Geometrix_Company_Profile_OCT2016 [Compatibility Mode]

- 1. Company Profile GEOMETRIX AUTOMATION AND ROBOTICS PVT LTD

- 2. Who We Are ? Geometrix is an engineering company, incorporated in Year 2010 Our VISION is to become, “ FIRST CHOICE “ of BIWOur VISION is to become, “ FIRST CHOICE “ of BIW Line Builders,Engineering Companies and Manufacturing units for acquiring automation & robotic solutions and services .We also provide the used and refurbished robots to various industrial applications.

- 3. Who We Are ? Qualification: DEE-Diploma In Electrical Engineering BE-Bachelor of Electrical Engineering Other Certifications and Publications: 1)Robotic Advanced level trainings from Fanuc and ABB Robotics. 2)Paper selected and awarded at SAE International USA-Virtual Plant Commissioning Methodology using Digital Manufacturing And Lean Principles Director Profile Methodology using Digital Manufacturing And Lean Principles 3)Deutsche Management Academye Niedersachsen,Celle Germany-Course in Industry 4.0-Application of IT in the modern industry.IT in Production,IT in After Sales. Total Experience: 19 Years in-Industrial Automation and Robotic application engineering, Maintenance,Production,Design and Simulation,Project Management,Business Development.

- 4. What we do? Engineering is our passion. We support world class BIW line builders for automobile ,engineering and manufacturing companies, from “CONCEPT TO COMMISSIONING” phase, through following systematic approach. a) Consultation: Group discussion, Strategy & RFQ preparation. b) Pre-SE:b) Pre-SE: Feasibility & Conceptualization. c) SE / ME (Product / Process / Facility): Detailing & verification through simulation using digital manufacturing softwares. d) Designing: Jig, Fixture, Conveyors, SPMs, Robotic cells, Press Tools, PLC controlled systems. e) Manufacturing: Jig, Fixture, Conveyors, SPMs, Robotic cells, Press Tools & PLC controlled systems. f) Installation, Commissioning & Proving: Green field & Brown field project execution.

- 5. Resources Simulation Softwares •Technomatrix Robcad 9.1, •Delmia V5, •ABB RobotStudio, •Fanuc Robot Guide •Siemens Plant Simulation Design softwares • Catia V5R19 • AutoCAD-2012 5 •Fanuc, •ABB, •Kuka, •Motoman •OTC •Kawasaki, •Nachi, •Panasonic, •Comau, •Universal Robotic Expertise •Siemens Plant Simulation • Allen Bradley • Siemens • Mitsubishi • GE-Fanuc •Beckhoff • Messung • Omron • Delta etc •Eplan •Autocad Elect. PLC /Controls Expertise

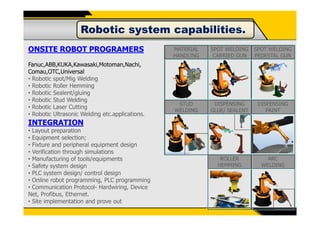

- 6. Robotic system capabilities. ONSITE ROBOT PROGRAMERS Fanuc,ABB,KUKA,Kawasaki,Motoman,Nachi, Comau,OTC,Universal • Robotic spot/Mig Welding • Robotic Roller Hemming • Robotic Sealent/gluing • Robotic Stud Welding • Robotic Laser Cutting • Robotic Ultrasonic Welding etc.applications. SPOT WELDING CARRIED GUN MATERIAL HANDLING DISPENSING GLUE/ SEALENT STUD WELDING DISPENSING PAINT SPOT WELDING PEDESTAL GUN • Robotic Ultrasonic Welding etc.applications. INTEGRATION • Layout preparation • Equipment selection; • Fixture and peripheral equipment design • Verification through simulations • Manufacturing of tools/equipments • Safety system design • PLC system design/ control design • Online robot programming, PLC programming • Communication Protocol- Hardwiring, Device Net, Profibus, Ethernet. • Site implementation and prove out ARC WELDING GLUE/ SEALENTWELDING ROLLER HEMMING PAINT

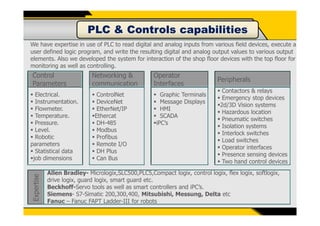

- 7. PLC & Controls capabilities We have expertise in use of PLC to read digital and analog inputs from various field devices, execute a user defined logic program, and write the resulting digital and analog output values to various output elements. Also we developed the system for interaction of the shop floor devices with the top floor for monitoring as well as controlling. Control Parameters Electrical. Instrumentation. Flowmeter. Temperature. Networking & communication ControlNet DeviceNet EtherNet/IP Ethercat Operator Interfaces Graphic Terminals Message Displays HMI SCADA Peripherals Contactors & relays Emergency stop devices 2d/3D Vision systems Hazardous location Temperature. Pressure. Level. Robotic parameters Statistical data job dimensions Ethercat DH-485 Modbus Profibus Remote I/O DH Plus Can Bus SCADA iPC’s Hazardous location Pneumatic switches Isolation systems Interlock switches Load switches Operator interfaces Presence sensing devices Two hand control devices Expertise Allen Bradley- Micrologix,SLC500,PLC5,Compact logix, control logix, flex logix, softlogix, drive logix, guard logix, smart guard etc. Beckhoff-Servo tools as well as smart controllers and iPC’s. Siemens- S7-Simatic 200,300,400, Mitsubishi, Messung, Delta etc Fanuc – Fanuc FAPT Ladder-III for robots

- 8. Projects delivered Auto Multi Gauging System of turned jobs with Robotic Auto loading and unloading.. For-ID,OD,Step depth,Ovality,Counter etc..(WIP)

- 9. Projects delivered Validation/Simulation of robotic spot welding workcell for Leading Automobile OEM through leading BIW Line Builder. Validation/Simulation/OLP-For BIW Line Up gradations using Robcad for Leading Automobile OEM through leading line builder.

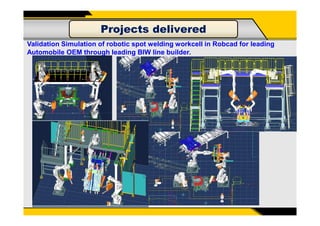

- 10. Projects delivered Validation Simulation of robotic spot welding workcell in Robcad for leading Automobile OEM through leading BIW line builder.

- 11. Projects delivered Validation Simulation of robotic spot welding/sealing/stud welding/marking/PSW and handling workcell in Robcad for leading Automobile OEM in Europe through leading BIW Engineering organization.

- 12. Projects delivered Simulation -Handling and spot welding-ABB Robots For Leading FMCG group. Simulation Of BIW Process and jig/fixture validation in Robcad for Leading Auto OEM in Europe through leading Engineering group. Conceptualization,simulation,design of Cupboard sheet Robotic bending line for leading FMCG group. Pre SE,SE,ME,Manufacturing,E&C of furniture packing line for leading FMCG group.

- 13. Projects delivered Leather Shoes-Robotic Roughing and Spraying for leading shoe exporter Robotic Spot Welding with Fanuc robot for Leading automobile OEM Robotic Roller Hemming for leading automobile OEM. Robot Programming Services at VW- Shanghai,China through GAG, China

- 14. Projects delivered Service-Robotic Spot Welding And Material Handling for Car Closures Line -Fanuc Robots-COMAU India For Maruti Suzuki Service-Rear And Front Frame Welding Robot Programming- TVS-Wego Service-Robotic Roller Hemming-ABB Robots- (For ABB India & Reno Nissan ) Service-Robotic Spot Welding –Nachi Robots for Wooshin Engineering Pvt .Ltd

- 15. Projects delivered Turnkey-Robotic Laser Cutting System-TACO For Mahindra Xylo Bumper Turnkey-Robotic Systems and Integration Support-Mig Welding And Material Handling Machine Tending Cylinder Welding

- 16. Projects delivered Turnkey-Laser Cutting Systems for Metals And Non Metals/Combined ABB Robot & Coherent Laser Source. Turnkey-Robotic Spot Welding System for car Rear Crash Turnkey-Robotic flaming and sealing Turnkey-Tractor Chassis part Robotic Welding-Fanuc/Motoman Robots for Windal

- 17. Projects delivered Turnkey-Packaging Line Automation Consulting and delivery( system for 1200 Wooden furniture parts) for Godrej & Boyce,Interiao. Turnkey-Robotic Ultrasonic welding 2-Axis-Turn Table-Sulzer India Ltd

- 18. Projects delivered Kalyani Techno Forge -Robotic Pick & Place System For Forging Job - ENDURANCE Die -Casting Machine -Robot – Trimming Press Integration( ABB Robot) Western Refrigeration- Robotic sheet metal bending with KUKA Robot. Varroc – Friction welding & Deflasher Machine Robotic Pick & Place system+SPM for auto job feeding

- 19. Projects delivered Robotic Pick & Place System For Forging Industry-Consulting,concepts and delivery- And Many More ........ Robotic Pick & Place System For hot Job (IBH output to Press Input ) - Robotic Spraying and foam pouring concept and delivery

- 20. Projects delivered Robotic Automization Consulting for Disc Spring manufacturing set up. Clip Sensing POKA YOKE SYSTEM For Vehicle parts And Many More ........ Cooper Corporation Pvt.Ltd Consulting for using PLM tools for optimizing the throughput,throughput analysis, production of mix model varients,contingency planning.

- 21. Our Clients And many more…And many more…

- 22. Thank You Contacts : Managing Director Prafullakumar Khachane Looking Forward To Have A Mutually Benefited Business Relationship With Your Esteemed Organization Prafullakumar Khachane +91 20 32319844 +91 9921001880 +91 7028012552 Email- praful@geometrixar.com prafulkhachane@geometrixar.com info@geometrixar.com Web: www.geometrixar.com