced by one Danish RAS farm are also mentioned.Implementing and learning from nutrition-sensitive fish agri-food systems, e....

Implementing and learning from nutrition-sensitive fish agri-food systems, e....WorldFish

╠²

Worldfish: Nutrition Sensitive Fish Agri-Food Systems Workshop, presented by Absalom Sakala, Principal Environment Management Officer, Ministry of Water Development, Sanitation and Environmental ProtectionDragon Water Group Aquaculture 2

Dragon Water Group Aquaculture 2Slava Avramenko

╠²

The document presents a vision for land-based, sustainable marine aquaculture in Germany using recirculating aquaculture systems. It aims to securely produce seafish and marine organisms for food while protecting the environment. This would be achieved through high water quality, nutrient recycling, and integration with algae and seaweed to uptake nutrients from fish farming discharge water. Calculations show the potential cost savings from water renewal rate reductions and nutrient recycling.Aquaculture System (1).ppt

Aquaculture System (1).ppthammadnoor3

╠²

This document discusses different types of aquaculture systems classified by level of inputs, including extensive, semi-intensive, and intensive systems. Extensive systems include culture-based fisheries and pond and enclosure aquaculture with very low levels of inputs and production of 50-350 kg/acre. Semi-intensive pond systems use some supplemental feeding and fertilization to boost production to 0.5-1.5 tons/acre. Intensive pond and tank systems involve high stocking densities, manufactured feeding, and water management for high production of up to 24 tons/acre.Water quality management

Water quality managementrongkup

╠²

This document provides information on aquaculture environment management and water quality management. It discusses analyzing water quality parameters, understanding ideal value ranges, and using chemical treatment and mechanical control. Specific parameters like nitrogen, pH, dissolved oxygen are analyzed. Common treatments include liming to adjust pH, using alum as a coagulant, and chlorination for disinfection. Filtration through gravel or activated carbon can be used for mechanical control. The objective is to manage water quality to provide optimal growing conditions for farmed fish.use-of-bioremediated-sewage-effluent-for-fish-survival-2332-2543-1-106

use-of-bioremediated-sewage-effluent-for-fish-survival-2332-2543-1-106Yousaf Riaz

╠²

This document summarizes a study that investigated the potential of using bioremediated sewage effluent from Shehzad Town, Islamabad, Pakistan for fish production. Two ponds were used, one with fresh water and one with the treated sewage effluent. Tilapia and common carp were stocked in both ponds. Less than 1% survival was observed in the pond with treated sewage water, while 100% survival occurred in the fresh water pond. Analysis found high levels of ammonical nitrogen, nitrate nitrogen, and chlorides in the treated water, which were the likely cause of fish mortality. Further treatment of the water using the Coontail plant significantly reduced the levels of these compounds andSewage fed fish culture.pptx

Sewage fed fish culture.pptxmonjit paul

╠²

The document discusses sewage-fed fish culture in the East Kolkata Wetlands and its socioeconomic impacts. Sewage is treated through various processes like primary, secondary, and tertiary treatment before being channeled into fish ponds. Fish farmers have developed unique techniques to utilize sewage for high fish production. Over 60,000 people depend on the wetlands for their livelihood through activities like aquaculture, agriculture, and garbage farming. While the area under sewage-fed fish culture has declined due to urbanization, it still supports local communities and meets fish demand for Kolkata.marineresouesppt-170306092008.pdf

marineresouesppt-170306092008.pdfSadaqat Ali

╠²

Marine resources are things from the ocean that organisms need to survive and include fresh water, minerals, energy sources, and food. The document outlines various types of marine resources like fresh water obtained through desalination, minerals dissolved in or deposited in seawater, energy from sources like ocean thermal energy conversion and tides, and food resources from fisheries. These resources provide benefits like food, fuel, minerals, and habitats but also face threats from pollution and overexploitation which requires proper management through techniques like regulated fishing and pollution control.Marine resoues ppt

Marine resoues pptNavjotpreet Kaur

╠²

Marine resources are things from the ocean that organisms need to survive and include fresh water, minerals, energy sources, and food. The document outlines various types of marine resources and how they are used. It also discusses conservation efforts like regulating exploitation and accurately estimating demand and supply to ensure sustainable use of resources like fisheries. Major threats to marine environments are also listed, such as pollution from waste, garbage, oil, and increased acidity from carbon dioxide.Water pollution by waseeq ur rehman

Water pollution by waseeq ur rehmanWaseeqrehman

╠²

Water Pollution

Water pollution occurs in many different forms, is produced in a variety of ways, and has a range of effects on the biological and physical environment. Consider some common examples:

A river dashing down a steep mountainside cuts into its rocky bed and carries away sand, silt, and pebbles. When the river reaches flat ground, it deposits these materials on the river bottom.

A farmer spreads herbicides, pesticides, and fertilizer on her land, knowing the increase in crop value this practice will produce. During the next rain, some of those chemicals are washed away into the nearest lake, where they remain suspended for weeks or months.

A small crack develops in an underwater pipe that carries oil from an offshore drilling rig to a holding tank on land. Crude oil seeps out of the crack and into the ocean, where marine plants and animals are exposed to its toxic effects.

Chapter 1; Water Pollution

Chapter 1; Water PollutionMuhammadAsifIdrees1

╠²

This document provides an introduction to a course on environmental issues related to the textile industry. It covers various topics related to water pollution, including unusual properties of water, the hydrologic cycle, stocks of water on Earth, water usage, and types of water pollutants such as pathogens, oxygen demanding wastes, and nutrients. The course modules will address issues like air, water, and noise pollution from different textile industry processes; environmental management systems; eco-labeling; cleaner production technologies; effluent treatment; and occupational health and safety.Aquaculture presentation in Al-Quds University by Dr.Mutaz Qutob

Aquaculture presentation in Al-Quds University by Dr.Mutaz QutobAnas Noor

╠²

The document discusses aquaculture, including its definition, history, and commonly cultured species. Aquaculture is defined as the farming of aquatic organisms under controlled conditions. Historically, aquaculture has been practiced for thousands of years, with carp farming in China dating back to 2500 BC. Currently, tilapia and carp are two of the most important species cultured globally due to their hardiness, prolific breeding, and high market value. The document also reviews considerations for aquaculture systems including water quality management.K013146471

K013146471IOSR Journals

╠²

1) The document evaluates the performance of a locally developed paddle wheel aerator on catfish effluent quality in Lagos, Nigeria.

2) Two basins containing diluted catfish effluent were used - one with a paddle wheel aerator and one without (the control).

3) Water quality parameters like suspended solids, nitrogen, phosphorus, ammonia, nitrite and biochemical oxygen demand were measured over time in both basins.

4) The results showed that the paddle wheel aerator significantly reduced levels of all water quality parameters measured compared to the control basin without aeration.Water recycling

Water recyclingRaquel Gavil├Īn P├Īrraga

╠²

Water is essential for life but limited on Earth. It is important to recycle and purify water to ensure a sustainable supply for human use. Various physical, chemical, and biological processes can be used to purify water through processes like filtration, sedimentation, chlorination, and the use of lagoons and reactors to break down organic pollutants using microorganisms. Proper treatment is needed to remove contaminants and pathogens to provide safe drinking water.Paper discussion Fabry et al. 2008

Paper discussion Fabry et al. 2008Loretta Roberson

╠²

1) Increased atmospheric CO2 is being absorbed by the oceans, raising CO2 levels and lowering pH, a process known as ocean acidification.

2) This affects calcifying organisms by decreasing carbonate ion concentrations needed to form calcium carbonate shells and skeletons. It impacts organisms' ability to calcify and causes dissolution of shells.

3) Pteropods, an important food source for salmon and other species, are especially vulnerable as they secrete the more soluble form of calcium carbonate, aragonite. Ocean acidification is restricting their habitat distribution.Ensuring ecosystem integrity in Indian Sundarbans

Ensuring ecosystem integrity in Indian Sundarbansaranyermajhe

╠²

Peer Assignment - Turn Down the Heat: Why a 4┬░C Warmer World Must be Avoided : This artifact is intended for decision makers in the state of West Bengal, India. There is relatively little knowledge on the status of the Sundarbans ecosystem resilience and biodiversity groups contributing to it. However, the loss of diversity within functional groups may weaken the ability of the system to adapt to climate change impacts and therein impact the dependant community. The ecosystem linkers that control resilience and ecological stability in the Sundarbans should be determined. Decision makers will hardly have any control over extraneous drivers of change such as the climate but can alter present policies and pattern of governance.Potential of recirculating aquaculture system in ornamental fish farming

Potential of recirculating aquaculture system in ornamental fish farmingHarsh Dhimmar

╠²

Combined information regarding ornamental fish, present condition of India, potential fish species, recirculating aquaculture system, case study

Aquatic Pollution (2).pptx

Aquatic Pollution (2).pptxAmitSharma3227

╠²

This document discusses agricultural wastes and their impacts on aquatic systems. It defines agricultural waste and lists common types. Nutrients in wastes like manure are described. Factors affecting the nutrient composition of manure are outlined. The document also discusses dissolved oxygen, biological oxygen demand, chemical oxygen demand, effects of organic matter on soil properties, eutrophication, and major and minor plant nutrients in aquatic systems.Eutrophication

EutrophicationJ K COLLEGE,PURULIA

╠²

Eutrophication is the accumulation of nutrients in aquatic ecosystems that alters plant and animal populations and brings changes to the community structure. It occurs naturally over hundreds or thousands of years but human activities like sewage, fertilizer runoff and industrial discharges can accelerate the process through cultural eutrophication over just decades. Major sources of excess nutrients are agricultural fertilizers, domestic sewage and livestock wastes which provide both inorganic and organic nutrients. Eutrophication impacts water chemistry by increasing levels of substances like pH, dissolved oxygen, carbon dioxide, ammonia, nitrates/nitrites and phosphates.Blue carbon research: An Indian Perspective

Blue carbon research: An Indian PerspectiveCIFOR-ICRAF

╠²

Presented by Dr Gurmeet Singh, Futuristic Research Division, National Centre for Sustainable Coastal Management Ministry of Environment Forest & Climate change at Mangrove Research in Indian sub-continent: Recent Advances, Knowledge Gaps and Future Perspectives on 8 - 10 December 2021Water Quality Management In Rivers

Water Quality Management In Riverskatsgame88

╠²

This document discusses various aspects of water quality management, including pollutants, oxygen demand, nutrients, and eutrophication of lakes. It notes that the nature of pollutants and aquatic life depend on factors like the river type, climate, and land use. Measuring dissolved oxygen, biochemical oxygen demand, and nutrients can assess a river's ability to self-purify and the impact of waste discharge. Excessive nutrients like phosphorus and nitrogen can lead to excessive algal growth and eutrophication in lakes.Organic farming

Organic farmingparulChaurasia6

╠²

Organic aquaculture refers to ecological production management systems that promote biodiversity and biological cycles. It is based on minimal off-farm inputs and holistic practices. Historically, organic aquaculture developed from the organic agriculture movement in the early 1990s in Europe. Standards were established and production has grown significantly since, now totaling over 50,000 tonnes globally per year. Major species include salmon, shrimp, and carp. Principles of organic aquaculture standards include an absence of GMOs, limited stocking densities, and nutrient recycling rather than intensive inputs. While still nascent, organic aquaculture is growing in India through projects like organic scampi farming in Andhra Pradesh.Rapid pulse drying of marine biomasses - Sigurd Sannan

Rapid pulse drying of marine biomasses - Sigurd SannanFaculty of Applied Chemistry and Materials Science

╠²

Rapid pulse drying of marine biomasses

Sigurd Sannan, SINTEF Energi AS, NorwayBiochar impregnation as slow release fertilizer - Violeta Alexandra Ion

Biochar impregnation as slow release fertilizer - Violeta Alexandra IonFaculty of Applied Chemistry and Materials Science

╠²

Biochar impregnation as slow release fertilizer

Violeta Alexandra Ion, University of Agronomic Sciences and Veterinary Medicine (USAMV), RomaniaMore Related Content

Similar to Fish in the Loop: Exploring RAS - Julie Hansen Bergstedt (20)

Aquaculture System (1).ppt

Aquaculture System (1).ppthammadnoor3

╠²

This document discusses different types of aquaculture systems classified by level of inputs, including extensive, semi-intensive, and intensive systems. Extensive systems include culture-based fisheries and pond and enclosure aquaculture with very low levels of inputs and production of 50-350 kg/acre. Semi-intensive pond systems use some supplemental feeding and fertilization to boost production to 0.5-1.5 tons/acre. Intensive pond and tank systems involve high stocking densities, manufactured feeding, and water management for high production of up to 24 tons/acre.Water quality management

Water quality managementrongkup

╠²

This document provides information on aquaculture environment management and water quality management. It discusses analyzing water quality parameters, understanding ideal value ranges, and using chemical treatment and mechanical control. Specific parameters like nitrogen, pH, dissolved oxygen are analyzed. Common treatments include liming to adjust pH, using alum as a coagulant, and chlorination for disinfection. Filtration through gravel or activated carbon can be used for mechanical control. The objective is to manage water quality to provide optimal growing conditions for farmed fish.use-of-bioremediated-sewage-effluent-for-fish-survival-2332-2543-1-106

use-of-bioremediated-sewage-effluent-for-fish-survival-2332-2543-1-106Yousaf Riaz

╠²

This document summarizes a study that investigated the potential of using bioremediated sewage effluent from Shehzad Town, Islamabad, Pakistan for fish production. Two ponds were used, one with fresh water and one with the treated sewage effluent. Tilapia and common carp were stocked in both ponds. Less than 1% survival was observed in the pond with treated sewage water, while 100% survival occurred in the fresh water pond. Analysis found high levels of ammonical nitrogen, nitrate nitrogen, and chlorides in the treated water, which were the likely cause of fish mortality. Further treatment of the water using the Coontail plant significantly reduced the levels of these compounds andSewage fed fish culture.pptx

Sewage fed fish culture.pptxmonjit paul

╠²

The document discusses sewage-fed fish culture in the East Kolkata Wetlands and its socioeconomic impacts. Sewage is treated through various processes like primary, secondary, and tertiary treatment before being channeled into fish ponds. Fish farmers have developed unique techniques to utilize sewage for high fish production. Over 60,000 people depend on the wetlands for their livelihood through activities like aquaculture, agriculture, and garbage farming. While the area under sewage-fed fish culture has declined due to urbanization, it still supports local communities and meets fish demand for Kolkata.marineresouesppt-170306092008.pdf

marineresouesppt-170306092008.pdfSadaqat Ali

╠²

Marine resources are things from the ocean that organisms need to survive and include fresh water, minerals, energy sources, and food. The document outlines various types of marine resources like fresh water obtained through desalination, minerals dissolved in or deposited in seawater, energy from sources like ocean thermal energy conversion and tides, and food resources from fisheries. These resources provide benefits like food, fuel, minerals, and habitats but also face threats from pollution and overexploitation which requires proper management through techniques like regulated fishing and pollution control.Marine resoues ppt

Marine resoues pptNavjotpreet Kaur

╠²

Marine resources are things from the ocean that organisms need to survive and include fresh water, minerals, energy sources, and food. The document outlines various types of marine resources and how they are used. It also discusses conservation efforts like regulating exploitation and accurately estimating demand and supply to ensure sustainable use of resources like fisheries. Major threats to marine environments are also listed, such as pollution from waste, garbage, oil, and increased acidity from carbon dioxide.Water pollution by waseeq ur rehman

Water pollution by waseeq ur rehmanWaseeqrehman

╠²

Water Pollution

Water pollution occurs in many different forms, is produced in a variety of ways, and has a range of effects on the biological and physical environment. Consider some common examples:

A river dashing down a steep mountainside cuts into its rocky bed and carries away sand, silt, and pebbles. When the river reaches flat ground, it deposits these materials on the river bottom.

A farmer spreads herbicides, pesticides, and fertilizer on her land, knowing the increase in crop value this practice will produce. During the next rain, some of those chemicals are washed away into the nearest lake, where they remain suspended for weeks or months.

A small crack develops in an underwater pipe that carries oil from an offshore drilling rig to a holding tank on land. Crude oil seeps out of the crack and into the ocean, where marine plants and animals are exposed to its toxic effects.

Chapter 1; Water Pollution

Chapter 1; Water PollutionMuhammadAsifIdrees1

╠²

This document provides an introduction to a course on environmental issues related to the textile industry. It covers various topics related to water pollution, including unusual properties of water, the hydrologic cycle, stocks of water on Earth, water usage, and types of water pollutants such as pathogens, oxygen demanding wastes, and nutrients. The course modules will address issues like air, water, and noise pollution from different textile industry processes; environmental management systems; eco-labeling; cleaner production technologies; effluent treatment; and occupational health and safety.Aquaculture presentation in Al-Quds University by Dr.Mutaz Qutob

Aquaculture presentation in Al-Quds University by Dr.Mutaz QutobAnas Noor

╠²

The document discusses aquaculture, including its definition, history, and commonly cultured species. Aquaculture is defined as the farming of aquatic organisms under controlled conditions. Historically, aquaculture has been practiced for thousands of years, with carp farming in China dating back to 2500 BC. Currently, tilapia and carp are two of the most important species cultured globally due to their hardiness, prolific breeding, and high market value. The document also reviews considerations for aquaculture systems including water quality management.K013146471

K013146471IOSR Journals

╠²

1) The document evaluates the performance of a locally developed paddle wheel aerator on catfish effluent quality in Lagos, Nigeria.

2) Two basins containing diluted catfish effluent were used - one with a paddle wheel aerator and one without (the control).

3) Water quality parameters like suspended solids, nitrogen, phosphorus, ammonia, nitrite and biochemical oxygen demand were measured over time in both basins.

4) The results showed that the paddle wheel aerator significantly reduced levels of all water quality parameters measured compared to the control basin without aeration.Water recycling

Water recyclingRaquel Gavil├Īn P├Īrraga

╠²

Water is essential for life but limited on Earth. It is important to recycle and purify water to ensure a sustainable supply for human use. Various physical, chemical, and biological processes can be used to purify water through processes like filtration, sedimentation, chlorination, and the use of lagoons and reactors to break down organic pollutants using microorganisms. Proper treatment is needed to remove contaminants and pathogens to provide safe drinking water.Paper discussion Fabry et al. 2008

Paper discussion Fabry et al. 2008Loretta Roberson

╠²

1) Increased atmospheric CO2 is being absorbed by the oceans, raising CO2 levels and lowering pH, a process known as ocean acidification.

2) This affects calcifying organisms by decreasing carbonate ion concentrations needed to form calcium carbonate shells and skeletons. It impacts organisms' ability to calcify and causes dissolution of shells.

3) Pteropods, an important food source for salmon and other species, are especially vulnerable as they secrete the more soluble form of calcium carbonate, aragonite. Ocean acidification is restricting their habitat distribution.Ensuring ecosystem integrity in Indian Sundarbans

Ensuring ecosystem integrity in Indian Sundarbansaranyermajhe

╠²

Peer Assignment - Turn Down the Heat: Why a 4┬░C Warmer World Must be Avoided : This artifact is intended for decision makers in the state of West Bengal, India. There is relatively little knowledge on the status of the Sundarbans ecosystem resilience and biodiversity groups contributing to it. However, the loss of diversity within functional groups may weaken the ability of the system to adapt to climate change impacts and therein impact the dependant community. The ecosystem linkers that control resilience and ecological stability in the Sundarbans should be determined. Decision makers will hardly have any control over extraneous drivers of change such as the climate but can alter present policies and pattern of governance.Potential of recirculating aquaculture system in ornamental fish farming

Potential of recirculating aquaculture system in ornamental fish farmingHarsh Dhimmar

╠²

Combined information regarding ornamental fish, present condition of India, potential fish species, recirculating aquaculture system, case study

Aquatic Pollution (2).pptx

Aquatic Pollution (2).pptxAmitSharma3227

╠²

This document discusses agricultural wastes and their impacts on aquatic systems. It defines agricultural waste and lists common types. Nutrients in wastes like manure are described. Factors affecting the nutrient composition of manure are outlined. The document also discusses dissolved oxygen, biological oxygen demand, chemical oxygen demand, effects of organic matter on soil properties, eutrophication, and major and minor plant nutrients in aquatic systems.Eutrophication

EutrophicationJ K COLLEGE,PURULIA

╠²

Eutrophication is the accumulation of nutrients in aquatic ecosystems that alters plant and animal populations and brings changes to the community structure. It occurs naturally over hundreds or thousands of years but human activities like sewage, fertilizer runoff and industrial discharges can accelerate the process through cultural eutrophication over just decades. Major sources of excess nutrients are agricultural fertilizers, domestic sewage and livestock wastes which provide both inorganic and organic nutrients. Eutrophication impacts water chemistry by increasing levels of substances like pH, dissolved oxygen, carbon dioxide, ammonia, nitrates/nitrites and phosphates.Blue carbon research: An Indian Perspective

Blue carbon research: An Indian PerspectiveCIFOR-ICRAF

╠²

Presented by Dr Gurmeet Singh, Futuristic Research Division, National Centre for Sustainable Coastal Management Ministry of Environment Forest & Climate change at Mangrove Research in Indian sub-continent: Recent Advances, Knowledge Gaps and Future Perspectives on 8 - 10 December 2021Water Quality Management In Rivers

Water Quality Management In Riverskatsgame88

╠²

This document discusses various aspects of water quality management, including pollutants, oxygen demand, nutrients, and eutrophication of lakes. It notes that the nature of pollutants and aquatic life depend on factors like the river type, climate, and land use. Measuring dissolved oxygen, biochemical oxygen demand, and nutrients can assess a river's ability to self-purify and the impact of waste discharge. Excessive nutrients like phosphorus and nitrogen can lead to excessive algal growth and eutrophication in lakes.Organic farming

Organic farmingparulChaurasia6

╠²

Organic aquaculture refers to ecological production management systems that promote biodiversity and biological cycles. It is based on minimal off-farm inputs and holistic practices. Historically, organic aquaculture developed from the organic agriculture movement in the early 1990s in Europe. Standards were established and production has grown significantly since, now totaling over 50,000 tonnes globally per year. Major species include salmon, shrimp, and carp. Principles of organic aquaculture standards include an absence of GMOs, limited stocking densities, and nutrient recycling rather than intensive inputs. While still nascent, organic aquaculture is growing in India through projects like organic scampi farming in Andhra Pradesh.More from Faculty of Applied Chemistry and Materials Science (20)

Rapid pulse drying of marine biomasses - Sigurd Sannan

Rapid pulse drying of marine biomasses - Sigurd SannanFaculty of Applied Chemistry and Materials Science

╠²

Rapid pulse drying of marine biomasses

Sigurd Sannan, SINTEF Energi AS, NorwayBiochar impregnation as slow release fertilizer - Violeta Alexandra Ion

Biochar impregnation as slow release fertilizer - Violeta Alexandra IonFaculty of Applied Chemistry and Materials Science

╠²

Biochar impregnation as slow release fertilizer

Violeta Alexandra Ion, University of Agronomic Sciences and Veterinary Medicine (USAMV), RomaniaComposting blue materials - Joshua Cabell

Composting blue materials - Joshua CabellFaculty of Applied Chemistry and Materials Science

╠²

Composting blue materials

Joshua Cabell, Norwegian Centre for Organic Agriculture (NORS├śK), NorwayTraditional, current and future use of fish and seaweed for fertilisation - ...

Traditional, current and future use of fish and seaweed for fertilisation - ...Faculty of Applied Chemistry and Materials Science

╠²

Traditional, current and future use of fish and seaweed for fertilisation

Anne-Kristin L├Ėes, Norwegian Centre for Organic Agriculture (NORS├śK), NorwayAnalytical methods for blue residues characterization - Oana Crina Bujor

Analytical methods for blue residues characterization - Oana Crina BujorFaculty of Applied Chemistry and Materials Science

╠²

Analytical methods for blue residues characterization

Oana Crina Bujor, University of Agronomic Sciences and Veterinary Medicine (USAMV), RomaniaAlgaeBrew project - Unlocking the potential of microalgae for the valorisatio...

AlgaeBrew project - Unlocking the potential of microalgae for the valorisatio...Faculty of Applied Chemistry and Materials Science

╠²

AlgaeBrew project - Unlocking the potential of microalgae for the valorisation of brewery waste products into omega-3 rich animal feed and fertilisers

Carmen Gabriela Constantin, University of Agronomic Sciences and Veterinary Medicine (USAMV), RomaniaClassification and role of plant nutrients - Roxana Madjar

Classification and role of plant nutrients - Roxana MadjarFaculty of Applied Chemistry and Materials Science

╠²

Classification and role of plant nutrients

Roxana Madjar, University of Agronomic Sciences and Veterinary Medicine (USAMV), Romania

MARIGREEN PROJECT - overview, Oana Cristina Pârvulescu

MARIGREEN PROJECT - overview, Oana Cristina PârvulescuFaculty of Applied Chemistry and Materials Science

╠²

MARIGREEN PROJECT - overview

Oana Cristina Pârvulescu, Project coordinator, POLITEHNICA Bucharest, Romania

Pharmaceutical Products and Cosmetics

Pharmaceutical Products and CosmeticsFaculty of Applied Chemistry and Materials Science

╠²

The presentation of the Master of Science Degree Program "Pharmaceutical Products and Cosmetics" at Faculty of Applied Chemistry and Materials Science, University POLITEHNICA of BucharestBiorefineries and Bioproducts

Biorefineries and BioproductsFaculty of Applied Chemistry and Materials Science

╠²

The presentation of the Master of Science Degree Program "Biorefineries and Bioproducts" at Faculty of Applied Chemistry and Materials Science, University POLITEHNICA of BucharestBiorafinarii si Bioproduse

Biorafinarii si BioproduseFaculty of Applied Chemistry and Materials Science

╠²

Prezentarea programului de studii de masterat "Biorafinarii si Bioproduse" de la Facultatea de Chimie Aplicata si Stiinta Materialelor din Universitatea POLITEHNICA din BucurestiSmart Polymers and Biopolymers

Smart Polymers and BiopolymersFaculty of Applied Chemistry and Materials Science

╠²

The document describes the Smart Polymers and Biopolymers master's degree program at the University Politehnica of Bucharest. The 2-year program provides students with knowledge in polymer science, access to research facilities and infrastructure, and involvement in research projects. It prepares students for careers in research and industry. The program utilizes state-of-the-art facilities like a 3D bioprinter and nano-CT scanner. Students can pursue a PhD and research topics include biomedical polymers, composites, and green materials. The program collaborates with industry partners for internships and employment.Smart Polymers and Biopolymers

Smart Polymers and BiopolymersFaculty of Applied Chemistry and Materials Science

╠²

Prezentarea programului de studii de masterat "Smart Polymers and Biopolymers" de la Facultatea de Chimie Aplicata si Stiinta Materialelor din Universitatea POLITEHNICA din BucurestiDIRECTII DE CERCETARE - Departamentul de Stiinta si Ingineria Materialelor Ox...

DIRECTII DE CERCETARE - Departamentul de Stiinta si Ingineria Materialelor Ox...Faculty of Applied Chemistry and Materials Science

╠²

DIRECTII DE CERCETARE - Departamentul de Stiinta si Ingineria Materialelor Oxidice si NanomaterialelorDIRECTII DE CERCETARE - Departamentul de Inginerie Chimica si Biochimica

DIRECTII DE CERCETARE - Departamentul de Inginerie Chimica si BiochimicaFaculty of Applied Chemistry and Materials Science

╠²

DIRECTII DE CERCETARE - Departamentul de Inginerie Chimica si BiochimicaDIRECTII DE CERCETARE - Departamentul de Chimie Organica

DIRECTII DE CERCETARE - Departamentul de Chimie OrganicaFaculty of Applied Chemistry and Materials Science

╠²

DIRECTII DE CERCETARE - Departamentul de Chimie OrganicaDIRECTII DE CERCETARE - Departamentul de Chimie Generala

DIRECTII DE CERCETARE - Departamentul de Chimie GeneralaFaculty of Applied Chemistry and Materials Science

╠²

DIRECTII DE CERCETARE - Departamentul de Chimie GeneralaDIRECTII DE CERCETARE - Departamentul de Chimie Analitica si Ingineria Mediului

DIRECTII DE CERCETARE - Departamentul de Chimie Analitica si Ingineria MediuluiFaculty of Applied Chemistry and Materials Science

╠²

DIRECTII DE CERCETARE - Departamentul de Chimie Analitica si Ingineria MediuluiDIRECTII DE CERCETARE - Departamentul de Chimie Anorganica, Chimie Fizica si ...

DIRECTII DE CERCETARE - Departamentul de Chimie Anorganica, Chimie Fizica si ...Faculty of Applied Chemistry and Materials Science

╠²

DIRECTII DE CERCETARE - Departamentul de Chimie Anorganica, Chimie Fizica si ElectrochimieDIRECTII DE CERCETARE - Departamentul de Bioresurse si Stiinta Polimerilor

DIRECTII DE CERCETARE - Departamentul de Bioresurse si Stiinta PolimerilorFaculty of Applied Chemistry and Materials Science

╠²

The document describes the research directions and infrastructure of the Department of Bioresources and Polymer Science at the University Politehnica of Bucharest. It discusses three main research teams: Advanced Polymer Materials Group, Bioresources Team, and Dyes and Pigments Team. It provides details on the significant growth and research output of the Advanced Polymer Materials Group over the past 10 years. It also outlines the department's extensive research infrastructure and major projects, including a 16 million euro project on innovative biomaterials and biomedical surfaces.Rapid pulse drying of marine biomasses - Sigurd Sannan

Rapid pulse drying of marine biomasses - Sigurd SannanFaculty of Applied Chemistry and Materials Science

╠²

Biochar impregnation as slow release fertilizer - Violeta Alexandra Ion

Biochar impregnation as slow release fertilizer - Violeta Alexandra IonFaculty of Applied Chemistry and Materials Science

╠²

Traditional, current and future use of fish and seaweed for fertilisation - ...

Traditional, current and future use of fish and seaweed for fertilisation - ...Faculty of Applied Chemistry and Materials Science

╠²

Analytical methods for blue residues characterization - Oana Crina Bujor

Analytical methods for blue residues characterization - Oana Crina BujorFaculty of Applied Chemistry and Materials Science

╠²

AlgaeBrew project - Unlocking the potential of microalgae for the valorisatio...

AlgaeBrew project - Unlocking the potential of microalgae for the valorisatio...Faculty of Applied Chemistry and Materials Science

╠²

Classification and role of plant nutrients - Roxana Madjar

Classification and role of plant nutrients - Roxana MadjarFaculty of Applied Chemistry and Materials Science

╠²

MARIGREEN PROJECT - overview, Oana Cristina Pârvulescu

MARIGREEN PROJECT - overview, Oana Cristina PârvulescuFaculty of Applied Chemistry and Materials Science

╠²

DIRECTII DE CERCETARE - Departamentul de Stiinta si Ingineria Materialelor Ox...

DIRECTII DE CERCETARE - Departamentul de Stiinta si Ingineria Materialelor Ox...Faculty of Applied Chemistry and Materials Science

╠²

DIRECTII DE CERCETARE - Departamentul de Inginerie Chimica si Biochimica

DIRECTII DE CERCETARE - Departamentul de Inginerie Chimica si BiochimicaFaculty of Applied Chemistry and Materials Science

╠²

DIRECTII DE CERCETARE - Departamentul de Chimie Organica

DIRECTII DE CERCETARE - Departamentul de Chimie OrganicaFaculty of Applied Chemistry and Materials Science

╠²

DIRECTII DE CERCETARE - Departamentul de Chimie Generala

DIRECTII DE CERCETARE - Departamentul de Chimie GeneralaFaculty of Applied Chemistry and Materials Science

╠²

DIRECTII DE CERCETARE - Departamentul de Chimie Analitica si Ingineria Mediului

DIRECTII DE CERCETARE - Departamentul de Chimie Analitica si Ingineria MediuluiFaculty of Applied Chemistry and Materials Science

╠²

DIRECTII DE CERCETARE - Departamentul de Chimie Anorganica, Chimie Fizica si ...

DIRECTII DE CERCETARE - Departamentul de Chimie Anorganica, Chimie Fizica si ...Faculty of Applied Chemistry and Materials Science

╠²

DIRECTII DE CERCETARE - Departamentul de Bioresurse si Stiinta Polimerilor

DIRECTII DE CERCETARE - Departamentul de Bioresurse si Stiinta PolimerilorFaculty of Applied Chemistry and Materials Science

╠²

Recently uploaded (20)

first law of thermodynamics class 12(chemistry) final.pdf

first law of thermodynamics class 12(chemistry) final.pdfismitguragain527

╠²

this is best note of thermodynamics chemsitry

2025-03-03-Data-related-Ethics Issues in Technologies for Professional Learni...

2025-03-03-Data-related-Ethics Issues in Technologies for Professional Learni...Graz University of Technology & Know-Center

╠²

How could modern LA research address data-related ethics issues in informal and situated professional learning? I will identify in this talk three relevant insights based on field studies around workplace LA interventions: Firstly, in informal and situated learning, data isnŌĆÖt just about the learners. Secondly, the affordances of manual and automatic data tracking for learning are very different, with manual tracking allowing a high degree of learner control over data. Thirdly, learning is not necessarily a shared goal in workplaces. These can be translated into seeing a potential for systems endowed with sufficient natural-language-processing capability (now seemingly at our fingertips with LLMs), and socio-technical design and scenario-based data collection analysis as design and research methods.(Journal Club) - AmpliconReconstructor integrates NGS and optical mapping to ...

(Journal Club) - AmpliconReconstructor integrates NGS and optical mapping to ...David Podorefsky, PhD

╠²

Journal Club (12/15/20)

AmpliconReconstructor integrates NGS and optical mapping to resolve the complex structure of focal amplifications(Journal Club) Focused ultrasound excites neurons via mechanosensitive calciu...

(Journal Club) Focused ultrasound excites neurons via mechanosensitive calciu...David Podorefsky, PhD

╠²

Journal Club (2/11/21)

Focused ultrasound excites neurons via mechanosensitive calcium accumulation and ion channel amplification(Journal Club) Folding DNA to create nanoscale shapes and patterns

(Journal Club) Folding DNA to create nanoscale shapes and patternsDavid Podorefsky, PhD

╠²

Journal Club (11/21/19)

Folding DNA to create nanoscale shapes and patternsDirect Gene Transfer Techniques for Developing Transgenic Plants

Direct Gene Transfer Techniques for Developing Transgenic PlantsKuldeep Gauliya

╠²

This presentation will explain all the methods adopted for developing transgenic plant using direct gene transfer technique.QUIZ 1 in SCIENCE GRADE 10 QUARTER 3 BIOLOGY

QUIZ 1 in SCIENCE GRADE 10 QUARTER 3 BIOLOGYtbalagbis5

╠²

QUIZ 1 in SCIENCE GRADE 10 QUARTER 3 BIOLOGYARepeatingFastRadioBurstSourceinaLow-luminosityDwarfGalaxy

ARepeatingFastRadioBurstSourceinaLow-luminosityDwarfGalaxyS├®rgio Sacani

╠²

Wepresent the localizationandhostgalaxyofFRB20190208A, arepeatingsourceof fast radiobursts (FRBs) discoveredusingCHIME/FRB.Aspartof thePinpointingREpeatingChImeSourceswithEVNdishesrepeater localizationprogramon theEuropeanVLBINetwork (EVN),wemonitoredFRB20190208Afor 65.6hr at Ōł╝1.4GHzanddetectedasingleburst,whichledtoitsverylongbaselineinterferometrylocalizationwith260mas uncertainty(2Žā).Follow-upopticalobservationswiththeMMTObservatory(i’éē25.7mag(AB))foundnovisible hostattheFRBposition.SubsequentdeeperobservationswiththeGranTelescopioCanarias,however,revealedan extremelyfaintgalaxy(r=27.32┬▒0.16mag),verylikely(99.95%)associatedwithFRB20190208A.Giventhe dispersionmeasureoftheFRB(Ōł╝580pccmŌłÆ3),eventhemostconservativeredshiftestimate( ~ z 0.83 max )implies TheAstrophysicalJournalLetters,977:L4(17pp),2024December10 https://doi.org/10.3847/2041-8213/ad8ce1 ┬®2024.TheAuthor(s).PublishedbytheAmericanAstronomicalSociety. 30BantingFellow. 31McGillSpaceInstituteFellow. 32 FRQNTPostdoctoralFellow. Originalcontent fromthisworkmaybeusedunder theterms of theCreativeCommonsAttribution4.0licence.Anyfurther distributionofthisworkmustmaintainattributiontotheauthor(s)andthetitle of thework, journalcitationandDOI. 1The Astrophysical Journal Letters, 977:L4 (17pp), 2024 December 10 Hewitt et al. that this is the lowest-luminosity FRB host to date (’éł108 Le), even less luminous than the dwarf host of FRB20121102A. We investigate how localization precision and the depth of optical imaging affect host association and discuss the implications of such a low-luminosity dwarf galaxy. Unlike the other repeaters with low-luminosity hosts, FRB 20190208A has a modest Faraday rotation measure of a few tens of rad mŌłÆ2, and EVN plus Very Large Array observations reveal no associated compact persistent radio source. We also monitored FRB20190208A for 40.4hr over 2yr as part of the Extragalactic Coherent Light from Astrophysical Transients repeating FRB monitoring campaign on the Nan├¦ay Radio Telescope and detected one burst. Our results demonstrate that, in some cases, the robust association of an FRB with a host galaxy will require both high localization precision and deep optical follow-up. Unified Astronomy Thesaurus concepts: Radio bursts (1339); Radio transient sources (2008); Very long baseline interferometry (1769); Dwarf galaxies (416)The Arctic through the lens of data visualization

The Arctic through the lens of data visualizationZachary Labe

╠²

26 February 2025ŌĆ”

Rider University, Global Biogeochemistry Class Visit (Presentation): Arctic climate change through the lens of data visualization, NOAA GFDL, Princeton, USA.Excretion in Humans | Cambridge IGCSE Biology

Excretion in Humans | Cambridge IGCSE BiologyBlessing Ndazie

╠²

This IGCSE Biology presentation covers excretion in humans, explaining the removal of metabolic wastes such as carbon dioxide, urea, and excess salts. Learn about the structure and function of the kidneys, the role of the liver in excretion, ultrafiltration, selective reabsorption, and the importance of homeostasis. Includes diagrams and explanations to help Cambridge IGCSE students prepare effectively for exams!History of atomic layer deposition (ALD) in a nutshell

History of atomic layer deposition (ALD) in a nutshellRiikka Puurunen

╠²

Lecture slides presented at Aalto University course CHEM-E5175 Materials engineering by thin films (by Prof. Ville Miikkulainen), in a visiting lecture Jan 28, 2025

Contents:

1 Invention of Atomic Layer Epitaxy 1974

2 Microchemistry Ltd and spread of ALE/ALD

3 Independent invention, Molecular Layering 1960s -->

4 Connecting the two independent development branches of ALD

5 Take-home message

(Extra materials on fundamentals of ALD, assumed as background knowledge)

║▌║▌▀ŻShare: /slideshow/history-of-atomic-layer-deposition-ald-in-a-nutshell/275984811

Youtube: https://youtu.be/FBLThDjRff0 Cell Structure & Function | Cambridge IGCSE Biology

Cell Structure & Function | Cambridge IGCSE BiologyBlessing Ndazie

╠²

This IGCSE Biology presentation provides a detailed look at cell structure and function, covering the differences between animal and plant cells, the roles of organelles (nucleus, mitochondria, ribosomes, etc.), specialized cells, and levels of organization. Learn about diffusion, osmosis, and active transport in cells, with clear diagrams and explanations to support exam preparation. A must-have resource for Cambridge IGCSE students!ABA_in_plant_abiotic_stress_mitigation1.ppt

ABA_in_plant_abiotic_stress_mitigation1.pptlaxmichoudhary77657

╠²

║▌║▌▀Ż describe the role of ABA in plant abiotic stress mitigation. ║▌║▌▀Ż include role of ABA in cold stress, drought stress and salt stress mitigation along with role of ABA in stomatal regulation. Drugs and Their Effects | Cambridge IGCSE Biology

Drugs and Their Effects | Cambridge IGCSE BiologyBlessing Ndazie

╠²

This IGCSE Biology presentation explores drugs and their effects on the human body, covering medicinal drugs, recreational drugs, and drug abuse. Learn about the impact of stimulants, depressants, painkillers, hallucinogens, and performance-enhancing drugs, as well as the dangers of alcohol, nicotine, and illegal substances. Ideal for Cambridge IGCSE students looking to understand this important topic for exams!(Journal Club) - Sci-fate Characterizes the Dynamics of Gene Expression in Si...

(Journal Club) - Sci-fate Characterizes the Dynamics of Gene Expression in Si...David Podorefsky, PhD

╠²

Journal Club (4/27/20)

Sci-fate Characterizes the Dynamics of Gene Expression in Single Cells2025-03-03-Data-related-Ethics Issues in Technologies for Professional Learni...

2025-03-03-Data-related-Ethics Issues in Technologies for Professional Learni...Graz University of Technology & Know-Center

╠²

(Journal Club) - AmpliconReconstructor integrates NGS and optical mapping to ...

(Journal Club) - AmpliconReconstructor integrates NGS and optical mapping to ...David Podorefsky, PhD

╠²

(Journal Club) Focused ultrasound excites neurons via mechanosensitive calciu...

(Journal Club) Focused ultrasound excites neurons via mechanosensitive calciu...David Podorefsky, PhD

╠²

(Journal Club) - Sci-fate Characterizes the Dynamics of Gene Expression in Si...

(Journal Club) - Sci-fate Characterizes the Dynamics of Gene Expression in Si...David Podorefsky, PhD

╠²

Fish in the Loop: Exploring RAS - Julie Hansen Bergstedt

- 1. Fish in the loop: Exploring RAS Julie Hansen Bergstedt & Carlos Octavio Letelier-Gordo Section for Aquaculture Technical University of Denmark DTU Aqua National Institute of Aquatic Resources

- 2. Challenges of the 21st century 2 Challenges: o Climate change o Population growth o Biodiversity o Water availability Actions ŌĆó Reduce: o Emissions o Water utilization o Land use

- 3. Global water availability 3 40% gap in water supply compared to demand in 2030 3% is freshwater, of which 1 % is easily accessible * 400 l in RAS

- 4. Aquaculture Consumption Ornamental Conservation 4 Ōüō425 species of animals, plants, and algae cultivated worldwide 22 species account for >75% of global production

- 5. Global aquaculture production 5 The largest volume (89%) of fish is produced in Asia SHARE OF AQUACULTURE IN TOTAL FISHERIES AND AQUACULTURE PRODUCTION BY MAJOR SPECIES GROUP, 2020 WORLD AQUACULTURE PRODUCTION, 1991ŌĆō2020

- 6. Production systems Cages and pens Open flow Recirculating systems 6 Land-based

- 7. Resource utilization 7 ŌĆó The degree of recirculating is based on make up- water (MUW) pr. kg feed ŌĆó Less CO2 emission, and water and land used System m3/kg feed Flow through >50 Re-use RAS 1-50 Conventional RAS 0.1-1 Next gen RAS <0.1 Martins et al. 2010 Increased energy consumption due to additional components

- 8. Selection of species 8 Seawater Cubes RAS Unit, 120 m2, 8 tonnes of fish Danish salmon, RAS in construction, 7500 m2, 1200 tonnes of fish ŌĆó Matching production cost with demand’āĀ Assessing the market and project profitability ŌĆó Geographical location: - Availability of electricity, water supply and work force - Ecology of selected species (cooling systems are expensive)

- 9. 9 Requirement of the fish Water flow Temperature Salinity pH Light conditions Dissolved gasses Stocking density Feed composition Feeding rate Noise Tank design Chemical stressors Physical/perceived stressors Overall animal health Growth Disease resistance Reproduction Ineffective utilization of nutrients Environment Feed Water quality

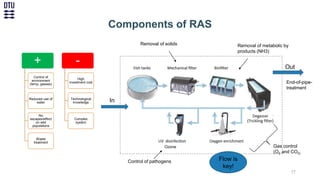

- 10. Recirculating aquaculture system 10 ŌĆó Gas control (O2 and CO2) ŌĆó Ammonia (NH3) ŌĆó Removal of solids ŌĆó Control of pathogens End-of-pipe- treatment Feed and O2 Solids and metabolic byproducts /Ozone

- 11. Feed 11 ŌĆó Standard growth rate (SGR) ŌĆó Feed conversion ratio (FCR) ŌĆó Digestibility The majority of the cost is due to feed (Ōüō46%) Feed input Biomass produced 1 kg feed 0.9 kg 0.45 kg 0.34 kg 0.24 kg Feed Egestion (faeces) Ingestion Growth= Assimilation-Respiration Assimilation Excretion (NH3) Respiration ŌĆó A large fraction of the animal can be eaten (Ōüō 60%)

- 12. Metabolism of fish ŌĆó Metabolic rate ’āĀEnergy expenditure during a specific period ŌĆó Oxygen consumption (MO2): ŌĆó Standard metabolic rate (SMR) ŌĆó Maximum metabolic rate (MMR/ MO2max) ŌĆó Aerobic scope (AS) 12 0 50 100 150 200 250 300 350 400 450 0 2 4 6 8 10 12 14 16 18 20 22 24 MO 2 (mg O 2 kg -1 h -1 ) Time (h) MMR SMR AS ŌĆó Increase in O2 demand after feeding while the fish are digesting + during increased activity levels Automatization of oxygen supply !

- 13. Controlling gasses ŌĆó Oxygen and carbon dioxide consumed and produced by fish and microbes (biofilter) ŌĆó Dissolved oxygen (DO) conc: 80-100% - Aeration (90-100% of air sat) - Pure oxygen for supersaturation ŌĆó Ōüō0.5 kg O2 pr kg feed ŌĆó CO2: >15 mg/L ŌĆó 1.4 g pr g O2 consumed 13 200-300% saturation Unfed Tench/doctor fish (Tinca tinca) O2 added CO2 removed O2 consumption

- 14. 14 Toxic ammonia absent at pH < 7 ŌĆó TAN produced 35g/kg feed ŌĆó TAN = total ammonia nitrogen = NH4-N + NH3-N Ammonia and biofilters Langenfeld et al. 2021 Nitrifying bacteria pH Addition of bicarbonate to maintain alkalinity and buffering capacity of the system pH of 6.5-8 NH3: >0.2 mg/L NO2: >0.5 mg/L NO3: >300 mg/L Summerfelt et al. 2015

- 15. Tank design: ŌĆó Meet species demand (pelagic of bottom dwelling) ŌĆó Circular, square, and octagonal ’āĀ utilization of space and strength of design ŌĆó Particle residence time ŌĆó Self-cleaning effect 15 Solids removal and tank design Egestion + feed waste Excretion (NH3) Respiration Feed Solids Protein, fat, carbohydrate Mechanical filtration Volume, numbers, life- stages to accommodate? 1 kg feed produces 8 L of waste (sludge) ŌĆó Total suspended solids (TSS) TSS= 0.25 * kg feed fed (DM)

- 16. 16 Control of pathogens UV Safe for the fish Turbidity of water affects efficiency ŌĆō supplement with proper filtration Ozone Efficient oxidation of organic matter Flocculation properties of suspended solids Hazardous to fish and people Chemical NaCl, H2O2, formalin, chlorine based compounds, NaOH, iodine solutions, No use of antibiotics Inlet water Staff Eggs Between batches Outbreaks Disease in one part of the system will spread to others ! Dose vs effect Treating the fish without harming the biofilter

- 17. Components of RAS 17 Control of pathogens Gas control (O2 and CO2) Removal of metabolic by products (NH3) Removal of solids Ozone + Control of environment (temp, gasses) Reduced use of water No escapes/effect on wild populations Waste treatment - High investment cost Technological knowledge Complex system Flow is key! End-of-pipe- treatment In Out

- 18. 18 Thank you Julie Hansen Bergstedt juhala@aqua.dtu.dk