Managing Complexity

- 1. Managing Manufacturing Complexity through Innovative Processes A Donnelly Custom Manufacturing Case Study Sam Wagner, Director of Advanced Manufacturing Donnelly Custom Manufacturing Company IndustryWeek ’09 Best Plants Conference Nashville, TN Tuesday, April 28, 2009 1

- 2. The Donnelly story • Donnelly was founded in 1984 as a custom, plastic injection molding company • A small, one-story building in Alexandria, MN • Four presses, eight people, no customers • One idea: to focus on short run, close tolerance parts 2

- 3. The Donnelly story • Today, the organization is over 225 people strong – Best-in-class technologies and quality systems – 24/7 operations, 110,000 square foot facility with 33 presses – 700+ materials used – 2700+ active molds and 3200+ active parts – Median run time of less than 8 hours – 40 to 50 changeovers per day – Industry-leading and world-renowned OEM customers – $29+ million in revenues 3

- 4. The Donnelly story 30 30 Sales Dollars Orders Shipped 25 25 20 20 15 15 10 10 5 5 0 0 1998 1999 2000 2001 2002 2003 2004 2005 2006 2007 2008 1998 1999 2000 2001 2002 2003 2004 2005 2006 2007 2008 2.0 Sales Dollars/Order Shipped 1.5 1.0 0.5 4 0.0 1998 1999 2000 2001 2002 2003 2004 2005 2006 2007 2008

- 5. The Donnelly story 200 35 Molding Hours Run # of Presses Available 30 150 25 20 100 15 10 50 5 0 0 1998 1999 2000 2001 2002 2003 2004 2005 2006 2007 2008 1998 1999 2000 2001 2002 2003 2004 2005 2006 2007 2008 7,000.0 Hours Run /Press Available 6,000.0 5,000.0 4,000.0 3,000.0 2,000.0 1,000.0 5 0.0 1998 1999 2000 2001 2002 2003 2004 2005 2006 2007 2008

- 6. The Donnelly story • Plastics News Processor of the Year Finalist 2007 6

- 7. What is short run? • Short run is not defined by part quantities/EAUs • Short run is defined by the number of hours per production run • Donnelly’s short run – Average production run is 11 hours – Median production run is 7+ hours – Production runs range from .25 to 240 hours – Short run is defined as more than one changeover per week, per press – We average 9 changeovers per week, per press 7

- 8. Why short run? • It is not possible to do short and long run well – Short run focus is on changeover optimization – Long run focus is on process optimization • A need exists for a supplier committed to short run expertise – Pressure to reduce inventory, but continue to meet stringent delivery dates – A supplier with short run expertise allows these vital needs to be met economically 8

- 9. 9

- 10. Donnelly’s mission and values • Vision: To be the recognized leader in setting the standards in short run molding and related services • Mission: To deliver good products on time • Core values – Do your best – Treat others the way you want to be treated – Don’t be afraid to ask for help – Always work as a team 10

- 11. Donnelly’s complexity factor • Complexity factor = active molds x materials used x presses • Comparative data – Plante Moran’s 2004 North American Study of the Plastics Molding Industry 0 Injection Molding Over 25% All participating Automotive Over $25MM Donnelly Medical Bottom quartile Over 25% companies in sales Over 50% 50th percentile Upper quartile 11

- 12. Complexity-driven challenges • Setting and holding priorities – making decisions • Shooting at a moving target – planning • Communication, alignment and teamwork • Training and continuous improvement 12

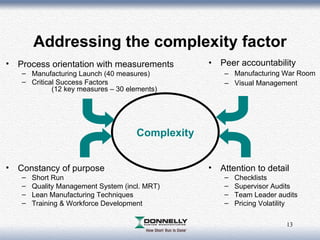

- 13. Addressing the complexity factor • Process orientation with measurements • Peer accountability – Manufacturing Launch (40 measures) – Manufacturing War Room – Critical Success Factors – Visual Management (12 key measures – 30 elements) Complexity • Constancy of purpose • Attention to detail – Short Run – Checklists – Quality Management System (incl. MRT) – Supervisor Audits – Lean Manufacturing Techniques – Team Leader audits – Training & Workforce Development – Pricing Volatility 13

- 14. Addressing the complexity factor • The cosmic Law of Nature g s s in e – Nothing is static o gr Pr Re g re ssi ng 14

- 15. Process orientation with measurements • Manufacturing launch process – Developed in 1999 • Hard work & diligence wasn’t enough with 250+ molds/year – 80 % of tooling launches will have no problem, but it is the 20 % that a highly defined process allows you to succeed at – Defined, comprehensive and measured so output is repeatable, reliable and profitable – Avoids the finger pointing at hand-offs • Responsibilities are defined and reviewable 15

- 16. Process orientation with measurements • Manufacturing launch process – Owned by the people who hold responsibility – Result is unique 3-pronged engineering model • Project Engineer on-site at customer location for design and mold-build support • Manufacturing Launch Engineer who oversees sampling, measurement and approval process • Process Engineer for day-to-day production – Value of a highly defined process is that you can evaluate and change it • Manage, measure and improve it 16

- 17. Donnelly Manufacturing Launch Process (2)

- 18. Peer accountability • Daily War Room meetings – This is a problem identification, not problem solving meeting – Action items are assigned with peer accountability to resolve them within 48 hours 18

- 19. Peer accountability • Daily War Room meetings Review last 24 hours Look ahead to the next 24 hours • Safety • Set priorities • Changeovers & efficiency • “At risk” shipments • Hours run & efficiency • High scrap jobs • Down time • Mold issues • Scrap • Problem jobs • Action items 19

- 20. Constancy of purpose • Donnelly quality system – Deliver good products on time – ISO 9001:2000 – ISO 13485:2003 Management Review Team • Management Review Team – Corrective action process Corrective Action Process RCA What other Why was the parts might defective part have this produced? same issue? Why was the defective part shipped? 20

- 21. Constancy of purpose • The Law of Prosperity/ Law of Compensation – What we make is in direct proportion to the quality and quantity of the services we deliver 21

- 22. Constancy of purpose • Results – Value added per employee – 14 years without increasing press rates 22

- 23. Attention to detail • 5S – Sort: Separate the necessary from the unnecessary – Set in Order: Put everything in its place, label its place – Shine: Keep everything clean, helps identify potential problems – Standardize: Defines how a task should be performed, sets the performance standard – Sustain: Most important – requires regular inspections, with action items identified, assigned, and addressed “Good factories develop beginning with the 5S’s. Bad factories fall apart beginning with the 5S’s.” Hirouki Hirano 23

- 24. Attention to detail • Early 5S process results Old Setup Carts New Setup Carts 24

- 25. Attention to detail • 5S event results – set in order Aisles before 5S Aisles after 5S 25

- 26. Attention to detail • 5S color coding Green White and blue Finished goods or inserts Trash Mobile Eqpt 26

- 27. Attention to detail • 5S: Middle section: Green – Notice the numbers on the wall and on equipment (204) – Numbers on the floor as well 27

- 28. Attention to detail • 5S: Back section: Orange 28

- 29. Attention to detail • 5S audit process – Next shift team leader audits section with current shift team leader – Record results on current shift schedule showing assignments – Highlight in green if OK, pink if a problem with notes on the bottom – Hang schedule on current shift clip board for supervisor to review 29

- 30. Attention to detail • 5S process benefits – Much more than just housekeeping – Develops the discipline to follow through – Teaches employees to work in teams – Creates a safer workplace – Attacks quality issues – Attacks waste of searching for things – Clean workplace is more inviting, making it easier to recruit and retain workers (and customers) – 5S is a fundamental to Lean 30

- 31. Attention to detail • 5S: Visual workplace progression Visual Guarantees Visual Controls Visual Measures Visual Standards Visual Order 31 Ref. Visual Workplace Visual Thinking, Gwendolyn D. Galsworth

- 32. Success in short run • Continuously develop and improve upon its leadership position in short run • Occurs as a result of aligning company’s people, processes and actions with business strategy • Donnelly employees’ ability to improve upon its hedgehog concept, help the company to grow and thrive • All actions are tied to processes rather than events, ensuring the business output is repeatable, reliable and profitable 32

- 33. Thank you Questions? Sam Wagner, Director of Advanced Manufacturing Donnelly Custom Manufacturing Company IndustryWeek ’09 Best Plants Conference Nashville, TN Tuesday, April 28, 2009 33