Hassan saad Mohamed khalil RV3 doc.CV

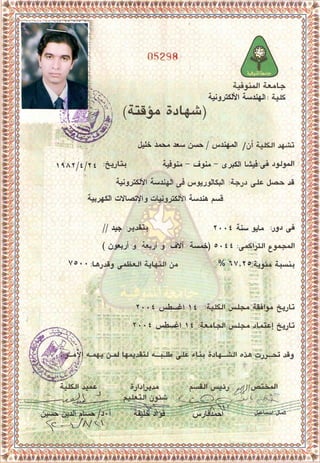

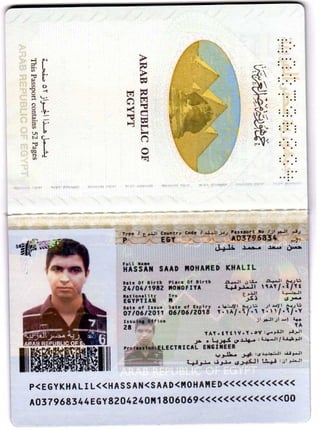

- 1. Hassan saad Mohamed Khalil 16 Elsheikh Hassan Elattar St. Misr El_Gededa - Cairo- Egypt E-mail ID : enghassankhalil@yahoo.com :hsskhalil@gmail.com Contact NO : 002 01287225115 (Egypt) : 00965 66009107 (Kuwait) Personal information: Birth date : 24th April 1982 Marital status : married Military status : exempted Driving license : valid Objective: Seeking for challenging job in an international company where my studies and skills can be employed and improved. Education: ’éĘ May 2004 B.Sc of electronic engineering. ’éĘ Department of electrical communication. ’éĘ Grade: good ’éĘ Grade project: mobile electro cardiogram (ECG). ’éĘ Project grade: excellent.

- 2. Professional experience: ’éĘ July 2012 ŌĆō present (International Naval Works Company). Located in Alexandria. Working as instrument engineer under supervision of Kuwait oil Company (KOC) responsible for maintenance of four calm buoys. Duties: ’éĘ Performs and directs maintenance on electric, pneumatic and electronic instruments and Control systems including microprocessor based system, HIMA PLC H41q and protection systems. Work carried out on Marine and onshore and offshore installations. ’éĘ Plans preventive maintenance/overhaul programmes for the CALM Buoys and other offshore facilities. ’éĘ Plans and performs preventive maintenance/ overhaul programme on electrical and instrument control systems and protective switches. ’éĘ Have the skill to check, calibrate and repair electrical, pneumatic, hydraulic electronic instruments and controls and protective interlock system. (Such as Panels, pumps, level gauges, flow indicators, pressure and temperature indicators and fire alarms equipment). ’éĘ Diagnoses problems or potential problems in control systems pneumatic, and electrical and DCS based system, installed at the CALM Buoys and the CompanyŌĆÖs offshore facilities. ’éĘ Participate in the disconnection/reconnection of CALM Buoys. ’éĘ Maintains the Navigational Equipment (electrical/ solar systems). ’éĘ Participates in the major maintenance and overhaul activities for CALM Buoys. ’éĘ Perform the maintenance of electric, instrumentation, control, and safety system of the buoy. ’éĘ Calibrating and testing all the pressure and temperature devices used in the system periodically using calibration devices to insure best operating quality. ’éĘ Provide maintenance of diesel engine on board of the buoy, responsible for providing hydraulic pressure for the system. ’éĘ Maintaining all the hydraulic system including solenoid valves. ’éĘ Carry out in depth investigation of equipment failure, submit reports of probable causes of failures with suggested remedial action with particular emphasis on instrumentation and control system. ’éĘ Witness important testing activities of the equipment on behalf of company as directed.

- 3. ’éĘ Coordinates with operations for routine matters. ’éĘ Able to direct the work, being mindful of the safety. Major jobs I participate in during this period: A. Participate in overhauling activities of CALM buoy #21 after the accident. ’éĘ Meger test was carried out for all the cable connection on board the CALM buoy and repair all the damage cables. ’éĘ All pressure transmitters on board the CALM buoy were tested and calibrated. ’éĘ All temperature transmitters on board CALM buoy were tested and calibrated. ’éĘ All gauges were tested and calibrated. ’éĘ All the solar system was tested and installed new set instead of the damage one. ’éĘ The valve control panel including solenoid valves and pilot valve were tested. ’éĘ Attend the repair of the new HPU in Al-Meer Company and supervise the work. ’éĘ Install the new HPU on board the CALM buoy. ’éĘ The function test were done to the H41q PLC and replacing all faulty modules. ’éĘ A complete maintenance was carried out for the diesel engine. ’éĘ Replaced the hydraulic swivel with new one. ’éĘ Install the 24VDc &12VDc battery sets on board the CALM buoy. ’éĘ Give all the required connection for RTU. ’éĘ Connect the communication modems and test the communication with shore. ’éĘ The hydraulic system was tested. ’éĘ Carried out function test of PLEM & buoy valves. ’éĘ The factory test was done for all the equipmentŌĆÖs on board the buoy. ’éĘ The buoy was commissioned and running satisfactory. B. Participate in repairing the submarine optic fiber cable. ’éĘ The optic fiber cable is responsible of carrying the communication between the four CALM buoys and the control room in the shore (NPP). ’éĘ The cable was damage in between CALM buoy 23 & CALM buoy 24 which causes the failure communication. ’éĘ The cable was recovered on CALM Buoy deck. ’éĘ Fusion splicing was carried out for the 24 SM fibers. ’éĘ The spliced fibers were secured inside the enclosure water proof box. ’éĘ The water proof box was secured inside the center well. ’éĘ The communication was tested and the operation was succeeded. ’éĘ The communication becomes healthy.

- 4. C. Participate in overhauling of CALM buoy #23 product swivel. ’éĘ As there was leaking in the seals of the product swivel so it should be replaced with new one. ’éĘ The product swivel including the slip ring and hydraulic swivel. ’éĘ Slip ring is responsible of transferring the electrical connection between the rotor part and stator part of the CALM buoy. ’éĘ The hydraulic swivel responsible of transferring the hydraulic fluid from the rotating part to stator part of the product swivel. ’éĘ The old connection of upper and lower slip ring was disconnected. ’éĘ The leak recovery tank piping was disconnected. ’éĘ The level transmitter was disconnected. ’éĘ Hydraulic hoses of rotor and stator was disconnected. ’éĘ Install new product swivel with new slip ring and hydraulic swive. ’éĘ All the new connection was connected to the upper and lower of the slip ring. ’éĘ All the new hydraulic hoses were installed for the rotor & stator part. ’éĘ The leak recovery system was installed. ’éĘ The factory test was carried out for all the new connection. ’éĘ The product swivel pressurized and tested. ’éĘ The CA LM buoy was commissioned and running satisfactory. ’éĘ November 2009 ŌĆō June 2012 (Maridive Oil Services Company). Located in Alexandria. Working as instrument engineer under supervision of Kuwait oil Company (KOC) responsible for maintenance of four calm buoys. Duties: ’éĘ Performs and directs maintenance on electric, pneumatic and electronic instruments and Control systems including microprocessor based system, HIMA PLC H41q and protection systems. Work carried out on Marine and onshore and offshore installations. ’éĘ Plans preventive maintenance/overhaul programmes for the CALM Buoys and other offshore facilities.

- 5. ’éĘ Plans and performs preventive maintenance/ overhaul programme on electrical and instrument control systems and protective switches. ’éĘ Have the skill to check, calibrate and repair electrical, pneumatic, hydraulic electronic instruments and controls and protective interlock system. (Such as Panels, pumps, level gauges, flow indicators, pressure and temperature indicators and fire alarms equipment). ’éĘ Diagnoses problems or potential problems in control systems pneumatic, and electrical and DCS based system, installed at the CALM Buoys and the CompanyŌĆÖs offshore facilities. ’éĘ Participate in the disconnection/reconnection of CALM Buoys. ’éĘ Maintains the Navigational Equipment (electrical/ solar systems). ’éĘ Participates in the major maintenance and overhaul activities for CALM Buoys. ’éĘ Perform the maintenance of electric, instrumentation, control, and safety system of the buoy. ’éĘ Calibrating and testing all the pressure and temperature devices used in the system periodically using calibration devices to insure best operating quality. ’éĘ Provide maintenance of diesel engine on board of the buoy, responsible for providing hydraulic pressure for the system. ’éĘ Maintaining all the hydraulic system including solenoid valves. ’éĘ Carry out in depth investigation of equipment failure, submit reports of probable causes of failures with suggested remedial action with particular emphasis on instrumentation and control system. ’éĘ Witness important testing activities of the equipment on behalf of company as directed. ’éĘ Coordinates with operations for routine matters. ’éĘ able to direct the work, being mindful of the safety. ’éĘ November 2006 ŌĆō November 2009 (Heavy Industries& Ship Building Company) (HEISCO) located in Kuwait. Working as senior instrument tech. under supervision of Kuwait Oil Company (KOC) in marine services at Mina Al ahmadi. Duties: ’éĘ Perform all the maintenance of the marine ships like (tugs, crew boats, mooring boats, work boats and pollution boats). ’éĘ Perform the maintenance of main engine and auxiliary engines control system. ’éĘ Providing maintenance for pneumatic system for main engines of boats.

- 6. ’éĘ Providing maintenance of hydraulic system of the fire fighting monitors and all others systems. ’éĘ Providing maintenance of control system of pumps. ’éĘ Adjusting and calibrating all the instrumentation devices like pressure switches and temperature sensors. ’éĘ Providing maintenance of 440 v distribution panels. ’éĘ Perform all the maintenance of the safety, shutdown and alarm system of the main engine and auxiliary engines. ’éĘ Participate in the major maintenance and overhauling main engine and auxiliary engine. ’éĘ Providing maintenance of navigation system like VHF radio, MOTOROLA radio and AIS system. ’éĘ May 2005 ŌĆō November 2006 (Heavy Industries& Ship Building Company) (HEISCO) located in Kuwait. Working as instrument engineer under supervision of Kuwait oil company (KOC) responsible for maintenance of two calm buoys. Duties: ’éĘ Working in touch with Allen Bradley plc, communication serials (RS232), communication modems and DH485 network. ’éĘ Perform all the maintenance electric, pneumatic, instrumentation and control system on board of calm buoy. ’éĘ Providing maintenance of diesel engine responsible for providing hydraulic pressure of the system. ’éĘ Providing maintenance for safety and alarm system of the buoy. ’éĘ Calibrating and testing all the pressure switches and temperature transmitters. ’éĘ Experience in installation and maintenance of pneumatic, hydraulic and control system. ’éĘ I have skill to disassemble and reassemble equipment according to specifications. Operational: ’éĘ Coordinates work functions of personal in my department and I involve in the actual maintenance activities, day to day operational technical services activities as may be assigned to me from time to time under my direct supervision of my company authorized technical staff. ’éĘ Implement the major overhaul program to meet maintenance goals. ’éĘ Organizing and implementing earliest completion of any rectification, repair program after any breakdowns in my assigned area.

- 7. ’éĘ Implement preventive maintenance to meet maintenance goals. ’éĘ Monitors works and worksites to insure safe working conditions. ’éĘ Update spare parts record and recommended procurement of new spare parts. Planning: ’éĘ Assist in planning major overhauls and preventive maintenance schedule. ’éĘ Assist in preparing overhaul/workshop forecasts for spare parts, special tools and personal requirements. ’éĘ Advises on maintenance programs forecasts on need to implement, increase or decrease procedure intervals. Training: ’éĘ Blue water company (April 2008) Completed the operation & maintenance training course of KOC turntable buoy system (1-9823-1). ’éĘ Panasonic Company. Completed the training course of GSM. Computer skills: ’éĘ Windows (98/2000/Xp/vista/win7). ’éĘ Microsoft office (word/excel/PowerPoint/FrontPage/access). ’éĘ Internet& network. Language: ’éĘ Arabic mother language. ’éĘ English (fluent in speaking& writing). Job specification: ’éĘ Preferred Location : anywhere. ’éĘ Employment type : employee ’éĘ Employment : full time