Inventory

- 1. Inventory BA 339 1

- 2. 2

- 3. Inventory Definitions ’ü¼ Inventory vs. Inventory system ’ü¼ Dependent vs. Independent environments ’ü¼ Types ’ü¼ Safety Stock ’ü¼ Anticipation Inventory ’ü¼ Hedge inventory (unusual events) ’ü¼ Transportation or Pipeline Inventory 3

- 4. Purposes of Inventory 1. Independence of operations. 2. Variation ’ü¼ Product demand ’ü¼ Material Delivery Time 3. Scheduling flexibility 4. Volume Discounts 5. Material price fluctuations 4

- 5. Inventory Costs ’ü¼ Holding (or carrying) costs ’ü¼ Setup (or production change) costs ’ü¼ Ordering costs. ’ü¼ Shortage costs. 5

- 6. Inventory Systems ’ü¼ Rules to manage inventory, specifically: ’ü¼ timing (when to order) ’ü¼ sizing (how much to order) ’ü¼ Continuous Review or Fixed-Order Quantity Models (Q) ’ü¼ Event triggered (Example: running out of stock) ’ü¼ Periodic Review or Fixed-Time Period Models (P) ’ü¼ Time triggered (Example: Monthly sales call by sales representative) 6

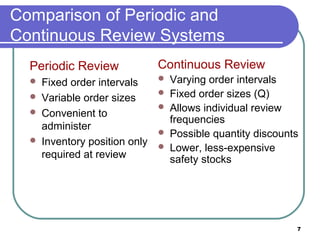

- 7. Comparison of Periodic and Continuous Review Systems Periodic Review Continuous Review ’ü¼ Fixed order intervals ’ü¼ Varying order intervals ’ü¼ Variable order sizes ’ü¼ Fixed order sizes (Q) ’ü¼ Allows individual review ’ü¼ Convenient to frequencies administer ’ü¼ Possible quantity discounts ’ü¼ Inventory position only ’ü¼ Lower, less-expensive required at review safety stocks 7

- 8. Inventory costs ’ü¼C = Unit cost or production cost: the additional cost for each unit purchased or produced. ’ü¼ H = Holding costs: cost of keeping items in inventory(cost of lost capital, taxes and insurance for storage, breakage, etc., handling and storing) ’ü¼ S = Setup or ordering costs: a fixed cost incurred every time you place an order or a batch is produced. 8

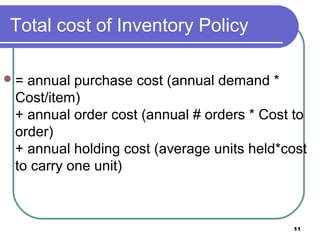

- 9. Total costs of carrying inventory ’ü¼ Assumptions ’ü¼ demand is constant and uniform throughout the period for your products (5 cases per day) ’ü¼ Price per unit is constant for the period ($16/case) ’ü¼ Inventory holding cost is based on an average cost. ’ü¼ TotalInventory Policy Cost annually = annual purchase cost + annual order cost + annual holding cost 9

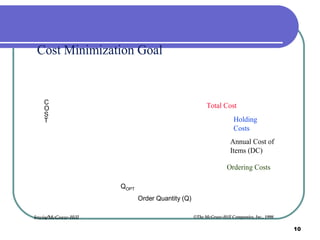

- 10. Cost Minimization Goal C O Total Cost S T Holding Costs Annual Cost of Items (DC) Ordering Costs QOPT Order Quantity (Q) Irwin/McGraw-Hill ┬®The McGraw-Hill Companies, Inc., 1998 10

- 11. Total cost of Inventory Policy ’ü¼= annual purchase cost (annual demand * Cost/item) + annual order cost (annual # orders * Cost to order) + annual holding cost (average units held*cost to carry one unit) 11

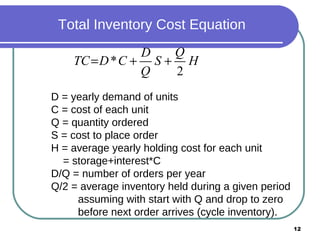

- 12. Total Inventory Cost Equation D Q TC = D * C + S + H Q 2 D = yearly demand of units C = cost of each unit Q = quantity ordered S = cost to place order H = average yearly holding cost for each unit = storage+interest*C D/Q = number of orders per year Q/2 = average inventory held during a given period assuming with start with Q and drop to zero before next order arrives (cycle inventory). 12

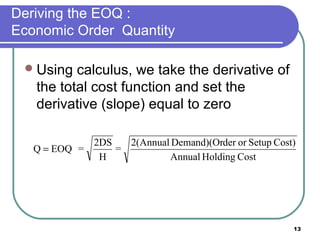

- 13. Deriving the EOQ : Economic Order Quantity ’ü¼ Using calculus, we take the derivative of the total cost function and set the derivative (slope) equal to zero 2DS 2(Annual Demand)(Order or Setup Cost) Q = EOQ = = H Annual Holding Cost 13

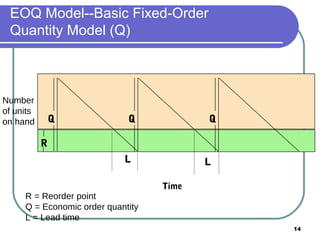

- 14. EOQ Model--Basic Fixed-Order Quantity Model (Q) Number of units on hand Q Q Q R L L Time R = Reorder point Q = Economic order quantity L = Lead time 14

- 15. The Reorder Point Reorder point = (average period demand)*Lead Time periods = d*L 15

- 16. Another EOQ Example Annual Demand = 1,000 units Days per year considered in average daily demand = 365 Cost to place an order = $10 Holding cost per unit per year = $2.50 ead time = 7 days Cost per unit = $15 Determine the economic order quantity & reorder point. 16

- 17. Minor Deviations Here ’ü¼ What causes minor deviations from the ideal order size? ’ü¼ Assumptions behind the regular EOQ Model? 17

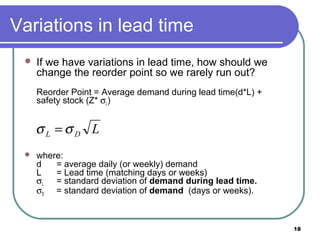

- 18. Variations in lead time ’ü¼ If we have variations in lead time, how should we change the reorder point so we rarely run out? Reorder Point = Average demand during lead time(d*L) + safety stock (Z* ŽāL) ŽāL =ŽāD L ’ü¼ where: d = average daily (or weekly) demand L = Lead time (matching days or weeks) ŽāL = standard deviation of demand during lead time. ŽāD = standard deviation of demand (days or weeks). 18

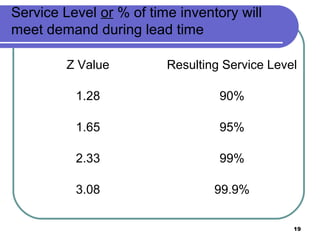

- 19. Service Level or % of time inventory will meet demand during lead time Z Value Resulting Service Level 1.28 90% 1.65 95% 2.33 99% 3.08 99.9% 19

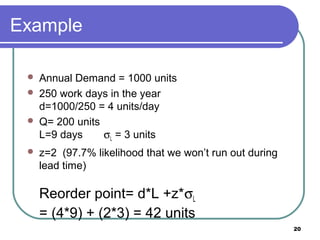

- 20. Example ’ü¼ Annual Demand = 1000 units ’ü¼ 250 work days in the year d=1000/250 = 4 units/day ’ü¼ Q= 200 units L=9 days ŽāL = 3 units ’ü¼ z=2 (97.7% likelihood that we wonŌĆÖt run out during lead time) Reorder point= d*L +z*ŽāL = (4*9) + (2*3) = 42 units 20

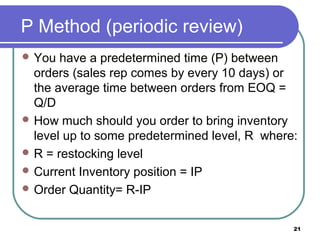

- 21. P Method (periodic review) ’ü¼ You have a predetermined time (P) between orders (sales rep comes by every 10 days) or the average time between orders from EOQ = Q/D ’ü¼ How much should you order to bring inventory level up to some predetermined level, R where: ’ü¼ R = restocking level ’ü¼ Current Inventory position = IP ’ü¼ Order Quantity= R-IP 21

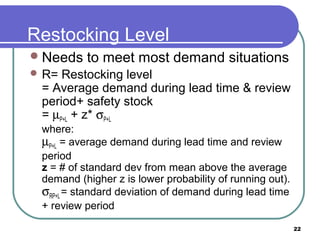

- 22. Restocking Level ’ü¼ Needs to meet most demand situations ’ü¼ R= Restocking level = Average demand during lead time & review period+ safety stock = ┬ĄP+L + z* ŽāP+L where: ┬ĄP+L = average demand during lead time and review period z = # of standard dev from mean above the average demand (higher z is lower probability of running out). ŽāRP+L = standard deviation of demand during lead time + review period 22

- 23. ABC Inventory Management ’ü¼ Based on ŌĆ£ParetoŌĆØ concept (80/20 rule) and total usage in dollars of each item. ’ü¼ Classification of items as A, B, or C based on usage. ’ü¼ Purpose is to set priorities on effort used to manage different SKUs, i.e. to allocate scarce management resources. ’ü¼ SKU: Stock Keeping Unit 23

- 24. ABC Inventory Management ’ü¼ ŌĆśAŌĆÖ items: 20% of SKUs, 80% of dollars ’ü¼ ŌĆśBŌĆÖ items: 30 % of SKUs, 15% of dollars ’ü¼ ŌĆśCŌĆÖ items: 50 % of SKUs, 5% of dollars ’ü¼ Three classes is arbitrary; could be any number. ’ü¼ Percents are approximate. ’ü¼ Danger: dollar use may not reflect importance of any given SKU! 24

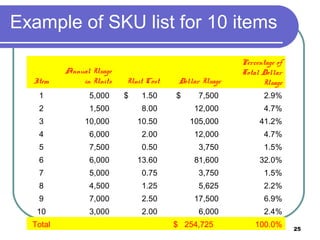

- 25. Example of SKU list for 10 items Percentage of Annual Usage Total Dollar Item in Units Unit Cost Dollar Usage Usage 1 5,000 $ 1.50 $ 7,500 2.9% 2 1,500 8.00 12,000 4.7% 3 10,000 10.50 105,000 41.2% 4 6,000 2.00 12,000 4.7% 5 7,500 0.50 3,750 1.5% 6 6,000 13.60 81,600 32.0% 7 5,000 0.75 3,750 1.5% 8 4,500 1.25 5,625 2.2% 9 7,000 2.50 17,500 6.9% 10 3,000 2.00 6,000 2.4% Total ╠² ╠² $ 254,725 100.0% 25

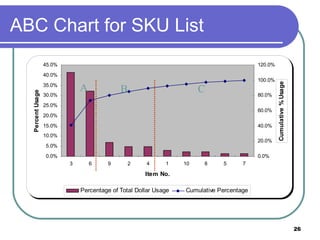

- 26. ABC Chart for SKU List 45.0% 120.0% 40.0% 100.0% Cumulative % Usage 35.0% A B C Percent Usage 30.0% 80.0% 25.0% 60.0% 20.0% 15.0% 40.0% 10.0% 20.0% 5.0% 0.0% 0.0% 3 6 9 2 4 1 10 8 5 7 Item No. Percentage of Total Dollar Usage Cumulative Percentage 26

- 27. ABC Application ’ü¼ Jewelry Store ’ü¼ Fine Dining Restaurant ’ü¼ Outdoor Retailer ’ü¼ Large Department Store 27

Editor's Notes

- #2: BA 339 03/20/13

- #3: BA 339 03/20/13

- #4: BA 339 03/20/13 3

- #5: BA 339 03/20/13 4

- #6: BA 339 03/20/13 5

- #7: BA 339 03/20/13 7

- #8: BA 339 03/20/13

- #9: BA 339 03/20/13

- #10: BA 339 03/20/13

- #11: BA 339 03/20/13

- #13: BA 339 03/20/13

- #14: BA 339 03/20/13

- #15: BA 339 03/20/13

- #16: BA 339 03/20/13

- #17: BA 339 03/20/13

- #18: BA 339 03/20/13

- #19: BA 339 03/20/13

- #20: BA 339 03/20/13

- #21: BA 339 03/20/13

- #22: BA 339 03/20/13

- #23: BA 339 03/20/13