Revised_Final_Presentation

This document discusses key concepts for inventory planning, including when and how much to order. It explains that the re-order point determines when to place an order based on factors like required quantity, lead time, and safety stock. Safety stock accounts for fluctuations in demand and supply. The economic order quantity model aims to minimize holding and ordering costs by determining the optimal order size based on annual demand, unit cost, ordering cost, and holding cost. The document provides examples of calculating re-order point, safety stock, economic order quantity, and the number of orders per year. It concludes that effective inventory planning can improve operational efficiency by supporting material availability as per project schedules.

Recommended

More Related Content

Viewers also liked (14)

Similar to Revised_Final_Presentation (20)

Revised_Final_Presentation

- 2. Introduction ŌĆó Inventory Planning is key activity of Stores Management to achieve successful Performance towards controlling the uncertainty in demand and supply. ’ā╝When to Order? ’ā╝How much to Order?

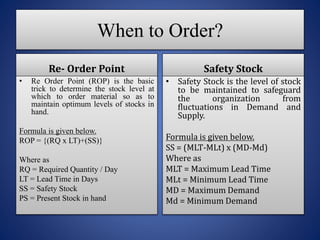

- 3. When to Order? Re- Order Point ŌĆó Re Order Point (ROP) is the basic trick to determine the stock level at which to order material so as to maintain optimum levels of stocks in hand. Formula is given below. ROP = {(RQ x LT)+(SS)} Where as RQ = Required Quantity / Day LT = Lead Time in Days SS = Safety Stock PS = Present Stock in hand Safety Stock ŌĆó Safety Stock is the level of stock to be maintained to safeguard the organization from fluctuations in Demand and Supply. Formula is given below. SS = (MLT-MLt) x (MD-Md) Where as MLT = Maximum Lead Time MLt = Minimum Lead Time MD = Maximum Demand Md = Minimum Demand

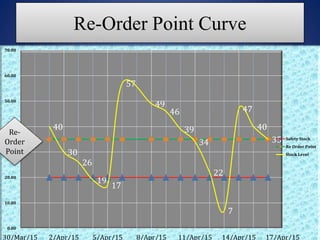

- 4. Re-Order Point Curve 40 30 26 19 17 57 49 46 39 34 22 7 47 40 35 0.00 10.00 20.00 30.00 40.00 50.00 60.00 70.00 30/Mar/15 2/Apr/15 5/Apr/15 8/Apr/15 11/Apr/15 14/Apr/15 17/Apr/15 Safety Stock Re Order Point Stock Level Re- Order Point

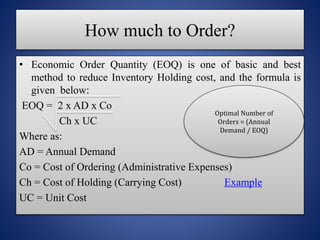

- 5. How much to Order? ŌĆó Economic Order Quantity (EOQ) is one of basic and best method to reduce Inventory Holding cost, and the formula is given below: EOQ = 2 x AD x Co Ch x UC Where as: AD = Annual Demand Co = Cost of Ordering (Administrative Expenses) Ch = Cost of Holding (Carrying Cost) Example UC = Unit Cost Optimal Number of Orders = (Annual Demand / EOQ)

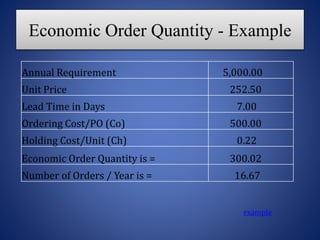

- 6. Economic Order Quantity - Example Annual Requirement 5,000.00 Unit Price 252.50 Lead Time in Days 7.00 Ordering Cost/PO (Co) 500.00 Holding Cost/Unit (Ch) 0.22 Economic Order Quantity is = 300.02 Number of Orders / Year is = 16.67 example

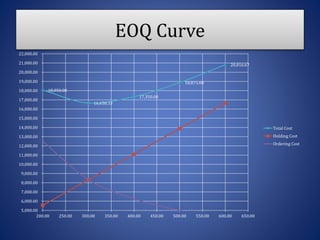

- 7. EOQ Curve 18,050.00 16,658.33 17,350.00 18,875.00 20,816.67 5,000.00 6,000.00 7,000.00 8,000.00 9,000.00 10,000.00 11,000.00 12,000.00 13,000.00 14,000.00 15,000.00 16,000.00 17,000.00 18,000.00 19,000.00 20,000.00 21,000.00 22,000.00 200.00 250.00 300.00 350.00 400.00 450.00 500.00 550.00 600.00 650.00 Total Cost Holding Cost Ordering Cost

- 8. Conclusion ŌĆó The Project Operational efficiency can be improved by supporting Execution team with on-time availability of material, as per their project schedule programme. ŌĆó Objective of Inventory Planning is to minimize Inventory Holding Cost and Ordering cost.

- 9. Thanking you

Editor's Notes

- #3: This method is applicable for Standardized and Fast moving items but not to Seasonable and Shelf life material.

- #6: This ŌĆ£Inventory Holding CostŌĆØ is differ from Industry to Industry, Project to Project and location to location, depending upon the structure and size of the company. However the Philosophers has defined that the cost is from 18 to 32% approximately / average.