Presentation

Download as pptx, pdf0 likes239 views

This document outlines a student project to design a carbon capture process for a cement plant. It assigns group members to tasks such as problem definition, process selection, material and energy balancing, and equipment design. The selected process uses sodium hydroxide to absorb CO2 from flue gas in a post-combustion capture system. Equipment is designed including a heat exchanger, pump, mixer, and rotary filter. An economic analysis shows the process is profitable with a two year payback period and annual revenue of $83 million. In conclusion, the carbon mineralization capture process has technical and economic advantages over other capture methods.

1 of 39

Downloaded 14 times

Ad

Recommended

UniCase Master®

UniCase Master®SECO/WARWICK

╠²

The UniCase Master® system provides a revolutionary innovation for precision case hardening using a single-piece flow with low pressure carburizing and 4D quenching. This allows for lean manufacturing integration, 100% traceability, reduced distortion, flexibility, and clean processing compared to traditional batch technologies. Key benefits include improved quality, precision, throughput, and reduced costs.Fyppt

Fypptnoman sabir

╠²

This document discusses a proposed process for separating carbon dioxide (CO2) and purifying hydrogen (H2) from syngas produced via integrated gasification combined cycle (IGCC) combustion. The process involves using a hydrate-based technology in conjunction with chemical adsorption. Diagrams and specifications are provided for the absorber, stripper, flash drum, and knock out drum units involved in the CO2 separation and H2 purification process.ALD Two Chamber Vacuum Furnace | DualTherm®

ALD Two Chamber Vacuum Furnace | DualTherm®ALD Vacuum Systems Inc.

╠²

The document describes the Dualtherm® vacuum furnace, highlighting its cost and space-saving benefits along with its safety features, such as minimal fire hazards and no need for toxic gas precautions. It emphasizes the furnace's energy efficiency, high temperature uniformity, and advanced gas flow control for optimal heat treatment processes. Additionally, the system is designed for low maintenance and high throughput, making it suitable for various heat treatment applications.Process Principles of High Pressure Gas Quenching in ModulTherm® and DualTherm®

Process Principles of High Pressure Gas Quenching in ModulTherm® and DualTherm®ALD Vacuum Systems Inc.

╠²

The document discusses the high pressure gas quenching (HPGQ) process, highlighting its advantages such as reduced distortion, adjustable quenching intensity, and clean working conditions. It details the effects of various quenching parameters and gas properties on microstructure and hardness, especially in low alloyed case hardening steels. The HPGQ method is presented as an improvement over traditional quenching techniques, allowing for more efficient manufacturing and reduced scrap rates.ALD Vacuum Carburizing and Low Pressure Carburizing | LPC

ALD Vacuum Carburizing and Low Pressure Carburizing | LPCALD Vacuum Systems Inc.

╠²

Vacuum carburizing provides advantages over traditional gas carburizing methods, including faster carbon transfer without surface oxidation, improved case depth uniformity, and integration into manufacturing processes with little consumption of carburizing gas and no need for furnace atmospheres. Vacuum carburizing allows for higher carburizing temperatures and shorter treatment times compared to gas carburizing. Parts treated with vacuum carburizing have cleaner surfaces without intergranular oxidation, more consistent case depths and carbon profiles, less distortion and variation, and potential operational cost advantages.Vacuum Purging - New Innovation for Controlled Atmosphere Brazing

Vacuum Purging - New Innovation for Controlled Atmosphere BrazingSECO/WARWICK

╠²

The document discusses vacuum purging in controlled atmosphere brazing (CAB) processes, highlighting its advantages such as improved brazing quality, reduced nitrogen consumption, and time savings. It explains the differences between vacuum and conventional purging systems, the configurations available for CAB with vacuum purging, and the resulting benefits including lower operational costs and superior joint quality. The findings suggest that integrating vacuum purging may serve as a cost-effective alternative to vacuum aluminum brazing (VAB).High Pressure Gas Quenching

High Pressure Gas QuenchingALD Vacuum Systems Inc.

╠²

High pressure gas quenching (HPGQ) offers advantages like reduced hardening distortion and adjustable quenching intensity through gas pressure and velocity. This clean and non-toxic process integrates well into manufacturing lines, producing reproducible and high-quality results without the need for washing. Key parameters influencing HPGQ include gas type, pressure, velocity, and chamber design, which collectively impact the material's microstructure, hardness, and overall distortion.Nitric Acid Production Plant

Nitric Acid Production Plant Sergio Joao

╠²

The document describes a proposed nitric acid production process with an integrated energy recovery system. Key details include:

- Nitric acid production of 109 tonnes/hour from ammonia and air feeds of 28 and 352 tonnes/hour respectively.

- A catalytic reactor converts ammonia and air into nitric acid using a platinum-rhodium catalyst at 1093┬░C and 538 kPa.

- An integrated waste heat boiler recovers high pressure steam from the reactor for power generation.

- The process is estimated to recover 60% of input energy through steam turbine generation, resulting in net energy requirements of 88 GWh per year.ALD Vacuum Systems Inc. - Integrated Heat Treating

ALD Vacuum Systems Inc. - Integrated Heat TreatingALD Vacuum Systems Inc.

╠²

This document discusses the integration of heat treatment into machining processes for gear components, highlighting a new technology called syncrotherm that allows for synchronized heat treatment in a 'one-piece flow' production system. The advancements include the use of high-temperature low-pressure carburizing (ht-lpc) and high-pressure gas quenching (hpgq) that significantly reduce cycle times and distortion. Future developments will focus on optimizing material specifications and further reducing heat treat distortions to improve overall manufacturing efficiency.presentation

presentationAmel Elamir

╠²

The document presents a design project for a ceramic products manufacturing plant in Sudan. It includes process descriptions and material and energy balances for the manufacturing of ceramic tiles. Key areas covered include the raw material preparation using a ball mill, firing in a roller hearth kiln controlled by a PID controller, ancillary equipment like storage tanks and pumps, and considerations around environmental impacts. The overall aim is to satisfy local demand for ceramics and export excess production to generate revenue.Amateur 500N Ethanol/Lox Nozzle design study

Amateur 500N Ethanol/Lox Nozzle design studySaiWaiPhyo

╠²

This document summarizes the design of a 500N ethanol/lox rocket engine. It provides key parameters such as an O/F ratio of 3.2 and a chamber pressure of 290 psi. Flow rates include 0.06348 kg/s of fuel and 0.20313 kg/s of oxidizer. Based on these parameters and equations of rocket engine design, it calculates pressure and temperature values at different locations in the engine. It then determines the throat area of 0.2864 in^2 and exit area based on an expansion ratio of 3.8075997. Manufacturing constraints such as a 50mm inlet diameter and 30 inch chamber length are also specified. CFD analysis is recommended to finalize the design.ethanol production from crude glycerol

ethanol production from crude glycerol Sonia Patel

╠²

1) The document presents a feasibility study for the production of bioethanol from glycerol using Enterobacter aerogenes TISTR1468. It discusses the process selection, raw materials, design constraints, and site location analysis.

2) A continuous process is proposed using two main fermenters in series. Mass and energy balance calculations show the process can produce 15,000 tonnes of ethanol per year.

3) Downstream separation will involve disc stack centrifugation, distillation, and molecular sieves to obtain concentrated ethanol and separate water and glycerol byproducts.L pac presentation

L pac presentationSonia Patel

╠²

The document presents a project on the production of L-phenylacetylcarbinol (L-PAC) through fermentation. It includes a literature review on the fermentation process and usage of L-PAC. An economy analysis of the global demand and supply of L-PAC from 2006-2013 is presented. The process description includes fermentation in a bioreactor, centrifugation, precipitation, filtration and drying. Mass and energy balances are calculated for the bioreactor and distillation column. The pressure vessel designs for the bioreactor and distillation column are discussed. Heat exchanger designs and heat integration are analyzed. Control loops for bioreactor level, feed rate and antifoam are proposed. Wastewsponge iron TCE NMD

sponge iron TCE NMDAsaman Patnaik

╠²

This document discusses challenges in producing sponge iron using rotary kilns. It outlines various technological options for direct reduced iron (DRI) making, including coal-based and gas-based processes. Coal-based DRI uses rotary kilns while gas-based uses shaft furnaces with synthesis gas. Factors affecting productivity and emissions from each process are presented. Opportunities for cleaner technologies like using beneficiated coal or synthesis gas from coal gasification in rotary kilns or shaft furnaces are discussed along with challenges. The MIDREX and HYL gas-based shaft furnace processes and use of synthesis gas in these furnaces are also summarized.Carbonisation of coal

Carbonisation of coalRiddhi Sarvaiya

╠²

Carbonisation is the heating of coal in the absence of air to produce coke. There are two main types of carbonisation: low temperature carbonisation (LTC) and high temperature carbonisation (HTC). LTC occurs at lower temperatures (around 700┬░C) and produces weaker coke and more by-products but with a higher coke yield. HTC occurs at higher temperatures (around 1,100┬░C) and produces stronger metallurgical coke and less by-products but with a lower coke yield. Modern coke making uses by-product coke ovens which allow for the recovery of coke oven gas and other by-products.Cryogenic air separation brochure19 4353 tcm136-414865

Cryogenic air separation brochure19 4353 tcm136-414865SonaTrak

╠²

ŌåÆ This document discusses the history and technological progress of Linde Engineering's air separation processes. It began with Carl von Linde's breakthrough invention of the first continuous air liquefaction process in 1895. [1]

ŌåÆ The document outlines the basic principles of air separation through rectification and double column distillation. It also describes technological developments like the use of structured packings and internal compression processes. [2]

ŌåÆ Linde Engineering has built over 3,000 air separation plants globally using these cryogenic separation techniques. They are the leading supplier of air separation technology. [3]Methanol Synthesis - Theory and Operation

Methanol Synthesis - Theory and OperationGerard B. Hawkins

╠²

This document summarizes the theory and operation of methanol synthesis. It describes the typical methanol synthesis flowsheet that involves natural gas processing, reforming, and methanol production and purification steps. It also discusses the methanol synthesis reactions, catalysts used including their properties and deactivation mechanisms. Key factors that affect the equilibrium and kinetics of the synthesis reactions like temperature, pressure and catalyst activity are described. Methods to maximize the reaction rate within operational constraints are covered.Paper id 41201605

Paper id 41201605IJRAT

╠²

1. The document describes a process to remove moisture from off-gas containing NOx and SOx from a zirconium oxide plant. The wet cake is dried, producing 450kg/hr of water vapor and visible plume from the stack.

2. A pilot plant test showed condensing 130kg/hr of the off-gas produced 3.55kg of condensate in 1 hour, indicating a condenser could capture around 460kg/hr. The document then details the design of a shell and tube condenser to remove the moisture.

3. The condenser design was based on pilot plant results and aimed to reduce the visible plume from the stack while meeting regulatory standards. ModelingMethanol Converter Types

Methanol Converter TypesGerard B. Hawkins

╠²

This document discusses different types of methanol synthesis reactors, including quench converters, ARC converters, tube cooled converters, and adiabatic bed reactors. It provides details on the benefits and drawbacks of each type, such as the quench converter being simple and reliable but prone to temperature maldistribution issues across the catalyst beds. The document also examines techniques for improving reactor design and operation, such as the ARC retrofit developed to improve gas mixing in quench converters.Natural gas processing: Production of LPG

Natural gas processing: Production of LPG Asma-ul Husna

╠²

The document presents a comprehensive analysis of gas processing, detailing the components and their mole fractions, separation methods, equipment specifications, and operational parameters. It includes information on three-phase separators, distillation columns, and heat exchangers, along with vendor details and performance data. The specifics cover equipment sizes, pressures, and fluid properties required for glycol cooling units in a gas separation setup.IA on effect of inhibitor concentration lead on enzyme catalase (yeast extrac...

IA on effect of inhibitor concentration lead on enzyme catalase (yeast extrac...Lawrence kok

╠²

The document discusses the catalytic properties of transition metals, emphasizing their ability to act as either homogeneous or heterogeneous catalysts that lower activation energy. It details an experiment measuring the effect of lead ion concentration on the activity of catalase enzyme in the decomposition of hydrogen peroxide, using pressure sensors to record the rate of oxygen production. The findings indicate that increasing lead concentration decreases the rate of decomposition, demonstrating lead's role as a strong inhibitor of the catalase enzyme.Design and balance : Styrene Oxide Production

Design and balance : Styrene Oxide ProductionARITRA MUKHERJEE

╠²

This project report summarizes the design of a plant to manufacture 50,000 tons per annum of styrene oxide. Key aspects of the design include:

1) Energy and mass balances are presented for the pre-heater, reactor, and distillation column sections. Steam and cooling water requirements are calculated.

2) The reactor is designed as a batch reactor with calculations showing a volume of 14.95 m3 and diameter of 2.013 m based on the desired residence time and conversions.

3) The distillation column is designed with 19 actual trays based on calculations from vapor liquid equilibrium data. The column has a height of 12 m and diameter of 1.223 m.

4Cumene Production ║▌║▌▀Ż Show (group 7)

Cumene Production ║▌║▌▀Ż Show (group 7)Ezika Kennedy Emmanuel

╠²

The document presents an undergraduate design report for a plant to produce 10,000 tons per day of cumene from the reaction of propylene and benzene using an acid catalyst. It describes the chosen reactive distillation process route and provides justification. It includes the process description with flow diagram and block diagram. Results and discussion sections provide material and energy balances, equipment design details, and economic analysis showing a net profit and payback period of 2 years. Recommendations include considering a yearly design basis and using more realistic cost data.Methane Steam Reformer Re-tube Studies

Methane Steam Reformer Re-tube StudiesGerard B. Hawkins

╠²

1) GBHE has extensive experience designing and evaluating methane steam reformer tubes and can perform detailed simulations and modeling to optimize reformer performance during retube evaluations.

2) The methodology involves understanding current operations, simulating the existing reformer, selecting improved tube materials and catalysts, and modeling stress levels and temperatures to determine maximum operating conditions.

3) Case studies demonstrate how optimizing tubes and catalyst can increase production by 3-15% while reducing pressure drop, temperatures, and methane slip.ppt cd

ppt cdSneha More

╠²

This document describes the development of an algorithm to calculate the interfacial heat transfer coefficient (IFHTC) for a sand casting process. The algorithm is developed through ANSYS simulations of heat transfer during casting of an aluminum plate. Two meshing techniques, free mesh and mapped mesh, are used. The inverse heat conduction method is applied to calculate IFHTC from heat flux and temperature difference data. IFHTC is calculated for different pouring temperatures and an algorithm is developed and coded in Java. Results from the algorithm match well with ANSYS simulations, with less than 2.5% error. Future work may involve extending the algorithm to other materials, shapes, and optimizing additional casting parameters.Is scr technology coming back to cement

Is scr technology coming back to cementJohn Kline

╠²

This presentation covers nitrogen oxides (NOx) formation in combustion processes and technology options for NOx reduction, including Selective Catalytic Reduction (SCR) and Selective Non-Catalytic Reduction (SNCR). It discusses different kiln systems and conditions, comparing their effectiveness, investment, and operational costs, while highlighting the evolution of SCR technology and its applications in various installations. Additionally, the document details case studies of NOx reduction implementations in cement production across different locations.Design of recuperative gas combustion chamber

Design of recuperative gas combustion chamberApurva Anand

╠²

1. The document details the design of a can-type combustion chamber for producer gas fuel for commercial use with the objectives of passive heat recovery and an engineering model for testing.

2. Design requirements include the chamber being less than 1m long and 500mm in diameter with the heat recovery technique ensuring a 200K-300K exhaust temperature rise.

3. Performance estimates show heat recovery with cross pattern fins can increase exhaust temperature by 44% to 1200K, improving efficiency.STUDYING THE EFFECT OF CAR TECHNOLOGY ON CO EMISSIONS AND BENEFITS OF UPDATIN...

STUDYING THE EFFECT OF CAR TECHNOLOGY ON CO EMISSIONS AND BENEFITS OF UPDATIN...IAEME Publication

╠²

This research investigates the carbon monoxide (CO) emissions from old and new technology vehicles through field tests in Egypt, revealing that old models emit significantly more COŌĆöup to 20 times moreŌĆöthan newer models. The analysis indicates that old passenger cars account for 81.9% of total CO emissions, and a proposed replacement of vehicles manufactured in 1990 or earlier could reduce emissions by 60%. The study emphasizes the importance of updating the fleet to improve air quality and suggests further research on various vehicle types and emissions.Citizens' potential in CO2 emissions reduction - English summary

Citizens' potential in CO2 emissions reduction - English summaryGaiaConsultingOy

╠²

The document summarizes a study on the CO2 emission reduction potential of consumer actions in Finland's energy sector by 2030. Key findings include:

1) Measures like installing heat pumps, purchasing CO2-free electricity, and using electric vehicles could reduce Finland's CO2 emissions by 5 MtCO2e by 2030, equal to 1/3 of the reduction needed to meet climate targets.

2) Heat pumps have the highest potential at 1,500 ktCO2e reduced annually followed by CO2-free electricity purchases and electric vehicles.

3) Citizens' actions have the potential to reduce end use of energy by 5% (13 TWh) with heat pumps providing most savings.Proving reduction of CO2 emissions after 2005

Proving reduction of CO2 emissions after 2005Minsu Kim

╠²

The document discusses a data-mining analysis conducted during the 2016 spring semester at Sungkyunkwan University, focusing on proving the reduction of CO2 emissions in relation to the Kyoto Protocol. It outlines the background of greenhouse gas emissions, the hypotheses regarding efforts to reduce CO2 emissions, and the datasets used for analysis, including CO2 emissions per capita and population data. The analysis includes basic statistics, predictions, and identifies countries that failed to meet emission reduction targets.More Related Content

What's hot (19)

ALD Vacuum Systems Inc. - Integrated Heat Treating

ALD Vacuum Systems Inc. - Integrated Heat TreatingALD Vacuum Systems Inc.

╠²

This document discusses the integration of heat treatment into machining processes for gear components, highlighting a new technology called syncrotherm that allows for synchronized heat treatment in a 'one-piece flow' production system. The advancements include the use of high-temperature low-pressure carburizing (ht-lpc) and high-pressure gas quenching (hpgq) that significantly reduce cycle times and distortion. Future developments will focus on optimizing material specifications and further reducing heat treat distortions to improve overall manufacturing efficiency.presentation

presentationAmel Elamir

╠²

The document presents a design project for a ceramic products manufacturing plant in Sudan. It includes process descriptions and material and energy balances for the manufacturing of ceramic tiles. Key areas covered include the raw material preparation using a ball mill, firing in a roller hearth kiln controlled by a PID controller, ancillary equipment like storage tanks and pumps, and considerations around environmental impacts. The overall aim is to satisfy local demand for ceramics and export excess production to generate revenue.Amateur 500N Ethanol/Lox Nozzle design study

Amateur 500N Ethanol/Lox Nozzle design studySaiWaiPhyo

╠²

This document summarizes the design of a 500N ethanol/lox rocket engine. It provides key parameters such as an O/F ratio of 3.2 and a chamber pressure of 290 psi. Flow rates include 0.06348 kg/s of fuel and 0.20313 kg/s of oxidizer. Based on these parameters and equations of rocket engine design, it calculates pressure and temperature values at different locations in the engine. It then determines the throat area of 0.2864 in^2 and exit area based on an expansion ratio of 3.8075997. Manufacturing constraints such as a 50mm inlet diameter and 30 inch chamber length are also specified. CFD analysis is recommended to finalize the design.ethanol production from crude glycerol

ethanol production from crude glycerol Sonia Patel

╠²

1) The document presents a feasibility study for the production of bioethanol from glycerol using Enterobacter aerogenes TISTR1468. It discusses the process selection, raw materials, design constraints, and site location analysis.

2) A continuous process is proposed using two main fermenters in series. Mass and energy balance calculations show the process can produce 15,000 tonnes of ethanol per year.

3) Downstream separation will involve disc stack centrifugation, distillation, and molecular sieves to obtain concentrated ethanol and separate water and glycerol byproducts.L pac presentation

L pac presentationSonia Patel

╠²

The document presents a project on the production of L-phenylacetylcarbinol (L-PAC) through fermentation. It includes a literature review on the fermentation process and usage of L-PAC. An economy analysis of the global demand and supply of L-PAC from 2006-2013 is presented. The process description includes fermentation in a bioreactor, centrifugation, precipitation, filtration and drying. Mass and energy balances are calculated for the bioreactor and distillation column. The pressure vessel designs for the bioreactor and distillation column are discussed. Heat exchanger designs and heat integration are analyzed. Control loops for bioreactor level, feed rate and antifoam are proposed. Wastewsponge iron TCE NMD

sponge iron TCE NMDAsaman Patnaik

╠²

This document discusses challenges in producing sponge iron using rotary kilns. It outlines various technological options for direct reduced iron (DRI) making, including coal-based and gas-based processes. Coal-based DRI uses rotary kilns while gas-based uses shaft furnaces with synthesis gas. Factors affecting productivity and emissions from each process are presented. Opportunities for cleaner technologies like using beneficiated coal or synthesis gas from coal gasification in rotary kilns or shaft furnaces are discussed along with challenges. The MIDREX and HYL gas-based shaft furnace processes and use of synthesis gas in these furnaces are also summarized.Carbonisation of coal

Carbonisation of coalRiddhi Sarvaiya

╠²

Carbonisation is the heating of coal in the absence of air to produce coke. There are two main types of carbonisation: low temperature carbonisation (LTC) and high temperature carbonisation (HTC). LTC occurs at lower temperatures (around 700┬░C) and produces weaker coke and more by-products but with a higher coke yield. HTC occurs at higher temperatures (around 1,100┬░C) and produces stronger metallurgical coke and less by-products but with a lower coke yield. Modern coke making uses by-product coke ovens which allow for the recovery of coke oven gas and other by-products.Cryogenic air separation brochure19 4353 tcm136-414865

Cryogenic air separation brochure19 4353 tcm136-414865SonaTrak

╠²

ŌåÆ This document discusses the history and technological progress of Linde Engineering's air separation processes. It began with Carl von Linde's breakthrough invention of the first continuous air liquefaction process in 1895. [1]

ŌåÆ The document outlines the basic principles of air separation through rectification and double column distillation. It also describes technological developments like the use of structured packings and internal compression processes. [2]

ŌåÆ Linde Engineering has built over 3,000 air separation plants globally using these cryogenic separation techniques. They are the leading supplier of air separation technology. [3]Methanol Synthesis - Theory and Operation

Methanol Synthesis - Theory and OperationGerard B. Hawkins

╠²

This document summarizes the theory and operation of methanol synthesis. It describes the typical methanol synthesis flowsheet that involves natural gas processing, reforming, and methanol production and purification steps. It also discusses the methanol synthesis reactions, catalysts used including their properties and deactivation mechanisms. Key factors that affect the equilibrium and kinetics of the synthesis reactions like temperature, pressure and catalyst activity are described. Methods to maximize the reaction rate within operational constraints are covered.Paper id 41201605

Paper id 41201605IJRAT

╠²

1. The document describes a process to remove moisture from off-gas containing NOx and SOx from a zirconium oxide plant. The wet cake is dried, producing 450kg/hr of water vapor and visible plume from the stack.

2. A pilot plant test showed condensing 130kg/hr of the off-gas produced 3.55kg of condensate in 1 hour, indicating a condenser could capture around 460kg/hr. The document then details the design of a shell and tube condenser to remove the moisture.

3. The condenser design was based on pilot plant results and aimed to reduce the visible plume from the stack while meeting regulatory standards. ModelingMethanol Converter Types

Methanol Converter TypesGerard B. Hawkins

╠²

This document discusses different types of methanol synthesis reactors, including quench converters, ARC converters, tube cooled converters, and adiabatic bed reactors. It provides details on the benefits and drawbacks of each type, such as the quench converter being simple and reliable but prone to temperature maldistribution issues across the catalyst beds. The document also examines techniques for improving reactor design and operation, such as the ARC retrofit developed to improve gas mixing in quench converters.Natural gas processing: Production of LPG

Natural gas processing: Production of LPG Asma-ul Husna

╠²

The document presents a comprehensive analysis of gas processing, detailing the components and their mole fractions, separation methods, equipment specifications, and operational parameters. It includes information on three-phase separators, distillation columns, and heat exchangers, along with vendor details and performance data. The specifics cover equipment sizes, pressures, and fluid properties required for glycol cooling units in a gas separation setup.IA on effect of inhibitor concentration lead on enzyme catalase (yeast extrac...

IA on effect of inhibitor concentration lead on enzyme catalase (yeast extrac...Lawrence kok

╠²

The document discusses the catalytic properties of transition metals, emphasizing their ability to act as either homogeneous or heterogeneous catalysts that lower activation energy. It details an experiment measuring the effect of lead ion concentration on the activity of catalase enzyme in the decomposition of hydrogen peroxide, using pressure sensors to record the rate of oxygen production. The findings indicate that increasing lead concentration decreases the rate of decomposition, demonstrating lead's role as a strong inhibitor of the catalase enzyme.Design and balance : Styrene Oxide Production

Design and balance : Styrene Oxide ProductionARITRA MUKHERJEE

╠²

This project report summarizes the design of a plant to manufacture 50,000 tons per annum of styrene oxide. Key aspects of the design include:

1) Energy and mass balances are presented for the pre-heater, reactor, and distillation column sections. Steam and cooling water requirements are calculated.

2) The reactor is designed as a batch reactor with calculations showing a volume of 14.95 m3 and diameter of 2.013 m based on the desired residence time and conversions.

3) The distillation column is designed with 19 actual trays based on calculations from vapor liquid equilibrium data. The column has a height of 12 m and diameter of 1.223 m.

4Cumene Production ║▌║▌▀Ż Show (group 7)

Cumene Production ║▌║▌▀Ż Show (group 7)Ezika Kennedy Emmanuel

╠²

The document presents an undergraduate design report for a plant to produce 10,000 tons per day of cumene from the reaction of propylene and benzene using an acid catalyst. It describes the chosen reactive distillation process route and provides justification. It includes the process description with flow diagram and block diagram. Results and discussion sections provide material and energy balances, equipment design details, and economic analysis showing a net profit and payback period of 2 years. Recommendations include considering a yearly design basis and using more realistic cost data.Methane Steam Reformer Re-tube Studies

Methane Steam Reformer Re-tube StudiesGerard B. Hawkins

╠²

1) GBHE has extensive experience designing and evaluating methane steam reformer tubes and can perform detailed simulations and modeling to optimize reformer performance during retube evaluations.

2) The methodology involves understanding current operations, simulating the existing reformer, selecting improved tube materials and catalysts, and modeling stress levels and temperatures to determine maximum operating conditions.

3) Case studies demonstrate how optimizing tubes and catalyst can increase production by 3-15% while reducing pressure drop, temperatures, and methane slip.ppt cd

ppt cdSneha More

╠²

This document describes the development of an algorithm to calculate the interfacial heat transfer coefficient (IFHTC) for a sand casting process. The algorithm is developed through ANSYS simulations of heat transfer during casting of an aluminum plate. Two meshing techniques, free mesh and mapped mesh, are used. The inverse heat conduction method is applied to calculate IFHTC from heat flux and temperature difference data. IFHTC is calculated for different pouring temperatures and an algorithm is developed and coded in Java. Results from the algorithm match well with ANSYS simulations, with less than 2.5% error. Future work may involve extending the algorithm to other materials, shapes, and optimizing additional casting parameters.Is scr technology coming back to cement

Is scr technology coming back to cementJohn Kline

╠²

This presentation covers nitrogen oxides (NOx) formation in combustion processes and technology options for NOx reduction, including Selective Catalytic Reduction (SCR) and Selective Non-Catalytic Reduction (SNCR). It discusses different kiln systems and conditions, comparing their effectiveness, investment, and operational costs, while highlighting the evolution of SCR technology and its applications in various installations. Additionally, the document details case studies of NOx reduction implementations in cement production across different locations.Design of recuperative gas combustion chamber

Design of recuperative gas combustion chamberApurva Anand

╠²

1. The document details the design of a can-type combustion chamber for producer gas fuel for commercial use with the objectives of passive heat recovery and an engineering model for testing.

2. Design requirements include the chamber being less than 1m long and 500mm in diameter with the heat recovery technique ensuring a 200K-300K exhaust temperature rise.

3. Performance estimates show heat recovery with cross pattern fins can increase exhaust temperature by 44% to 1200K, improving efficiency.Viewers also liked (8)

STUDYING THE EFFECT OF CAR TECHNOLOGY ON CO EMISSIONS AND BENEFITS OF UPDATIN...

STUDYING THE EFFECT OF CAR TECHNOLOGY ON CO EMISSIONS AND BENEFITS OF UPDATIN...IAEME Publication

╠²

This research investigates the carbon monoxide (CO) emissions from old and new technology vehicles through field tests in Egypt, revealing that old models emit significantly more COŌĆöup to 20 times moreŌĆöthan newer models. The analysis indicates that old passenger cars account for 81.9% of total CO emissions, and a proposed replacement of vehicles manufactured in 1990 or earlier could reduce emissions by 60%. The study emphasizes the importance of updating the fleet to improve air quality and suggests further research on various vehicle types and emissions.Citizens' potential in CO2 emissions reduction - English summary

Citizens' potential in CO2 emissions reduction - English summaryGaiaConsultingOy

╠²

The document summarizes a study on the CO2 emission reduction potential of consumer actions in Finland's energy sector by 2030. Key findings include:

1) Measures like installing heat pumps, purchasing CO2-free electricity, and using electric vehicles could reduce Finland's CO2 emissions by 5 MtCO2e by 2030, equal to 1/3 of the reduction needed to meet climate targets.

2) Heat pumps have the highest potential at 1,500 ktCO2e reduced annually followed by CO2-free electricity purchases and electric vehicles.

3) Citizens' actions have the potential to reduce end use of energy by 5% (13 TWh) with heat pumps providing most savings.Proving reduction of CO2 emissions after 2005

Proving reduction of CO2 emissions after 2005Minsu Kim

╠²

The document discusses a data-mining analysis conducted during the 2016 spring semester at Sungkyunkwan University, focusing on proving the reduction of CO2 emissions in relation to the Kyoto Protocol. It outlines the background of greenhouse gas emissions, the hypotheses regarding efforts to reduce CO2 emissions, and the datasets used for analysis, including CO2 emissions per capita and population data. The analysis includes basic statistics, predictions, and identifies countries that failed to meet emission reduction targets.Green concretre2

Green concretre2faishalniet

╠²

The document discusses green concrete, a sustainable alternative to traditional concrete that reduces CO2 emissions by utilizing waste materials and energy-efficient production methods. It highlights the applications, materials, and benefits of green concrete, including its thermal and fire resistance. The text emphasizes its potential to decrease environmental impact and its current scope in India.Cement carbonation: can it help or hinter CO2 storage? - presentation given b...

Cement carbonation: can it help or hinter CO2 storage? - presentation given b...UK Carbon Capture and Storage Research Centre

╠²

The document discusses the effects of cement carbonation on CO2 storage in boreholes, addressing the dual potential for both aiding and hindering CO2 containment. It outlines various chemical reactions between cement and CO2, potential leakage pathways, and findings from laboratory and field studies, suggesting that well construction and quality significantly influence the sealing ability of boreholes. Long-term studies are necessary to understand the implications of these reactions and to improve CO2 storage strategies.Global carbon emissions

Global carbon emissionsMayank Mittal

╠²

This document provides an overview of global carbon emissions. It discusses that the electricity/heat generation and transportation sectors account for about two-thirds of global CO2 emissions. Coal combustion is a major contributor and emissions have been increasing in developing countries like China and India. The document also examines carbon emissions by region, sector and country for India. It outlines various ways that individuals and organizations can reduce their carbon footprint through more efficient energy use and purchasing carbon offsets.ferrock cement

ferrock cementRajbir Singh

╠²

Ferrock is a proposed substitute for traditional cement that could significantly reduce greenhouse gas emissions. It is composed partly of recycled steel dust and captures between 8-11% of its weight in CO2 as it cures. Tests show Ferrock has stronger compressive and flexural strength than Portland cement. Researchers are studying its potential to make structures like building columns more blast resistant, helping to save lives in disasters. Adopting Ferrock could help cement-producing countries like India and China move to a more sustainable future.Cement and co2 what's happening

Cement and co2 what's happeningJohn Kline

╠²

This document summarizes strategies for reducing carbon emissions in the cement industry as outlined in the Cement Industry Technology Roadmap. It discusses various levers such as clinker reformulation, energy efficiency improvements, use of biogenic and alternative fuels, and clinker substitution. Specific technologies covered include oxy-fuel combustion, post-combustion carbon capture, and use of algae to sequester CO2 from cement plant flue gases. The document evaluates the potential and challenges of different approaches and provides recommendations for industry-wide cooperation on reducing carbon emissions.Cement carbonation: can it help or hinter CO2 storage? - presentation given b...

Cement carbonation: can it help or hinter CO2 storage? - presentation given b...UK Carbon Capture and Storage Research Centre

╠²

Ad

Similar to Presentation (20)

PRESENTATION ON HYDROGEN GAS PRODUCTION BY PARTIAL OXIDATION OF HEAVY FUEL OI...

PRESENTATION ON HYDROGEN GAS PRODUCTION BY PARTIAL OXIDATION OF HEAVY FUEL OI...Adebayo Bamidele Olanrewaju BSc, ASM, AMNIM, MNSE, MNSChE, CSSBB

╠²

The document outlines the production of 20 million standard cubic feet of hydrogen per day with at least 95% purity from heavy fuel oil feedstocks, detailing hydrogen's properties, demand, and various production methods including partial oxidation. It discusses process design, mass and energy balance, necessary equipment, safety considerations, and concludes that the hydrogen produced will meet purity standards while specifying energy and conversion rates required for production. The design includes measures for safety and operational efficiency in the hydrogen production process.LECTURE 5-10 IIB FUEL AND INDUSTRIAL GASES.pptx

LECTURE 5-10 IIB FUEL AND INDUSTRIAL GASES.pptxChemical Engineering Dept. NIT Rourkela-769008, Odisha, India

╠²

The document outlines various aspects of inorganic chemical industries, focusing on processes for producing synthesis gas and acetylene, including engineering challenges such as sulfur contamination, catalyst design, and burner efficiency. It also details quantitative requirements for raw materials, process conditions, and plant capacities needed for efficient production. Key production methods and thermodynamic considerations emphasize the importance of optimizing chemical reactions in industrial settings.Capture from Cement and UK Calcium Looping Research, Paul Fennell (Imperial C...

Capture from Cement and UK Calcium Looping Research, Paul Fennell (Imperial C...UK Carbon Capture and Storage Research Centre

╠²

This document summarizes research on carbon capture and storage (CCS) technologies for industrial processes. It reviews CCS research for cement production, focusing on post-combustion capture using amine solvents and calcium looping technologies. Post-combustion capture for cement plants has an estimated cost of $107/tonne, while calcium looping averages $38/tonne. Oxy-fuel combustion is also discussed and estimated at $60/tonne. Current UK academic research on CCS for cement includes integrating calcium looping with cement manufacturing and examining the effects of high CO2 concentrations during cement production.01 fuel and industrial gases

01 fuel and industrial gasesNaveen Choudhary

╠²

This document discusses different types of fuel gases, including their composition, production methods, and uses. It covers producer gas, water gas, coke oven gas, natural gas, and LPG. Producer gas is made from coal or coke with air and steam. Water gas involves heating carbon with air and producing gas through reactions with steam. Coke oven gas is a byproduct of coking coal to produce coke. Natural gas and LPG are extracted from natural gas wells and oil refineries. The key engineering challenges involve designing reactors and purification processes to efficiently produce and treat these various fuel gases.Reduction of CO2 emissions_Global refineries

Reduction of CO2 emissions_Global refineriesGeorge Demiris

╠²

This document is a report from a student group at the Eastern Macedonia and Thrace Institute of Technology on refinery operations, products, and pollution problems. It discusses refinery complexity and products like transportation fuels. It also outlines pollution issues like CO2 emissions and proposes options to reduce emissions like carbon capture and storage, energy efficiency through heat integration and combined heat and power, and innovative CO2 conversion technologies. The group recommends improving existing plants, investing in research to transform CO2 into a raw material, and combining carbon capture storage with CO2 conversion to fuels.Catalytic Reforming Technology - Infographics

Catalytic Reforming Technology - InfographicsGerard B. Hawkins

╠²

The document contains a list of typical process equipment used in reforming and catalyst regeneration sections of a refinery, including reactors, columns, vessels, furnaces, heat exchangers, pumps, compressors and blowers. It also provides comparisons of different reforming processes and their key parameters such as RON, reaction pressure, LHSV, H2/HC ratio, yield and cycle length. Finally, it summarizes the assessment of a recommended process/technology for criteria such as performance, reliability, safety, costs and flexibility.Technologies for Carbon Capture in Oil Refineries

Technologies for Carbon Capture in Oil Refineriescanaleenergia

╠²

Saipem has experience providing engineering services for carbon capture, transportation, and storage projects for oil and gas companies. This includes designing pipelines, conducting environmental impact studies, and modeling wells and reservoirs. The document then discusses differences between capturing carbon from power stations versus refineries, sources of emissions in refineries, and options for capturing carbon from fluid catalytic cracking units, hydrogen production plants, and heaters/boilers in refineries. It concludes by outlining two overall approaches - converting a refinery to run on hydrogen or using oxygen combustion.Styrene Production by Catalytic Dehydrogenation of Ethylbenzene

Styrene Production by Catalytic Dehydrogenation of Ethylbenzene Michelle Otutu

╠²

This document summarizes a proposed process for producing styrene via the catalytic dehydrogenation of ethylbenzene. Key points include:

- Styrene is produced from ethylbenzene in a main reaction with byproducts. A feed containing 98% ethylbenzene, 1% benzene, and 1% toluene achieves a 72.92% single-pass conversion to styrene with 97.91% selectivity.

- Separation involves a three-phase separator to produce light gases, an intermediate oil, and wastewater, followed by sizing of storage tanks.

- Heat integration analysis finds a heat duty of 5426 kW can be achieved through heat exchange between processPaul Fennell (Imperial College London) - Cost comparison of different technol...

Paul Fennell (Imperial College London) - Cost comparison of different technol...UK Carbon Capture and Storage Research Centre

╠²

The document presents a cost comparison of various carbon capture and storage (CCS) technologies applied in industrial contexts, focusing on sectors such as iron and steel, petroleum refining, chemical manufacturing, cement, and pulp and paper production. It details the systematic review methodology used to analyze relevant literature and outlines the economic data pertaining to the levelized cost of electricity (LCOE) and cost of CO2 avoided for different technologies. Key findings indicate that while amine scrubbing is prominent in post-combustion capture, costs vary significantly across technologies and sectors, with calcium looping often being the most cost-effective solution for cement production.Ammonia production from natural gas.

Ammonia production from natural gas.Ajay Nagar

╠²

The document details the operational processes of National Fertilizers Ltd. in Bathinda, focusing on the ammonia production from natural gas, involving various sections such as desulphurization, reforming, methanation, and ammonia synthesis. Each section outlines specific chemical reactions and conditions, emphasizing the removal of impurities and optimizing reaction environments. Ultimately, the facility produces 99.80% pure ammonia for further urea production.CO2 Capture - Jon Gibbins, UKCCSRC, at the UKCCSRC ECR Winter School 2015

CO2 Capture - Jon Gibbins, UKCCSRC, at the UKCCSRC ECR Winter School 2015UK Carbon Capture and Storage Research Centre

╠²

The document discusses carbon capture technologies that are likely to appear in future phases of carbon capture and storage (CCS) deployment. It provides information on various carbon capture technologies including post-combustion capture using solvents like amines, pre-combustion capture through integrated gasification combined cycle (IGCC) plants, and oxy-fuel combustion. Examples of large-scale CCS projects currently in operation or development are also mentioned, such as the Kemper County energy facility and White Rose CCS project.LECTURE 06 industrial gages BET-CHET.ppt

LECTURE 06 industrial gages BET-CHET.pptMEILCAHDEMECILLO1

╠²

The document discusses various industrial gases, focusing on carbon dioxide and hydrogen, detailing their production methods and purification processes. Carbon dioxide is used in food preservation and wastewater treatment, while hydrogen is essential for chemical production and as a potential renewable fuel source. Oxygen manufacturing is also covered, emphasizing the air separation processes that yield high-purity oxygen for various applications, including metalworking and rocket fuel.CO2 capture and utilisation for industry

CO2 capture and utilisation for industryDawid Hanak

╠²

This document discusses assessing the feasibility of implementing carbon dioxide (CO2) capture and utilization at the Quorn mycoprotein process to help decarbonize its operations. The project aims to develop mass and energy balances for the Quorn process, model selected CO2 capture technologies, and evaluate the techno-economics and carbon footprint of potential CO2 utilization pathways. Preliminary results found that amine scrubbing would increase steam and power demands while carbonate looping could help Quorn become more energy independent by producing steam and power. Next steps involve analyzing CO2 utilization options like sodium bicarbonate production and gathering social perceptions on CO2 capture and use from workshops with Quorn staff and local industry.First Review for chemical engineering students

First Review for chemical engineering studentsDhavalHirpara4

╠²

This document outlines the process for producing carbon black from waste tires. It describes the objectives of gaining skills and knowledge of the process. The key steps involve preheating air and oil, spraying the preheated materials into a high-temperature reactor to produce carbon black, quenching and filtering the product, pelletizing, drying, and storing the carbon black. Issues addressed include salt waste and maintenance of refractory reactor components. Lessons learned include safety practices at high temperatures, communication, and incorporating feedback. Future work proposed involves mass and energy balancing and heat exchanger design.Carbon Capture & Storage - Options For India

Carbon Capture & Storage - Options For IndiaAniruddha Sharma

╠²

The document outlines the challenges and opportunities for implementing carbon capture and sequestration (CCS) technology in India, focusing on its cost, technology, scalability, and associated risks. It discusses various CO2 capture methods, transport infrastructure, and potential storage solutions, while emphasizing the importance of significant investment and policy support for CCS development. The presentation concludes with recommendations for enhancing CCS in India by addressing legislative, financial, and technical challenges.CO2 Reduction in a Calciner Reactor at a Cement Factory Memorandum

CO2 Reduction in a Calciner Reactor at a Cement Factory MemorandumAlfonso Figueroa

╠²

The memorandum outlines WEAP LLC's initiative to reduce CO2 emissions from a cement processing plant by investigating alternative reactants for the calciner reactor, specifically using slag and fly ash instead of pure limestone. A HYSYS model determined that using slag results in a reduction of 443,782 tonnes of CO2 emissions annually, along with significant cost savings of over $24 million per year compared to traditional methods. The implementation of these changes aligns with the goals set out in the Paris Climate Agreement to mitigate climate impact.Industrial Process for CO2 Sequestration by Aqueous Mineral Carbonisation Usi...

Industrial Process for CO2 Sequestration by Aqueous Mineral Carbonisation Usi...UK Carbon Capture and Storage Research Centre

╠²

This document outlines a workshop focused on alternative carbon capture and storage pathways, particularly mineral carbonation using mining waste in Qu├®bec. It discusses the development and testing of a process for CO2 sequestration and by-product recovery, highlighting laboratory and pilot-scale experiments, economic analyses, and future objectives for commercial demonstration. The findings suggest a potentially profitable and efficient method for reducing greenhouse gas emissions in the industrial sector.World Coal-to-Liquids Presentation

World Coal-to-Liquids Presentationrcarpe

╠²

The document discusses GE's experience and leadership in gasification technologies, describing their proposed configuration for an indirect coal-to-liquids plant using Illinois #6 coal to produce 28,000 barrels per day of diesel and 14,000 barrels per day of naphtha. It outlines critical elements like syngas quality treatment, and notes project complexities involving integration challenges and the enormous capital costs required for large-scale plants. Key performance metrics highlighted include a CO2 production rate of 0.23 tonnes per barrel of CTL product and a water requirement of 2.3 barrels of water per barrel of CTL.Ammonia Presentation On the Urea Ammonia Plant

Ammonia Presentation On the Urea Ammonia PlantMuradAli619307

╠²

The document provides details about the ammonia unit of Dawood Hercules Chemicals Limited, including:

- The unit uses M.W. Kellogg technology and has a capacity of 815 MTPD of ammonia.

- Natural gas is desulfurized through hydrotreating and desulfurization units before reforming to produce syngas.

- Syngas then undergoes shift conversion and CO2 removal to produce a stream suitable for ammonia synthesis.

- The CO2 removal system uses a Catacarb absorption/stripping process to separate CO2 from the syngas.OIL PROCESSING

OIL PROCESSINGanureddy58

╠²

This document details the visits and observations made at the Gram Tarang Foods oil processing unit in Odisha, focusing on an analysis of oil processing techniques, operating risks, and financial management. The processing methods for ginger oil are described, along with equipment used, such as CO2 cylinders, extractors, and separators, highlighting the unit's challenges and potential improvements. The financial analysis shows current losses despite a significant turnover, along with suggestions to improve waste management and operational safety.PRESENTATION ON HYDROGEN GAS PRODUCTION BY PARTIAL OXIDATION OF HEAVY FUEL OI...

PRESENTATION ON HYDROGEN GAS PRODUCTION BY PARTIAL OXIDATION OF HEAVY FUEL OI...Adebayo Bamidele Olanrewaju BSc, ASM, AMNIM, MNSE, MNSChE, CSSBB

╠²

LECTURE 5-10 IIB FUEL AND INDUSTRIAL GASES.pptx

LECTURE 5-10 IIB FUEL AND INDUSTRIAL GASES.pptxChemical Engineering Dept. NIT Rourkela-769008, Odisha, India

╠²

Capture from Cement and UK Calcium Looping Research, Paul Fennell (Imperial C...

Capture from Cement and UK Calcium Looping Research, Paul Fennell (Imperial C...UK Carbon Capture and Storage Research Centre

╠²

Paul Fennell (Imperial College London) - Cost comparison of different technol...

Paul Fennell (Imperial College London) - Cost comparison of different technol...UK Carbon Capture and Storage Research Centre

╠²

CO2 Capture - Jon Gibbins, UKCCSRC, at the UKCCSRC ECR Winter School 2015

CO2 Capture - Jon Gibbins, UKCCSRC, at the UKCCSRC ECR Winter School 2015UK Carbon Capture and Storage Research Centre

╠²

Industrial Process for CO2 Sequestration by Aqueous Mineral Carbonisation Usi...

Industrial Process for CO2 Sequestration by Aqueous Mineral Carbonisation Usi...UK Carbon Capture and Storage Research Centre

╠²

Ad

Presentation

- 2. Project Advisor: Miss Iqra Sohail ŌĆó Problem Definition ŌĆó Equipment(Mixer) Design Shahbaz Ali (CH-301) ŌĆó Process Selection ŌĆó Process Description Hafiz Muhammad Ali Ejaz (CH-051) ŌĆó Material/Energy Balance ŌĆó Equipment (Exchanger/Pump) Design Hafiz M. Arsalan Aslam (CH-064) ŌĆó Equipment (Rotary Filter) Design ŌĆó Economic Evaluation/Conclusion Mustafa Hussain (CH-305)

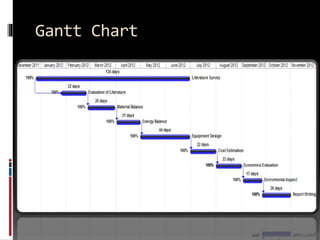

- 3. Gantt Chart

- 6. ŌĆó Global warming is the rise in the average temperature of Earth's atmosphere and oceans since the late 19th century and its projected continuation. ŌĆó Since the early 20th century, Earth's mean surface temperature has increased by about 0.8 ┬░C (1.4 ┬░F), with about two-thirds of the increase occurring since 1980. ŌĆó It will increase to about 2-5 ┬░C by the end of this century. ŌĆó CO2 level (October 2012) 391 ppm

- 9. ŌĆó Cement industry is responsible for 5% of global CO2 emissions ŌĆó 932 MT CO2 (approx.)emission per year per cement plant ŌĆó Each ton of cement emits 0.7-1.1 tons of CO2. ŌĆó Calcination Process (50%) ŌĆó Combustion of fuels in kiln (40%) ŌĆó Transportation (5%) ŌĆó Electricity (5%) ŌĆó High CO2 concentration in their flue gases of about 14-33% compared to 12-14% CO2 for coal -fired power plants and 4% for gas fired plants.

- 10. Our Project

- 11. ŌĆó We have taken a basis of 0.1 MT Cement production per year and our cement industry produces more than 0.3 MT of CO2 per year ŌĆó Our process is capable of removing 0.267 MT CO2 per year ŌĆó This includes the CO2 from the kiln and fuel

- 12. So WhatŌĆÖs New?

- 13. Hafiz Muhammad Ali Ejaz Process Selection Process Description

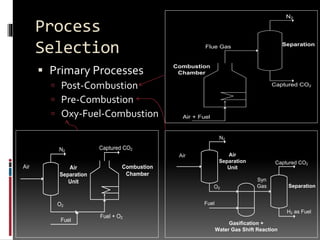

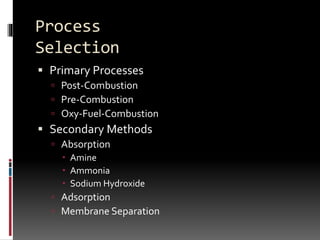

- 14. Process Selection ’é¦ Primary Processes ’ā║ Post-Combustion ’ā║ Pre-Combustion ’ā║ Oxy-Fuel-Combustion Combustion Chamber Air + Fuel Flue Gas Separation N2 Captured CO2 Air Air Separation Unit N2 O2 Gasification + Water Gas Shift Reaction Fuel Syn Gas Separation Captured CO2 H2 as Fuel Air Air Separation Unit N2 O2 Fuel Captured CO2 Combustion Chamber Fuel + O2

- 15. Process Selection ’é¦ Primary Processes ’ā║ Post-Combustion ’ā║ Pre-Combustion ’ā║ Oxy-Fuel-Combustion ’é¦ Secondary Methods ’ā║ Absorption ’ā║ Adsorption ’ā║ Membrane Separation

- 16. Process Selection ’é¦ Primary Processes ’ā║ Post-Combustion ’ā║ Pre-Combustion ’ā║ Oxy-Fuel-Combustion ’é¦ Secondary Methods ’ā║ Absorption ’éĀ Amine ’éĀ Ammonia ’éĀ Sodium Hydroxide ’ā║ Adsorption ’ā║ Membrane Separation

- 17. Our Selection ’é¦ Post-Combustion ’ā║ Sodium Hydroxide Absorption (Mineralization Process )

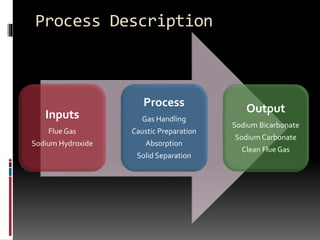

- 18. Process Description Inputs Flue Gas Sodium Hydroxide Process Gas Handling Caustic Preparation Absorption Solid Separation Output Sodium Bicarbonate Sodium Carbonate Clean Flue Gas

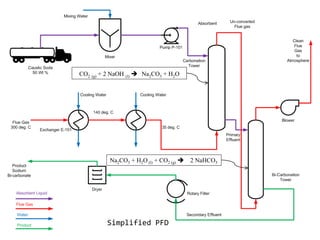

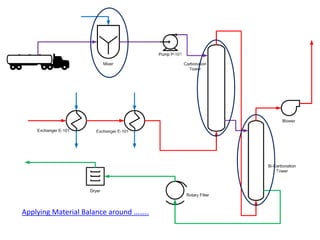

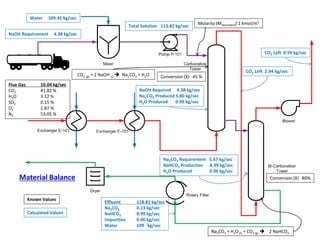

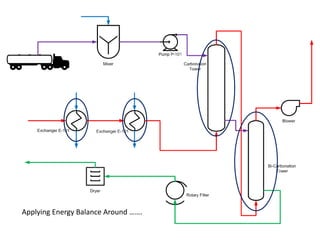

- 19. CO2 (g) + 2 NaOH (l) ’ā© Na2CO3 + H2O Na2CO3 + H2O (l) + CO2 (g) ’ā© 2 NaHCO3 Simplified PFD

- 21. Hafiz Muhammad Arsalan Aslam Material/Energy Balance Equipment(Pump/Exchanger) Design

- 22. Material Balance ’é¦ Basis ’ā║ 0.1 Mton Cement Production

- 23. Applying Material Balance around ŌĆ”ŌĆ”..

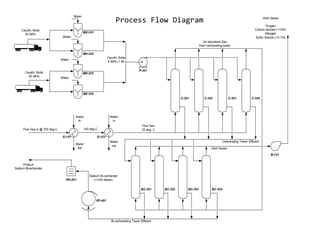

- 24. Known Values Flue Gas 10.04 kg/sec CO2 41.82 % H2O 3.12 % SO2 0.15 % O2 1.87 % N2 53.05 % Conversion (X) 45 % Molarity (MAbsorbent) 1 kmol/m3 Conversion (X) 80% Calculated Values NaOH Required 4.38 kg/sec Na2CO3 Produced 5.80 kg/sec H2O Produced 0.99 kg/sec NaOH Requirement 4.38 kg/sec Total Solution 113.82 kg/sec Water 109.45 kg/sec Na2CO3 Requirement 5.67 kg/sec NaHCO3 Production 8.99 kg/sec H2O Produced 0.96 kg/sec CO2 Left 2.94 kg/sec CO2 Left 0.59 kg/sec Effluent 118.81 kg/sec Na2CO3 0.13 kg/sec NaHCO3 8.99 kg/sec Impurities 0.06 kg/sec Water 109 kg/sec Material Balance CO2 (g) + 2 NaOH (l) ’ā© Na2CO3 + H2O Na2CO3 + H2O (l) + CO2 (g) ’ā© 2 NaHCO3

- 25. Energy Balance

- 26. Applying Energy Balance Around ŌĆ”ŌĆ”.

- 27. Known Values Calculatd Values TFue,out,1 = 140 oCTFlue = 300 oC TWater,in = 35 oCTWater,in = 35 oC TFue,out,2 = 30 oC Heat Produced = 5728 kW Q = 5428 kW mWater = 21.9 kg/secmWater = 34.25 kg/sec Q = 3469 kW Heat of Formations @ 25oC Reactants kJ/mol NaOH -470 CO2 -394 Products Na2CO3 -1152 H2O -286 Heat of Formation @ 25oC Reactants kJ/mol Na2CO3 -1152 CO2 -394 H2O -286 Products NaHCO3 -930 Heat Produced = 3001 kW E-101 E-102 R-1 R-2 TWater,out = 70 oC TWater,out = 35 oC

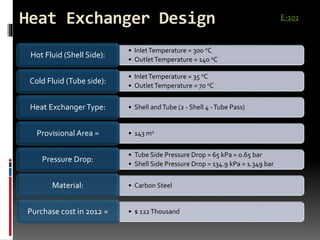

- 29. Heat Exchanger Design ŌĆó InletTemperature = 300 oC ŌĆó OutletTemperature = 140 oC Hot Fluid (Shell Side): ŌĆó InletTemperature = 35 oC ŌĆó OutletTemperature = 70 oC Cold Fluid (Tube side): ŌĆó Shell andTube (2 - Shell 4 -Tube Pass)Heat ExchangerType: ŌĆó 143 m2 Provisional Area = ŌĆó Tube Side Pressure Drop = 65 kPa = 0.65 bar ŌĆó Shell Side Pressure Drop = 134.9 kPa = 1.349 bar Pressure Drop: ŌĆó Carbon SteelMaterial: ŌĆó $ 122ThousandPurchase cost in 2012 = E-101

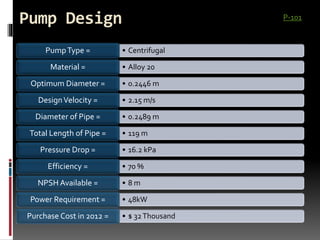

- 30. Pump Design ŌĆó CentrifugalPumpType = ŌĆó Alloy 20Material = ŌĆó 0.2446 mOptimum Diameter = ŌĆó 2.15 m/sDesignVelocity = ŌĆó 0.2489 mDiameter of Pipe = ŌĆó 119 mTotal Length of Pipe = ŌĆó 16.2 kPaPressure Drop = ŌĆó 70 %Efficiency = ŌĆó 8 mNPSH Available = ŌĆó 48kWPower Requirement = ŌĆó $ 32ThousandPurchase Cost in 2012 = P-101

- 31. Feed Mixer Design ŌĆó 113.82 kg/ secNaOH Feed = ŌĆó 19000 gallon = 72 m3 Volume = ŌĆó 4.5 mTank Diameter = ŌĆó Carbon SteelMaterial = ŌĆó 1.5 mAgitator Diameter = ŌĆó 90 rpmRotations = ŌĆó 75 %Liquid Fill = ŌĆó 3.37 %Fluid Height = ŌĆó 35 CTemperature = ŌĆó 26 secondsMixingTime = ŌĆó 153 kWPower Required = ŌĆó 7 m/sTip Speed = ŌĆó $ 110ThousandPurchase Cost in 2012 = MX-101

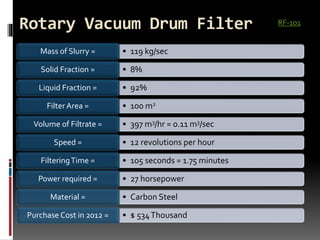

- 33. Rotary Vacuum Drum Filter ŌĆó 119 kg/secMass of Slurry = ŌĆó 8%Solid Fraction = ŌĆó 92%Liquid Fraction = ŌĆó 100 m2Filter Area = ŌĆó 397 m3/hr = 0.11 m3/secVolume of Filtrate = ŌĆó 12 revolutions per hourSpeed = ŌĆó 105 seconds = 1.75 minutesFilteringTime = ŌĆó 27 horsepowerPower required = ŌĆó Carbon SteelMaterial = ŌĆó $ 534ThousandPurchase Cost in 2012 = RF-101

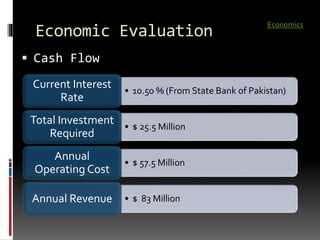

- 34. Economic Evaluation ’é¦ Cash Flow ŌĆó 10.50 % (From State Bank of Pakistan) Current Interest Rate ŌĆó $ 25.5 Million Total Investment Required ŌĆó $ 57.5 Million Annual Operating Cost ŌĆó $ 83 MillionAnnual Revenue Economics

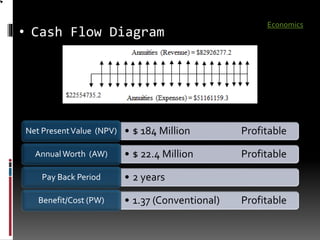

- 35. ŌĆó Cash Flow Diagram ŌĆó $ 184 Million ProfitableNet PresentValue (NPV) ŌĆó $ 22.4 Million ProfitableAnnualWorth (AW) ŌĆó 2 yearsPay Back Period ŌĆó 1.37 (Conventional) ProfitableBenefit/Cost (PW) Economics

- 36. Conclusion

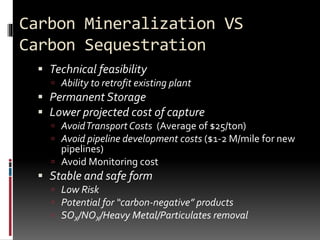

- 37. Carbon Mineralization VS Carbon Sequestration ’é¦ Technical feasibility ’ā║ Ability to retrofit existing plant ’é¦ Permanent Storage ’é¦ Lower projected cost of capture ’ā║ AvoidTransportCosts (Average of $25/ton) ’ā║ Avoid pipeline development costs ($1-2 M/mile for new pipelines) ’ā║ Avoid Monitoring cost ’é¦ Stable and safe form ’ā║ Low Risk ’ā║ Potential for ŌĆ£carbon-negativeŌĆØ products ’ā║ SOX/NOX/Heavy Metal/Particulates removal

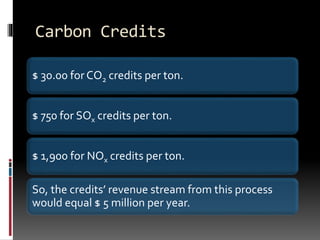

- 38. Carbon Credits $ 30.00 for CO2 credits per ton. $ 750 for SOx credits per ton. $ 1,900 for NOx credits per ton. So, the creditsŌĆÖ revenue stream from this process would equal $ 5 million per year.

- 39. THANK YOU

Editor's Notes

- #19: In the gas handling phase the hot flue gas is cooled and heat is harvested. The harvested heat is used to undertake the cost of chemical production and while the water is reused In absorption (Chemisorption), the now-cooled flue gas is scrubbed to remove the CO2 and acid gases such as SOX and NOX. In a reaction with sodium hydroxide, the CO2 forms sodium bicarbonate, and the acid gases form sulphate and nitrate salts.